Cladding a wooden house with brick is carried out to protect and insulate old walls. Logs and beams of natural moisture crack, lose strength, and do not tolerate precipitation well - therefore, over time, a wooden house is lined with facing bricks. In the article we will tell you why to cover a wooden house with bricks, we will show the pros and cons of the technology, structural elements, and how to do everything right. Note: Cottages made of laminated veneer lumber do not require cladding. The walls remain strong without additional protection and do not require insulation. Clinker tiles, natural or artificial stone are used only when decorating a facade made of laminated veneer lumber.

House in St. Petersburg: individual project with partial finishing of the facade with stone

Features of facing works

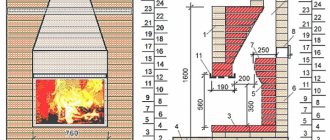

Scheme of options for insulating log and timber walls.

A house made of timber is decorated with bricks in such a way that the final thickness of the masonry is ¼ or ½ the thickness of the product.

This can only be done if there is a ledge; the masonry will rest on it. Before covering the building with bricks, it should be taken into account that the ledge should be located slightly below the lower frame of the wooden walls; as an alternative location of the ledge, you can use the place below the starting crown. If this requirement is not taken into account, moisture will accumulate on the ledge, which will lead to undesirable consequences.

It should be remembered that brick and wood are completely different materials in structure and composition, this causes different degrees and rates of their shrinkage.

Among other things, wood undergoes a process of changing moisture content over a long period of time, which ultimately affects its appearance, as well as its linear dimensions. Thus, after cycles of swelling and drying, wood is capable of deformation, unlike brick. Based on the above features, cladding work on log houses should begin after complete shrinkage of the building, which can take up to 3 years.

A house made of timber should be faced so that the top line of the masonry does not reach the height of the walls of the building by 1-1.5 cm. This will prevent damage to the eaves by wood, which can occur due to seasonal fluctuations in temperature and humidity.

A house made of timber can be protected with bricks using one of the existing technologies. The first involves the use of brick in tandem with sheathing made of insulation, which has a protective shell. The second involves the creation of a so-called ventilation facade, for which, in the process of carrying out work, a space is created between the wall of the main building and the cladding to ensure the movement of air masses.

Options and selection of PVC panels

All types of plastic panels are made on the basis of polyvinyl chloride. In this case, the products are divided into 2 types.

The first option is panels that are made entirely of high quality PVC or vinyl. The structure of such elements is homogeneous, which ensures the strength and reliability of the products. Such PVC panels are in demand on the market and are often used for cladding the facades of buildings.

PVC panels can imitate any material for facade finishing

The second type of PVC products is combined and consists of two layers. The outer shell protects the panels from fading and exposure to atmospheric factors, and the inner layer provides rigidity and strength to the elements. Such panels are more expensive and are rarely used for facade finishing.

Panels are elements with holes for fastening

Depending on the appearance, PVC products are divided into the following types according to the type of simulated surface:

- stone; brick; wood, timber; marble.

External differences do not affect the characteristics of products and are taken into account only when developing the facade design

When choosing a material, you should pay attention to its thickness, which can be 15, 17, 18, 21 mm. A specific option is selected depending on the climatic conditions of the region

It is also important to take into account the installation principle by which the elements will be attached. Panels can be mounted horizontally or vertically

In the first case, small panels are chosen, and for vertical installation, products with large parameters are needed, covering the entire height of the wall.

Preparation process

Technical characteristics of facing bricks.

You can begin to clad a house made of timber if it has a solid strip foundation.

If there is a blind area, it cannot be used as a base. A house made of timber may not have a sufficient foundation width for the work, then you can resort to laying a strip foundation, which will be used for masonry. Its width should be 13-15 cm; as a more acceptable option, it is preferable to use a width of 20-25 cm.

It is worth remembering that such a solution in the form of laying an additional foundation is not the best option, since different parts of the resulting foundation will shrink differently. This can cause the building to skew, cracks can form in the base and walls, and mismatched openings in the main and facing walls can occur.

Waterproofing should be laid on the foundation; traditional roofing felt can be used as it. It should be installed in 2-3 layers; moreover, it is necessary to ensure that the material protrudes beyond the base by an average of 5 cm on both sides.

The lining of the building involves laying a heat insulator, which must be fixed to the walls. Mineral wool, which is produced in sheets, has proven itself to be excellent. If you want to save money, you can use a budget option for insulation, for which you should use expanded clay, which will have to be filled in during the work process.

Materials for external thermal insulation

In this case, the house can be insulated with any materials suitable for external thermal insulation.

You can insulate brick walls using:

- polystyrene foam;

- mineral wool;

- extruded polystyrene foam;

- polyurethane foam,

- thermal panels.

Characteristics of insulation

Insulation materials

- Today, foam insulation is very common. This is an inexpensive material that retains heat well, is easy to install, and holds its shape well.

- One of the best insulation materials is extruded polystyrene foam. It has minimal water absorption and low thermal conductivity. In addition, EPS is very durable, which is why it is often used for thermal insulation of blind areas and foundations.

- When insulating a facade with mineral wool, you need to take into account that only stone and basalt wool with a density of at least 80 kg/m3 is suitable for external thermal insulation. Less dense material may lose its shape.

- Polyurethane foam is excellent for thermal insulation of a brick wall. It has low density, high thermal insulation characteristics and good adhesion. However, the material is not resistant to UV radiation, therefore, when insulating the facade, immediately after installation it must be covered with finishing.

- Thermal panels simultaneously perform the function of both heat insulation and finishing. They consist of several layers of PPU and EPS, and their front part is made of clinker tiles, ceramics, porcelain stoneware or concrete. They have many advantages, but they are also quite expensive.

Cladding technology

You can cover a wooden building with bricks using mortars of different compositions. These can be mixtures based on cement, limestone, clay. The best option is to use cement mortar.

The brand of the final mortar depends on the brand of cement used in the work. This dependence is directly proportional: the higher the grade of cement, the higher the strength of the masonry mixture.

Brick cladding scheme.

Before using the solution, you should check it for mobility, during which you need to use a cone whose weight is 300 g, height - 15 cm, and apex angle - 30°.

Thus, mobility is determined by the depth of immersion of the tool into the finished mixture. If the work involves using hollow bricks, the mobility indicator should be 7-8 cm, and for solid products the indicator can vary from 9 to 13 cm. Mobility indicates the ability of the mixture to spread under the influence of its weight.

Before bricking a house, you should prepare the mortar. So, to obtain a lime-cement mixture, you need to use 1 part M-500 cement, 2 parts lime paste and 8 parts sand. To prepare the cement mixture, you need to use 1 part M-500 cement and 4 parts sand.

Another method of preparing a solution involves adding glue to the composition, which is necessary to increase the strength properties; Liquid soap can also be added, which guarantees increased plasticity and prevents excessive fluidity. To obtain such a mixture, you need to use 4 parts sand, 1 part M-500 cement, 0.5 parts Fliesenkleber glue and a little liquid soap. This solution will be more expensive than the previous ones, but the quality characteristics will fully compensate for this disadvantage.

Brick layout.

In addition to the above advantages, such a composition will not come off the products, and its waterproofing characteristics will be excellent.

During the work process, you can trim the brick with a hammer-pick; the main masonry tool is a trowel or trowel; you need to spread it out and then level the mixture on the products.

Seams can be processed by jointing, and ventilation and smoke openings can be cleaned, and seams in channels can be smoothed and filled with a mop. It looks like a rubber plate that is secured between the flanges. To control the verticality and horizontality of the masonry, it is necessary to use control and measuring tools: a plumb line and a level.

The corners of the masonry, when the house is lined with bricks, also need to be checked; a square can be used for this. In order for the seams to be ultimately uniform and aesthetically pleasing, a tie cord must be used.

It is recommended to check the straightness of the masonry with a straightening rod, the length of which is also 2 meters, its cross-section should be 50x50. In addition, the tool must have notches on each row, which are necessary for marking the masonry. Fastening the ordering strip to the brick surface can be done using brackets with a transverse strip.

The house should be covered with bricks in polyproducts.

Thus, in the end, the thickness of the wall will be equal to 12.5 cm. In some cases, the masonry is carried out in a quarter of a brick, the product must be installed on the edge, the thickness of the masonry will be equal to 6.5 cm. If you decide not to lay the foundation, then mount brick can be placed on the protrusions of the plinth.

Review of manufacturers

In order not to make a mistake in choosing a suitable facing brick, we present you with an overview of the most attractive options for this material on the domestic construction market.

LSR. A domestic company that has concentrated on the production of facing bricks with a “white rustic” texture. This material boasts pleasant textures such as “antique brick”, “water touches” or “birch bark”. This material pleases with its price, but buyers receive many complaints regarding the geometric accuracy of the products.

Zheleznogorsk brick factory. Among Russian manufacturers, this plant is distinguished by its consistently high quality of products. Re-equipping the enterprise and installing European lines allows us to produce bricks of impeccable precision and high aesthetic qualities.

Buyers note a decent color palette and variety of types of facing bricks. The only disadvantage is that this material cannot be found in all stores.

Nelissen. This is a Belgian manufacturer that produces mainly solid bricks. It is distinguished by high strength, as well as a variety of interesting textures. Nelissen clinker bricks, which are distinguished by clear geometry and a varied palette, have earned special love from buyers.

Kirov brick factory. It is no coincidence that this company is included in the list of the best manufacturers. In the product line of this brick factory, the lion's share is occupied by sand-lime brick, and the overall range is much narrower than that of other, more famous manufacturers. But the brick from this manufacturer is of high quality and an attractive price.

ABC and Janinhoff. These German brands are united by excellent product strength at the M400 level, as well as low water absorption (no more than 4%). At the same time, both the first and second companies specialize in the production of smooth hollow bricks. It's just that ABC company specializes in yellow and tan-colored products, while Janinhoff prioritizes red and red-brown finishing materials.

In any case, both companies are distinguished by the production of high-quality products of the European level at an appropriate price.

By choosing brick as a facing material, you get a reliable, durable and very attractive material that will serve you for decades and delight your eyes with its splendor!

Additional recommendations

The facing wall should be connected to the main wall with clamps made of galvanized steel roofing; nails or pieces of steel wire can be used.

It is preferable to use galvanizing, since ordinary metal will be destroyed by condensation.

One end must be fixed to the main wall, the other must be placed in the masonry seam. Fasteners can be placed in 2 rows with a step that does not exceed 1 m. When cladding the timber, you should use moisture-resistant products.

There should be a distance between the wall and the masonry, the maximum length of which is 10 cm. A ventilation groove of 10-15 mm should be installed in the upper part of the wall; nets can be used to protect them. The masonry should be carried out with bandaging of the seams, the size of the bandage should not be less than ¼ of the length of the product. Expansion joints should be located closer to the corners, the step between them should be 10-14 m.

You can do the wall cladding yourself; it is only important to follow all the rules.

Wooden houses have been built throughout human history; they have an incredible number of advantages, but they also have their disadvantages. Covering a house made of timber with bricks will not be difficult even for a person who has taken up such an undertaking for the first time. The process is quite simple and fast, but requires considerable material costs.

Cladding timber with bricks does not take much time and is a quality component.

Before starting work, you need to make sure that the width of the foundation allows you to implement the idea. Facing the timber with bricks is envisaged during the design process in order to leave an additional 8 cm. In total, facing a log house with bricks does not take much time, but the whole process must be carried out systematically and clearly, after which the result will not be long in coming.

The particular importance of facing timber with bricks also lies in the quality component, because the tree will no longer be affected by the external humid environment.

But before starting work, you need to wait until the wood dries out in natural conditions, if there was precipitation before the installation began.

Which brick to use

Facing bricks are produced using different technologies, due to which they have different characteristics and prices:

Ceramic. Of all the finishing materials, it is the most inexpensive. One of the disadvantages is high hygroscopicity: 6-15% depending on the technology and batch. When water gets into the pores, it expands when it freezes, causing destruction and the brick begins to crumble. Even the special finishing one, in which in factories the bed (the part that ends up outside) is specially protected. The solution is to cover the wall with a hydrophobic compound after installation. Only those that do not form a vapor-proof film

When choosing, pay attention to this: excess moisture must be removed. Frost resistance of ceramic facing bricks is 25-75 cycles (how many times it can withstand freezing/freezing without deterioration). The higher this indicator, the higher the price

This is explained by the high production costs

The higher this indicator, the higher the price. This is explained by high production costs.

Hyperpressed or non-firing. This type of facing brick is produced not by firing, but by pressing. It no longer contains clay, but lime with various fillers and pigments. The ability to use pigments allows you to obtain a wide range of colors. The front surface is often nonlinear, imitating wild stone. Looks decorative. But such nonlinearity threatens delamination: an uneven surface allows water to flow into the pores more abundantly and freezes in cold weather. This is treated in the same way as in the case of ceramics: hydrophobic impregnation. The frost resistance of high-quality unfired bricks is stated by manufacturers to be from 75 to 150 cycles.

Clinker. This brick is also ceramic, but a special technology gives it very high strength and density. Denser material absorbs water much worse. This is good for use, but when laying it it leads to difficulties: in order for the wall not to “float”, it must be laid on a hard, low-plasticity mortar, and it is more difficult to work with. Another disadvantage that limits the wide distribution of a material with excellent characteristics is that it is expensive compared to previous materials: prices are 50-150% higher, depending on the manufacturer. Frost resistance of clinker is from 100 to 150 cycles. Clinker cladding of a house with bricks is not a cheap pleasure, but it is the most attractive in appearance.

Silicate. The cheapest, but also the most “quickly perishable” of facing bricks: its frost resistance is 25-50 cycles. It conducts heat better. Not much, but still: the average thermal conductivity of ceramic is 0.16, silicate is 0.18. In addition, it is heavier: on average, the weight of ceramics is 2.4 kg, silicate of the same size is 3 kg. More weight requires a more powerful foundation and the price gain (silicate is cheaper) is not so great. If you consider that heating costs will also be higher, then the gain is questionable. It is advisable to cover the house with sand-lime brick in warm regions. In the northern regions this is completely unprofitable.

Choosing the type of brick is not everything

It is also necessary to pay attention to the size and shape of the holes. Solid finishing bricks are rarely used: they are more expensive and weigh more. On average, voids occupy about 28%, but they can be large and small

Given equal characteristics, give preference to bricks with small holes: the mortar will not flow into them. This will reduce the consumption of masonry mortar and increase the strength of the masonry

On average, voids occupy about 28%, but they can be large and small. Given equal characteristics, give preference to bricks with small holes: the mortar will not flow into them. This will reduce the consumption of masonry mortar and increase the strength of the masonry.

If you decide to clad the house with hyper-pressed brick, it should be made no earlier than 15-20 days ago. During this time, it gains basic strength (about 80%) and can be transported and loaded without fear.

Please note that the brick packaging should not be exposed to water during storage. This is especially true if you are planning to leave it for the winter.

Basic aspects and getting started: instructions

Concrete grade M 200 is suitable for concreting.

To complete this stage of work you will need:

- Shovel. Edged board. Hammer with nails. Perforator. Mastic. Reinforcing rod 10 mm. Concrete mortar m300.

The most difficult thing is to achieve ideal vapor transmission so that a house made of timber does not begin to rot. The reason for this reaction is that wood walls and brick cladding have different densities.

Despite the large mass, houses made of timber are almost never built with more than 3 floors, i.e.

That is, strip and slab foundations will withstand them with a bang. To be sure, you need to retreat 3 cm in each direction beyond the final walls.

The foundation itself is made of exceptional quality (poured on site from M300 concrete mortar), since with its small dimensions it will have to bear considerable weight.

Scheme for facing a wooden wall with bricks: 1-vapor barrier, 2-load-bearing wall, 3-thermal insulation, 4-fiberglass or metal connections, 5-facing brick.

There are also moments when there is a desire to reface a house, but the old foundation does not allow this to be done due to its weakness. Strengthening the foundation will require some investment of effort, time and money, but the resulting result will last at least 50 years:

The foundation is being dug around the perimeter outside the house.

The width of the trench should not be large, so that later you don’t have to bury a lot of soil back; formwork panels are made, which will then be located at a distance of 10 cm from the base structure; using a hammer drill with diamond drills, grooves (10 mm) are made in the concrete to a depth of 10 cm They are spaced horizontally at a distance of 50 cm, and vertically at 25 cm (rounding towards additional holes). It often happens that a diamond drill gets dirty in concrete, so you should always keep a piece of brick on hand, which will remove the plaque with a bang; a small amount of mastic is applied to the very end of each groove, after which a rod is immediately inserted exactly in diameter.

The length of the rod outside the base is 8 cm, since contact of the metal with the ground is strictly unacceptable (the metal rots rapidly); the formwork is installed, and an M300 concrete solution is poured into the resulting trench.

It is necessary to allow 3 weeks for the solution to completely harden, after which the formwork can be dismantled and the work activity of interest can be continued. It is worth remembering that the foundation is not monolithic, but prefabricated, which slightly weakens the structure, but taking into account the fact that the mass will press from above is relatively small, the negative impact of the seam is neutralized.

Return to contents

Types of facing bricks: silicate, ordinary ceramic, hyperpressed, clinker.

You will need:

- Facing brick. Cement mortar m300. Grids \ slotted brick. Reinforcing rod 5 mm. Trowel. Cutter.

The laying is carried out using the spoon method on a thin layer of mortar of 3-4 mm. During the laying process, it is necessary to remove excess mortar using a cutter so that the seams look good. Each subsequent row is offset from the previous one so that the vertical seams do not coincide.

After row 1 is laid out, row 2 will need to be made with a number of ventilation gaps.

Each gap is located at a distance of 0.5 m from the previous one. In order for air to circulate without difficulty, you need to calculate the walls, where for every 10 m2 there will be a 35 cm2 gap. There are several approaches - slotted bricks, special gratings and partial filling of vertical joints.

Particular attention should be paid to the insulation, since it should not be damaged in the process (the need to bevel into the outer part of the building is determined by the weakness of thermal insulation materials to moisture).

Which option to choose depends solely on the wishes of the owner, since each is considered ideal.

On the cornice row, as well as on the second row, air outlets are made. Thanks to this approach, a complete ventilation system will be implemented between the walls and the cladding.

Many craftsmen work using technology that does not regulate the connection of the cladding to the wall, which is why the structure turns out to be quite shaky. You need to connect, and this is done with enviable regularity (5 joints per 1 m2). For joints, a 5 mm reinforcing rod or 2-3 mm thick sheet steel is used.

On the one hand they are mounted in the timber, but on the other - in the horizontal seams of the cladding. When attaching the cladding, you don’t need to try to do anything unusual, but just deepen the metal into both bases. It is very important that the frame is connected to the last row of masonry, otherwise it will significantly weaken the structure.

Return to contents

Every person who loves not only external beauty, but also the quality component should know how to brick a house made of timber. There will not be any particular difficulties during the work, but despite this, you need to do everything as efficiently as possible.

Once the timber is covered with bricks, lining the outside with polystyrene foam will no longer be possible. Physically sheathing it with foam plastic is not difficult, but it will bring absolutely no benefit.

When facing a house with brick, there are several factors that must be taken into account - a cement solution not weaker than m300 (cement comes without gravel, unlike concrete), the presence of air passages and a mandatory binding system. When covering a beam with a brick, you need to take the process as seriously as possible, so that the results will last at least 100 years. At this point, facing the house with brick can be considered complete, and you can begin any new venture.

Many owners like a house made of timber. The appearance of the log house is not always preserved, or the preferences of the residents change over the years.

What to do? Is there a way out of this situation? The owners begin to come up with different solutions: covering the house with decorative panels, siding, clapboard.

Is it possible to cover a house made of timber with bricks? The question worries many developers. Modern brick attracts with its reliability, beauty, and durability.

Is everything so good when covering the timber with bricks? Perhaps there are nuances that need to be taken into account when deciding to renovate the facade. Let's find out the intricacies of the process.

Selection of finishing materials

So, we have to cover the outside of the house from timber.

For these purposes, you can use the following materials:

- vinyl siding;

- metal siding;

- block house;

- thermal panels;

- lining;

- fiber cement panels;

- brickwork.

- . Again, this material is not afraid of direct sunlight, since the plastic is resistant to ultraviolet exposure.

The photo shows vinyl siding

Today, such material is considered the most popular, but not only because it practically does not age, but because it is easy to install and requires virtually no subsequent maintenance.

- . Therefore, this material is not widely used in the finishing of individual buildings.

Metal siding

- . A building finished with a block house is often confused with a house built using rounded logs. The block house is made from residual lumber obtained during the manufacture of wooden beams.

Connection of block house panels

Structurally, this finishing material is very similar to lining, as there is a tongue-and-groove connection. But the block house, unlike ordinary lining, repeats the relief of the log, and therefore is widely used for cladding low-rise buildings.

- .

Thermal panels

This finishing material is based on polyurethane foam, so thermal panels are characterized by low heat and noise conductivity. Again, this finishing material is lightweight and easy to install. Among the significant disadvantages is the high cost of finishing.

- . The advantage of this material is not the highest price and ease of installation. You can probably handle installing this material yourself.

Wooden lining

- X. Gradually, this finishing material is penetrating the domestic market.

Color versions of fiber cement panels

A distinctive advantage of this material is its relatively light weight with a wide range of colors; the panels, when installed on the wall, not only protect the wooden house from destruction, but also perform the function of heat and sound insulation. Installation of the panels is simple, as it is performed directly on the wall of the house without the use of lathing.

- . After all, through decorative brickwork you can protect wooden walls as much as possible from the negative effects of environmental factors. But the problem is that it is difficult to lay such masonry with your own hands, therefore, for such work, professionals should be involved.

Decorative brickwork

We think through the details at the design stage

Covering a house made of timber with bricks is not difficult even for a person who has no experience in bricklaying. But here the question is not about the skill of the workers, but about the reliability, stability and longevity of the structure. You need to make sure that the brick wall does not harm the timber frame and the house as a whole:

We check the reliability of the foundation and the possibility of laying a brick wall.

Brick is heavier than wood. The new wall will put additional pressure on the foundation. Will he be able to withstand the load?

If a house made of timber is built according to your design, it is easy to find out the properties of the foundation by looking at the surviving drawings and estimates. It is problematic if the house was built by the previous owner quite a long time ago. There may be no design documents left.

We inspect the existing foundation of the house and draw conclusions: is it necessary to strengthen the foundation, is there a basis for laying a new wall. Don't put the brick on the ground. We make notes on the new house project. To strengthen it, you will need to dig a narrow ditch around the perimeter to the depth of the foundation, pour in cement mortar, and create a new strip foundation.

Sometimes reinforcement is required from inside the home. This must be taken into account. We calculate the amount of required bricks and mortar for masonry. It’s better to take it with a reserve. Is there a need to insulate walls made of timber?

Is there enough heat in the house or do you have to constantly increase the temperature during cold weather? It is better to insulate the walls before starting to lay the walls. We calculate the amount of insulation and do not forget about the vapor barrier.

A house made of timber breathes, condensation can form, which is contraindicated for any structure. A vapor barrier will prevent the formation of condensation. The brick wall must be tied to the main wall of the house made of timber. Fastenings are provided that will tighten two materials: metal mesh or pins, which must be galvanized.

Perhaps these are all the points that need to be thought through before facing a house made of timber with brick. The project and estimate will give an idea of the cost of the desired upgrades. Now let's look at each moment in the process.

Do-it-yourself cladding of various types of houses with bricks

Cladding the external walls of a building is one of the most aesthetic finishing methods. Such a simple and obvious solution to cover a house with bricks, at first glance, does not imply any difficulties in implementation. The walls become smooth and beautiful. In addition, decorative brick has additional functions - it improves the thermal characteristics of the house and protects load-bearing walls from the effects of adverse external factors.

What types of bricks are used for cladding?

Facing (or facade) bricks are designed specifically for finishing the external elements of houses. In most cases, its dimensions are 250x120x65 mm, but there are also smaller widths - 85 mm. Decoration and exterior cladding of buildings is carried out mainly by three types of bricks:

When lining a house with bricks made using hyperpressing technology, the walls acquire a pleasant, well-groomed appearance. However, its structure is very dense, the air gap is completely absent.

Cladding a wooden house with hyper-pressed bricks does not require additional insulation for the winter; for other types of buildings this measure cannot be avoided.

When choosing ceramic for finishing, it is best to choose its hollow version - this will prevent an excessive increase in loads on the foundation. An inevitable negative point is the increased consumption of mortar entering the cavities during the laying process. Clinker is made from special clay, fired (sintered) in tunnel kilns at a very high temperature. Thanks to this treatment, it acquires unique characteristics: increased strength, resistance to moisture and cold, but its cost is quite high.

Requirements for facing bricks

Finishing brick differs significantly from ordinary ordinary ceramic brick in its shape, color, density, type of facade surface, sometimes size and other parameters. Its surface does not tolerate the presence of shells and cracks, the edges are smooth and have a uniform color, the edges are even, always sharp, chips are not allowed.

The requirements for finishing bricks are very strict: it must have a certain color, be quite durable, have a certain surface structure, and successfully withstand all kinds of atmospheric influences. In addition, it should have low thermal conductivity, since the brick lining is supposed to increase the house's ability to retain heat.

- durability;

- strength;

- no need for any maintenance.

Strengthening the foundation of a timber house

During a preliminary inspection, it was decided that the foundation needed to be strengthened.

A brick wall gives a lot of load. Even though we will cover a house made of timber with bricks in one layer, the weight will be decent. Let's get started:

We remove the decorative trim from the base part, if any. We dig a ditch around the perimeter of the house, stepping back from the walls by 100 mm (this will be a technical gap for ventilation). The ditch should be to the full depth of the foundation, but not wide. 100 mm is enough.

This will serve as a reinforcement of the previous foundation and the basis for the brickwork. We assemble the formwork and pour the mortar. The foundation needs to dry out and be waterproofed. Watch a video about what the foundation for facing bricks should be like. After the foundation has dried, we move on to brick work and insulation of the walls of the house made of timber.

Combined construction

To begin with, it is worth determining the basic properties of both brick and wood in order to have an idea in which direction it is best to use them.

Properties of materials

Brick:

- Environmental friendliness. Natural components, sand, water, clay, make this material an ideal “neighbor” for humans.

- Strength. For example, double silicate brick m 150, which is often used in the construction of houses, can withstand a load of 150 kg per square meter. cm.

- Duration of operation. Here we can talk not so much about years, but about decades and even centuries.

- Easy to use. Brickwork can be carried out even without having certain special knowledge in construction.

- Frost resistance. High performance makes it possible to build houses in any climate zone.

To be completely objective about bricks, it is necessary to note the disadvantages, which are associated primarily with low thermal insulation qualities. If a brick house does not require additional insulation from the outside or inside, then the wall should be 50-60 cm thick.

However, it is extremely difficult for building bricks to give off heat, so in the cold season it is possible to quite comfortably maintain a constant temperature in the premises.

Wood, timber:

- Environmentally friendly, as in the case of brick.

- Easy to use.

- Availability.

- Thermal insulation and sound insulation properties.

Of course, timber has a lot of disadvantages; after all, we are talking about wood, and this includes the possibility of rotting, the formation of mold, mildew, and a fire hazard.

We lay out a brick wall, following the rules

Before starting to work with bricks, it is necessary to process the timber around the perimeter of the house.

Do not neglect the impregnation of the walls. Wood is not a brick; it has the ability to rot and collapse. By closing the walls without treatment and gaps for ventilation, you risk reducing the service life of the wooden part.

If insulation is necessary, do it after the impregnation has weathered. The insulation should not reduce the ventilation gap, which is 50 mm wide between the brick and wooden walls. This space is necessary to remove moist air from the wooden wall.

Any wood breathes, allows vapors, air, and humidity to pass through. As long as the wall is not lined with brick, fumes escape unhindered. After facing a log house with brick, this opportunity disappears.

It must be created artificially. To get outside, special holes are made in the brickwork at the bottom of the house and in front of the eaves. It can be:

- ventilation grilles; special brick with holes; space in the connecting horizontal mortar joint.

The openings should not be accessible to rodents, which are unwelcome in the house.

Features of wall cladding made of different materials

The facing masonry runs in half a brick. The self-supporting capacity of such a false wall is low. It must literally be tied to the facade. For this, different materials are used: ready-made flexible connections, anchors, nails, strips of sheet metal, masonry mesh.

The method of bonding, the need for insulation, the presence of a ventilated gap and vents depend on many properties of the facade material: strength, vapor permeability, holding force of fasteners, size of building blocks, etc.

Brick

In this case, everything is relatively simple. Both the wall and the cladding have almost the same parameters, including the dimensions of the brick. The most common fastening method is ready-made flexible connections made of metal or fiberglass. A flexible connection is a rod that has seals at the ends in the form of a “powder” of quartz sand (to improve adhesion). Such a rod is attached at one end to the horizontal mounting seam of the wall, and at the other to the cladding. If the seams do not match, then in the facing masonry the rod is placed in a vertical seam. Such cladding usually takes place simultaneously with insulation. For a newly built brick house, this makes it possible to reduce the thickness of the external walls and the total load on the foundation.

If polystyrene foam is used as insulation, then a ventilation gap is not needed. When using mineral wool, there is a need to ventilate water vapor from it. Therefore, on the side of the facing layer, a washer with a lock is put on the flexible connection, which presses the insulation mat against the wall of the house and leaves a ventilated gap between it and the facing. That is, the flexible connection also serves as a fastening for the insulation (there is no need to use umbrella dowels, as in curtain wall facades).

Number of connections per 1 sq. m walls - 4 pcs. (in openings - along the perimeter every 30 cm), minimum penetration into the seam is 90 mm, maximum - 150 mm.

Cinder block or monolithic cinder concrete houses

Cinder block is a lightweight concrete. Depending on the hollowness, the material can act in different capacities, including as thermal insulation. Its main disadvantages are its unattractive appearance and low resistance to precipitation and wind loads. Therefore, insulation of a cinder block house is usually not required, but cladding is required. The best material for this is considered to be brick with low water absorption (for example, clinker or hand-molded).

The vapor permeability of brick is lower than that of cinder block. As a result, in cold weather the dew point may “get” onto the cinder block, and water vapor will not be able to erode through the cladding. To prevent the main wall from becoming damp and collapsing, you need a ventilation gap and vents at the bottom of the cladding (at the base) and at the top (under the roof).

As a flexible connection, a masonry mesh is used, one edge of which is fixed to the wall with a bracket and dowel, and the second (in the masonry seam of the cladding) should not come out. The mesh is laid in every fifth row of brickwork.

Building blocks made of cellular concrete

Despite the differences in the manufacturing technology of aerated concrete and foam concrete, their load-bearing and thermal insulation properties are similar, there are only differences in vapor permeability (aerated concrete is higher). Facing for blocks made of cellular concrete is mandatory - the reasons are, in principle, the same as for cinder blocks.

As with cinder blocks, insulation is not necessary, but a ventilation gap is needed. Therefore, the method of attaching the facing masonry to the wall is similar.

Wooden houses

This is perhaps the rarest case of brick cladding.

It is almost impossible to veneer a log house with bricks due to the characteristic corner cuts of the crowns. Log houses do not have this problem, but the feasibility of cladding is very doubtful - the acquired advantages are much less than the disadvantages.

Frame (or frame-panel) wooden houses are attractive due to the absence of “wet” work, speed of construction and relatively low cost. Brick cladding is possible and practiced, but it neutralizes these advantages.

In any case, insulation when facing a wooden house with brick is, in principle, not necessary, but a gap is necessary - the lack of ventilation and weathering of excess moisture will lead to rotting of the wood. In addition, it is mandatory to treat the walls with antiseptics.

If insulation is carried out, it is performed using mineral wool mats, which have high vapor permeability. Installation of insulation is carried out over the lathing, using the technology of ventilated facades - with laying on top of a windproof, vapor-permeable membrane.

When insulating, it is not a masonry mesh that is used as a flexible connection, but pieces of wire attached to the wall with nails or self-tapping screws (at the rate of 4 pieces per 1 sq. m).

Working with bricks

The brick laying stage has arrived.

Wall covering can be done independently or by a team of masons. Depends on your abilities. A brick wall cannot stand on its own.

We fix it to a wooden wall. We take the prepared pins and mesh. We fix it on the timber frame, observing the distances:

- along the length of the wall every meter; along the height of the wall through 4 rows of brickwork.

The second side of the screed is walled up in the masonry.

We make the connection around the perimeter of the house. It is important to secure the last brick row so that the wall does not collapse in the future. You can see how to properly strengthen and cover the timber with bricks from the video report.

The house must be faced with brick from the bottom up along the entire perimeter, using mortar. Shift the brickwork to the side so that the vertical lines do not coincide with each other. Check the horizontal level of the new wall.

There should be no deviations or blockages. You can pull the thread. It will allow you to complete work faster and smoother.

We bring the wall to the top link of the frame. We get a new brick-lined house. How to lay bricks correctly, watch the video:

But is everything as happy as it seems at first glance? Is it possible to cover a house made of timber with bricks without problems in the future? Only construction experts or experienced users of brick-lined houses can answer the question.

Specific recommendations from experts

Even if you strictly follow the above instructions, knowing the principles of laying bricks for cladding houses, you should listen to the recommendations from professionals - their experience will give you a lot. Here are the basic tips to help you properly line the walls of your house with bricks:

- to find out the height of filling the joints between bricks with cement mortar, lay out two or three rows “on dry ground” - you will immediately understand how much mortar should be placed on the brick;

- choose the laying method in advance - it cannot be changed until the brick lining work is completed with your own hands;

- before laying a brick, immerse it in water - this will preserve the condition of the mortar;

- every 1-2 rows, carry out a control measurement of the horizontal and vertical levels - the rows must be absolutely even;

- be sure to take bricks for masonry from different pallets - this will guarantee a uniform shade of the entire future structure;

- the solution for the type of facing work in question must be used without adding any plasticizers or anti-frost additives - only classics! Otherwise, efflorescence will certainly appear on the facing surface.

In addition, you need to remember that the laying of facing bricks should be carried out extremely carefully, without rushing. If cement mortar gets on the outside/front side of the brick, it should be removed immediately with a damp cloth. If this is not done in time, then the solution will harden and it will be almost impossible to clean the wall.

Do not forget that the amount of mortar between the bricks should be approximately the same - experts recommend a joint height of 1 - 1.2 cm, no more. And after all the work with the facing bricks has been carried out, it is necessary to undo the joints - this is done with a specific construction tool.

Do-it-yourself cladding is not a quick process, even slow, especially considering the lack of experience and skill of a novice builder. But with all this, such work belongs to the category of creative processes. Judge for yourself - you can buy bricks of different shades, lay out real compositions on the walls with them, highlight only the corners and the space above window and door openings

In any case, you need to put aside fear and get to work - albeit slowly, albeit with great caution, but soon you will be able to show off your “golden” hands to your loved ones

(58 votes, average: 4.81 out of 5)

What construction forums discuss on this topic, and what reviews and recommendations they give

Having looked through various construction forums, it cannot be said that there is a consensus on the question - is it possible to cover a house made of timber with bricks without consequences? Many forum users are convinced that a brick-lined house made of timber will not lose its properties and longevity. Main:

- follow the rules and stages of the process described above; prevent excess moisture from entering the space between the walls; monitor the ventilation holes so that the wooden walls do not “suffocate.”

The only bewilderment among people is the very fact of covering the timber with bricks.

Construction stores offer a large assortment of facade materials that are less expensive and do not require much effort or skill. But the timber wall itself looks complete. You don't have to do any cladding.

Exception: ordinary timber. Profiled and glued have a beautiful texture and refined appearance. Why then build a wooden house and then line it with brick?

You can immediately build a house from brick or other available material other than wood. It is necessary to take into account the fact of shrinkage of the wooden structure and inter-seasonal fluctuations of the walls. Will a lined house be able to cope with the process without cracks in the brick wall. The foundation and brick wall must follow the movements of the log house. Cladding a house made of timber is only required if the house is old, there are cracks, and the wood looks unsightly.

It is not possible to correct shortcomings with less expense. Then you can use brick. Calculate the costs needed to cover the timber with brick. Are they worth the result?

To complete all the work on lining a house on one floor, you will need at least 300,000 rubles, maybe more. It depends on where you live and the square meters of the house. There are alternative methods for less money.

It is better to try to restore a house made of timber to its previous appearance using sanding, caulking of walls, and paints and varnishes for wood.

Brick is good, but if the initial choice was made in favor of wood, is there any point in covering it up? Decision is on you. Situations are different and require an individual approach.

Similar articles

No comments yet

Building a brick house today is relatively expensive.

In addition, its finishing and insulation will require considerable expenses. A more economical solution would be to build a house from wooden beams and line it with brickwork on the outside. Such a warm and environmentally friendly building looks great from the outside and combines the best qualities of wood and stone.

A timber house lined with brick) has a number of advantages obtained as a result of this type of finishing

A timber house lined with brick) has a number of advantages obtained as a result of this type of finishing:

- Brick lining provides strong protection for a wooden house from adverse influences. Effective insulation of the structure allows you to save on heating costs. This cladding gives the building a solid appearance. Using a brick of one type or another and decorative finishing, it is possible to give the house originality. The fire safety of the building increases. A house made of timber, lined with brick, is distinguished not only by good thermal insulation, but also by sound insulation.

How to calculate the number of bricks

When calculating the amount of material, the formula is used: 50-55 bricks are needed per square meter of masonry. Therefore, for calculations, you need to obtain the area of all walls and multiply it by 55. For accurate calculations, the area of door and window openings is subtracted from the total area.

It is recommended to increase the resulting value by 10-15% - this is necessary to provide a reserve in case of combat during construction and transportation or in case of detection of a defect.[P3]

To predict the cost of work, the consumption of the solution should also be taken into account. It is calculated according to the rule: 2 kg of mixture is used for each square meter. Brick cladding not only makes a home more attractive, but also protects it from aging, weather, and outside fires. This technology requires precise calculations, but you don’t have to be a professional builder to use it. The main thing is to be consistent and attentive.

Foundation

To drain groundwater from the building, a concrete blind area must be installed

Facing a wooden house made of timber with bricks is an additional load on its foundation.

Therefore, it must be initially prepared for it: have the required size, take into account the soil conditions on the site and the magnitude of the total load. If this was not foreseen in advance, then the existing foundation is strengthened and expanded. To drain groundwater from the building, a concrete blind area must be installed.

Prerequisites for the work

If you have a house built from high-quality timber, its attractiveness is beyond doubt. Cladding work will only lead to unnecessary additional costs. The log house should be covered when a plank or frame building is built. It is especially advisable to carry out exterior finishing when the house was built a long time ago. Over time, the wood dries out, which causes cracks to appear. Brick cladding will not only improve the aesthetic properties, but also thoroughly strengthen the structure.

When covering a wooden house with siding, air access to the wood is blocked, which leads to its premature rotting.

Some “experts” claim that the log house of a wooden house can be made attractive by finishing it with siding. But this is a fundamentally wrong design decision. Using siding will not allow the wood to “breathe”. As a result, it will rot. Climatic conditions play an important role when cladding a log house. When cold winter or wet weather prevails in the region, it is imperative to clad a wooden structure with brick. Firstly, it will increase the thermal insulation and sound insulation properties of the building. Secondly, the service life of a wooden house will increase.

Bundle of timber and brick wall

The walls are fastened to each other using flexible or rigid ties

The walls are fastened to each other using flexible or rigid ties.

In European countries, they do not associate rigid brick cladding with a brick wall, preferring flexible ones.

To do this, welded galvanized mesh is cut into strips of 30-40 cm and bent in half at a right angle. One “shelf” of binding is nailed with galvanized nails to a wooden wall. The other is walled up in a horizontal seam of the brickwork.

Instead of a mesh, you can use regular drywall hangers sold in stores. Such bundles will be made every 4-5 rows of brickwork.

The step between them is about 1 meter. Fastening the last row of masonry is mandatory. In this case, the multilayer structure can withstand increased loads.

Features of timber buildings

Houses made of profiled timber do not differ in construction technology from log houses. The material itself is very attractive. The building is made of natural wood with a beautiful grain pattern and looks organically against the backdrop of the natural landscape. For low-rise private construction, sawn, glued and profiled timber is used, which determines the installation technology. Structures made from timber are environmentally friendly; this material is breathable.

The cross-section of the material ranges from 10 to 20 centimeters. The cross-sectional size is the thickness of the walls. For cold climates this is clearly not enough, so the walls outside and inside have to be insulated so that the final thickness of the walls is at least 40 centimeters for a temperate climate. There is a need to cladding facades with insulation, which is done with various materials that match the style of construction. Disadvantages include the ability of wood to absorb moisture, the tendency to form corrosion from excessive moisture, and high flammability. Exterior decoration is designed to reduce the influence of negative atmospheric factors, insulate and increase the safety of the home.

Carrying out masonry

The first row of bricks is laid on a layer of waterproofing. This may be roofing felt or other insulating material. The thickness of the walls is half a brick.

Cement grade M400 is used as a solution. You can clad the house using either special facing bricks or regular bricks – silicate or red. To reduce the penetration of moisture through a brick wall, treat it with a moisture-repellent impregnation.

The bottom gap between the rafters and the masonry should be at least 15 cm, otherwise the rafters may hang on the cladding when the building shrinks in winter.

Important! It is worth paying special attention to fastening and sealing slopes and window sills on a multi-layer structure.

Methods of external insulation

- Insulation with polystyrene foam and expanded polystyrene can be done in two ways: laying tile insulation in the cells of the frame or gluing the slabs directly to the wall. A detailed algorithm for insulating a house with EPS is described in the article “Step-by-step instructions for thermal insulation of a log house with polystyrene foam.” Thermal insulation with foam plastic is carried out in a similar way.

- Thermal insulation with polyurethane foam (PPU) is carried out by spraying using professional equipment.

- Installation of thermal panels is quite simple. Each element is provided with a “groove and tenon” type fastening. First, a starting profile is installed on which the elements are laid, joining them to each other. After final installation, the space between the wall and the panels is filled with foam.

- When laying mineral wool, installation of lathing is mandatory. The material strongly absorbs and accumulates moisture, which causes a decrease in its thermal insulation characteristics. The frame installation method allows you to make a ventilation hole between the wall and the insulation, as well as install a hydro- and vapor barrier layer on both sides of the insulation. Detailed instructions for installing mineral wool can be found in the article “Features of external insulation of a house with mineral wool.”

Building design requirements

Brick cladding is one of the heaviest types of facade finishing. Moreover, even part of its mass cannot be transferred to a wooden house, but not because the permissible loads on the frame are exceeded, but because the outer side of the wooden wall must remain ventilated. Thus, the building requires a sufficiently wide plinth projection to accommodate the cladding and, if necessary, thermal insulation, as well as the possibility of installing flexible connections.

As for the foundation projection, it must have a width of at least 110 mm, provided that facing bricks with a minimum thickness of 65 mm are used and a minimum permissible unventilated gap of 40 mm is provided. The reinforcing frame should be positioned in such a way that the outer rods are positioned with a protective layer of 50–60 mm. It is allowed to install an L-shaped foundation with a vertical dimension of the canopy of at least 250 mm. If the requirements for the foundation were not provided for during the construction of the house, the outer wall of the base is opened with a trench along the perimeter, a cushion is installed, formwork is installed and reinforced to a width of at least 150 mm and a depth of 500 mm. The reinforcement is reinforced with a mesh of 10 mm ribbed rods with a cell size of 200x200 mm. If there is no possibility of a rigid connection to the foundation of the house, you can cast a separate strip with a width of 300 mm and a depth of at least 600 mm, while the reinforcement is performed with a rectangular frame made of 12 mm class II reinforcement.

The requirement for the implementation of flexible connections lies in the preparation of the wall surface. You should get rid of the old exterior wall decoration. In a situation where the house has already been used outdoors for more than 10 years, it is recommended to remove the paint coating, re-impregnate it with a bioprotective agent and apply a coating waterproofing agent. Additionally, we note the importance of waterproofing between the foundation and the cladding. For these purposes, it is convenient to use aerated concrete blocks, thereby imitating the high base of stone buildings and providing additional protection for the casing.

What is wood brick?

If you want to build an environmentally friendly, warm and reliable house, it is recommended to use bricks made from natural material - wood. Such a house or dacha is called a frame panel house. The laying of wooden bricks is specific in its own way, so it is recommended to contact specialists who know how to handle such material. It is faster and cheaper to build a frame house than a block or brick one, and there is no need to carry out additional brick cladding work. You can also sheathe a brick house with wooden blocks, additionally insulating the structure with mineral wool. If the construction of wooden cladding is carried out correctly, such a house will become warm, strong and beautiful.

Finishing the base of a wooden house

There is a fairly large selection of materials for finishing the base. If we talk about brick, it is excellent because it has good resistance to external influences, and the base, as is known, serves as protection from the effects of groundwater and precipitation. When choosing a brick for a plinth, you should not save money; you need to choose a material with low moisture absorption, since if the brick is moisture-intensive beyond the norm, this threatens to deform the surface. The masonry should be made the width of half a brick on both the outer and inner parts, somewhat wider than the wall being built.

Advantages of exterior finishing

The undoubted advantage of properly finishing a wooden house with brickwork is increased heat and sound insulation, protection from weather conditions, reduced risk of rapid fire, extended life of the house, improved appearance (if you were dealing with an old house or if low grade wood was used during construction) .

Advantages and disadvantages

In construction it is very difficult to combine materials with different properties. In this case, nuances and negative aspects always appear. Finishing the facade with brick for a wooden building has three disadvantages:

- decreased ventilation, likelihood of moisture accumulation in the insulation;

- different shrinkage of parts of the wall, which does not allow rigid connection between the cladding and the main wall;

- the high mass of brick compared to wood (more than 3 times) forces the construction of more powerful and expensive foundations.

In general, we can say that it is better to decorate an old house with brick. For new construction, it is recommended to consider other more economical and efficient options.

But the technology has its advantages:

- improvement of thermal performance (especially when using ceramics);

- reducing the level of fire danger;

- reliable and durable protection of wood from negative weather conditions.