Despite the fact that carpet and wood flooring are some of the most beautiful, they still belong to a rather high price category. Therefore, not everyone can afford such luxury.

However, today in the materials market you can find an excellent solution to this problem, because many materials have appeared that look just as interesting, but have a more affordable price.

Families with a fairly small budget can also purchase such material. In this article we will look at several main types of flooring and tell you what the cheapest flooring can be found on the market and how not to make a mistake with your choice.

Classification of linoleum

Linoleum is divided into types and depending on its wear resistance. Guided by manufacturing technology, manufacturers cover the image, which is first applied to a PVC base, with a protective layer on top. The wear resistance of the material depends on the thickness of this layer. The thicker the “shield”, the more expensive the coating. Household linoleum, which has a low level of wear resistance, is usually laid in residential premises; The material is of a semi-commercial type, which is considered to have an average level of wear resistance, which is why it is laid in rooms with average traffic: hallways, kitchens, offices. One is quite rigid, which is why there are no marks left on the surface from heavy pieces of furniture and other objects. Commercial linoleum is endowed with increased wear resistance. For this reason, it is laid in industrial premises, as well as in areas with high traffic. However, please note that these are just general guidelines. In your apartment or house, you may prefer linoleum of any kind. Still, when choosing a flooring, do not forget about its purpose and the load it can withstand. Linoleum classes

You can lay different types of linoleum on a wooden floor. Wood is a material with excellent sound and cold transmission. Therefore, the PVC coating must have excellent heat and sound insulation properties.

Reliability

When considering reliability, it makes more sense to consider critical vulnerabilities. In general, the reliability of the coating is ranked as follows:

Ceramic tiles and porcelain tiles

Most of all, these floor coverings are afraid of directed strong impacts from hard objects. They are most vulnerable in cases where there are voids under the tiles. Glazed ceramics are more vulnerable to impact and abrasion.

If the coating is selected for the street or unheated premises, it is necessary to take into account frost resistance and the level of water absorption. If for these purposes you select a tile intended for use in other conditions, and it quickly deteriorates, then such ceramics cannot be called unreliable. The buyer just made a wrong choice.

In general, tiles and porcelain stoneware have proven themselves to be the most reliable floor coverings. They are not afraid of water, household chemicals, most mechanical loads and tolerate operation well in different conditions. Their scope of application ranges from residential premises to industrial facilities.

Laminate

Despite its popularity, laminate flooring has many vulnerabilities. He is afraid of water, high temperatures and shocks. You should also be careful with chemical compounds. For example, with solvents that can corrode the top protective layer. In terms of reliability, laminate is superior to carpet and linoleum, but inferior to ceramic tiles, porcelain stoneware and quartz-vinyl coating.

PVC tiles

Only ceramics are more reliable than PVC tiles. Moreover, the quartz-vinyl coating does not crack, like tiles, from directed impacts. However, PVC tiles are easier to scratch or damage with hard sharp objects (this is more true for coatings with a low wear resistance class). It is also necessary to take into account the vulnerability of the quartz-vinyl coating to thermal and chemical influences.

Linoleum

This coating is inferior in reliability to ceramics, laminate, PVC tiles and is superior only to carpet. An exception is special linoleum for objects with high traffic and unfavorable operating conditions. This flooring can be torn, burned and even pushed through. It is not suitable for use in rooms with high humidity levels. Synthetic linoleum is afraid of low temperatures.

Carpet

The most “delicate” floor covering is carpet. Even taking into account coatings that are designed specifically for use in public facilities. Carpet can be burned by cigarette ash, torn by hard sharp objects, or damaged by household chemicals. Under conditions of intensive use and careless use, it quickly loses its aesthetic appeal. But it is superior to ceramics in one quality - it is not afraid of heavy objects falling.

Preparing the foundation

Wooden floor as a base In order for the linoleum to last a long time and to avoid problems during installation, the rough surface should be carefully prepared. Any flaw or defect in the installation base will degrade the appearance of the finish. And it can even lead to rupture of the material in this place. The covering is laid close to the walls, so the old skirting boards are first removed, which can be returned to their place after the work is completed. Sometimes new linoleum is laid on top of the old one. But this is only possible if the old material that was glued to the floor is in perfect condition. If this is not the case, then the old covering needs to be removed, and then just lay a new one. A primer must be applied to a flat concrete base before laying the covering. Before laying linoleum on a wooden floor with your own hands, it is first leveled with plywood.

Leveling the concrete base The floor covering also requires preliminary preparation. It is laid out on the floor surface and left for a while to allow all creases and kinks to be smoothed out. Only after this can you begin to trim the material. This floor covering is unpretentious to use and requires only a flat surface for installation.

Types of flooring for apartments

The flooring is an object that directly determines how comfortable it will be in a particular place in the apartment. Therefore, choosing flooring for an apartment is a very important and crucial stage of any renovation.

Among the variety of modern building materials for floor finishing, several main varieties can be distinguished.

The most popular are:

- carpet;

- linoleum;

- parquet board;

- laminated panels;

- tile;

- self-leveling polymer floors with 3D effect.

It is worth noting that each of these coatings has its own operating conditions under which the floor will last as long as possible. Therefore, when deciding what is best to lay on the floor, it is worth considering the advantages and disadvantages of one or another type of covering, so as not to make a mistake with the choice.

Aesthetics

It’s hard to argue about tastes, and imposing them is a thankless task. Therefore, when considering aesthetic characteristics, one can only rely on generally accepted standards, which are advisory in nature. The beauty of the coatings was ranked as follows:

Tiles and porcelain tiles

The rich history of this type of flooring speaks for itself - over thousands of years, humanity has created an incredible number of decors that provide a combination with different interiors. Tiles or porcelain stoneware can enhance any room. To do this, it is enough to choose the right decor.

Laminate

A relatively new type of flooring benefits from the fact that it reliably imitates expensive types of wood. Modern technologies have ensured that laminate flooring is as similar as possible to natural boards and parquet.

Carpet

If the laminate duplicates the decors of natural wood, then the carpet can imitate carpets. In fact, both of these floor coverings compete in beauty, but modern fashion has so far ensured the leadership of laminate.

PVC tiles

Recently, many beautiful collections of quartz-vinyl coating have appeared. However, even in premium PVC tiles one can discern their artificial origin, so they are slightly inferior to laminate and carpet of a similar class.

Linoleum

Linoleum developers have never been able to provide a reliable imitation of natural stone, ceramics or wood. For older generation buyers, linoleum mentally takes them back to the Soviet past. That is why it is mainly bought for practical reasons, sacrificing beauty.

Methods of applying protective agents

There are two methods for treating wood with protective agents:

- Surface treatment. This method allows you to preserve all the decorative properties of the tree and at the same time protect it from various influences. This operation is carried out in any private construction, from finishing wooden beams in houses to any wooden buildings.

- Deep processing. The implementation of deep coloring is possible only in production, where there are special industrial devices. The essence of this treatment is to penetrate the product deep into the wood fibers, thereby ensuring high-quality protection of the entire part.

Cork tile floor

Nowadays, people's desire to have everything environmentally friendly in their home is becoming more and more relevant, and if there is such a desire, but at the moment financial possibilities are limited, it is worth opting for cork flooring. Cork tiles are the cheapest natural covering. Therefore, the colors are appropriate, natural - numerous shades of yellow and brown. This coating has a beautiful, natural look and is very soft, even compared to linoleum.

Why is a substrate placed under linoleum?

What is a standard linoleum underlay? This is a special material used for insulation that prevents the floor covering from coming into contact with the subfloor.

It performs the following functions:

Leveling the floor

Often the floor is uneven, be it a concrete screed or a wooden surface. Irregularities can do a disservice - linoleum laid on such a floor wears out very quickly, and its overall service life becomes significantly shorter.

Insulation

In some cases this is also an important factor.

If there is a cold basement under the floor level that is not heated, and the linoleum does not have a layer of insulation, then the underlay can play its role.

Soundproofing

Underlayment can help if you have problems with this, which is often the case in cheap new builds or older homes.

Sounds that reach you from below can be absorbed by the substrate, which significantly increases the comfort of living in the apartment.

When is it needed?

There are three main cases when you cannot do without a substrate:

- Cold floor in the room.

If you have a cold basement underneath the room, then you definitely need a substrate, because what you shouldn’t skimp on is your health.

In this case, it is worth using a warm substrate based on jute, or a mixture of jute with wool and linen. It will keep you warm and protect your feet from drafts.

- Uneven floor base.

A perfectly flat floor is rare, and microscopic differences will not cause much harm to the linoleum, but if they are noticeable, the underlay will help straighten them out.

A level base is a prerequisite for the long service life of your PVC coating, while throughout its entire service life it will delight the eye with a smooth surface.

- Using linoleum without a base.

This single-layer material is much cheaper, but the floor will be cold. The substrate will help eliminate this drawback.

When can you lay linoleum without a backing?

If you are laying linoleum over linoleum or another old floor covering, you will not need underlayment. The main thing in this case is to carefully check this coating for defects, cracks and other imperfections.

The second case is the use of linoleum, which already contains a jute backing or a foam base. This material is multilayered and consists of several components, the bottom of which replaces the substrate, providing sound and heat insulating properties.

Main types

Which substrate for linoleum is better?

Most often, the following materials are placed under linoleum:

Jute based

These are natural plant fibers that are treated with substances that prevent the substrate from burning and rotting.

Moisture passes through it freely without the substrate getting wet.

Among the disadvantages of jute backing for linoleum, it is worth noting that it does not have the best soundproofing properties.

From the traffic jam

The use of cork underlay for linoleum is the best insulation and soundproofing component. This is a completely natural material consisting of crushed tree bark. Cork backing for laminate flooring is widely used.

Among the disadvantages, one can note the high cost.

Flax-based

This underlay provides natural air circulation between the floor covering and the linoleum.

As a result, it is possible to avoid excess moisture and the appearance of fungus. The insulating properties, like those of jute material, are not the highest.

Combined option

The combination of jute, wool and flax allows the underlay not only to successfully resist moisture, but also to make the floor warm, while significantly muffling any sound.

Among the disadvantages, it is worth noting its higher cost.

Backing made of sheet material: plywood, OSB or fiberboard

Such sheets are used to level wooden floors and serve as an excellent underlay in this case.

The downside is that such a substrate does not withstand water well, and with high humidity it gets wet and loses its properties.

Carpet

The same story as with tiles - there are a huge variety of coatings on the market, which you can’t figure out without a consultant: which fabric accumulates static electricity and which does not, how the coatings differ in the manufacturing method, how wear-resistant they are, whether they cause allergies... In general , it is not immediately clear how justified the savings are.

The cheapest carpet is thin, made of polypropylene or olefin, without additional processing. The most expensive is on a woven jute base, with natural wool pile. The truth we are looking for is somewhere in the middle: truly affordable, and at the same time high-quality carpets are made by needlepunching or flocking; their pile, as a rule, is made of pure polyamide or in combination with wool and acrylic. It can be of different heights, but without synthetic shine, soft and uniform. Special treatment eliminates the problem of electrostatic field.

What's good:

You should clean the carpet in the bedroom (especially if you don’t eat there or wear outdoor shoes) no more often than you should wash the kitchen floor. The lint does not emit volatile substances, which means that in the absence of dust, allergy sufferers can sleep peacefully. Good sound insulation, warmth, a cozy look and a variety of colors are a wonderful investment, say, in renovating an apartment with cold floors or noisy neighbors.

What to fear:

almost nothing. Bright coatings may fade in direct sunlight - and not all of them. Carpet is sensitive to moisture. And it’s better to get the most reliable vacuum cleaner.

Trending:

The most popular variety is carpet tiles in bright colors. In addition, carpet with a woven texture fits well in “ecological” interiors. Choose lush pile in pastel colors with a relief pattern for bedrooms and children's rooms in a nostalgic style. But velvety coverings with low pile in signal shades are suitable for modern minimalist interiors.

Multilayer insulation

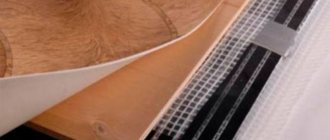

Also, a backing for linoleum on a concrete floor is also used as part of multi-layer insulation. For example, a film heated floor is very convenient; it will maintain a constant floor temperature at 26–30˚C, which will not allow the coating to melt.

A layer of thermal insulation material is laid on the subfloor, and sheets of film heated flooring are laid on top. The structure is connected to the electrical network. The thermofloor is covered with plastic film, then sheets of plywood are laid. You should not use fiberboard; you can damage both the linoleum and the film thermofloor. You need to carefully ensure that the plywood sheets are attached directly to the floor without touching the thermal film. The backing and linoleum are laid on top of the plywood. This design guarantees high-quality insulation of the concrete floor.

When to use mastic and glue

When laying linoleum yourself in non-residential rooms, even small ones, it is better to glue it. In living rooms, glue or mastic is used only on large areas (more than 25 m2), having previously prepared the base of the floor. Before applying the glue, the linoleum is rolled from both sides towards the middle into a roll. The choice of mastic and glue on the market is presented in a wide variety. All that remains is to choose the right glue for a certain type.

Laying with glue The container indicates how thick the layer of glue should be on the floor surface. It is usually applied using a notched spatula. The higher the height of the teeth, the greater the thickness of the glue that can be applied. Correctly apply from the middle to the walls. After applying the adhesive mass, the roll is gradually rolled out. In this case, a roller is passed over the surface of the linoleum to remove air between the floor and the coating. Such actions improve the quality of the connection with the base of the floor due to the uniform distribution of the adhesive. If when laying linoleum you cannot do without seams, then they can be connected by cold or hot welding.

Adhesive for cold welding Cold welding does not require special training or tools, so it can be used at home. To connect the seams you only need glue. For a new, just laid coating, use glue A, and to eliminate defects on the old coating, choose thicker glue C. To ensure a strong and durable connection, hot welding of joints is used. This requires the availability of appropriate equipment: a welding torch, a compressor and rods for filling joints. The molten rod from the burner flame is placed in the joint between two sheets of coating. This method is applied 24 hours after laying the coating.

Painting the floor

Paint applied to the floor can greatly extend its service life, protecting the wood from various biological influences. You can even apply paint to a surface that has already been painted - you just need to treat the surface with an antiseptic.

If we are talking about what can be used to cover the floor in a wooden house without compromising safety, then water-dispersion paints are definitely the best choice, since they do not contain solvents, withstand moisture well and adhere well to the surface.

In cases where humidity regularly increases in a room (for example, in the kitchen or bathroom), it is worth using moisture-resistant acrylic paints. Alkyd solutions are best suited for covering parquet.

The market for protective products for wooden floors today has no shortage of materials - everything is available, and the biggest problem remains choosing the best option. To know exactly what is best to cover the floor in a wooden house, it is worth considering all the factors in detail, and making a choice based on the conclusions.

Types of bases for linoleum

Now let's look at all the possible bases on which such a floor covering can be installed.

Concrete

A concrete base leveled using a special leveling mixture, concrete screed or “floating floor” is considered ideal. This is actually the best substrate for linoleum.

Before laying the coating on the concrete screed, it must be allowed to dry completely. Drying time depends on room temperature, humidity and ventilation efficiency. But according to the standards, the period of drying and hardening of the concrete screed cannot be less than 30 days.

You can very easily check whether the screed contains moisture using a simple piece of cellophane film. You just need to put it on the screed overnight and secure it with tape. If in the morning it turns out that the film is dry, then you can begin installation. In this case, the base must first be thoroughly cleaned of dust.

Under no circumstances should a concrete base be leveled by laying sheets of plywood or other wood material on it. They absorb moisture and become deformed, so linoleum on such a base will quickly lose its performance characteristics.

Wood

A wooden floor is also a good base, but if there are cracks, irregularities, nail marks or other flaws in it, then plywood 8-12 mm thick is pre-installed on top of it. It is this that will perform the function of an insulating and leveling material.

In the case where the floorboards are well preserved, the use of plywood is not required. Minor unevenness and microcracks are eliminated using a special putty.

Linoleum

Provided that the old linoleum adheres firmly to the base and has no unevenness, torn spots or deformations, a new coating can be laid on it. Before doing this, the base needs to be degreased and glue applied to it.

Under other circumstances, the old coating must be removed. You can read more in the article.

Ceramic tile

In this case, we are talking about an ideal base for linoleum. If the tiles have come off, cracked or the seams between the tiles have become deformed, then before installing the linoleum, all defects are eliminated using a leveling compound.

When it is completely dry, everything is sanded with sandpaper and the dust is removed. On this basis, the floor covering will serve for a long time and properly.

Based on the information above, we can safely say that neither cork, nor jute, nor linen, nor felt materials, which are presented in a wide range on the market, are absolutely irrelevant. They are designed to level the base and insulate it.

But, firstly, all bases are pre-leveled according to the rules and regulations, and, secondly, household-type linoleum in its design is based on a fabric, jute and polyvinyl chloride base, that is, it is insulated.

The exception is a coating without a base, which requires a substrate as additional insulation. Moreover, it must have increased strength and rigidity.

Bamboo parquet

If you want the cheapest flooring, then you should consider purchasing bamboo flooring. Surely many are accustomed to thinking of bamboo as a tree, but in fact it is just grass, which is why this option will be the most cost-effective.

The undeniable advantage of this material is that in appearance it is very similar to its wooden counterpart, however, its cost is an order of magnitude lower. Such a serious difference in cost is due to the fact that this material will only need three years to grow, while a tree will need about fifty.

Installation

Laying linoleum on a wooden floor is considered the most profitable and economical way to repair. The material has a low price and a long service life. In addition, installation is quite simple, even when starting work for the first time, the master will be able to lay the covering himself. The ease of installation, however, requires knowledge of some nuances in the work, which we will discuss below.

Surface preparation

To lay linoleum you need to have a flat base. A level is used for checking. Detected protrusions are removed with a grinding machine.

Carrying out floor scraping The presence of large flaws and potholes on the surface can be removed using plywood, fiberboard or chipboard flooring on a wooden floor under linoleum. The sheets are fastened to the floor with nails or self-tapping screws. After laying the plywood under the linoleum on a wooden floor, it is necessary to seal all the seams and recesses for the screws. Otherwise, even linoleum with a foam base will not be able to hide the existing irregularities. Finally, the base of the floor is cleaned of dirt, debris and dust.

Which mounting method to choose

There are several methods for gluing linoleum to a wooden floor. The easiest way is to lay the coating without using glue. This method can only be used for rooms with an area of no more than 20 m2. For a larger area, this method of fastening is not suitable, due to the possible appearance of waves and folds on the surface.

Gluing is carried out in stages, in narrow strips. The next fastening option is laying on double-sided tape. In this case, the tape is applied to the base of the floor in the form of a grid, and linoleum is laid out on it. This method is good because the coating is well attached to the floor, which extends its service life, and if dismantling is necessary, it can be easily removed. The last method of fastening is based on the use of an adhesive mixture or linoleum glue. This method is used for large areas. Flooring in this way is very labor-intensive, and dismantling the covering is quite difficult.

Laying

After you have managed to level the wooden floor under the linoleum, you can begin the installation process. Laying the coating should only be done indoors at room temperature, after it has been left for several days and has leveled out. After this, smooth out the coating again from the middle to the edges. Depending on the fastening method, the flooring will have its own characteristics. Laying on a wooden floor (steps 1-3) When attaching linoleum without glue or using tape, the material is secured around the perimeter. When laying without glue, the remaining covering around the perimeter is removed with a sharp knife and secured in the doorway with a batten. When laying on adhesive tape, the tape is pasted in the form of a grid without removing the protective coating. We bend half of the linoleum onto the second part. Then remove the protective layer from the tape and lay the coating, smoothing it from the center to the walls. We do the same with the second part. After this, the plinth is installed. When attaching the flooring with glue, half the sheet is folded back and the glue is applied to the floor with a spatula. After application, you need to leave it for at least half an hour, and then bend it back and carefully align it. We do the same with the second half of the coating. Laying on a wooden floor (steps 4-6) The installation process is accompanied by constant leveling of the coating. You can do this right away with your hands, and then go through it with a special roller to remove any remaining air inside. Linoleum flooring should be carried out carefully, because defects that arise during the work will be difficult to eliminate. In a large room, the flooring is made from several sheets. The joints of the two pieces must be glued together. The strips overlap about 10 cm

It is very important that the drawing matches. We cut both strips in the middle of the overlap

This will make it possible to get a good joint. It is best to glue two strips using cold welding. Painting tape is applied along the seam. The glue is applied along the joint of the strip, so that penetration into the seam is up to 2-3 mm. Do not remove excess glue, but leave it to evaporate. After welding the seam, the masking tape is removed. Having completed the work on fixing the linoleum, you can proceed to installing the baseboard and installing slats in the doorways. Knowing all the nuances that may arise during the process, laying linoleum with your own hands will not be difficult. Laying on a wooden floor (steps 7-9)

Laminate

Parquet boards made of natural wood are beautiful, environmentally friendly, but not budget-friendly. Piece parquet is a luxurious floor “like in a palace”, it retains its appearance for centuries and requires special care. But unfortunately, it is prohibitively expensive. An economical solution for wood lovers is laminate.

Durable floor panels look like natural wood, but in principle do not contain it - only wood products: fiberboard, several layers of paper, on top of which is a lamination of acrylate or melamine resin. Unlike natural wood, laminate does not change configuration depending on humidity.

Obvious advantages:

sunlight, abrasion, pressure - laminate can withstand all these “misfortunes” with honor. And daily cleaning too: to the delight of allergy sufferers, rooms with laminate flooring can be kept almost perfectly clean, there is no dust and there are no conditions for mold. And laminate, unlike parquet, can be laid yourself - and you can save a lot of money on it.

Not so simple:

There are problems with using laminate in wet rooms. And we’re not even talking about the bathroom - it’s better not to put laminate in the hallway and kitchen: the material is not afraid of excess air humidity, but from direct contact with water it swells at the edges and joints. There are types of high-quality waterproof laminate, but they cost much more. When placed on an uneven surface, laminate flooring may squeak.

Trending:

The most fashionable laminate for today is super-glossy, with a mirror surface. But it has a rather high price. From budget options, choose a regular wood-look laminate, but in a non-standard shade - almost black (wenge or graphite - depending on the “warmth” of the main interior palette), almost white (bleached golden or light gray), greenish, gray-blue, shabby and “aged”. Some samples (usually a little more expensive) are decorated with stamps, like on wine boxes.

warm floor rolls under linoleum

Which self-leveling floor is better

Where does any good renovation begin? Off the floors! It is necessary to clearly understand what floors will be in an apartment or house, because the floor is the foundation of the entire home.

Self-leveling floors are becoming more and more popular. Self-leveling mixtures are used for self-leveling flooring, which means it is very easy to install and easy to use. Many people wonder what self-leveling floors are best for an apartment, because there are several types of them? The most convenient option for an apartment may be a finishing self-leveling floor. However, there are several types of them - polyurethane, epoxy and epoxy-urethane. And in this case, which finishing self-leveling floor is better? Which self-leveling floors are best to choose is a question for a specific person; the approach here is purely individual. This may depend on where you plan to install the flooring, as well as how much money you have available.

Features of self-leveling floors

Self-leveling floors have advantages over conventional coatings:

- they do not shrink;

- they do not need expansion joints;

- they level themselves to a horizontally flat surface;

- the coating can withstand heavy physical loads;

- the floor hardens quickly;

- The coating of the final self-leveling floor is completely environmentally friendly.

Finish self-leveling flooring is an ideal solution for an apartment, but if you plan to lay parquet or linoleum on top of such a floor. tile or laminate. A cheaper version will suit you - a cement or gypsum based screed. It hardens quickly and levels the floor, but does not have a beautiful finish so that you can leave only a self-leveling floor. You will have to put another covering on top. This type of self-leveling floor is ideal for rooms where you first need to level the floor.

Anyone can install a self-leveling floor using the instructions on the packaging, so you can save on a construction team. The finished floor looks great - no worse than tiles, it is very easy to clean and you don’t have to worry that cracks will appear in the floor and it will have to be replaced.

With the help of such a cabinet it is easy to revive the interior, add lightness and originality to it. We will talk about the features of sliding wardrobes with a sandblasted pattern in the article.

Today, the ceiling is a full-fledged detail of a modern interior, so its design should not be neglected. We will talk about the options for a modern ceiling in the article.

Such designs look stylish and elegant, and they are also easy to install. We will talk about the features of single-level stretch ceilings in the article.

Thanks to their versatility, originality and durability, such coatings are incredibly popular today. In this article we will find out which self-leveling floor is best to choose.

Tips and solutions

And in the end, we will try to summarize and provide general recommendations for choosing a coating for the base and advice given by experienced users. The basic requirements for any coating are as follows:

- easy care;

- safety for human health;

- beauty;

- pleasant tactile sensation;

- durability.

Choosing flooring for an apartment

These indicators may vary in priority and other parameters depending on the requirements of the homeowner, budgetary capabilities and personal wishes. For some, the main indicator when choosing a material will be its price, while for others - strength and environmental safety. And all people will have different approaches to the choice of material for the foundation, each from their own “bell tower”. Thus, you need to start choosing coverage with a thorough analysis of your own life, your habits and the behavior of your family members.

There are a number of factors to consider when choosing flooring

If children and animals live in the house, then one of the main requirements for the base coating will be compliance with the required environmental friendliness indicators. That is, the material must be safe for health. These are ceramic tiles, wood, parquet. Also, the chosen option must be non-slippery, non-traumatic and resistant to various influences. It is desirable that it is easy to clean - just imagine that a child painted the newly laid carpet with his paints. Or your favorite Labrador ran all over it after playing in the dirt outside. It is immediately clear why this covering option is completely unsuitable for a house where such residents live.

Light-colored carpeting is not the best option if there is a child in the house.

If you have a habit of walking barefoot, then in most of the apartment the floors should be tactilely pleasant, not cold in sensation. Otherwise they will be uncomfortable to use. Alternatively, there may be wood, fleecy coverings, or materials that imitate wood covering. But you can also lay tiles if you worry about heating them

It is important to understand that constantly running heated floors waste a lot of electricity, which will definitely affect utility bills

Beautiful self-leveling floor in the apartment

You will also have to take into account what building the apartment is located in or what kind of floors it previously had. For example, not all houses can be filled with screed. It is usually installed in new buildings or houses that structurally allow this to be done. In most old panel houses, this option for a rough foundation is unacceptable. This means that coatings that require screeding will have to be completely eliminated.

It is important to think about what color of the floor you would like to see, how harmoniously the texture and shade of the floor covering will be combined with the rest of the interior. Dark looks solid and contrasts well with a restrained and light interior

But a room with such a base needs good lighting. For dark rooms, it is better to choose a light floor - it will be fresher and will not absorb light.

Combination of colors in the interior

Also, you should not make one covering option for the entire apartment. This will be a mistake, especially for small rooms. The coating should be chosen depending on the purpose of the room. By the way, floors with a pronounced relief coating are also not the best option. Keeping them clean will not be easy - dirt will get into all these reliefs and grooves if they are very deep. At the same time, in the bathroom, for example, it is worth putting a relief covering in order to reduce the risk of injury to the floor. It's easy to slip on glossy surfaces if you spill water on it.

Video - How to choose a floor covering

Repair is a costly business, so many owners of apartments and houses try to choose the cheapest coatings. This also applies to gender. Some people believe that only expensive materials will last a long time and will not require replacement after a few years. But in fact, if you choose the right coating, it will in any case please its owners for a long time

When determining which floors are the cheapest, buyers most often pay attention to linoleum, laminate or carpet. You can also consider a bulk option

Each material has its own pros and cons.

Parameters influencing choice

Tiled kitchen floor

Floors in kitchens differ from others in certain requirements, including:

- Wear resistance, because the kitchen is the most visited place, so the flooring must be resistant to wear, abrasion, and various loads. Otherwise it won't last long.

- Easy to maintain: the coating must be resistant to high levels of moisture and easy to clean from various contaminants.

- Durability: the kitchen floor should also be strong and durable. And it should last at least ten years.

In addition, the appearance of the coating should be taken into account. For example, large-format elements can optically make already small rooms smaller, while a glossy finish, on the contrary, can expand the smallest and cramped kitchen. It is best if either plain, dim elements or contrasting ones are used for the floor. Warm shades will add comfort, cold shades will create a strict atmosphere.

When choosing a coating, you should also pay attention to its safety, environmental friendliness, and hygiene.

Is it possible to install heated floors in the kitchen?

When installing a floor in the kitchen, you must immediately decide whether an additional heating system is needed. This depends on the thermal insulation of both the base itself and the floor covering.

Warm floors can be installed on ceramic or porcelain tiles, laminate, and parquet. But for cork floors this is not necessary, since they themselves are quite warm.

When installing such heated floors in kitchens, it is necessary to ensure reliable waterproofing, on which a cement screed is laid.

Self-adhesive PVC tiles

Such self-adhesive tiles are universal; you don’t need to hire expensive specialists, but you can do the work completely yourself. Remove the protective film and stick it on, that’s all the work. Preparatory work is more important here - the floor must be completely dry and clean before gluing. You don’t have to limit your imagination and glue tiles of different colors and surfaces of different textures, the main thing is that it is beautiful and practical enough for further use, but you don’t have to worry about the assortment that can provide your flight of thought - it is huge.

Epoxy floors

An excellent option for those who are puzzled by the question of which self-leveling self-leveling floor to choose for their apartment. Epoxy coating is considered absolutely safe, since it is based on an inert substance that does not enter into any reactions.

These floors are easy to keep clean. They are not afraid of dust or dirt, mold never appears on them, and they do not rot. Even a very thin coating can last at least 40 years, not to mention thicker epoxy coatings.

Many people are interested in which self-leveling floor to choose for an apartment, in terms of the fact that each room has its own purpose. Indeed, it makes no sense to fill the entire apartment with one composition, and for living rooms or children's rooms a cheaper option is suitable - this is a polyurethane coating.

This approach will save a lot of money. There is another option and it’s not expensive - it’s a cement self-leveling floor, which is better, this is up to the apartment owner directly (read: “How to make a cement-based self-leveling floor with your own hands”).

Before deciding which finishing self-leveling floor is better, you need to pay attention to:

- the purpose of the future coating;

- number of preparatory stages;

- load on future coverage;

- individual coating requirements.

Having received answers to such questions, you can safely move on to another question – which company’s self-leveling floor is better.

What to lay on the floor in the kitchen requirements for flooring

Of course, when deciding which is best to choose for the flooring in the kitchen, we first talk about comfort. And only then do we think about how the floor we have chosen will last as long as possible. What does this depend on?

That's right, it depends on what the product was made from and what the properties of these materials are. Plus, don’t discount the appearance of the floor. Because kitchen design can either win or, on the contrary, lose.

What properties do manufacturers give their kitchen flooring? So they should:

- be resistant to wear;

- do not absorb moisture;

- be easy to clean and maintain;

- not be subject to mechanical stress;

- respond normally to cleaning products;

- be beautiful in appearance.

It is important to remember that each type of floor covering has its own additional conditions (such as, say, requirements for increased aesthetics, etc.). After all, someone may limit themselves to the practicality of the solution, while others may not have enough money

It seems that the requirements are not enough? Are there materials that fully correspond to them? Are you choosing what kind of flooring you want in your kitchen? Let's look at the possible flooring options for the kitchen:

- Ceramic tile

- Cork coverings

- Natural wood

- Laminate

- Polymer self-leveling floor

- Porcelain tiles

- Linoleum

Economical carpets

If you really really want a soft carpet https://comfort-room.com.ua/ under your feet, then you need to purposefully look for something cheaper, there are always options. It goes without saying that you can always count on a discount if you decide to install such a floor throughout the entire house and plan to cover a large area. And if you just need to hide a problem area in a certain area of your home, without replacing the entire floor, a small carpet is also a good solution.

Preliminary preparation

Any floor surface on which the material will be laid must be carefully prepared (this applies to all materials without exception). Between the concrete base and linoleum there must be a specific layer that simultaneously absorbs noise and serves as a heat-insulating layer.

The stages of preparing the floor surface can be summarized in a sequence of actions:

- The surface level is first assessed, the absence or presence of unevenness and cracks is assessed. If defects are present, they must be repaired.

- Next, the concrete surface is cleaned of dust, debris and other foreign elements, which in the future can also cause cracks to appear on the surface of the linoleum or lead to unevenness.

- After the above preliminary steps, material with thermal insulation properties is laid on the concrete. An additional layer can be insulation. This will not only make the floor warmer, but will also significantly increase the service life of the linoleum.

Agree that these tips are really simple, but they allow you to lay linoleum taking into account the necessary requirements.

Why is it needed, what types are there?

The underlay prevents the material from coming into contact with the floor. It serves for:

- Compensation for unevenness of the base. If the base has defects, they will be reflected in the coating. All the depressions, cracks and tubercles will be drawn on its surface. This will subsequently lead to destruction. The material underneath, by compensating for small irregularities, will protect the linoleum from premature wear.

- Soundproofing. This is especially helpful in apartment buildings, where noise from the lower floors is clearly audible.

- Thermal insulation. In rooms located on the first floors, the floors are always cold. The same applies to apartments under which non-residential premises are located. Floors in houses built on the ground also require additional insulation. In this case, it is an excellent insulation.

There are several types of insulating materials

Jute

Jute backing consists of fibers of plant origin. This is a unique material made from natural jute fibers. It contains a fire retardant that prevents rotting and burning. It is able to absorb and remove moisture over time without getting wet.

Cork

This type consists of crushed tree bark. Its production process eliminates the use of synthetic substances. However, it has the best thermal and sound insulation properties.

In addition to its high price, cork material has another significant drawback. Due to its low rigidity, its surface bends under heavy furniture. And this leads to deformation of the linoleum.

Linen

The linen underlay maintains natural ventilation between the floor and the floor covering. And this prevents the appearance of moisture and fungus. Since flax is used in the manufacture of this material, it is an absolutely natural product.

During the production process, the material is treated with fire retardants, which prevent insects from infesting and prevent rotting.

Don't know what to use to keep the room warm and dry? Use a backing that contains equal proportions of linen, jute and wool. It has additional wear resistance and thermal insulation properties.

Foamed

Regarding this type, experts have long come to the conclusion that it is not suitable for linoleum. It quickly wrinkles and loses its shape without performing its functions.