Construction of new and expansion of existing openings in load-bearing walls are one of the most common solutions when remodeling apartments.

Moreover, in the catalog of standard redevelopments developed by MNIITEP for houses where this design institute is the author, most of the presented options assume an opening in the load-bearing wall.

However, despite the popularity of such solutions, their implementation in practice is not allowed everywhere. Where it is possible to construct an opening, the load-bearing structures must be reinforced with a special metal frame that absorbs part of the load.

When should it be strengthened?

There are many reasons to renovate reinforced doors.

The most common ones are:

- Changing the plan of a house or apartment, in which a new door appears in the supporting structure.

- Complete dismantling and replacement of the door frame.

- The appearance of cracks, chips, and various damages on the wall.

- Shedding of walls, particularly bricks and cement.

Many property owners, during major renovations, immediately think about strengthening holes in load-bearing walls. In this way, you can avoid many problems that can later spoil the repairs made, such as the appearance of cracks and crumbling of the wall.

Foundation

Let's study the general principles of reinforcement of foundations of the most common types in private construction (find out here how aerated concrete is reinforced).

Slab

For its reinforcement, corrugated rod reinforcement with a diameter of 12 millimeters is usually used. Bending loads under load-bearing walls will be significant; If so, good adhesion between steel and concrete plays a decisive role.

What is worth knowing about this type of foundation?

- The thickness of the slab is determined by the number of floors of the house and the material used for construction. It is clear that a log frame will create a much lower bending load than a brick or monolithic concrete structure. As a rule, the thickness of the slab varies from 15 to 30 centimeters.

A nuance: with a small structure, it is permissible to use reinforcing mesh with a cross-section of rods of 6-10 millimeters.

- Reinforcement is always done in two layers. In this case, the lower and upper lattices are not rigidly connected to each other; It is only permissible to use supports that form a gap of the required size.

The structure of the slab foundation.

- By the way, about gaps: the lattice or mesh should not extend to the surface of the concrete anywhere. At the edges between the reinforcement and the formwork there is approximately a 10-centimeter gap; The gratings are separated from the lower and upper surfaces of the slab by a layer of 1.5 - 3 centimeters. To create appropriate gaps, supports made of annealed wire are used.

- The reinforcement is not welded into a lattice, but knitted with the same annealed wire.

- The optimal pitch for rod reinforcement in a slab is 20-22 centimeters. If a ready-made mesh is used, the reduced wire thickness is partly compensated by the smaller mesh size (15 cm).

Tape

The instructions for reinforcing a strip foundation in some points repeat the recommendations for a slab foundation:

- The grating must be present at the top and bottom of the concrete strip.

Strengthening methods

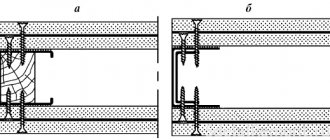

To strengthen the door structure, the following products can be used:

- channels , which are used to achieve a binding effect and tighten the structure;

- corners _ They can be secured using anchors or cross plates. And they increase the reliability of the structure due to the contour effect;

- metal frames that are fixed at each corner of the opening;

- reinforced concrete lintels . This material strengthens the supporting function well, but is not suitable for small rooms, as it is voluminous.

The most expensive way to reinforce holes in a wall is to install a metal frame. However, sometimes this is the only possible way to avoid wall deformation.

For a panel or monolithic house, the best option is to install channels. This method will reliably strengthen the structure. In addition, it is much easier to carry out this kind of work than installing an entire opening frame.

What to do with a DP if there is a door in it?

In this case, it is advisable to use the simplest options. It is worth considering where this structure is located.

The easiest way to finish a DP is with a door frame and adjacent elements. You must:

- Install the box. It can be with or without a threshold.

- Use extensions for facing slopes. The standard sizes of these parts are 12-15 cm.

- Secure the extensions with the groove on the box. If it is missing, self-tapping screws are suitable for fixation. Make a hole for them through the end of the part.

- Exterior finishing is done with platbands. They will frame the DP.

This technology is suitable for cladding non-expanded structures.

Strengthening instructions

Regardless of the type of materials used, strengthening the doorway takes place in three stages:

- Applying markings to the wall.

- Installation of fixing fasteners for the future design.

- Placing a support frame on them.

In addition, before starting work, measurements of the doorway are taken.

Rectangular areas are easier to strengthen, since for round or arched openings it is necessary to weld a fastening frame of an unusual shape that follows the bend of the wall.

Wall marking

The marking is applied along the entire perimeter of the hole in the wall. It is necessary to remove the places where the fasteners will be installed. It is important that they have the same height on each side of the door, since without this it will not be possible to create an even frame.

Installation of fasteners

Before installing the fastening part of the structure, it is necessary to make holes in the wall niche, into which the fasteners will be placed. Then the fasteners are placed in the wall and secured depending on the selected type of product.

Installation of the structure frame

After the fasteners are installed, all that remains is to secure the frame. Work at this stage depends on the choice of reinforcement. For example, the channels are tightened with special pins, and the metal frame is welded onto the fastening points.

Technology

Reinforcement is designed to strengthen the wall structure, leaving it strong. And you need to start not with step-by-step actions, but with rules, without knowing which it is impossible to reinforce in principle.

- The reinforcement is supposed to be tied outside the formwork walls. The frame can be installed in large parts.

- Where the rods intersect, the rods will have to be tied together. But without much harshness. Nevertheless, the low mobility of the assembly must be preserved, otherwise, when the concrete is stretched, the wire inside may break, as a result of which the integrity of the frame will be under attack.

- The rods in the frame should initially be given a strict direction: either horizontal or vertical. If the angle of inclination of the rod shifts, a shift in the load distribution will occur, that is, part of the wall may collapse.

- To reduce the risk of corrosion processes, special additives are added to concrete.

- When the frame is connected and stands in the formwork, the solution is poured. This is done simultaneously throughout the entire volume. The poured monolith must be covered with film, and it remains untouched until it hardens completely. To prevent concrete from cracking, it is moistened for the first 8-10 days.

Tips and lifehacks

The process of strengthening the wall can be simplified using the following tips:

- You can use a laser level to level the wall on both sides. This tool allows you to achieve maximum accuracy.

- Brick walls cannot be tapped. It is better to use diamond drilling. This method will allow you to quickly and easily make holes in the wall, as well as reduce the amount of dust and noise.

- In brick houses, before carrying out strengthening work, it is necessary to install a temporary support in the opening.

Before carrying out work, it is necessary to select the correct type of fastenings.

The way work is carried out is influenced by a large number of factors, including:

- the year the house was built (age) and the material from which it was built;

- technical condition of the walls (presence of cracks and chips);

- the budget that the property owner is counting on.

The use of channels and corners are the simplest options for strengthening a doorway, however, they are not highly durable compared to creating a full-fledged supporting frame.

An example of reinforcing a monolithic concrete wall with steel reinforcement: photos, drawings and diagrams

In order to study the technology in more detail, let's look at an example of how to correctly reinforce a monolithic wall 25 cm thick. The main rods are A500C class reinforcement with a diameter of 12 mm, the cell size of the main mesh is 200x200 mm. For structural elements we use class A1 reinforcement. The reinforcement is knitted using crochet, using 1.2 mm thick knitting wire.

It should be remembered that the minimum percentage of wall reinforcement is 0.1% of its cross-sectional area, and the maximum area of working longitudinal reinforcement is 5%. The consumption of reinforcement per 1 m3 of concrete also depends on the percentage of reinforcement.

As mentioned above, the frame is assembled either before the formwork is installed or after. In our example of strengthening the concrete walls of elevator shafts, it is most convenient to first expose the inner cores and then assemble the frame around them.

Before starting to perform reinforcement, the reinforcement outlets should be cleared of concrete and leveled vertically.

The process of knitting the main mesh begins with the installation of vertical rods, then horizontal ones are tied to them in increments of 20 cm. The size of the overlap of the reinforcement in the wall according to the drawing is 40 reinforcement diameters, for 12 mm this is 48 cm, no more, no less. The joining of horizontal rods must be done in a checkerboard pattern.

After we have connected 2 layers of the main mesh, we reinforce the corners of the walls according to the diagram below.

To tie the corner, “pawns” of reinforcement with a diameter of 12 mm are used, their size is 750x175x750 mm.

Below in the photo is the final view of the completed reinforcement of the corner of the concrete wall.

At the next stage, we install “eski”, they received this name because of their shape. Their installation step is 40 cm, in a checkerboard pattern.

It happens that the “esks” cannot be placed, for this one end is not completely bent, then they are put on, and the other end is bent manually, using a homemade device as in the photo below.

The diagram below shows how to reinforce an opening in a wall. For framing, reinforcement with a diameter of 16 mm and a pitch of 100 mm is used. The protective layer of concrete for the reinforcement that is located on the sides of the opening is 50 mm, for the top one – 40 mm. “Pawns” made of rods 8 mm thick, size 350x175x350 mm, are knitted to the main reinforcement.

It is important that the reinforcement from the edge of the opening extends into the wall by 40 rod diameters; for 16 mm, this is 64 cm.

The principle of strengthening the opening is the same as for doors. It’s just that in this drawing the hole is located at the edge of the wall, which does not allow 16 reinforcement to be launched at 64 cm. Therefore, it is launched at 37 cm on the sides, and at 27 cm they make a bend into the other wall. See the photo below for what it looks like.

The protective layer clamps for the reinforcement are installed on the assembled frame, after which the formwork is installed and concrete is poured.

As you can see, reinforcing concrete walls is not such a simple process; it has its own characteristics and nuances. It is important to study the issue in detail and in depth in order to avoid mistakes in the reinforcement process that could affect the monolithic structure in the future. Finally, we recommend a video material on the topic, where an experienced reinforcer explains and shows the features of reinforcing reinforced concrete walls.

If, after studying the article, you still have questions, ask them in the comments, we will definitely help you.

Source

Cutting openings in Moscow

one of the most popular services provided by our company. Diamond cutting is a highly efficient and versatile technology for creating openings, windows and vents. Our company works with any types of walls and ceilings, including load-bearing walls (both brick and concrete). We use only the most modern equipment, and our employees literally “ate the dog” in the redevelopment, reconstruction and refurbishment of residential, public and industrial buildings.

Making and strengthening openings using diamond cutting is fast and safe. We conclude official contracts with each of our customers, and also provide a hidden work certificate and SRO approval. Among other things, our company arranges openings in load-bearing walls according to the plans of design bureaus.

Features of amplification in various homes

The material of the walls in which the door is located plays an important role in strengthening the doorway:

- In panel houses, it is enough to install edging from channels or corners. Panel walls are considered the strongest and safest and rarely collapse.

- The walls of a monolithic house require delicate chipping without making major changes to the wall structure.

- Owners of brick houses should refuse to use corners, or their dimensions should be at least 100/63/8 cm. This size is not suitable for every door.

The need to strengthen openings also depends on the floor. For example, on the lower floors of a tall building, the likelihood of a wall collapsing is much higher. Residents of the lower floors do not approve of any layout changes that affect the load-bearing wall.

Doorways in a load-bearing wall certainly require high-quality reinforcement. This is especially true in cases where, during renovations, a new door appears in a load-bearing wall. With each new opening, the wall loses its strength, threatening the reliability of the entire building.

MANUFACTURING OPENINGS OF DIFFERENT TYPES

Our company produces the following types of openings:

Door

We make doorways in brick and concrete walls using special wall-cutting machines, which are characterized by high accuracy. They are also suitable for creating fire and basement entrances, garage doors, interior doors in residential buildings, cottages and private sector buildings.

Window

Many older buildings have very small basement windows, which do not let in enough light and can even complicate evacuation during an emergency. Cutting window openings allows you to set them to the dimensions that you need. And we’re not just talking about basement windows - often when replacing old frames with new ones, it is necessary to enlarge existing ones. It is most convenient to cut them out from the outside, since in this case the concrete or brick dust will go directly into the ground along with the water.

On the floor

Such openings may be needed when combining separate apartments or when converting a basement/attic into living space. The optimal way to make them is horizontal sawing with a diamond blade, which can easily cope with both reinforced concrete floors and asphalt road surfaces.

Questions and answers

Why can't a brick wall be tiled?

Brick walls crumble easily. When chipping, pieces of mortar may break off or even parts of the brick may fall out.

Why is it important to strengthen the wall?

Any violation of the integrity of load-bearing walls can lead to serious consequences, including the collapse of the entire building. In addition, cracks in the wall can ruin the repair.

In what cases does strengthening doorways require approval from the housing inspection?

In case of large-scale work related to the redevelopment of the premises. Example: creating an additional doorway.

How is the approval process carried out?

After submitting a work plan, a specialist engineer studies the house design and makes a decision. Complete demolition of a load-bearing wall is not approved. Attention is paid to maintaining the strength of the walls.

Which walls are most likely to collapse and which are the most resilient?

Brick walls are susceptible to collapse, as this material crumbles easily. Panel houses are considered to be very strong.

How to reinforce monolithic concrete walls?

Concrete is the most popular building material in the world. It is used in the construction of foundations, walls of private and multi-storey residential buildings, bridges and tunnels, dams and roads. However, it is often not concrete that is used, but reinforced concrete - various types of reinforcing material are used during construction. In this article we will analyze in detail why, how and when it is necessary to reinforce monolithic concrete walls.

Repair work

Methods for dealing with defects on the surfaces of concrete structures depend on the depth of the damage. Shallow sinks are easy to eliminate, unlike the second group of damage in the form of voids, deep and through recesses.

Minor deficiencies are eliminated as follows:

- The gravel surface is cleaned with a steel brush and thoroughly washed with ordinary tap water.

- Carefully plaster the defect areas with a mixture of M400-500 cement and sand in a ratio of 1 part cement to 2 parts sand.

- If the sinks are deep, use a chisel to clear the edges of loose concrete, then the surface is again treated with a steel brush, the defective area is washed and caulked with cement mortar.

The technology for repairing major damage to partitions is selected taking into account the number and scale of defective areas. For example, in vertical highly loaded columns, shells are protected up to the reinforcement, thoroughly washed and concreted with fine-grained concrete M 500.

You can learn more about the intricacies of repairing concrete walls in this article.

Comprehensive protection with insulation

Considering the expensive price of sound protection systems, it is practically not used anywhere in its pure form. Despite its good strength properties, concrete is a cold building material, so even in the southern regions it requires insulation. According to modern urban planning standards, insulation and waterproofing of such structures is mandatory.

The most common complex material for several types of protection is mineral plates. Today, after the release of a new soundproof modification of Penoplex, it is becoming a real competitor to mineral boards, especially for external wall protection. This is a complex insulation material with good heat-, water-, frost-resistant characteristics and noise protection.