Reinforcing the opening with a channel

When expanding existing or constructing new openings in load-bearing walls, an apartment redevelopment project may contain various methods of metal reinforcement. Here we will look at such a common option as channel reinforcement.

Channel reinforcement in the form of a U-shaped frame or horizontal lintel is suitable for concrete and brick load-bearing walls.

A frame or lintel made of metal profiles takes on the load that previously fell on the dismantled section of the wall, which allows you to maintain the load-bearing capacity of the wall without reducing it. Thus, strengthening the doorway with a channel helps prevent cracking or even collapse of the wall.

Examples of strengthening openings in concrete walls

An example of strengthening openings in brick walls

Strengthening openings. Strengthening load-bearing walls.

Cheap openings with reinforcement and fixing defects

If you do not have a project and you are going to make an opening without permission or you do not need documents from us, we can offer you to make an opening reinforced with a channel or corner for a standard solution.

Below is the cheapest cost of finished openings with channel reinforcement without documents from us.

An opening in a panel house with standard channel reinforcement, including metal and its delivery. The connection nodes have a corner and a strip. Anchors and plate (heels) for the channel.

Separately, removal of the remaining construction waste: 4,000 rubles for removal of waste into a container (openings in the walls 14-18 cm thick), if there is no container + 6,500 rubles for a container within the Moscow Ring Road. Completion time is one or two working days (depending on the thickness of the wall and breaks for noisy work). Metal to the size for reinforcement is prepared at the work site.

Strengthening openings in brick walls

Different types of reinforcements for openings and load-bearing walls

Complete dismantling of the load-bearing monolithic wall with subsequent box reinforcement according to the project.

Preparing metal to strengthen openings on the first floor. Metal is always prepared to size on site.

Installation of combined reinforcement of load-bearing walls.

Completed combined reinforcement of the opening on the top floor in a 2-room apartment after partial dismantling of the load-bearing walls and dismantling of the reinforced concrete lintel according to the MNIITEP project (type A).

Completed combined reinforcement of the opening on the top floor in a 2-room apartment after shortening the load-bearing walls and dismantling the reinforced concrete lintel according to the MNIITEP project (View B from the kitchen).

Complex reinforcement of wide openings after dismantling the walls with 27 channels on bolts according to the project.

Box reinforcement of openings with channels.

When expanding the opening to a wide size, the project provided for reinforcement with 20 channels under the ceiling with additional piping with 140 corners.

Reinforcement of openings according to the project of the author of the house. Framing the opening with metal.

Before cutting a wide opening, the opening is first reinforced with a tie rod.

The finished opening is reinforced with a tie rod according to the design.

A standard opening with double-row reinforcement with a tie rod according to the project.

Reinforcement of a wide opening in a load-bearing wall as prescribed by the Moscow Housing Inspectorate with partial sealing of the opening.

An opening with reinforcement for a niche and a doorway with reinforcement according to the design in a load-bearing brick wall.

Complex reinforcement of an opening in a 20 cm wall according to the project of the developer SU-155 (Mosaic).

Combination of two apartments, complex combined reinforcement of the opening according to the project.

The upper unit of the combined reinforcement of the opening.

The lower unit of the combined reinforcement of the opening.

Combined reinforcement of an opening from a channel and a corner in a monolithic wall.

Framing the opening with metal according to the project.

Strengthening a wide opening in a panel house on the top floor according to the project.

Strengthening an opening from a 140 corner in a 24 cm monolithic wall according to the project.

Combined opening reinforcement. Before cutting a wide opening, preliminary reinforcement with a channel is installed under the floor slab of the upper floor (standard MOSPROEKT design).

The opening is ready, only after installation of the main reinforcement is the preliminary reinforcement dismantled.

Fixing the marriage. According to the project, strengthening the previously made opening and tying the column 125 with a corner.

Strengthening an opening in a brick wall and tying a column.

Expansion of a monolithic floor with reinforcement from 27 channels according to the project.

Partial dismantling of the ceiling and installation of reinforcement, 24 channels are placed under the walls.

Finished opening with reinforcement in the ceiling according to the project.

And such projects for strengthening openings are not uncommon. The channel is welded to the reinforcement in the wall.

To open the reinforcement, you have to knock down the edges with a jackhammer.

Strengthening the opening in monolith 22 according to the project

Reinforcement of openings by welding of exposed reinforcement according to the project.

Strengthening a wide opening in a concrete wall according to the project.

Strengthening the opening, the project involves “recessing” the channel into the wall and tying it with studs.

What consumables and tools are needed?

To strengthen the walls, some tools and materials will be useful:

Tools:

- Machine with diamond disc.

- Hammer.

- Welding machine.

- Drill and drill bits.

Materials:

- bolts and studs;

- channels, corners or metal frame (depending on the thickness of the wall);

- metal plates that must first be cut according to the thickness of the wall;

- concrete mixture.

All consumables are purchased depending on the calculations made.

Strengthening the vertical sides of the opening

If the wall is a thin interior partition, then strengthening the opening can be limited to installing crossbars from a channel or a corner (which is even easier to do) in the upper part. Before strengthening a doorway in a wall more than 20 cm thick, you will need to install vertical supports in the form of corners, hot welded to the top crossbar and to each other. In order to strengthen the walls of the opening with a corner, you should make vertical grooves into which to mount a metal profile. The upper ends are welded to the channel. And only after this the actual excavation of the opening begins.

After the opening is completely cleared of masonry and the walls are sufficiently leveled, metal strips are welded between pairs of corners along the entire height of the opening. At this point, the strengthening of the doorway can be considered complete.

A few important points to consider when moving a wall opening:

- It is impossible to use fendering equipment on a concrete wall - microcracks may form, significantly reducing the strength of the wall.

- The width of the doorway in the premises of the lower floors is recommended to be no more than 90 cm.

- In new panel buildings, the load on the external and internal walls is distributed, so even the interior wall can be considered load-bearing; accordingly, it is not recommended to redo the openings in it.

The presence of an electronic level and a functional wall cutting machine greatly facilitates the work of strengthening the doorway. However, even with a conventional drill, with some skill, the goal is quite achievable.

Cutting methods

To cut a doorway with your own hands, you will need a tool, but you can choose it correctly after determining the method of work being carried out. The method depends on the wall material. It is not advisable to chisel and sledgehammer, as the integrity of the entire partition will be compromised. You can carefully cut the opening using diamond, laser, waterjet or oxygen cutting.

Diamond cutting

For concrete partitions, the method of diamond cutting of a doorway using a grinder or circular saw is used. The cutting element of the tool is a metal disk coated with diamond.

The diamond cutting method has many advantages:

- low level of vibration eliminates the appearance of cracks even on loose partitions;

- during the cutting process, an accurate thin cut is entrusted along the marked contour and at the desired angle;

- the noise level of a working tool does not exceed the permissible threshold specified in sanitary standards;

- a small amount of debris due to the absence of chips, which is impossible to achieve when using a hammer drill.

Disadvantages cost of purchasing expensive diamond blades. During work, the concrete wall is moistened with water, but fine dust still spreads into the room.

Laser cutting

Expensive equipment is used for laser cutting of openings. Previously, it was bulky and was used only in production. Modern laser cutting equipment is compact, but its high cost and specific purpose have made it popular only among specialized repair teams. The cutting of a concrete wall is made with a laser cutter due to the gas-discharge action.

Before starting work, the wall parameters :

- thickness;

- the presence of a reinforcing frame;

- passage of communications inside the partition;

- grade of reinforced concrete wall.

Additionally, the floor of the apartment building where cutting is planned is taken into account, as well as the admissibility of wetting the concrete structure with water.

Waterjet cutting

Cold cutting of an opening in a wall refers to the waterjet method. A special installation is used for work. It creates a strong stream of water at a speed of 1 thousand m/s. The liquid in the tank is mixed with abrasive particles with a diameter of about 0.4 mm. The prepared mixture is fed through a nozzle onto the reinforced concrete structure and destroys it at the point of contact. The cutting force depends on the pressure. At the maximum power of the equipment, a reinforcing frame made of steel rods is cut along with the concrete.

PRICES FOR OPENINGS IN BRICK WALLS

- Removing garbage and loading 1 container of 8 m3 and weighing 5 tons with an elevator - 4,000 rubles. Ordering a container 8m3 and weighing 5t – 4,500 rubles.

- The minimum cost of work is 8,000 rubles.

The noise level during cutting has acceptable standards determined by Moscow Government Decree N 73-PP “On the procedure for reconstruction and (or) redevelopment of residential and non-residential premises in residential buildings on the territory of the city of Moscow.”

How we are working

Application You leave an online application or order a call back

Consultation Our manager advises and clarifies the details of the service

Cost calculation Visit of a specialist and preliminary estimate of the cost of work

Agreement We place an order and conclude an agreement

Execution of work Prompt execution of work in accordance with the contract

Acceptance of work Acceptance of work and payment by the Customer for our services

Stages of work

To ensure that a door cut in a new location does not create problems in the further operation of the building, the wall should be correctly marked, accurately cut, perhaps even on both sides, and strengthened. Important! It is better not to make arched openings; they are extremely difficult to strengthen. It is more convenient to cut out a rectangle, and then create the required shape using drywall.

Marking

First you need to mark the surface of the wall, and if it is thick, then this will have to be done on both sides. A wall-cutting machine has a disk diameter of, for example, 1 meter, but when cutting a meter-long wall from both sides, it can go to a depth of less than 50 cm. For this, double-sided markings are made. It is very important here that the marks on both sides match perfectly, otherwise there will be problems with reinforcement later. For accuracy, it is convenient to use a laser level.

Grilling

It is better not to use chipping of bumpers in brickwork; this will lead to the mortar crumbling out of the seams and pieces falling out, as cracks may appear on them. Afterwards it will be difficult to attach metal structures. If the house is brick, it is better to use diamond drilling, and in other houses too, this speeds up the work, reduces the level of noise and dust.

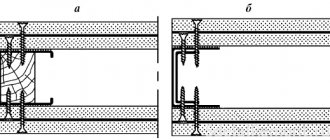

Strengthening

It is easy to strengthen the opening with a channel; two are placed vertically in the doorway, their walls should touch the wall. They are tied together through the wall with studs. If the wall is brick, you can bury them in the groove. It is easier to strengthen with a channel; it can be placed at the marking level. It is also convenient to fasten with an angle; it saves labor, metal and money. The corners are installed in concrete and secured with anchors.

The cost calculation depends on the type of building, the size of the opening or their number. The price for strengthening the opening is finally calculated after the visit of the specialist and the type of work that should be performed. This figure is also influenced by the type of reinforcing material.

Coordination of redevelopment

Complete demolition of the partition is simply impossible; approval for the redevelopment of the apartment in this option will not be signed by any authority. Documents for redevelopment of premises are obtained according to the plan and design documents. Everything is determined by an engineer, and the owner of the apartment will need to write a statement to the housing inspectorate. Documents for redevelopment price in Moscow from 10,000 rubles.

Why are openings strengthened and is it necessary to do so?

Cutting openings in a load-bearing support is complex; it must be done in accordance with technical standards and then strengthened. Failure to comply with this rule leads to a weakening of the wall, as a result of which the neighbors below may crack the slabs, which ultimately can lead to the destruction of the building. It should be noted that residents of the first and second floors are almost never given such a document allowing intervention in the supporting structure.

We serve individuals and legal entities and provide clients with good discounts when ordering a large volume of work. Payment for services is carried out both in cash and by bank transfer. Are you looking for where you can urgently order the service of strengthening openings? Our company is ready to help you in this matter and carry out urgent strengthening of walls in any volume in a short time!

When you need to strengthen

If a new house is being built, then when drawing up the project, the most suitable method of strengthening door and window openings and arches is taken into account. But there are situations when it is necessary to strengthen the opening in an existing building.

Cases when it is necessary to strengthen openings:

- If the walls of the building have become deformed, cracked due to time or mechanical damage. The technical condition of the house needs to be monitored. If cracks appear, the cement bonding layer is destroyed, or bricks fall out, restoration work must be urgently carried out. Timely measures taken will help keep the premises in good condition longer.

- When redevelopment is carried out, the holes are widened or they are made in other places. In these cases, reinforcements are installed even before new openings are dismantled. First, you need to draw up a project for carrying out the work, after consulting with a specialist, whether it is possible to break through the wall in the chosen place, and whether this will weaken the structure of the building.

- When replacing windows, you need to check before carrying out the work how strong the opening is, and, if necessary, pre-strengthen it before dismantling the old window.

Do I need permission?

Reconstruction and strengthening of a finished window or door unit is not reconstruction and therefore does not require special permission.

But during redevelopment, when you have to punch a new hole in the wall, you must fill out the appropriate documents. Without them, such work will be considered unauthorized and may entail not only administrative problems, but also lead the building into disrepair. First of all, you need to conduct a survey of the premises, inviting specialists to do this. If the house is already old and multi-storey, then due to its dilapidation it is unlikely to be able to obtain such permission. Another situation is when the neighbors above or below have already done redevelopment. Then the new door can only be made on the same level as the one in their apartment. Because placing openings in one wall at different levels can greatly weaken its load-bearing capacity.

Do I need permission to install openings in load-bearing walls?

If the opening is made in a load-bearing wall, it is definitely necessary to collect a package of permits. Violating the integrity of load-bearing walls without appropriate inspections and permits can lead to structural failure. The rights of neighbors are violated, as there is a threat of deformation of the house.

If we are talking about an opening in a regular partition, then the design takes place after the work has been completed.

Preparing materials to strengthen the doorway

To strengthen an opening in a concrete or brick wall, as a rule, rolled metal is used - a channel, a beam, a corner, a strip. Reinforced concrete lintels are rarely used due to their heavy weight.

Channels, metal plates, beams and corners are cut according to the dimensions specified in the project for strengthening the opening, and holes are drilled to tighten the lintel with nuts. After the metal rods are cut to specified sizes, the metal must be primed. To do this, you can use a special primer or any metal paint. Without a primer, after some time, the metal may oxidize, and as a result, rust may occur - and rust spots will appear on the walls and wallpaper.

How to strengthen an opening in a wall

Currently, installation work is carried out using diamond cutting. This method allows you to get a perfectly flat wall for perfect contact of metal elements with the wall. That is, after cutting with a diamond disc, no additional processing of the walls is required, unlike the good old combination of a hammer drill and a sledgehammer.

The cut opening is strengthened with temporary timber. Then the metal is prepared and cut to size. Depending on the type of reinforcement, a metal frame made of a channel or angle is installed in the opening, after which it is scalded. The opening is reinforced according to the customer’s design or one of the standard reinforcement solutions is used.

To perform high-quality reinforcement, it is important not to skimp on materials. Rolled metal must correspond to the steel grade specified in the project. Reinforcement of the opening is carried out in accordance with the developed project, strictly adhering to the designer’s instructions.

It is important to know

- A strong and reliable connection will be achieved by complete welding of the reinforcement elements along the seam. Spot welding will not provide sufficient rigidity.

- The best way to create an opening in a concrete or brick wall is cutting with a diamond blade.

- Before installation, it is imperative to treat metal elements with anti-corrosion agents.

- To safely distribute the load, the lintel stop on the sides should be 20-30 cm wider than the opening.

All work on dismantling and strengthening structures and openings is carried out in accordance with SNiP of the Russian Federation. All required documents are listed below:

- SNiP - II-22-81 “Stone and reinforced stone structures”,

- SNiP - 01/52/2003 “Concrete and reinforced concrete structures. Basic provisions",

- SNiP - II-23-81 “Steel structures”,

- SNiP - 3.03.01-87 “Load-bearing and enclosing structures.”

What else can be useful during work?

Before starting the construction process with your own hands for redevelopment, do not forget about personal protective equipment. All areas of the body must be covered with overalls; if there is no special suit, then you can limit yourself to an old wardrobe. It is important that all clothing fits snugly to the body. Hands must be covered with work gloves or gloves - this will avoid serious injuries or minor cuts and scratches.

The face must be protected by a mask or respirator, since dismantling walls involves heavy dust, which can lead to problems with the respiratory system. When working with a hammer drill or grinder, you must use safety glasses, which will help prevent eye injury from small fractions of brick.

Punching a doorway in a brick wall

Despite progress, impact is still the leading method of constructing doorways. This can be explained both by its low cost and by the fact that it does not require special qualifications from the performer.

The work can be divided into several stages:

- Marking the future opening. In the absence of special instruments, it is better to do this with a large square and a meter ruler. In this case, it is advisable to make the markings on the outside of the wall, and remove all existing coatings (plaster, whitewash, wallpaper, etc.) at the marking site so that the masonry is visible. This is necessary in order to correctly install the support jumpers at the required height. Having noted the position of the jumpers, you need to make more marks for the supports at a distance of 15 cm from them.

- Installation of supports. They are installed only when the opening width is more than 90 cm, because... The brickwork will withstand a shorter distance on its own. The distance from the supports to the walls is 60-90 cm. The supports are either brick pillars (but this takes a long time, since you need to wait for the mortar to set and is expensive) or reinforced concrete beams.

- We make holes for supports and studs. Through holes are drilled at the previously marked points; then you will have to work with a hammer and chisel to make the holes rectangular. The studs themselves have a size of approximately 75*100 mm and are made from beams. The finished pins are inserted into the holes and supported by vertical supports. After adjusting the structure vertically, you can secure everything with nails. The result will be the outline of the future opening, separated from the rest of the masonry by supports. This is necessary so as not to damage the entire wall when knocking it out.

- All covering materials (plaster, paint, etc.) are removed from the wall inside the contour - using the same hammer and chisel. Outside the contour too, about 2-3 cm. We begin to disassemble the wall from the lintel, that is, from top to bottom. A hammer drill can help here. Having made the hole level, you can insert a support beam that will hold the arch. All holes are filled with mortar, and work is stopped until it completely hardens.

- Now you can disassemble the wall using a hammer and a hammer drill. You can, of course, do it the old fashioned way, knocking it out with a sledgehammer, but the consequences are doubtful. Drilling holes at several points with a hammer drill will weaken the masonry and allow you to use less impact force. Ideally, work should be carried out on both sides of the wall at the same time. After dismantling the wall, you will need to carefully remove the protruding bricks and clean the opening from debris, protrusions and plaster.

Strengthening a doorway in brick walls

If the opening is located in a load-bearing wall, it will need to be strengthened; without this, the remodeling project will not be approved. Most often, steel channels are used for these purposes, less often angles or I-beams. The hot-rolled profile copes well with loads and is resistant to torsion, compression, bending and stretching. The only drawback of the channels is the rounded edges and bevels, which do not allow for 100% fit to the edges of the opening.

When installing channels, they either grind the edges (which requires a hammer drill and a diamond cutter), or fill all the cavities with solution, but this is also not always possible, since after installation it is no longer possible to approach their interior. That is why the channel is often replaced with corners. Their technical characteristics are no worse, but the corners and planes are even. Therefore, the corners fit snugly into the edges of the opening and the load-bearing wall. All that remains is to tighten them with bolts. The reinforcement technology is absolutely the same for all materials. A pair of corners (channels) are fastened one at a time on the outer and inner sides of the opening into a horizontal hole specially made for them in the masonry, and then (also through previously made holes) they are tightened with bolts. The main thing is to remember that it is not the opening that is being strengthened, but the wall above it, so the protruding part of the reinforcing element should be directed towards the wall above the opening.