Drywall partitions quite often become a lifesaver in designing an apartment renovation. Just a few decades ago, walls made of brick or concrete were erected in their place, which was quite troublesome and required a lot of financial costs for the purchase of materials and the work of specialists. Therefore, the design of partitions was used extremely rarely, when it was really necessary. Nowadays, with the advent of such material as plasterboard, the construction of false walls has become completely commonplace, which you can cope with yourself. How to make a partition from plasterboard, as well as its positive and negative characteristics will be discussed in this material.

Plasterboard sheet - what is it?

Gypsum plasterboard (GKL) is a modern building material that belongs to the so-called dry construction. Allows you to get a flat, smooth wall surface without resorting to the long and costly procedure of leveling the walls with plaster.

A gypsum board sheet consists of a layer of gypsum covered on both sides with sheets of cardboard. When choosing, you need to take into account that there are four types of drywall:

- Normal - for rooms with normal humidity, covered with gray cardboard.

- Moisture resistant – for rooms with high humidity up to 75%. Suitable for use in bathrooms and toilets. Painted green.

- Fire-resistant - used for the construction of hearths and fireplaces. Non-flammable, easily tolerates heat, painted pink.

- Acoustic - with increased density of the gypsum base and reinforcement. Has improved sound insulation properties. Suitable for finishing walls and ceilings of bedrooms and recording studios. Painted blue.

The advantages of gypsum boards include environmental friendliness, ease of installation, low weight, and the ability to create curved structures. The main disadvantage is fragility - drywall does not withstand impact loads well and crumbles easily.

Therefore, when using it in children's rooms, hallways and other rooms where critical loads on the walls are possible, you need to think through everything carefully. And if the strength of gypsum plasterboard is not enough, you can use gypsum plasterboard.

Advantages and disadvantages of plasterboard partitions

Simple and figured gypsum plasterboard partitions have their advantages and disadvantages.

The advantages are:

- fairly easy bending of drywall, which helps achieve any design solutions;

- the finished model weighs little;

- there are absolutely no flaws on the plane of the septum;

- Even a person with little experience can assemble the frame and cover it with plasterboard;

- the material itself has a number of advantages: fire resistance, environmental friendliness, green and gray gypsum boards are moisture resistant;

- Plasterboard products are easily and quickly manufactured.

Among the shortcomings, perhaps, we can highlight:

- fragility of drywall;

- weight limit when placing objects on it.

The material cannot be replaced in the manufacture of design models used to create certain areas, or even full walls. Most new apartments have only load-bearing internal partitions. Using gypsum plasterboard, owners can successfully redevelop and create comfortable partitions.

Gypsum fiber sheet - what is it?

Gypsum fiber sheet (GVL) is a building board made of gypsum mixed with cellulose and reinforced with reinforcing mesh. The material is very strong, high density. GVL is initially non-flammable, since its components are mixed with gypsum, and with the addition of special components it can also be moisture resistant.

High strength makes it possible to use GVL for leveling not only walls and ceilings, but also floors. And the high density allows you to mount furniture on the walls, easily withstanding a force of up to 80 kg per anchor.

- But these same advantages also determine its disadvantages. If drywall is easily fastened with ordinary self-tapping screws, then the gypsum board must be secured by pre-drilling holes or using self-tapping screws.

- Greater strength gives almost a third more weight and makes installation more difficult. Well, the cost of GVL is almost twice as high, which is also a very significant indicator.

We fix the plasterboard

Do not forget that the structure is curved, so before sewing it with gypsum plaster boards, the material must be cut into the necessary fragments.

Sheathing of gypsum plasterboard structure

Working with gypsum boards

Drywall is a material that has qualities that facilitate quick installation:

- malleable when processed;

- lasting;

- environmentally friendly;

- has a small specific gravity.

In addition, there will not be a lot of dust and dirt when working with this material. However, it is worth understanding that drywall is produced in the form of a flat slab, so to create a curved structure you will have to bend the drywall. There are several ways to make a flat gypsum board element curved:

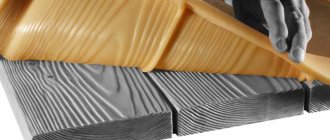

- "Wet" method. The elements are moistened with water using a roller; it is advisable to do this on both sides and leave for 10-15 minutes for moisture to penetrate to the core of the material. Attach the element to a previously prepared pattern and leave to dry for a day. Bend drywall using cuts

- Roll the slab with a needle roller and wet it, this will make the moistening process go much faster. Then the structure is bent and left to dry.

- "Dry" method. Using a drywall knife, make shallow cuts on the inside of the slab. The notches should run perpendicular to the fold.

- Make cuts using a router, which will select V-shaped grooves that help bend the sheet to the desired curvature.

It is necessary to describe another option for covering a radius structure - using arched gypsum board. This material is only 6 mm thick, so it bends very easily without breaking. You need to secure the material from the highest point, moving towards the edges.

Options for using partitions

There are several options for using plasterboard partitions:

- Moving or changing the size of doorways;

- Increasing the number of rooms in a room by erecting false walls;

- Zoning is the division of a room into functional zones.

As an example, separating the cooking area from the living room in a studio apartment. And if the walls do not carry a special decorative load, then partitions for zoning can give scope to the designer’s imagination, becoming bookshelves, decorative niches and much more.

Interior use

There are specialized options for drywall, namely arched. This type will help you easily build any non-standard partition from sheets of plasterboard. It is very convenient that for each individual style of room decoration there is its own design option.

There are other additional functions for partitions made of this material. For example, you can easily install additional lighting for the room in the partition. In this case, all communication wires will remain inside the structure.

Very often in modern times, plasterboard partitions are made in the form of niches for placing cabinets. Just add a wardrobe door and a hanger to the niche and you don’t have to buy a wardrobe.

This type of partition is also suitable for a place for a TV. This same place can be shelves for books, photo frames and other small items. Next we will look at how to make an interior partition.

Materials for constructing the frame

To construct the frame, profiles made of ferrous or galvanized metal with a thickness of 0.5 to 2 mm are used. Galvanized metal is less susceptible to corrosion, so it can be used in damp areas. If the work is carried out in rooms with normal humidity, a corridor or a bedroom, then there is no point in overpaying for galvanizing.

Guide profiles ranging in size from 50/40 to 50/100 are laid horizontally. And rack-mount ones, with sizes ranging from 50/50 to 100/50, are installed vertically.

It is possible to construct a frame from dry wooden beams of comparable dimensions. If the goal is to achieve maximum sound insulation, then the wooden frame will resonate less, transmitting sound, and the room will be quieter.

Required materials and tools

- Guide and rack profiles,

- Drywall sheets,

- Damper tape,

- Dowel – nails 50*40,

- Self-tapping screws,

- Gypsum based putty,

- Hammer,

- Screwdriver,

- Metal scissors,

- Stationery knife,

- Building level,

- Putty knife,

- Tape measure and pencil.

Types of profiles

The wall frame for plasterboard is made of a metal profile. Due to the strength of the structure and the rigidity of the metal, the manufactured partition does not differ from the wall.

The profile is divided into two categories:

- PS (rack profile). The following sizes are available: 50x50 mm, 65x50 mm, 75x50 mm, 100x50 mm

- PN (guide profile). Dimensions: 40x40, 65x40, 75x40, 100x40. Their length can be 3 m, 3.5 m, 4 m.

Marking the future wall (step by step instructions)

The best solution for marking is a laser plane builder or laser level. Having established the level, we get ready-made marking lines that you can work on immediately, or you can transfer them to the walls with a tapping thread or a simple pencil.

In the absence of a laser, a regular building level, plumb line and tape measure are used. The location of the future partition is marked on the floor, not forgetting to mark the space for the door opening, if one is planned. And from the floor, measuring with a plumb line, markings are made on the walls and ceiling.

Finishing a finished decorative wall from gypsum plasterboard

The shape of the walls, decor and finishing need to be thought out at the marking and planning stage, since this will determine how harmoniously it will fit into the overall interior of the apartment.

False wall in loft style Before finishing, be sure to use primer for deep penetration.

This will help increase adhesion between the drywall and the finishing material. Particular attention should be paid to the correct sealing of the joints between the slabs, otherwise cracks may appear on the partition over time. Do not seal seams without using reinforcement. As a decorative finish for walls, you can use various facing materials:

- painting drywall;

- plaster with a relief effect;

- finishing with photo prints;

- clinker stone;

- stucco;

- backlight;

- stained glass;

- wallpapering.

Many designers advise making a curved decor on the wall using various materials, for example, drywall and:

- aluminum;

- plastic;

- wood;

- polycarbonate;

- MDF.

How to arrange the walls in the apartment is decided by the owner himself; it all depends on the family’s budget, the area of the room and the overall design of the apartment.

Installation of guides

The next step is installing the guides. Having cut the guide profile to size using metal scissors or a grinder, stick the damper tape on the profile surfaces that will lie on the floor or walls.

This will avoid the transfer of vibrations from the concrete foundations to the profile, which will significantly reduce the noise level in the room.

The marked and pasted profiles are attached to the floor with dowels - using 6/40 nails, into holes drilled with a hammer drill, every 40 - 60 cm, but at least three pieces per profile.

How to assemble a gypsum board wall

Making a false wall from plasterboard will not be difficult. To do this you will need: fasteners, profiles, a screwdriver, a hammer drill, plasterboard, spatulas, putty and a little patience. The algorithm for performing the work is as follows:

- make a design drawing and mark the installation area;

Mock-up of a false wall with sound insulation - assemble the sheathing from a metal profile or from wooden blocks. It is worth noting that it is better to use arched structures;

- lay wiring under drywall, insulation or sound insulation;

- sheathe the structure with gypsum board slabs;

- perform finishing cladding;

- connect the backlight.

Now let's look at these stages in more detail.

Drawing and marking

This stage should not be neglected; the final result will depend on it. So:

- We draw up a drawing on paper that will determine the installation of guides and rack profiles;

- We carry out the markings; for this we need a building level. Straight stripes should be drawn on the floor and ceiling, check their parallelism relative to each other using a plumb line;

- Then we mark the installation locations of the wall profiles, the pitch of which should be 40 cm. Important! Since the decor will be mounted on a plasterboard wall, the structure must be rigid enough to support the metal frame of the decor; Options for the location of the frame and joints of gypsum boards when installing a decorative wall

- If the wall is very uneven, you will have to install direct hangers, which will additionally support the structure, connecting it to the base. Their installation locations should be noted.

The marking is completed, you can begin installing the frame.

Assembling the sheathing

This process will not be difficult if you approach the issue with due responsibility. We will assemble the frame in the following way:

- Attach a guide profile to the line on the floor and screw it onto dowel nails, the pitch of which is 25-35 cm. To ensure that the work goes quickly and without stopping, use a hammer drill with a 6 mm drill. Then check the level; Horizontal fastening of the profile to the floor

- The same action must be performed on a plasterboard ceiling. Check by plumb line how parallel the guide profiles are;

- Now it's time for hangers, if required. The hangers are fastened in a checkerboard pattern on two dowel-nails;

- It's time for wall profiles. Each profile is inserted into the guide elements at the top and bottom. Next, they are attached to them using “seeds” - small self-tapping screws for the profile;

Fastening wall and ceiling profiles - Wall profiles need to be secured to hangers; two small self-tapping screws are screwed on each side;

Vertical installation of profiles - We make lintels from sections of rack profiles that will connect the wall profiles to each other and strengthen the structure.

Lathing frame for false wall

We check the level of the structure. Then you need to lay the wiring in a special corrugation and lay a sound insulator, if one is to be used.

Sheathing the gypsum board frame

Now you can start sheathing the sheathing with plasterboard. You need to do it like this:

- You must first sheathe whole sheets from the corner. Place the sheet against the sheathing and screw it onto the black screws - a step along the edges of 15 cm on the sheet is 25 cm. Important! If the height of the wall is greater than the dimensions of the gypsum board sheets, then the material must be screwed in a checkerboard pattern. If the first whole sheet goes from below, then the second from above and so on; Covering the frame with plasterboard

- As soon as all the whole sheets are attached to the frame, you need to cut the material, if there are segments, and secure it.

At this point, the sheathing of the sheathing is completed, you can proceed to the final stage - finishing.

Drywall finishing

Some people believe that it is not necessary to finish a plasterboard wall, on which there will be decoration later, since most of the wall will be covered. But this is a wrong statement. So, let's start finishing:

- First of all, we embroider the seams between the plates at an angle of 450, then prime the joints with a brush. We seal the joints and seams of drywall

- As soon as the soil dries, fill the seams with plaster mixture using a spatula.

- Until the plaster layer has dried, we glue the serpyanka, pressing it well into the plaster.

Primer and putty of the wall - Then we apply a layer of plaster so that the joint is smooth, but the serpyanka is completely hidden. Leave the seams to dry.

- As soon as everything dries, you need to go over the plaster with sandpaper and putty the entire surface of the drywall in one layer.

The plasterboard wall is ready, now you can start building decorative elements.

We plaster and lightly sand the wall. It is worth noting that no matter what decor you perform on the wall, be it complex or simple, the algorithm for performing the work will be the same. Do not forget that decorative elements must match the design of the room. Too large and bulky decor in a small room will look out of place, and a small one may get lost.

Drawing of a wave on a gypsum plasterboard wall So before starting installation, draw the plasterboard decoration that you plan to apply to the wall, first on paper and then on the plasterboard wall.

Installation of racks and sheathing

Having finished with the power circuit, install vertical racks. They are installed every 50 - 60 cm. The profile is fastened together with a cutter. The tool punches a hole in the metal and moves apart parts of the profile, fastening it together.

Some craftsmen attach the profile to each other with self-tapping screws, which is not acceptable. With this type of fastening, the heads of the screws protrude above the surface, preventing a tight fit of the drywall sheet and the surface turns out to be uneven.

Sheathing and sound insulation

The next step is installation of drywall. The sheets are attached to self-tapping screws, the length of which should be 1 cm greater than the total thickness of the gypsum board sheet and the profile. Shorter screws will not create the required force.

An important point: the head of the screw is recessed into the sheet by 1 mm. If you screw it deeper, there is a high risk of crumbling the drywall, which leads to a loss of strength of the entire structure. To make this task easier, you can use a special screwdriver attachment.

Having sheathed the frame on one side, fill the space between the posts with sheets of mineral wool to improve sound insulation and sheathe the second side.

The finished wall is puttied with gypsum putty, filling the joints of the sheets and marks from the screws, and the finishing is carried out.

Fastening drywall

Let's start attaching the drywall sheets to the frame. We start from the wall. We fasten the sheet with self-tapping screws. The hats should sink slightly into the drywall. Later they will be covered with putty and will not be visible.

It is not recommended to screw in screws near the corner of drywall. The material is fragile, for this reason there is a high probability that the corner will break. It is advisable to deviate from the corner by about 5 cm.

Drywall joints must be located on the profile. If this does not happen for you, then you will have to either cut off a piece of the canvas or move the profile.

Note!

Insulate the foundation with your own hands - a step-by-step description of the use of the best materials and technologies (90 photos)

- Do-it-yourself pergola on a summer cottage: step-by-step instructions with photos and descriptions

- Laying laminate flooring with your own hands: a detailed description of how to lay laminate flooring. Laminate calculation, step-by-step description and installation secrets (105 photos and videos)

After installing the whole sheet, we will have to cut the necessary pieces. To do this, the required size is marked on the sheet, and the top layer of cardboard is cut through with a knife.

It is advisable to use a knife two or three times to completely cut through the layer. After this, moving it to the edge of the table, you need to bend it at the place of the cut and break the gypsum core.

Then the sheet is turned over, bent at an angle of 90 degrees and the second layer of cardboard is cut through.After finishing fixing the drywall, soundproofing material or insulation should be installed on one side. If necessary, communications should be carried out. After this, fastening is carried out on the second side of the partition.