Apartments built at the end of the last century, as a rule, do not have a very convenient arrangement of rooms. The bathroom is located too close to the kitchen or living room, which often brings some inconvenience for household members. The noise of water flowing into the bathroom or the flushing of the toilet tank can not only turn you away from eating, but also simply create discomfort. The only solution to this problem will be high-quality sound insulation of the bathroom and toilet.

@Shumoizolyatsiya_vannoi

To perform high-quality soundproofing of a bathroom, it is first of all important to take into account the features of this room. Bathrooms and toilets are rooms with high humidity, and it is important to remember this when choosing soundproofing materials. When working with a bathroom, in addition to soundproofing, you must do waterproofing, only in this case your work will be completed for a long time.

When planning soundproofing of a bathroom, it is also important to take into account the parameters of the room. In some houses, the bathtub and toilet are combined in a small room, which forces the use of thin insulating materials. When the bathroom has large dimensions and there is room to spread out, then with the use of modern insulating materials it will be possible to do everything in the best possible way.

Important! Soundproofing a bathroom must be carried out comprehensively, from waterproofing to finishing, since the room has high humidity.

How to soundproof a bathroom correctly

The first thing you need to take into account is the peculiarity of such a room - high humidity. It is important to remember this when purchasing soundproofing materials. In addition to insulating various surfaces from noise, it is imperative to make high-quality waterproofing in the bathroom. Only in this case will the completed repair last a long time.

Additionally, it is worth considering room parameters. If the toilet and bath are combined in a small room, it is advisable to use thin insulating building materials. Large bathrooms provide the opportunity to use any variety of high-quality modern materials, which means soundproofing the toilet in the best possible way.

Important! Due to the high level of humidity, soundproofing a bathroom must be carried out comprehensively: work should begin with waterproofing and end with finishing.

Waterproofing a bathroom includes treating the floor and walls in areas with high levels of humidity Source vanna-prosto.ru

Clamps with rubber inserts and damping pads

This method of dealing with excess noise is based on reducing the level of pipe vibration associated with the beating of the flow against the walls. Due to the fact that the clamps are equipped with internal ring inserts made of dense but elastic rubber, the pipe maintains a stable position, vibrations are damped and are not transmitted (or transmitted to a lesser extent) to building structures.

The video shows a simple method of installing a riser using clamps with damping inserts. Also, such inserts are convenient for isolating the riser where it passes through the wall and/or ceiling of the building (photo below).

When using the last option, a hole is cut in the building structure with a diameter that corresponds to the diameter of the pipe, taking into account the damping insert. The pipe should pass through the hole with little effort, “with interference.” If the riser must pass not through solid material (concrete, wood, panels of various kinds), but through masonry or a frame wall, the hole is reinforced and limited by a metal insert ring.

How to soundproof a toilet with your own hands

Cotton wool (basalt, mineral) is well suited as a sound-proofing building material for wet rooms. It does not absorb moisture and is protected from the development of fungus and mold.

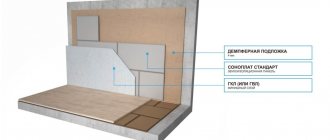

If the dimensions of the bathroom do not allow the use of frame sound insulation, it is recommended to use thinner soundproofing membranes. The finishing of the frame can be done with moisture-resistant plasterboard. It contains special additives, so it is not at all afraid of water.

Soundproofing work should begin from the riser. The sounds of sewerage drainage and structural noise can often be heard from it. During housing construction, soundproofing of such a pipe is done occasionally. Often it is simply sealed with cement mortar.

Sequencing:

- Remove the layer of cement from the surface of the riser.

- Wrap the prepared section of the pipe (preferably from the floor to the ceiling) with vibration-proof tape.

- Fill the lower part of the tube with cement mortar and wait until it dries.

Combined protection

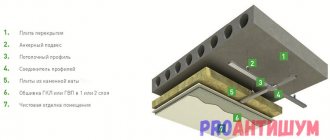

Let's look at how to create reliable sound insulation using membrane sheets and ceramic fiber fabric:

- First, a base layer of ceramic fiber cloth is glued to the ceiling surface;

- using mushroom dowels, the membrane layer is secured;

- install direct hangers;

- secure profiles;

- perform lathing;

- fill the space between the profiles with mineral slabs;

- attach the first layer of drywall to the profiles;

- Glue the membrane onto the drywall for the second layer and secure it with self-tapping screws on the first layer.

On a note! You might also be interested in learning how to waterproof a bathroom ceiling

Soundproofing plaster

Soundproofing plaster consists of porous fillers that impart soundproofing properties. Applying a thin layer provides protection against noise penetration from neighboring apartments. This method is suitable for a small bath with low flow.

The above sound insulation methods are used in stretch and suspended ceilings. Everyone can choose the optimal sound-absorbing coating for their bathtub.

Acoustic fabric

Acoustic fabric is a polyester fabric with perforations. It is used in combination with other methods, providing the desired soundproofing effect. If you cover the ceiling with mineral wool slabs, you can achieve an increased level of sound insulation. Installing such a ceiling is not difficult; you can do it yourself. In addition to good sound insulation, this way you can achieve a constant temperature in the room.

Video description

How to soundproof a sewer riser.

Soundproofing of a toilet riser is carried out only after a detailed consideration of the causes of extraneous sounds Source static.tildacdn.com

When soundproofing a bathroom, it is important to install high-quality doors. Even ordinary veneered ones will do if all the cavities inside the structure are filled with construction foam and mineral wool. You can perform this procedure yourself or use the services of specialists. In any case, you will have to disassemble the door.

Externally, soundproofed doors are similar to standard ones, but inside they are layers of soundproofing material Source doors777.ru

The flooring needs sound and waterproofing. To implement the latter, you can use bitumen mastics containing rubber. In order to vibration-proof the floor of the bathroom, it is possible to make a simple screed, then cover it with tiles.

Soundproofing methods

The best insulation for sewer pipes is the absorption of noise by the pipe itself. Products have been developed whose plastic composition includes mineral powder. It can be microcalcite, consisting of marble flour or powder. Instead of marble, dolomite, limestone and chalk are also used. Such sound-absorbing products are distinguished by thicker walls, color (white) and longitudinal markings with red and green stripes. 2).

Figure 3. Plastic pipe with a polyethylene cup.

Between them there are inscriptions about the manufacturer, the amount of noise attenuation and other parameters of the pipe. Such materials are quite expensive. Their service life is approximately 20 years.

Such pipes consist of several layers. The inner one is made of polypropylene with fillers. The middle one is made of polypropylene with minerals. The outer layer is the most durable, made of polyvinyl chloride. Pipe installation procedure:

- a piece of pipe is cut to size;

- O-rings are placed;

- the internal and external surfaces are cleaned of dirt;

- silicone is applied to the end;

- the pipe is inserted into the socket until it stops, then moves out of it by 10 mm;

- the pipe is attached to the wall.

Not every owner can buy such pipes. But it doesn't matter. Soundproofing of ordinary plastic and cast iron sewer pipes is also possible. Cast iron risers are removed in parts and washed with “Mole” products.

Figure 4. Pipe mounting clamp.

Then you can put them in place or replace them with plastic. The advantages of such a repair:

- no need to touch building structures;

- all work can be done with your own hands;

- material costs are not very high;

- the noise level is reduced hundreds of times.

If the riser is assembled entirely from plastic pipes, then it must be separated from the ceilings with a plastic cup. It consists of polyurethane foam filler (Fig. 3). The riser is separated from the walls by special fastening clamps (Fig. 4). Replacing polyurethane foam with regular polystyrene foam or mineral wool will not work. A special clamp can be replaced with an insert made from a car inner tube or microporous rubber. They cope well with infrasounds.

Insulating pipes and risers in straight sections is quite simple. You need polyurethane foam, which is sold in stores in the form of narrow and wide mats. They are usually rolled up. A piece is cut from the mat wide enough to wrap around the pipe.

The pipe is wrapped, the soundproofing material is secured with tape. A narrow mat is wound around the riser in a spiral and is also fixed with tape. The sounds of water flowing in the sewer will not be heard.

Materials

To make a quality soundproofing of a bathroom, you need to choose the right insulating building materials. Today there is a huge variety of them. Therefore, choosing the most suitable products is not difficult at all. If difficulties arise during the selection process, you should contact specialists for help or use the services of a consultant at a hardware store.

Under tiles

In the toilet, soundproofing of the floor base must be done simultaneously with reliable waterproofing. In this case, it is allowed to use the following building materials:

- bitumen mastic;

- special impregnation;

- hydrobarrier;

- soundproofing membrane.

In addition, it is possible to use floating floor technology. It involves laying an insulating layer under the screed. Despite the fact that such sound insulation is quite effective, it is used only occasionally for the bathroom.

Before laying tiles on the flooring, it must be treated with a sound-proofing sealant or a special adhesive composition. Waterproofing the resulting seams will extend the life of the floor and will prevent the appearance of mold and the development of bacteria at the joints. It is quite possible to carry out such work on your own, without involving professionals.

Ceramic tiles are a popular floor covering in the bathroom, which is characterized by high strength, wear resistance, practicality in maintenance and cleaning Source chudopol.ru

Measures to reduce noise levels

All of the measures listed below are aimed at reducing the noise level arising from the transmission of vibrations from the floors to the pipe.

suitable for those who have not yet replaced the old water supply

Using "quiet" pipes

At the moment, some manufacturers of plastic pipes produce a special type called “silent pipes”.

made of polypropylene with some differences

- firstly, the walls of such a pipe are thick;

- secondly, the structure of the material is different;

- thirdly, the pipe is multilayer.

The outer surface of quiet pipes is made of durable and resistant to mechanical damage polypropylene. The inner surface is also made of this material and is perfectly smooth and wear-resistant. The main feature of the pipe is its “filling”. Between the outer and inner walls there is a layer of plastic, which contains particles of various mineral powders. This composition has increased sound insulation properties.

It is very easy to distinguish quiet pipes from ordinary ones - they are white and marked in the form of two longitudinal stripes of red and green or yellow. Experts note that they really reduce the noise level to almost zero. But they also have disadvantages:

- They have a high cost;

- Provide a shorter service life - about 20 years.

Partial replacement of the riser

If your old pipes are made of cast iron, a partial replacement can be done.

- Before you begin dismantling a cast iron riser, which involves breaking apart concrete slabs to remove the cores, perform a visual inspection of them;

- If no defects such as cracks are found on the crosspieces, and the riser in this place has always been sealed, a partial replacement can be performed while preserving these elements;

- To do this, cut out the main part of the pipe and leave a distance to the upper and lower cross, which will allow you to connect the cast iron elements with the plastic pipe;

- The condition of the inner surface of cast iron pipes is assessed. It is necessary to remove the layer of plaque formed during operation. This can be done mechanically, or using various chemicals such as “Mole”. The liquid must be carefully applied to the surface and left overnight, after which it will be easier to remove the petrified plaque. There is no need to completely clean the inner surface of the pipes. The main thing is to provide clearance.

This method has several advantages:

- You eliminate the possibility of the formation of the most harmful type of noise - structural, since cast iron crosspieces passing through concrete floors can dampen vibrations;

- Fewer materials will be required to complete the work, which will lead to lower costs;

- There is no need to dismantle part of the concrete floor to remove the crosspieces. For this type of work, some teams require additional payment;

- Since the length of the plastic pipe section will not exceed 2-3 m, the sounds in it will be much quieter than if you completely changed the riser together with the neighbors below and above, and the pipe was solid.

lack of plasterboard box

Installing retaining rings and damping pads

This is an additional measure that can be carried out both with a ready-made water supply system and directly at the time of replacement.

- If the riser is being replaced completely, make sure that workers insulate the pipe in the place where it passes through the ceilings. Typically, a special sleeve filled with polyurethane foam is used for these purposes;

- If the riser has already been installed, but there is still a gap in the ceilings around the passage, you can install your own gasket. To do this, you will need to buy a piece of pipe with a larger diameter than the riser, cut two fragments of the required length, saw the resulting glass lengthwise and secure it around the pipe. You can connect the two halves with construction tape or special soundproofing tape. The gap between the pipe and the glass must be filled with polyurethane foam filler;

- To ensure the immobility of the pipe and minimize vibrations transmitted from the walls to the pipe, it is better to use special clamps with a rubber layer to fix it. They are called damping. If you have already purchased regular clamps, you can modify them yourself. To do this, it is enough to attach a piece of rubber seal, porous rubber or a piece of rubber from an old tire to the inner surface of the ring.

Video description

Soundproofing the ceiling. Installation of soundproofing suspended ceiling.

On the floor

To finish the flooring in the bathroom, it is best to use ordinary tiles. Thanks to its porous base (on the reverse side), it is able to absorb extraneous sounds. After installing the tile products, it is recommended to lay a rug on top. It will add attractiveness to the room and provide additional sound insulation.

Combined protection

High-quality soundproofing of a bathroom will only be achieved if the walls, ceiling, flooring, and doors are properly insulated. The latter should not allow any sounds or annoying noises to pass through at all. Only an integrated approach to solving such a problem will help achieve high-quality results.

Today there is a huge assortment of various soundproofing materials on sale that make it possible to carry out sound insulation in accordance with all technological requirements, with maximum benefit. If you create a project correctly, then all the work can be done quickly and efficiently, without turning to professionals.

To arrange high-quality sound insulation for a combined bathroom, it is advisable to take an integrated approach and think through the stages of all work in advance Source design-homes.ru

Types of insulation for sewer networks

Whether sound insulation is needed for sewer pipes and which is better is not difficult to decide. Only for this you will have to study all its types in detail. Then the choice will not be difficult.

To solve the problem of sound insulation in the drainage system in an apartment, the following methods are recommended.

- "Silent" pipes. Some manufacturers make products that are called "quiet". They are made of high-density polypropylene, their multi-layer nature allows for excellent sound attenuation. At the moment, the only disadvantage of such products is the high price.

- Soundproofing materials. The drain network, tightly covered with a soundproofing coating, operates silently. It is divided into the following types.

- Most often, foamed polyethylene is used for such work, which not only perfectly muffles sound, but also has high thermal insulation characteristics. Plus, to all this, it prevents the formation of condensation on pipelines, which is a prevention against the appearance of fungus and mold.

- No less often, roll insulation is used to reduce noise levels. This is not new to the construction market, and the popularity of this insulation has not diminished over the years.

- And one more material that can be found during such work is soundproofing tape.

The list of insulation materials can be supplemented with the following main types:

- polyethylene foam;

- fiberglass;

- mineral wool;

- various porous materials;

- synthetic rubber.

Each of the sound insulation presented above has positive characteristics and individual properties that must be taken into account when installing in an apartment.

If this is not taken into account, then the sound insulation simply may not be suitable for the sewer pipes installed in the apartment.

IMPORTANT! Soundproofing pipes is a very responsible task that requires care. Damage to the covering of the sewerage system must not be allowed.

Rating of the best mobile phones for games

Rating of the best mobile phones for games and the Internet. Features of choosing a gaming smartphone. Main technical characteristics, CPU frequency, amount of memory, graphics accelerator.

Polyurethane foam

Construction foam is actively used by craftsmen for repairs or construction of a new building. It is also suitable for creating sound absorption in the bathroom. You can purchase it at any construction or hardware store. Before use, protect your hands, head (wear a hat or scarf), and face. Read the instructions.

How to use: turn the container over and degrease the surface. It is enough to treat it with an alcohol-containing composition. Then slowly cover the bathtub with a thick layer of this foam. Apply carefully in a dense, even layer, trying to avoid gaps. Act slowly, then the foam has time to harden without dripping. Having finished processing the side of the bathtub, turn it over to the second one, but after the foam has completely dried.

Plastic film will help enhance the effect. Polyethylene, used by summer residents to create greenhouses, is suitable. It is dense, inexpensive and quite elastic. After applying the foam, cover it with a piece of film prepared in advance. Pressing it more tightly with your hands, form a crust resembling a shell.

Important instructions:

- foam intended for indoor installation is suitable;

- It is better to carry out very presentable processing in the summer;

- To ensure an even layer, you should buy a special nozzle or “gun”;

- before processing, preheat the container (hold it under the tap, turning on the water hot) and shake;

- leave the overflow area free;

- review the indicated expiration date and use the foam before it expires.