Building a house from timber or rounded logs requires significant costs. Many owners build a frame house using imitation logs and timber for finishing, and achieve an aesthetic effect with a minimum of investment. During installation, a layer of insulation is laid under the sheathing so that the house retains heat better. Imitation timber for exterior finishing of a house is popular in low-rise construction due to the optimal combination of price and appearance.

What is imitation timber

This is a type of building material used for interior and exterior decoration of low-rise residential buildings and buildings and is indistinguishable in appearance from thick wooden beams. Another name is false timber or lining. Various types of wood can be used for production. The shape of the false beam is made in the form of boards connected to each other using grooves and tenons.

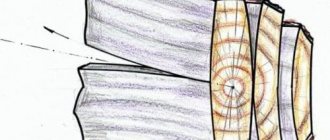

Connection using a tongue-and-groove system Source remontik.org

Fasteners

Since panels with a thickness of 16-21 cm are used indoors, they can be fastened using clamps or self-tapping screws.

Reinforced clamper

These are special metal elements in the form of brackets that allow you to securely fasten the panels to the sheathing, while remaining invisible; the size of the clamps (number) is chosen taking into account the thickness of the rear groove of the panels.

The reinforced clamp is suitable for fastening imitation timber both indoors and for façade cladding.

Self-tapping screws

In addition, the imitation timber can be fastened with galvanized screws or self-tapping screws, as well as construction, screw or finishing nails.

Types of home finishing with imitation timber

Interior decoration of the walls of a house with imitation timber can be of the following types:

- Monolithic. According to this type of finishing, all surfaces of the rooms are covered with false timber, creating a continuous monolithic panel. Thanks to the tongue-and-groove system, high protective characteristics and finishing properties are created.

- Combined. Already from the name it is obvious that interior decoration includes not only cladding with imitation timber, but also other types of finishing materials, for example, wallpaper, tiles, fabric, etc. And if in the first finishing option there is no room for the designer’s imagination to run wild, then in the second there are a lot of options, each of which will be unique and original.

Material calculation

To perform the correct calculation, you will need to know the width of the simulated beam. This will help determine the exact number of panels for finishing. For a correct calculation, it is necessary to determine the surface area of the wall, excluding openings, including the ceiling and floor. Each value is divided by the area of one panel.

Having calculated the number of boards for the surface, all indicators are summed up to purchase goods for finishing. This calculation method is recommended for monolithic finishing. If false timber will be used in combination with other materials, then you need to determine the area of the surface to be processed using only the board, and calculate the quantity using a similar method.

During the calculation, be sure to take into account additional elements for corners and cornices. It is better to buy goods from one batch so that the color does not differ.

How to make the right choice

When choosing imitation timber panels, you should remember that the thickness of the boards should be no more than 20 mm, and the width should be within 100-150 mm, since a wider board will visually reduce the size of the rooms.

Each room in the house has its own microclimate, and when choosing material for imitation timber in the interior (false timber), you must take this into account first. The same applies when you want to make an imitation of logs for interior decoration of a house.

So, for rooms that do not have heating (terraces, verandas, summer cottages), pine timber is used. Conifers tolerate seasonal temperature changes well, and due to their resin content, they can easily tolerate high air humidity. Additionally, the panels are treated with antiseptics, impregnations or drying oil.

An example of cladding a house with imitation timber, treated with drying oil Source stroisam2.ru

In heated rooms, false timber of any material can be used without treatment. For example, oak is well suited for children's rooms; this material is highly durable and is not afraid of moisture. Other deciduous tree species, such as maple, linden, and aspen, are also perfect.

For rooms with a high moisture content, as well as those with sudden temperature changes (baths, kitchens, bathrooms), you can use larch, spruce or pine. These materials easily tolerate high moisture content in the room and calmly react to sudden temperature changes.

Finishing with imitation timber inside the house, in this case the bathroom Source glo.by

In bathrooms, softwood can replace the use of artificial fragrances.

The shape of the pattern of each breed is unique in itself, and if you treat the panels with stain, the pattern will turn out not only original, but also unique in its copy. Therefore, the design of a room made of imitation timber is always a unique work of art.

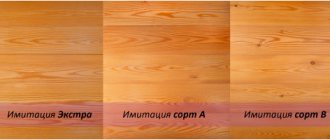

Coloring and natural pattern of imitation timber Source plotnikov-pub.ru

Pros and cons of finishing with imitation timber

Sheathing with imitation timber has both positive and negative aspects.

The advantages include the following:

- high sound insulation properties;

- low thermal conductivity;

- reliability and durability;

- uniqueness, originality of the drawing;

- feeling of coziness and comfort;

- relatively simple installation;

- saving money and time.

A room finished with imitation timber Source brigadi.by

Not a single finishing material has had only positive qualities, and imitation timber for interior decoration is no exception. Therefore, when making a choice in favor of this material, you need to be prepared for the following disadvantages:

- the need to constantly renew the protective layer - treat the wood with antiseptics, paint and/or varnish;

- increase the fire resistance of wood by applying special protective agents.

Rules of care

After the entire wall is covered with imitation timber, it is necessary to protect the material from external influences. To do this, staining or varnishing is performed, if this has not been done in production. The work is done like this:

- treatment with transparent primer;

- sanding to remove fine fibers;

- coating with paint and varnish material. Typically 2 coats are required.

During operation, façade cladding with imitation timber requires annual careful inspection. If any deficiencies appear, they immediately begin to eliminate them. If none are found, then the protective coating must be renewed every 3–5 years in order to extend the service life of the cladding and maintain its attractiveness.

Installation of false beams

Work on cladding with imitation timber is carried out according to the following algorithm:

- Surface preparation. At this stage, the surface is cleaned of dirt and dust and, if necessary, leveled with a primer.

- Fastening the vapor barrier film. On wooden surfaces, you can use a stapler; when facing walls made of blocks or bricks, the film is secured with lathing elements.

- Installation of load-bearing sheathing. For the sheathing you will need a beam with a cross section of 25*25 mm or a stainless metal profile.

- Laying electrical wires, designing pipeline outlets and sewer pipes.

- Laying insulation.

- Fastening the second layer of vapor barrier film with counter lathing.

- Fastening imitation timber.

- Surface treatment with protective agents, painting and/or varnishing.

External cladding of a house with imitation timber Source dysecal.bapelonu.ru.net

Video description

An example of interior decoration of a house using imitation timber in the video:

And then a few more options for interesting solutions:

Combination of timber and plaster finishing

As practice shows, facade cladding can be done with different types of finishing. For example, imitation timber and plaster. The appearance of the house is distinguished by smooth lines, severity and elegance, and the resulting “striped” pattern will visually increase the height of the building.

Combined finishing of a two-story house Source betonicum-stroy.ru

Full exterior cladding of the house with imitation timber

Anyone can become the owner of such a wooden tower. The layout of the house is suitable for both active recreation and year-round living. Finishing with false beams can be done not only outside, but also inside, then your guests will definitely be able to find themselves in an old Russian fairy tale. The main thing is that the interior design matches this.

Finishing a 9x9 house with imitation timber Source www.hmkmos.ru

Timber and stone

Wood and stone go well together in decoration. This can be seen in the following project. Moreover, if in the first option the ratio “wooden covering - plaster” is approximately 1:1, and they are equally responsible for the appearance of the building, then in this case the “stone” decorations are minimal and are designed to emphasize the naturalness and superiority of wooden compositions.

Timber and stone in home decoration Source zillow.com

House with attic

Wood always remains the most environmentally friendly material. Many people strive to make it a cozy home or cottage. Here is an option for a small cottage with an attic floor. It looks like an ordinary house, but to add color, the imitation timber is painted with stain, wrought iron railings give it an intriguing look, and finishing the foundation with a stone finish completes this ensemble. This is how even an ordinary house can be turned into a small miracle of design by adding a couple of highlights.

A combination of false timber, stone and forged elements Source woodeco.org

Imitation of log walls

At first glance, it seems that the house is made of rounded logs, but, as in previous versions, this is just finishing with imitation timber. A simple way to replace expensive rounded wood, while maintaining the naturalness of the materials used, without compromising the quality of the construction project.

House project with rounded wood trim Source profibrus.ru

The cost of finishing with imitation logs depends primarily on the price of the lining that will be used for the cladding, plus the geometry of the house - the simpler it is, the less labor costs.