12 October 2015

Currently, developers give preference to natural materials, not only during construction, but for the exterior decoration of finished buildings. Today, natural materials are becoming popular again not only for construction, but also for cladding a house. Wood is an environmentally friendly material that will not only preserve the house, but also make it attractive.

There are many technologies for performing finishing work.

Today, many home owners prefer to clap their houses with shiplap boards. This method is most often used to decorate low houses or country houses. To increase service life and add originality, wood can be:

- Cover with varnish. Paint. Impregnate with special oils.

Sheathing a house does not cause any particular difficulties, so most often they do not resort to the help of specialists to carry out the work, but do everything themselves. The main thing is to have the necessary skills and follow the recommendations. In addition, choose high-quality materials and necessary additional elements.

House cladding rules

Sheathing the house with herringbone boards is carried out after preliminary marking.

It is necessary to create a frame on which the outer board will later be attached. It's best to use a regular hammer rather than a nail gun. Of course, the operating time will increase significantly, but this particular tool will provide the required quality.

Sometimes self-tapping screws are used as fasteners for boards.

They are attached using a screwdriver. The work will be done quickly. But a number of boards that are located inside will have to be hammered only with nails, the length of which is at least 80 mm.

Boards need to be prepared in advance:

- Dry thoroughly. Treat with antiseptic.

When covering, the front side of the board is exposed outward, and the bend is directed upward.

Source https://hvrax.ru

In which lines do we use overlap assembly?

Line of bathhouses with a rounded roof “Bukhanochka”:

Modified version of “Loaf” with an entrance in the middle:

Baths with a terrace and a prominent side wall “Bourget”:

Transportable bathhouses with a roof to the ground “Rounded”:

Finnish baths "Suomi":

Large stationary frame-assembled bathhouses according to the “Corner” project:

Inexpensive mobile baths "Quadra":

We hope that the material is presented clearly. If you have any questions, write to us or ask in the VKontakte group, where we answer quite quickly.

Features of installing an external board

After installing the internal boards, they begin to fasten those that will be outside. This part of the finishing work must be approached with the utmost seriousness, strictly following the recommendations.

Each plank is laid on top of the other, overlapping.

Simply put, the boards should overlap each other by at least 2.5 centimeters. To prevent mistakes and avoid distortion, the overlap location must be marked in advance. To prevent the wood from deforming, you need to use only well-dried lumber.

When performing façade cladding work, the following tools are used:

- Screwdriver. Jigsaw. Hammer. Ruler. Building level.

Without the tool listed last in the list, it is simply impossible to trim a house with an American quality and accuracy.

There are many possibilities for attaching edged boards to the facade of houses. Here are some examples:

In rustic. In this case, the end part will protrude. The groove is at the bottom.

With a bevel into a tongue and groove. It should be noted that this cladding option has its own difficulties, but the end result is very attractive and beautiful. The board for finishing is taken thick.

Semi-rustic.

On a flat surface, triangular grooves are obtained. The board must be cut at an angle. There are no grooves as such, and the overlap itself will be angular.

With a quarter slope. The facade of the house will be smooth. The connection of the boards is complex.

If we use a straight quarter, we get a smooth and beautiful façade.

This option gives a tight and durable installation, so no moisture gets under the sheathing boards. The grooves are selected at an angle of 90 degrees. In addition, performing such cladding is not at all difficult.

A tongue and groove connection is considered reliable, but for this you need to correctly cut the grooves using templates. If a mistake is made, the strength of the joint will be compromised.

The outer walls of the building are smooth, neither snow nor rain will get under the cladding. Moreover, this facade decoration is a heat-insulating layer. In gluing. This option involves gluing the boards together, so there is no overlap.

Selection of materials

How to decorate the facade of a house made of timber? It is more convenient to cover a wooden body with materials that are easily attached. Therefore, they choose lining, block house, imitation timber, thermal panels, etc. The main condition for cladding is the presence of ventilation in the walls, which is created due to the gap between the wall and the finishing material. When using facing materials (brick, tile, plaster), they try to create ventilation holes so that the wood does not end up in thermal insulation. If the walls do not breathe, fungus and mold will form inside.

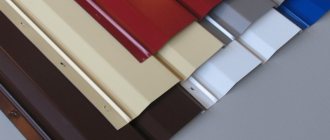

The building materials market is always ready to offer suitable material for the exterior decoration of a wooden house. Options are chosen based on your capabilities and needs. Any building material has its advantages and disadvantages:

- Imitation timber is an environmentally friendly material that allows you to decorate and insulate a house after curing; has unique wood characteristics, since it is made from coniferous trees; resistant to external factors due to its resin content. The disadvantages are that there are too dense knots and an increased fire hazard;

- Wooden lining is a wood material that retains all its natural properties; has high wear resistance with proper surface treatment; increases the steam exchange functions of the timber. Disadvantages: requires periodic processing and coating;

- Block house is one of the types of lining with imitation of the rounded surface of a log; easy to install; Often ready-made structures are made from such material. Disadvantages: like other natural materials, it is susceptible to moisture;

- Vinyl siding is a lightweight, practical material that is resistant to weather conditions; Available in different colors; budget option compared to natural wood. Disadvantages: does not always withstand loads, gaps may appear between elements at high and low temperatures;

- Metal siding - imitates wooden materials, while remaining a fire-resistant material; There are different colors and shapes; surface care is minimal; Easy to install and does not require a foundation. Disadvantages: does not allow the escape of steam formed in the walls;

- Thermal panels - made from high-quality concrete with virtually no water; the product does not crack, withstands low temperatures and retains heat; have a unique design solution, imitating brick, tile, stone, etc. Disadvantages: can be destroyed by moisture;

- Decorative brick – provides a high level of thermal insulation; durable and reliable material in a variety of shades. Disadvantages: requires a reliable foundation and sufficient roof overhang;

- Facade stone - used more often for laying paths; made of natural stone, so it is expensive; laid on walls according to the principle of tiles; withstands any temperature changes, is moisture resistant, but allows the house to “breathe”. Disadvantages: expensive, requires professional skill when installing;

- Facing tiles - made from baked clay; for outdoor work, choose a frost-resistant product with a moisture-repellent coating; Comes in different configurations and colors. Disadvantages: for laying on timber it requires preliminary leveling of the walls;

- Fiber cement panels - made using the latest technologies from cement, reinforcing fibers, mineral fillers; resistant to loads and temperature changes; come in different colors or are painted after installation. Disadvantages: in the absence of ventilation, they retain escaping moisture, exposing the wood to rot;

- Plaster is a simple and affordable material that allows you to level any walls; gives the house a modern look; you can choose any color that is added to the finished mixture; Acrylic paints are considered the most durable. Disadvantages: tightly covers the wooden wall, making the room unventilated.

Having decided on the appropriate type of material for cladding the house from timber on the outside, they prepare everything necessary for finishing work. If you plan to do everything yourself, make sure to purchase a sufficient amount of materials and also have the necessary tools and equipment on hand. Finishing walls in a house made of timber will require work at height, so you must adhere to safety rules to prevent work-related injuries.

Listen to advice

What material the house itself is made of does not matter.

Covering a brick house with wood is quite possible. The main thing is to follow the advice of experts. Then the house will not only be beautiful, but will also last much longer:

The board for covering must be well dried. It only needs to be planed on one side. The rough side is taken out.

The fact is that subsequent wood processing will be of better quality. Primer and paint will last longer on such a surface, and the house itself will attract attention. The choice of wood depends on the requirements of the home owners. You can use cedar, pine, spruce or redwood boards.

Let's consider these options in more detail.

Experts suggest choosing cedar planks. They are durable, easy to process, and most importantly, give the building a unique look.

As for mahogany boards, they last a long time. But it is very difficult to work with them: it is almost impossible to forget nails.

Pine boards are an excellent material, but not for external cladding. Cracks quickly appear on them, and natural disasters lead to deformation.

Spruce boards are good for everyone: they don’t warp or crack for a long time. But the presence of a large number of knots contributes to a decrease in the quality of the cladding. It is for this reason that facade cladding with spruce boards is practically not carried out.

- It is better to use ordinary steel nails as fasteners, but galvanized ones are not a suitable option. After all, the coating on them will be destroyed during installation work, which will lead to the appearance of rust. Don't skimp on nails if you want the sheathing to be of high quality and last a long time.

You can cover the facade with wooden boards in any country house. This method will make it not only attractive, but also maintain its environmental friendliness. After the facing work is completed, the board needs to be further processed: Covered with a special varnish. Painted with paint for external work. Impregnated with oil. The choice will depend on the requirements of the owner.

In addition, you need to take into account the style of construction. If you want to sheathe your own house with overlapped boards, then usually they try to solve two main problems. Sheathing a house with overlapped boards. First of all, this concerns atmospheric influences. Therefore, it is necessary to protect the walls of the building, for example, those made using foam concrete. It is necessary to provide reliable protection for the laid layers of insulation. The building will also receive a beautiful, original and decorative look.

Facade preparation and waterproofing

We spent several days preparing the house. Finishing the outside with boards requires protecting the walls from dampness. The logs were impregnated with a fire retardant, an antistatic agent and three layers of water repellent. Apply with brushes and rub in well. All this slightly worsens the vapor permeability of wood. But it protects the walls from fungus and makes them more resistant to moisture and even fire.

Finishing with lapped boards

I also checked the waterproofing of the basement at the same time. Along the foundation stone, moisture from the soil rises to the walls and higher. The sheets of roofing felt lay intact, protruding several millimeters beyond the plane of the wall. The blind area around the house was made after the finishing of the walls and basement was completed.

Sheathing a house with boards: some features

To cover a house with boards, you will need finishing materials that must be suitable for solving these problems. They should make the house beautiful and provide reliable protection.

Horizontal sheathing around the window: a—overlapping sheathing, b—sheathing with overlapped tongue-and-groove boards, c—half-tongued profiled sheathing, d—tongue-and-groove profiled sheathing, e—base molding board, f—without base molding board, g—sheathing of corner with corner board, h , and - lining the corners in erunok.

In most cases, cladding a house with wooden boards requires the construction of a fastening frame. Certain exceptions are assembled panel houses. Such houses can be sheathed directly on the assembled load-bearing frame.

The creation of the frame depends on the material used to cover the walls.

The types of fastening of the future cladding play an important role. The choice of fastening is influenced by the structure of the facade. Sometimes his device does not have ventilation.

The construction material for covering the walls of a house is very often boards, which come in two types.

It can be cut to a certain size or unedged. It all depends on the design of the frame and the materials used. In some cases, wooden blocks of different sizes are also used.

They make house cladding using other materials, for example, siding. It is installed on factory metal profiles.

However, you will be interested in the external cladding of the building with wooden edged boards or clapboards. This block house imitates the surface of the walls; they look like the walls of a log house.

Return to contents

Roof cornice lining diagram.

Sheathing a house with boards (lining) begins from its lower part.

The lower part is installed according to the level. It is attached to the frame, and the tenon should be at the top. The next product is put on it with a groove made in it.

It must be said that in some cases the elements are difficult to place. This is due to manufacturing defects and deformation that occurred during drying. The length of the system determines its uniform installation on the bottom board.

To properly seat the element, gaskets are made, for which a small piece of the same lining is taken. A board is hammered through the gasket in the places where the gap has formed.

You often hear the phrase "shipping."

This refers to the overlap of the internal structure with two external parts.

To sheathe a house, use products with a width of 100 mm. The amount of overlap is 25 mm on each side. In other words, the best distance from the front board to the inner board is 150 mm.

This size must be maintained along the entire perimeter of the cladding. When covering the floor, so that there are no gaps between the laid sheathing and the tiled floor, you need to attach an additional board to the tiles and install a screed. In this case, the cladding of the house will turn into a kind of continuation of the base.

Before sheathing the house with boards begins, it is necessary to decide on the length of the products themselves. Since finishing work will be carried out in the future, there is no need to maintain high accuracy.

Return to contents

Options for joining boards for external wall cladding.

The board is installed according to pre-made marks. Fastening is carried out in the middle with a metal nail. You should not use a nail gun to install this type of sheathing.

But if the board is fastened with a self-tapping screw, a mechanical screwdriver will provide effective assistance. Elements located in the inner row are fastened with nails (80 mm); self-tapping screws should have a similar length.

Before installation, the product is measured and cut to the appropriate length. When sheathing a roof that does not have a very large angle of inclination, you can immediately cut off two or three elements.

When installing, you must remember that the boards are installed with the “front” side out. On this side the veins have a curve directed upward, very reminiscent of a smile.

Fastening the boards can be done using a nail gun. But to use such a tool, you need some experience. A beginner is unlikely to be able to drive nails exactly in a straight line. This is why it will be better to use a mechanical screwdriver.

Return to contents

After installing the internal products, you can install the external ones. Installation is carried out with an overlap.

The previous one is placed on the adjacent one with an overlap of 250 mm. To make the operation faster, you need to measure 250 mm on each board, starting from the rear edge. External products are secured with two nails where they intersect with the frame slats.

It happens that some of the boards may move, but this will not affect the reliability of the structure. Wet boards will inevitably become slightly deformed when drying.

Long nails will be needed to secure the outer row. Before you start hammering nails, you must first make markings using a level. The row of hammered nails will be even, neat and beautiful.

Today, natural materials are becoming popular again not only for construction, but also for cladding a house. One of these materials is wood, which is not only environmentally friendly, but also gives the structure an unusually attractive appearance.

Sheathing a house can be done using different techniques, but edged boards laid with an overlap look best. This option is usually used when finishing a low building, a country house in a country style. After covering, the board can be varnished, painted, or impregnated with special oils to preserve its original appearance.

Roof cornice lining diagram.

The process itself, how to sheathe a house with edged boards with your own hands, is not so complicated, but it is necessary to strictly follow all the conditions and stages, use high-quality boards, and special additional elements in the form of corners.

For work, two types of boards and corner elements are used. The internal one acts as a frame, the corners are mounted for the internal and external parts of the facade. The outer board will be the front board.

Installation technology

One of the most important points in the work will be the preliminary treatment of all surfaces with special impregnations that protect your home from the appearance of fungus and mold, as well as from pests. In addition, treatment with fire retardants and other protective compounds of your choice will not hurt. When all these operations are completed, they proceed directly to the design of the walls. The technology is simple and does not cause any difficulties if everything is done carefully and slowly.

- Markings are applied on the walls for attaching a frame made of bars or slats.

- The frame slats are attached strictly vertically.

- The first part is nailed to the slats - a support for the first plank, with a thickness equal to the sheathing board, is attached to the lower part of the wall.

- The first board is fixed. You need to start from the bottom.

- The next part is fixed with a slight overlap of 20 to 25 millimeters over the first. Further assembly occurs in the same order until the entire wall is sheathed.

After all the walls are lined with wooden parts, all that remains is to decorate the corners of the house by attaching decorative wood overlays to them and trim the window openings, also decorating them with additional elements.

Installation of internal board

Sheathing the house with overlapping boards.

Covering the house with boards is carried out according to pre-made marks; a frame for fastening the outer board is required. During work, it is recommended to use a regular hammer; a special nail gun is not used. It is this feature that makes the work of cladding a house with wood so long and requiring patience.

If you will use self-tapping screws to attach the inner board, you can purchase a screwdriver. This will speed up the work and make it better, but the inner row will still have to be fastened with nails; they should be 80 mm long.

Before you start attaching the board, you must first treat it with an antiseptic and dry it. After this, each element is cut to obtain the required length. The front side of the board is placed outward, the bend should be directed upward.

1 Christmas tree (Canadian way)

Continuous skin without gaps, the elements of which can easily expand and contract with changes in humidity. If you nail only the top edges of the boards, the nail heads will be hidden from view and protected from moisture, but the likelihood of warping of the sheathing will increase (this fastening option is only applicable for thermowood and wood-polymer composite products). The disadvantages of the herringbone include, first of all, the increased consumption of material and the need to cover the corner joints with fairly wide vertical strips.

Exterior board installation

After all the internal boards have been installed, it is necessary to begin fastening the external ones. How to do this correctly?

Installation is carried out in an overlapping manner, with each previous board being laid on the adjacent board with an overlap of 250 mm.

Horizontal trim around the window.

Each board is pre-marked with an overlap so that the work is done quickly and efficiently. When drying, the material may become slightly deformed. Therefore, when purchasing, it is best to use well-dried wood.

Tools for work:

- screwdriver; jigsaw; hammer; ruler and building level.

During the exterior cladding of the house, it is necessary to use a building level so that the surface of the façade finish is smooth and beautiful.

Options for joining boards for external wall cladding.

There are many options for fastening external edged boards:

In rustic style, with lower end parts protruding at an angle, the groove is made at the bottom. With a bevel into a tongue and groove.

A complex profile is used, the external cladding is beautiful and stylish, the thickness of the board is significant. It is semi-rustic. The surface of the wall is smooth with small triangular grooves, the board is cut at an angle, the groove joint is not used, the overlap is angular. With a quarter slope. The surface of the facade turns out to be smooth; a complex straight quarter profile is used for the connection.

The surface of the facade is smooth and beautiful, the board is laid firmly and tightly, moisture does not have any opportunity to flow under the cladding. The grooves for fastening are cut at right angles, the connection is one of the most reliable and simplest. Into a tongue and groove. To lay the boards, a tongue and groove connection is used; it is important to cut the grooves using a template.

Otherwise, reliable docking will not work. The facade has a smooth and beautiful surface, moisture does not flow inside the wall, drafts will not bother you, as will heat loss. Installation is glued in place. The board is glued together, there is no overlap.

Wood finishing

Many owners of wooden houses, when decorating them, prefer wood as a natural, environmentally friendly material. Manufacturers of materials for exterior finishing of buildings offer consumers three types of wooden cladding - block house, imitation timber and the well-known lining.

Lining is the most affordable material and is easy to install. However, when choosing this material, do not forget that using lining will require additional costs. It will be necessary to impregnate with a composition to protect against insects and carry out external painting. In modern construction, painting is often replaced by impregnation with compounds that simultaneously perform two functions. They protect the lining from the effects of the external environment and give it a beautiful shade.

Ordinary lining can transform the appearance of a wooden house

The cost of a block house is higher, but its appearance is much more attractive than inexpensive lining. After finishing a house using it, it looks like it was built from rounded logs. The block house also needs treatment to protect it from the effects of precipitation.

High-quality finishing material, the design of which allows the finishing parts to be tightly connected to each other

Imitation timber is essentially the same lining, only made larger in width and thickness. Manufacturers offer this material in various sizes. Its width can reach 200 mm and its length is 4 meters. Externally, a house with such finishing does not differ from a building built from solid timber.

finishing with imitation timber is a great way to update the finish of an old house while at the same time insulating it

All these materials are easy to install and serve as excellent insulation and additional protection from external noise. At the same time, they give even an old building a beautiful and modern appearance. Wood trim is made from softwood.

When building a new house, you can plan the foundation taking into account the additional load from the finishing material. To decorate a building built many years ago, the use of wooden cladding most often becomes the only possible method of insulation and restoration.

Useful tips

When covering a house with wooden boards, experts advise adhering to certain rules that will ensure a beautiful and durable finish:

For work, it is best to take a board that is planed on one side and not on the other. The rough side of the material is mounted outward. Then the primer, and then the paint, will last much better and longer, and the appearance of the house will be more attractive. The boards do not need to be nailed only at the bottom and at the top, since the material will easily split and absorb moisture.

It is necessary to use the staggered fastening option, when the boards are fixed on the surface of the facade in increments of 30-45 cm, i.e., in a checkerboard pattern. Wood of various species can be used for cladding the house.

It can be cedar, pine, spruce, mahogany. Based on their experience, it is best to use cedar planks. They are not only durable, but also easy to process and have a beautiful appearance.

Mahogany is difficult to process; it is difficult to drive a nail into the surface, although it does not warp over time. Pine has numerous beneficial properties, but it is not very good for external use, as it easily warps and splits. Spruce is rarely used for exterior work on facades, although its performance is much better than that of pine.

Spruce boards are full of knots, and this does not have the best effect on quality. Sheathing a house is best done using ordinary steel nails, not galvanized ones. The problem is that the galvanized layer is easily peeled off during installation, and when exposed to moisture, the nails quickly rust. Stainless steel is much more expensive, but the quality of finish is higher.

Sheathing a building with edged boards is an attractive and simple option for any country house.

This facade is not only stylish, but also environmentally friendly. After installation, the board can be varnished, painted, or impregnated with oil. It all depends on the imagination of the owner of the house and the general style of construction.

Today, natural materials are becoming popular again not only for construction, but also for cladding a house. One of these materials is wood, which is not only environmentally friendly, but also gives the structure an unusually attractive appearance.

Sheathing a house can be done using different techniques, but edged boards laid with an overlap look best. This option is usually used when finishing a low building, a country house in a country style. After covering, the board can be varnished, painted, or impregnated with special oils to preserve its original appearance.

Roof cornice lining diagram.

The process itself, how to sheathe a house with edged boards with your own hands, is not so complicated, but it is necessary to strictly follow all the conditions and stages, use high-quality boards, and special additional elements in the form of corners.

For work, two types of boards and corner elements are used. The internal one acts as a frame, the corners are mounted for the internal and external parts of the facade. The outer board will be the front board.

Lathing

A board façade, like any other, needs ventilation. And not only from the front side, but also from the back: dampness under the cladding will not benefit the walls, regardless of their material.

The boards are usually attached horizontally to the sheathing to prevent water from flowing between them. If so, the sheathing must be vertical. A block with a cross section of 50x50 mm is used for it.

How can the beam be attached?

- To a wooden wall, provided that the facade will not be insulated - with ordinary nails 100 mm long;

- To brick walls or facades made of gas and foam concrete - with dowel screws;

- When laying insulation of considerable thickness into the sheathing, the block is attached to direct hangers for the profile under the plasterboard.

Useful: to secure the entire sheathing in one plane, it is enough to place the two outermost bars at the required distance from the wall. Then two or three threads are stretched between them, which serve as a guide when attaching the remaining elements of the sheathing.

To protect the sheathing from rot and mold, antiseptic impregnation is used. The antiseptic is diluted in water and applied to the surface of the bar with a regular brush.

The pitch of the sheathing is selected so that the length of the board is a multiple of it. The typical step for lathing without insulation is 1.5 meters; When laying insulation, the bars are packed in increments equal to the size of the slab of heat-insulating material.

The sheathing pitch is equal to the width of the insulation boards.

Installation of internal board

Sheathing the house with overlapping boards.

Covering the house with boards is carried out according to pre-made marks; a frame for fastening the outer board is required. During work, it is recommended to use a regular hammer; a special nail gun is not used. It is this feature that makes the work of cladding a house with wood so long and requiring patience.

If you will use self-tapping screws to attach the inner board, you can purchase a screwdriver. This will speed up the work and make it better, but the inner row will still have to be fastened with nails; they should be 80 mm long.

Before you start attaching the board, you must first treat it with an antiseptic and dry it. After this, each element is cut to obtain the required length. The front side of the board is placed outward, the bend should be directed upward.

How to mount everything

Typically, finishing the facade of a house with unedged boards begins with applying waterproofing compounds to the walls. This will protect the walls from moisture and you won’t have to think about the condition of the base surface after decoration. Next comes the insulation operations - if necessary, it is at this stage that an additional layer of insulation can be installed on the outside of the buildings. Only after all this work does the actual finishing begin. It is performed in the following sequence:

- Slats or bars are attached to the walls, which will serve as lathing for the outer covering. You can place them horizontally or vertically, depending on the orientation of the decorative covering strips.

- Insulation is installed if necessary and covered with protective membranes.

- The wall is sheathed with planks from bottom to top in the chosen method. The choice of covering option will be influenced by two factors: ease of installation and preference for appearance. If you cover the wall with overlapping strips, you will need a little more planks, but everything will be easier to do. Installation with a herringbone pattern will require more effort, but the appearance of the coating will be more attractive. However, this is a matter of personal preference.

- The joints of the boards are sealed with sealant and the final design of the wall is carried out.

There will be two cladding methods - overlapping, checkerboard or herringbone. The first option involves placing the boards in such a way that the upper one covers the edges of the lower ones on both sides. The second option is similar to a siding plane - the lower edge of the upper plank overlaps the top of the lower one. In both cases, the overlap must be at least two centimeters to ensure maximum aesthetics of the structure and to prevent the formation of large gaps between the dies.

Exterior board installation

After all the internal boards have been installed, it is necessary to begin fastening the external ones. How to do this correctly?

Installation is carried out in an overlapping manner, with each previous board being laid on the adjacent board with an overlap of 250 mm.

Horizontal trim around the window.

Each board is pre-marked with an overlap so that the work is done quickly and efficiently. When drying, the material may become slightly deformed. Therefore, when purchasing, it is best to use well-dried wood.

Tools for work:

- screwdriver; jigsaw; hammer; ruler and building level.

During the exterior cladding of the house, it is necessary to use a building level so that the surface of the façade finish is smooth and beautiful.

Options for joining boards for external wall cladding.

There are many options for fastening external edged boards:

In rustic style, with lower end parts protruding at an angle, the groove is made at the bottom. With a bevel into a tongue and groove.

A complex profile is used, the external cladding is beautiful and stylish, the thickness of the board is significant. It is semi-rustic. The surface of the wall is smooth with small triangular grooves, the board is cut at an angle, the groove joint is not used, the overlap is angular. With a quarter slope. The surface of the facade turns out to be smooth; a complex straight quarter profile is used for the connection.

The surface of the facade is smooth and beautiful, the board is laid firmly and tightly, moisture does not have any opportunity to flow under the cladding. The grooves for fastening are cut at right angles, the connection is one of the most reliable and simplest. Into a tongue and groove. To lay the boards, a tongue and groove connection is used; it is important to cut the grooves using a template.

Otherwise, reliable docking will not work. The facade has a smooth and beautiful surface, moisture does not flow inside the wall, drafts will not bother you, as will heat loss. Installation is glued in place. The board is glued together, there is no overlap.

OLIMP Omicron-Maximum – Wood-protective glazing thixotropic composition with a UV filter.

Why OLYMPUS? Everything is simple - budget-friendly and proven by repeated use on other objects. I first became acquainted with Olympic impregnations when I was making a balcony in my apartment in Moscow. There we made a bar counter from pine boards. And then we covered it with this same “NUT” color impregnation... Now almost 8 years have passed... It’s just that the “convergence” of the paint layer has become noticeable. But this is the 19th floor of the northern part of Moscow, blown by the most terrible winds and practically this table is always very heavily flooded when it rains. We have covered the walls in the rest room of the bathhouse with azure from OLYMPUS, covered the pediment of the guest room from the street side, covered all the roof linings of a large house ... After using it for a long time, it still shows its good side. Therefore, we didn’t think twice and also bought glaze from OLYMPUS for the walls.. The only difference is that this time we chose a non-water-based glaze. Therefore, it smelled strongly, was quite thick, you only need to dilute it with white spirit, and, accordingly, different care for brushes and rollers. What I liked was that we covered both the pediment of the roof and walls with azure, and the material there is different (on the pediment - OSB, on walls - a board), then the visual effect turned out to be different. Otherwise, I was very worried that everything would turn into mush... The glaze lay flat on the OSB and formed a glossy shiny film. And on the walls it became matte. You need to apply at least 2 layers. The first layer is absorbed into the wood and the color does not reach the desired saturation. The second layer is already showing itself well. I applied the glaze - sometimes with a roller, sometimes with a brush. It was imperative to paint the ends of the board - the boards usually rot at the ends... I liked it most of all with a wide flute brush. The glaze dries quickly from dust - which perfectly protects fresh walls from sand, which with gusts of wind could be applied to the walls in bad weather. Let's wait the five years stated by the manufacturer - and see how everything will look.

At this moment, I want to immediately answer the question - why is it so difficult to mess with the board... Yes, I know that there is modern siding, thanks to which I can, in principle, achieve the same result... Almost, but still not ideal.. .I didn’t want any siding - I wanted wood...

And there is always a BUT. Firstly, we already HAD a board. Secondly, the siding is good, which does not fade in the sun, does not lose its position from strong storm winds, from snowdrifts two meters high... it would cost us significantly more than the board at the moment. Thirdly, yes, after some time I will have to paint the house again, and for now I don’t know how the azure from Olympus will behave in 7-10 years.. But it will be in 7-10 years... not today.

What to do with the corners? That's right - beautifully hidden behind a corner element. We also made it from boards. Only it was already a board 15 cm wide and 3 cm thick. Everything fell neatly into place and was painted white.

How it was before the sheathing

Porch to…..

And how it turned out after... my special pride is the porch :)

Porch after)))

Dusya is happy

Thank you all for your attention - stay with me! And... come to my website ON THE WAVE OF DECOR.

GOOD LUCK WITH THE REPAIR!

Cost per cube

I would like to say right away that the difference is quite significant. Of course, a lot depends on what material it is made from. If these are coniferous varieties, then the cost is somewhat cheaper, if these are deciduous “durable” varieties (for example, oak) - more expensive. Also, the price greatly depends on the type of wood, there are 5 in total (according to GOST), you can read about them here.

Unedged option, cost per cube starts from 2000 to 5000 rubles.

Edged version, cost per cube starts from 3,500 to 8,000 rubles.

How to calculate a cubic meter - read this article .

Installed parameters

Its application depends on the characteristics of the unedged board. Most often, these products are distinguished by length and thickness. The first parameter depends on the size of the sawn log and, generally, ranges from two to six and a half meters. However, it all depends on the height of the tree, and the board can be much longer.

The second ranges from 16 to 90 millimeters and depends on the type of wood being cut and the purpose of the board during construction. The width for this type of timber does not matter and is not a standard, since the edge when sawing it is not adjusted to the established dimensions.