Home renovations should not only be of high quality, but also beautiful. They greet you, as they say, by their clothes. Therefore, finishing materials must combine both quality and attractive appearance. Wooden panels for interior wall decoration have these properties. This is a universal option, used both for finishing residential premises and for storage and household premises. They come in different types and have their own positive sides.

Types of 3d wood panels

According to the principle of production and fastening, wall panels for interior decoration made of wood can be divided into two types:

- Panel structures. In this case, the wooden fragments are pre-fixed on plywood boards with a certain step along the edge; this run-up will serve as a joining seam for fastening without intervals. The texture of such a product can be any, flat or with a three-D effect;

- Structures that are assembled directly on a section of wall by fastening individual pieces of wood. Here the texture is formed on the spot, all small elements are sequentially glued to the load-bearing wall from bottom to top based on a pre-drawn drawing.

The appearance of both the first and second types is practically no different, so their difference is very arbitrary.

Separately, we can highlight this type of decorative 3D panels for wall cladding, such as wooden mosaic on a mesh base. This product is similar to ceramic tiles, only there are pieces of wood on it as small fragments. This type of panels can be used in any room, including rooms where direct contact with water is provided, for example, a bathroom or sauna.

Also, wooden wall panels can be divided into end panels and those made from plane wood. In the first case, the relief is created from pieces of timber or round timber, sawn perpendicular to the trunk; the appearance resembles a pixel pattern with protruding areas.

In the second case, a decorative panel is created from long sections of the trunk, the boards are sawn lengthwise into small sections, after which the wane is trimmed and adjusted. This type of wall decor is often used on wide sections of the wall, which visually increases the area of the room.

Horizontal panels

Panel sizes and types of coatings

Wood-effect panels for interior decoration differ in many ways - color, surface texture, choice of wood type, size. Each manufacturer has a standard set of panel sizes, which is systematically produced in production. They depend on the size of the GSP slab from which a certain number of panels are produced in order to reduce the number of scraps and reduce the cost of the process. “Many manufacturers do not undertake the production of panels according to the dimensions and design of the customer. At the Wallhof factory we produce wall and ceiling panels of any size, shape and complexity. We implement even the most daring architectural projects.”

It is worth highlighting the technology for creating a “wood-like” surface:

- Veneering. The GSP base is covered with veneer. Veneer is the thinnest cut of wood. In nature, there are no two identical trees, so when decorating a room with veneer panels, the overall design in the interior will be different, but at the same time retain its natural exclusivity.

- Finished with FineLine veneer. This is also natural wood, but this type of veneer is made from fast-growing wood and painted in the color of any type of wood chosen by the customer. When finishing, the interior turns out to be homogeneous, because... the texture of the desired rock is the same on each panel.

Beautiful design ideas

Below are specific examples of decorating different interiors using various types of 3D wooden panels:

In this option, the wall becomes the real “highlight” of the room. And this despite the color of the material, because it is very modest. Classic furniture combined with original wall coverings gives stunning results.

In this case, the design becomes the personification of the excellent taste of the owner of the room. Discreet, elegant and at the same time incredibly stylish design option.

Such wall decoration will undoubtedly attract many looks. The walls are decorated with wooden planks of different sizes. This creates a very unusual visual effect: the size and shape of the walls literally blur.

This is another option for elegant and beautiful room decoration. The noble color of natural wood combined with an unusual volumetric texture turns a classic-style living room into a room with elements of real art.

An example of a successful and effective wall decoration with slats. The color of the planks can be very different.

For information about the technical characteristics of 3D wooden panels, see the following video.

Wood panels for wall decoration: varieties and classification

There are many finishing materials made of wood on the construction market, which are classified according to the following criteria:

- Form. Slats and plates. The slats are 2.5-3.7 meters long. The width is also different. The slats are assembled using tenons and grooves. Installation is carried out in different ways: horizontally, vertically, diagonally. The slabs are square in shape. Will they line the wall from the floor to the middle? And also used as a separate insert.

- Material. The facing material is made from natural wood, fiberboard, chipboard, MDF.

Cladding has different costs. It depends on the material being made - it will be a valuable type of wood or chipboard.

Decorative slatted

These are long slats, up to 3.7 meters long, up to 30 cm wide, their thickness varies. They are made from wood, PVC, fiberboard and other materials containing wood shavings.

They are used to decorate small rooms where there are many protrusions (corners). If the decoration is light in color, its use visually enlarges and brightens the room or corridor.

Fixing the slats horizontally stretches the room lengthwise; vertically fixes it to visualize a high ceiling. Installation is carried out on the frame base with staples or self-tapping screws.

Made from natural wood

Cladding material made from various types of wood is valued for its unique pattern, shades and play of colors, as well as for its warmth and comfort. During processing, the wood is handled carefully to preserve its textured pattern and shade. In most cases, the panels are not painted, but coated with colorless varnish for expressiveness and protection from external factors.

Wood material can be called capricious - it does not tolerate moisture or sudden temperature changes. Constant exposure to hot air is also unacceptable. Humidity and temperature must be optimal.

The cladding is attached to the created grid of metal profiles or wooden slats.

Pressed panels

Cladding made from pressed wood chips today is non-toxic. Thanks to new technologies, the composition does not contain phenol glue. Production takes place under great pressure. The pricing policy has not changed. The panels are still affordable to the middle class and perfectly decorate the premises.

The facing material is produced in various colors, with patterns or “wood-like”, plain.

Some of them are coated with clear varnish, while others can be painted yourself, adding individuality and achieving the desired result.

There are three ways to mount the material on a rough base: frameless: with glue, screws and a frame.

Artificial wood-look wall panels

The cladding is made of polyvinyl chloride. Painted to match the color of wood. The textured pattern can be exactly like a tree in cross-section. These panels are used for finishing wet rooms, balconies, corridors, living rooms in private houses, loggias and attics. In places where natural wood may swell or crack, PVC will retain its original appearance for a long time.

This material has basically a slatted shape. It is attached to glue and a frame base.

Self-adhesive panels

Self-adhesive panels are made from PVC and MDF. They are easy to install (without dirt, dust, without reducing the space of the room), and they are also durable.

The material has a number of features, including the influence of humidity is unimportant, improved sound insulation, long service life without loss of appearance. Shape: different, slats, squares

Mounted on the entire wall or partially, randomly

The shape is different: slats, squares. Mounted on the entire wall or partially, chaotically.

The manufactured material is safe for human health.

Types of finishing boards

Designers actively use five types of finishing boards to decorate walls. They have a lot in common, but they also have their differences. They play a decisive role in shaping the aesthetic effect.

Lining

This decorative board is used most often for wall decoration. And all because the material is the most affordable. This fact does not deprive it of all the advantages of wood finishing.

Lining is thin wooden slats that are manufactured in a factory. They are carefully polished from the outer front side, a small chamfer is formed on the sides, which makes the relief of the finished finish textured.

Scandinavian style and wooden walls Source 1povagonke.ru

Special grooves are created at the ends; they greatly simplify the installation procedure of the lining. It is installed on a wooden frame. Under it you can hide utilities and electrical wiring. If the void formed between the wall and the finished finish is filled with mineral wool slabs, the heat and sound insulation of the room will improve. The decorative characteristics of the lining depend on what kind of wood was used for its manufacture.

See also: Catalog of wooden house projects

Imitation of timber

Until recently, this material was used for finishing the facade; today, it is actively used to cover the inside of the house. This technique helps to completely change the living space, making it intimate but cozy. If you cover all internal surfaces with false timber, you will create the feeling of being in a real timber house. Manufacturers produce two types of false beams:

1. One is a clean, untreated finishing board for walls, not coated with protective compounds.

2. The second is a tinted finish, impregnated with antiseptics and a special color.

Imitation of timber helps create a feeling of presence in a wooden house Source askhome.me

If you want to save money, it is better to choose the first manufacturing option for wall decoration. Then cover it yourself with compounds that protect the wood from fungus and mold. Treatment with a protective varnish will extend the life of the finish. Tinted false beams are more suitable for façade cladding. But it can also be used for interior decoration if its color fits perfectly into the overall style of the interior.

Tinted timber in the interior Source derevyannyy.com

Imitation timber differs from lining in that the width of the lamellas is much larger, and the thickness of the board is also greater. There is no chamfer at the edges of the false beam. Otherwise, the design of both boards is similar: there is a tongue-and-groove system at the ends. The materials and installation method are similar.

Block house

The outer front side of the block house has a semicircular cross-section. If you lay such decorative boards on the wall, you will get the feeling that it was assembled from a natural wooden frame. Essentially, a block house is one of the four sides of a square-shaped log trunk from which the core has been removed. The material has the most natural appearance.

For production, manufacturers prefer to use pine or spruce. They are easier to process and look very interesting in interiors with different functionality. If such a material is chosen to create interior cladding, experts advise you to buy boards for walls made of category “A” wood. They have a perfectly smooth surface, which looks especially impressive in the design of living rooms.

The use of a block house allows you to create a feeling of presence in a house made of solid timber Source grumy.ru

Wood panel manufacturing process

These products can be produced on an industrial scale at a specialized enterprise or independently by a craftsman who performs the finishing. It is worth noting that the quality of a factory-made decorative board is much better than that assembled by hand, since the factory has all the necessary equipment in the form of a press and a drying chamber for wood, but in domestic conditions it is not possible to comply with all processing conditions. But both at the factory and at home, the procedure for producing 3D panels for walls should be carried out in accordance with the following algorithm of actions:

- Preparation and processing of the base for the panel product. Most often, a plywood sheet of varying thickness is used as a supporting material, onto which an antibacterial composition and special impregnations are applied to protect against the penetration of moisture and mold;

- Pieces of natural wood are laid out on plywood with glue previously applied to it, which is not active when dry. The drawing can be arbitrary or pre-applied with a pencil on the base. All joints between elements are processed with a milling cutter or sandpaper to ensure a tight fit to each other;

- At the next stage, the assembled mosaic is placed under a hydraulic press equipped with a device for heating the site. When the temperature rises to certain values, the adhesive composition is activated and glues the pieces to the plywood base. The product is under pressure until it completely solidifies and forms a monolith. This condition is mandatory, since when the glue dries, the plane of the wood may move, and the final part will not fit tightly to the fastening site;

- At the final stage, the entire surface of the resulting product is treated with impregnation, which adds shine and highlights the texture of the wood, and also protects it from temperature changes and moisture penetration.

Important! This procedure must be carried out in accordance with safety precautions and in compliance with the rules governing the manufacture of such parts

Wood processing

The pieces of wood from which the design will be formed must be prepared and processed in advance. To do this, their surface is sanded, then the entire volume is sent to a drying chamber to remove excess moisture, after which an antifungal composition is applied. It is not recommended to use untreated fragments, since after installation and during operation the material will absorb water from the air, and when exposed to ambient temperature, lose moisture and crack. The base will be visible through the cracks, and mold and other microorganisms can form inside them.

Advantages and disadvantages of 3D wood panels

There are a number of advantages that these products have over similar parts. They include:

- Durability of the material used and the design as a whole. Wood is a natural product and, if properly processed and dried, can last for many years;

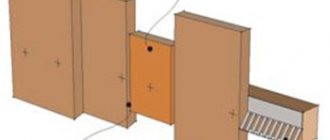

Installation of 3d panels

Easy to install and operate

If a panel fastening system is used, then even one worker can handle this work, besides, all the work can be done independently with your own hands, it is only important to follow the assembly algorithm. After installation, these panels do not require any maintenance, except for periodic wet cleaning of protruding sections; Wide range and unusual texture of parts

Thanks to this factor, panels of this type can be used in most interior styles, while fitting perfectly into the current style of the apartment; In the case of installing wooden panels on a frame base, an empty space is formed between the load-bearing wall and the finishing, which can be used as passage channels for electrical wiring and ventilation, as well as for additional noise and thermal insulation. Why are slabs of mineral wool or foam plastic installed in the resulting cavity? Variability in installation, which can be carried out on a frame or by gluing tiles to the base of the wall. Also, these panels can be used to decorate not only walls, but also ceilings.

Along with numerous advantages, products of this type have only one drawback, which is the cost of manufacturing and installation of the structure. Due to the high cost of natural materials, as well as the complex manufacturing procedure using a hydraulic press, the resulting finished part is somewhat more expensive than simple finishing elements. But this factor can be challenged by the service life and beauty of the resulting interior.

Thus, when carrying out finishing work in an apartment and using 3D wood panels, you can use them to hide shortcomings or emphasize the advantages of a particular room, fill it with functionality, and also solve any design ideas, regardless of the chosen interior concept. This material allows you to create a unique composition, fill the room with a “living” atmosphere and a source of natural environment.

Installation technology

Walls are not always smooth; with regular wallpapering or painting, the walls are leveled. There are also some nuances in order to hide communications. Usually all the wires are hidden under the baseboard or under the cable duct. In the case of installing wall panels, everything is much simpler. The panels are mounted on an aluminum frame, there is no need to level the walls, and all wires and communications are hidden behind the panels. The wall panels are attached to each other with special profiles developed by Wallhof factory engineers. Therefore, any panel can simply be removed and installed back, if necessary. Wood-effect wall panels are an excellent solution for interiors of any style, from classic to modern. Wood evokes peace, a state of comfort and closeness with nature.

You can see all the information about panels and slats on our website or contact the managers, [email protected]

Types of wall panels

Types of finishing

Depending on the shape, the following types of panels are distinguished:

• slatted typesetting – are oblong planks made of wood, chipboard, PVC, fiberboard or MDF. These panels for interior wall decoration have a length from 240 to 370 centimeters, a width from 12.5 to 30 centimeters and a thickness from 0.8 to 1.2 centimeters. To connect to each other, the panels have grooves and tenons. Installation of cladding in horizontal and vertical orientation is allowed;

• tiled typesetting – are squares with side lengths from 30 to 98 centimeters. Such wall panels are great for creating mosaics, because each of them has its own color and texture. Covering materials are MDF, fiberboard, PVC and chipboard. To connect the plates, grooves and inserts are used;

• sheet – they have proven themselves better than others when finishing large walls. The dimensions of their sides can vary from 122 to 244 centimeters with a thickness of 0.3 to 0.6 centimeters. Unlike other materials, sheet wall panels are made only from wood or resin-impregnated fiberboard.

Slatted panels of various widths

Methods of fastening the plates vary. Thus, slatted panels for wall finishing are fixed on the sheathing, while tile panels are fixed with clamps or an adhesive. Glue is also used to fasten sheet panels, and the seams between the covering elements are masked with moldings. How to install PVC on the ceiling yourself? watch the video and read here.

Classic paneling solutions

When finishing with plastic panels with your own hands, you need to take into account not only the type of coating elements, but also the material of their manufacture.

Wooden products are considered reliable; they are made from wood species such as alder, maple, oak or cedar.

Sometimes the finish has a wax coating, thanks to which it can be used in rooms with high humidity levels. Since wooden wall panels are environmentally friendly, they are recommended for use in residential areas.

Products made from fiberboard, a material consisting of woody plant fibers, are popular. They are also safe for human health, resistant to high humidity, but become unusable when in direct contact with water. In turn, cladding panels made from chipboard for interior wall decoration are similar in appearance and quality to wood. This is explained by the fact that chipboard is pressed waste from wood production. The disadvantage of this material is its poor tolerance to sudden changes in temperature and humidity conditions.

Panels made from MDF are highly resistant to almost any environmental factors. Fiberboards are obtained by using the dry pressing method, so they are not afraid of moisture and mechanical stress. It is recommended to decorate walls with MDF panels, such as those in rooms where conventional materials are short-lived or ineffective.

All types of panels mentioned are recommended for use in residential premises. With proper care, their service life will be more than 10 years. Wooden wall panels for wall decoration have a particularly long service life: if they are made of high-quality wood, they will retain their original appearance for several decades.

Panels made from new materials

Panels made from gypsum vinyl are known for their reliability and durability. The material they are made of is a modification of drywall, and is similar in properties. Plastic wall panels for interior decoration, which are not demanding in terms of operating conditions and are easy to maintain, have also demonstrated their best performance.

New products on the building materials market are glass panels and 3D panels. The former are intended for applying photographic drawings to the surface of walls, the latter have an unusual texture with an exaggerated relief. 3D panels are made from all of the materials listed above, as well as from aluminum.

Plastic panels are allowed to decorate walls in residential, commercial and public buildings. This coating is often used in schools and kindergartens because it is considered environmentally friendly. In turn, glass panels are as safe as plastic and can withstand significant mechanical loads, but they are less common because they are more expensive. The same applies to the increasingly popular 3D panels.

3D panels create an unusual effect

Options for covering walls with wood panels in an apartment

There are 3 ways to attach the cladding to a rough surface.

The most popular is lathing. For this type of fixation, there is practically no need to prepare or level the rough surface. Electrical wires and cables for the Internet and television are hidden behind the panels. They are insulated with mineral wool, which also contributes to better sound insulation.

When installing with glue, the rough surface must be flat, without obvious slopes or defects. In this case, the room should have moderate humidity and no sudden temperature changes (the wall should not be cold and wet).

When using staples, there should be no holes or bumps on the wall, no blown plaster or cracks.

Glue

Before gluing, the wall must be thoroughly inspected for cracks. If there are differences of more than 5 mm, plastering and puttying work must be carried out.

Purchase glue designed for working with wood and follow this plan:

- The wall is cleaned of dust and primed. You need to let the surface dry.

- Dilute the glue according to the instructions.

- The adhesive solution is applied to the wall with a notched trowel.

- The first strip is fixed in the corner.

- The second panel is applied to the first and gently tapped with a hammer. So that the 2 planks are connected. The tenons fit into the grooves.

- Each subsequent element is glued in a similar way until the end of the surface.

We must remember that until the glue has dried, no action can be taken on the surface.

If glue gets on the front side of the cladding, it must be removed immediately with a sponge or rag. After drying, this will be difficult to do, and the appearance may be ruined.

Staples

To fix the wooden cladding onto the brackets, you need to make markings on the rough surface. Using this marking, the staples are secured with self-tapping screws.

The first panel is installed in the corner of the surface and secured with a bracket. The next one is adjusted under the first one and to the end of the wall.

Profile

The cladding is also carried out on a metal profile. This is the most time-consuming option, but it has advantages.

To create the lathing, the surface is treated with an antiseptic.

After this, markings are made and a metal profile is attached to it. Sequence of work:

- Installation of temporary beacons. They are fixed vertically at the corners. A thread is pulled between the beacons and the curvature of the surface is controlled. If the surface has differences (touches the thread), the beacons must be moved a certain distance.

- After determining the location of the sheathing, the metal profile is fixed. Vertical racks are attached to the wall in increments of 30 cm, while the slatted panels will be fixed horizontally.

- If the cladding is carried out vertically, then the profile must be fixed horizontally. The fastening pitch is equal to the width of the strip.

- After the profile is installed, the panels are fixed to it with small self-tapping screws.

The panels begin to be installed from the corner to the end of the wall. After fixing the surface, you can carry out further work: paint, stick a film, wipe off dust.

Methods for installing wooden panels

Although installation is simple, it is important to understand the intricacies and features of the work. There are two options for finishing with wood panels:

- On glue.

- On the sheathing.

Each is good at something different and is used in certain circumstances.

Glue mounting

The method, although simple, requires a lot of time and preparatory work. The idea is to attach the wooden panels for wall decoration to a special glue. It can be liquid nails or even polyurethane foam. The sequence is as follows:

- Surface preparation. All cracks, chips, defects and, most importantly, irregularities must be eliminated. The wall is made perfectly flat, without protruding elements. Afterwards, the surface must be primed in two layers to improve adhesion.

- Next, according to the instructions, you need to dilute the glue.

- The substance is applied to the surface of the panels and to the wall if required by the instructions. This applies to a special dry adhesive composition, similar to tile adhesive.

- Laying starts from the corner. The panel is pressed into place.

- The second element is applied to the first and knocked down with a rubber hammer. This way the tenon will fit into the groove.

According to this scheme, walls are covered with wooden panels using glue. The method is lengthy, but if we talk about using typesetting elements, there is no other way to fix them.

Frame mounting

For fixation, a sheathing pre-installed on the wall is used. It can be made of metal or wood. The advantages of this option are that insulation and communications are placed in the frame. Sequence of work:

- The surface is marked for installation of the sheathing. Everything is done according to the level, in increments of 30–40 cm.

- According to the markings, planks are attached to the wall.

- Wooden slats are placed on them, starting from the corner.

- The planks are fixed to the sheathing with self-tapping screws or nails.

This completes the finishing of the walls with wooden panels. If everything is done correctly, then the efforts will not be in vain. This finish will last for decades and will delight the owners.

Panels in the interior are a modern solution that has many advantages. This includes a variety of products, ease of installation and excellent material characteristics. All that remains is to make a choice and do the finishing yourself.

The use of wooden panels in an apartment

Decorative 3D wood panels are often used in various apartment finishing techniques to solve the designer’s problems in decorating a room. For example, using this type of product you can make a partition inside a room, thereby dividing it into several zones without constructing additional load-bearing walls. Such a structure will look like a lightweight structure, does not take up much space and is an excellent addition to the interior.

Since wood is a natural material, it can be used to create a design in a chalet or country style. This style of interior decoration involves the presence of elements made from natural raw materials with minimal processing. Unfortunately, the apartment does not have the opportunity to place boards or logs on the walls, so in this case panels with a texture that imitates solid wood of various types are used.

Wooden panels in the bathroom

Often these products are used in rooms with high humidity, for example, a bathroom or toilet. To do this, mesh-based panels are glued to the wall, the glue is absorbed into the cells and comes into contact with the wooden pieces, thereby forming a monolithic joint. The wood is treated with a moisture-resistant composition, so it does not absorb water and does not dry out, and its appearance looks much more elegant than ceramics, in addition, natural wood has excellent thermal insulation properties, which are much better than those of stone tiles.

Also, wooden 3D panels can be used in the kitchen to highlight the dining area or decorate the facade of furniture. It is worth noting that it is prohibited to place wood slabs above the work area of the kitchen table and in the place where there is a gas or electric hob and oven. Even if the panels are treated with a fire-resistant compound and other impregnations, exposure to high temperatures and open fire on the surface can cause a fire, so you must follow this rule and choose the right location for the product.

Advantages of panels

MDF board does not have the same complex structure as ordinary wood, so this material is easy to process and allows you to carry out any other work, for example, drilling, supplying wires and equipment, etc. This type of panel is often used when you just need a good, a clean and inexpensive material with a classic look that would be appropriate in a variety of settings. MDF is also significantly less expensive than real wood and is easier to paint due to its smooth surface.

- A great opportunity to bring natural wood texture into your interior!

- Wood-look MDF is inexpensive, but at the same time high-quality and varied; are in an affordable price segment.

- The production of MDF is environmentally friendly and allows you to save trees, since it uses the process of processing (pressing, drying) wood materials.

- The plates are easy to texture and paint; you can choose many colors from a range of ready-made panels.

- MDF has no knots or kinks, its surface is smooth, which is an undeniable advantage of modern coatings.

- This type of panel is resistant to insect pests, as some protective substances are used in their production.

- The material, despite its artificial origin, is durable, reliable and utilitarian. Many of the problems of conventional wood are eliminated in modern coatings, such as wood-look MDF.

- MDF does not have such a sensitive structure as wood, so it is easy to cut and drill without damaging it.

Advantages and disadvantages

Volumetric panels have many advantages:

Aesthetics. Decorating walls or ceilings with 3D wood panels instantly transforms any space: it immediately becomes more beautiful and interesting. This decoration effectively emphasizes the good taste of the apartment owner. Modern technologies allow you to choose any pattern, shade and finish of the material. You can complement the panels with elements made of leather, textiles, glass or imitate honeycombs

You can also order such panels with backlighting.

Environmental friendliness In modern conditions, it is especially important to pay attention to the environment and take care of it. Since wooden panels are made of natural material, they are absolutely safe for human health and all living things. Natural wood does not provoke an exacerbation of allergic reactions, which means that such panels can be mounted even in the bedroom and children's room.

- Durability. If you install the panels correctly with the help of a specialist or even with your own hands, they will last for quite a long time. After all, everyone knows that wood is one of the most durable materials, so these volumetric panels will delight the homeowner for decades.

- Practicality. You don’t have to spend a lot of time caring for the finish - it’s enough to occasionally wipe the volumetric panels to remove dust from them. Manufacturers also recommend rubbing the structure with special wax from time to time to give the planks shine and increase their resistance to external influences.

- Moisture resistance. Unlike flat panels, volumetric options resist moisture much better - they do not deteriorate or become deformed from water. This is due to the fact that during production the structural parts are covered with a special laminating film and also treated with water-repellent impregnation.

Despite the large number of advantages, such panels have several disadvantages

For example, before choosing such a material for decorating your home, you should pay attention to the fact that it is highly susceptible to atmospheric fluctuations: any changes in temperature or humidity can affect the external characteristics of the entire structure. In addition to this factor, there is another drawback: their relatively high cost.

However, to a greater extent this applies to panels that are entirely made of solid natural wood.

But for those who want to save money, there is a great alternative option. It is worth choosing hybrid structures that are made of natural wood and, for example, MDF. You can also opt for panels that are made entirely from cheaper raw materials: bamboo, plywood, MDF or chipboard. Analogues of wooden 3D panels, which are made of pressed bamboo, are very popular. Outwardly, they practically do not differ from real wood, but they are much cheaper.

Peculiarities

3D panels are strips of the same size with printed three-dimensional patterns of a different nature. Structural elements are usually in the shape of a rectangle or square. After installation, the individual planks form a single beautiful canvas, and the joints of the parts remain almost invisible. To slightly reduce the cost of the panels, their base and front side are made from different materials. For example, plywood or MDF are most often chosen for the base, which are treated with special compounds to improve their characteristics.

For the outside of volumetric panels, natural wood is usually chosen: ash, oak, chipped wood and other environmentally friendly materials.

All parts of the planks are equipped with special fasteners, which guarantee a tight connection between the parts. In addition, this fastening technology greatly facilitates and speeds up the installation process. Modern volumetric panels are characterized by a long service life - sometimes for maximum durability, the panels are coated with a layer of special wax, as well as environmental safety and a wide variety of colors, textures and sizes. However, the cost of such finishing material is quite high.

Technical characteristics of the modules:

- width – 400 mm;

- length – 200 mm;

- thickness – 8-15 mm;

- weight 1 sq. m – 6 kg.

The parameters of the panels may vary depending on the material they are made of.