A log house attracts people due to the naturalness of the material. However, the owners of such a structure must carry out protective finishing. Typically, painting a house made of timber is used. It helps improve external characteristics, and external paints for timber can create a protective coating from the effects of negative environmental factors. The dyeing process will be described in detail below.

General painting rules

Painting the outside of a log home may seem like an easy job. However, in order to get a high-quality and durable result, you should know the general rules of operation. The following points can be noted when painting a wood surface:

- The surface is sanded, it is more convenient to use a grinder, the process will go faster. Even fresh material should be sanded a little. Afterwards, the dust is removed with a vacuum cleaner, paying special attention to the seams;

- Apply protective agents - antiseptic and fire-fighting. You should make 2-3 layers;

- After priming, when the layer dries, they proceed to painting the timber. For best results, apply at least two layers.

The paint and varnish material can be applied to completely dried timber; they usually work in the summer.

Even fresh material should be sanded a little.

Step-by-step instructions for painting a wooden wall indoors

By adopting all the little tricks listed above, it will be easier to cope with the preliminary stage and painting the walls. Having prepared all the tools and workplace necessary for the process, you can proceed to the finishing itself.

The “lion’s share” of the total amount of work in the process of painting wooden walls is always occupied by the preparatory stage

The main part of the work is preparing the surface for painting, which is why they require a more detailed description.

| Illustration | Brief description of the operation performed |

| For preparation and painting, you need to have at your disposal some of the tools shown in the illustration. In addition to them, you will need a grinder with replaceable abrasive paper blades and, possibly, a grinder with an iron brush. If the wooden wall has an old coating, you can use a hair dryer and a scraper (trowel) to remove it. | |

| The first step is to clean the surface of the old paint coating (if there was any). To do this, the paint layer is heated until it softens and peels off from the wood, and then is removed with a scraper or spatula. This work is quite time-consuming and labor-intensive, but it must be done efficiently, otherwise the remaining paint will appear through the new decorative layer as unaesthetic irregularities. | |

| If the wall does not have an old coating in the form of a paint layer, but has acquired an unrespectable appearance during use, or wallpaper has previously been glued to it, its surface must be thoroughly cleaned by removing the top thin layer of wood. | |

| Restoration of such a surface is carried out using a grinder, on which a brush with soft metal bristles is installed, and then a grinding machine with first coarse-grained (P80÷P120) and then fine-grained (P150÷P180) sandpaper attached to it. In addition, cleaning the wall or its individual areas protruding above the general surface can be done using an electric plane. | |

| When the wood is cleaned, its surface should be sanded with a fine bristle brush or sandpaper. In the case where a wall made of new wood is being prepared for painting, it also needs to be sanded smooth. Cleaning and polishing difficult places, for example, between two logs of a log house, can cause a lot of difficulties. But here, as they say, there’s nothing you can do—you’ll have to “sweat” if you want to get a high-quality result. | |

| If you don’t have a sanding machine, you will have to sand the walls manually - this is a very difficult and time-consuming process, so it’s still better to purchase a specialized tool, since it will come in handy more than once in a wooden house. The sanded surface must be cleaned with a vacuum cleaner to remove any dust generated during the sanding process. | |

| The dust-free wooden surface is then coated with one of the selected protective agents - it can be an antiseptic and fire retardant, or one of the compositions described above. This operation can be carried out using a roller, a wide brush or a spray gun, depending on the topography of the wall and its area. If it is log, then the work will go faster if you carry out this process using a sprayer. At the same time, we must not forget about the need for increased precautions - many protective primers are very toxic before absorption and drying. | |

| As a preparatory, and sometimes even the main decorative layer, one of the types of varnish is used, which is applied with a wide soft brush. | |

| If, after the primer has dried, you plan to apply paint or a dark tinting varnish to the surface, then you should protect the ceiling from contact with the solution. To do this, it is recommended to stick masking tape onto the ceiling along the upper edge of the wooden wall, which can be easily removed upon completion of the work and will not damage the plastered or painted ceiling surface. | |

| To paint wooden walls, you will definitely need a soft brush and roller. The roller will significantly speed up the work, as it covers a large area of the wall at once and evenly distributes the paint solution over it. True, this is only possible on flat surfaces - when painting a log wall, a roller will not be a great help. | |

| A brush is needed for painting hard-to-reach places, for example, corner areas or horizontal joints between logs. It is recommended to paint in two or three approaches, but each layer must cover the entire area of the wall, otherwise the paint will lie unevenly. Each subsequent layer is applied only after the previous one has completely dried. |

So, the process of painting wooden surfaces in a house is a very labor-intensive, large-scale task, which, however, any owner must cope with. And for successful work, in addition to your own desire, you must:

- Have the necessary tools of good quality.

- Select and purchase high-quality primers and paints for preparing and painting surfaces.

- Carefully, without simplification, carry out all the preparatory processes, without convincing yourself that “it will do.”

- Do the painting without rushing and without trying to complete it in one go, that is, do not apply the paint in one thick layer - this approach will result in nothing but drips, overuse of paint and a sloppy surface.

If you strictly adhere to all these conditions, the coloring will definitely turn out the way it was originally intended, that is, neat and uniform, and the finish will last as long as possible.

And at the end of the publication, we invite you to watch an informative video in which the master tells and shows how to properly paint the inside of the walls of a house made of natural wooden beams.

Features of the harmful effects of the environment

It is recommended to paint wood due to the need to protect the surface from many harmful natural factors to which the façade of a house is constantly exposed. The following impacts can be identified:

- Water has a destructive effect on a wooden structure; over time, the material becomes covered with unsightly stains and stains appear. The result will be darkening and deterioration of integrity;

- Ultraviolet radiation also leads to a change in surface color;

- Insects and pests destroy the tree;

- Humidity can lead to biological formations.

You need to move on to coloring faster; usually you can wait no more than 3-4 months.

It is recommended to paint wood due to the need to protect the surface from many harmful natural factors to which the façade of a house is constantly exposed.

Required tools and supplies

In order to paint wooden walls from the inside of the house, use the following materials and tools:

- masking tape. It is necessary to protect the surfaces bordering the walls from staining;

- film to cover the floor, doors and furniture;

- sander for preparing walls;

- construction hair dryer and scraper for cleaning old paint;

- brushes, rollers and paint trays;

- sprayer for automatic application of the product;

- protective clothing: rubber gloves, safety glasses, respirator;

- a bucket of water, a rag for wiping away spills.

Varieties of painting compositions for exterior use

Before painting the outside of a timber house, you need to study the range of products offered by manufacturers. There are two types of substances suitable for this purpose - impregnation and paint.

Before painting the outside of a timber house, you need to study the range of products offered by manufacturers.

Antiseptic impregnations and solutions

Antiseptic impregnations help create a barrier against the formation of mold and fungi on the surface of wood. They penetrate deeply into the wood structure, creating a protective layer.

Fireproofing solutions are also commercially available that reduce the flammability of wood, which is known to burn quickly. They are called fire retardants.

Antiseptic impregnations help create a barrier against the formation of mold and fungi on the surface of wood.

How to paint a wooden facade yourself

If there is a need to paint the facade of an already used house, it is quite possible to do this work yourself. To do this, you need to take care of having free time, you will need a lot of it. Purchase consumables in advance: primer and paint in the required volume, coloring pigment (color) and solvent as needed. The approximate consumption rates of the compositions and the service life of the coating are in the table below.

Table 2. Composition consumption rates and coating service life

| Type of paintwork | Consumption (g/m²) | Service life (years) |

| Silicone | 150 — 200 | 20 or more |

| Alkyd | 100 — 120 | 20 |

| Acrylic | 130 — 200 | 15-20 |

| Oily | 100 | 2-3 |

| Water-dispersed | 110 — 130 | 20 or more |

Scaffolding is very convenient for working at heights

In order to put the facade in order, in addition to materials, you will need the following tools:

- stepladder or scaffolding,

- different brush widths,

- rags

- Angle grinder (grinder) with discs for grinding,

- putty knife,

- construction mixer with an attachment for mixing paint.

Depending on the type of paint used, you will need various personal protective equipment: gloves, a respirator, goggles.

Video - An example of incorrect painting of a wooden facade

Types of paints for timber houses

The modern market offers a huge number of paints and varnishes that can create not only a decorative coating on wood, but also serve as protection against natural factors. The options differ in their properties and may be suitable for different situations.

The modern market offers a huge amount of paint and varnish materials.

Latex

This type is suitable for working with wood. They obtain a reliable coating that is distinguished by a high level of adhesion, protection against mold and mildew, safety, vapor permeability, mechanical protection, and elasticity.

However, they do not withstand exposure to low temperatures.

They receive a reliable coating that is distinguished by a high level of adhesion, protection against mold and mildew, and safety.

Acrylic

A popular type that has an affordable price. High levels of protection against various phenomena, as well as the durability of the coating, distinguish this product from others. The surface can be washed with abrasive agents. The composition dries quickly, but this can also be called a disadvantage. The composition in an open container must be applied within 5-6 hours for it to remain of high quality.

They receive a reliable coating that is distinguished by a high level of adhesion, protection against mold and mildew, and safety.

Oily

The protective properties of oil paints are high, and the color palette is varied. But they emit a pungent odor, take a long time to dry, are also not resistant to ultraviolet radiation, and the coating does not last long.

The protective properties of oil paints are high, and the color palette is varied.

Alkyd

The alkyd composition helps protect the wood from moisture, frost and other external factors. But it is difficult to adhere to the base and does not allow air to pass through.

The alkyd composition helps protect the wood from moisture, frost and other external factors.

Rubber

A new type of paint that has a number of positive aspects and no negative ones. Excellent for wooden bases. They last a long time. The high price is probably the only negative, but it is justified by the resulting properties.

Excellent for wooden bases.

Why protect wooden facades

It doesn’t matter whether the house is clad with construction boards using a curtain wall system or is entirely assembled from timber, the wood used in outdoor decoration requires protection. There are objective reasons for this; any wooden material has the following unattractive properties:

- easy flammability and excellent flammability;

- porosity and, as a result, moisture saturation;

- deformation under the influence of different temperatures;

- exposure to fungus and mold, as well as bugs and pests.

Wood damaged by mold requires treatment

Unprotected wood dries out over time, loses its attractive texture and color (turns gray), becomes loose, and therefore not durable. That is why the wood on the facade should be protected from the following factors:

- effects of UV rays;

- high humidity;

- insect pests.

In order to enhance the natural excellent characteristics of wood, and at the same time reduce risk factors for unpleasant situations, wood is impregnated with special compounds and treated with paints and varnishes.

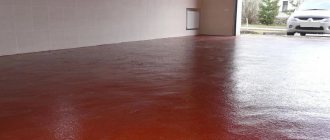

Painted wall of a wooden house

Impregnations

Primer solutions or impregnations can be used as a preparation material for painting, or can also be used as a finishing material. There are 3 types of primers:

- antibacterial (from fungus and mold);

- flame retardants (from fire);

- water-repellent.

Since it is difficult to give preference to only one method of protection, fire-bioprotection compositions have been developed that include 2 mechanisms. Water-repellent primers generally protect against UV rays and strengthen wood.

On a note! All primers have a short lifespan as a topcoat. Therefore, without further painting, facade treatment will have to be carried out regularly every 2-3 years.

Primer treatment is a simple and mandatory process when processing a wooden facade.

Impregnation treatment will not only improve the appearance, but also increase the service life of the wood. For facade work, you should choose deep penetration compositions on an organic basis. Such solutions are usually toxic and have a characteristic unpleasant odor. When working with them, PPE (personal protective equipment) is used: gloves, goggles, respirator.

On a note! Most primers have a transparent base, which means that treatment with this composition will preserve the natural grain and color of the wood.

Prices for glaze impregnation for wood

Glaze impregnation for wood

Main stages of painting

To get the desired result you need to do some preparatory work. It will help improve grip. The next stage is directly applying the selected composition.

To get the desired result you need to do some preparatory work.

Preparing for painting

The house is prepared for processing by first grinding. After which it is necessary to thoroughly vacuum the surface. They polish the walls and clean them of dirt. Next, primer mixtures with antiseptic properties can be applied. They must be completely dry before the next step.

The house is prepared for processing by first grinding.

Impregnation and painting

It is recommended to paint in dry weather. Keep the surface dry. The substance can be applied with a brush, roller, or spray gun. It is more convenient to work with the latter; the process will not take much time. Usually several layers of paint are applied. Each layer must dry before the next.

Paint consumption can be calculated; the average is indicated by the manufacturer on the packaging. You need to know how many square meters will be painted.

It is recommended to paint in dry weather.

Compositions for interior painting works

When working indoors, the main thing is the safety of the equipment for humans. Therefore, when purchasing, pay attention to the manufacturer’s instructions to determine whether they are suitable for this painting. In rooms with high humidity, it is important to create protection against moisture.

When working indoors, the main thing is the safety of the equipment for humans.

Wax and mastic

You can treat the wood with wax to provide a protective function. It may be colorless or slightly change the tone of the surface. The shade will be known only after drying. Therefore, it is advisable to test the product by applying a small amount to the surface.

You can treat the wood with wax to provide a protective function.

Materials for preparing and painting wood for interior decoration

Solutions for preparing wood for painting

The entire process of preparing wooden interior wall surfaces for painting consists of three stages - cleaning, sanding and treatment with protective agents.

Before moving on to the characteristics of paint and varnish decorative compositions, it is necessary to first consider solutions designed to protect wood from negative influences that destroy its structure, such as high humidity and ultraviolet rays, from damage to the material by various harmful insects, mold, fungus, moss and other parasites representatives of microflora. Some solutions include not only antiseptics, but also fire retardants, which are designed to significantly reduce the risk of wood fire in the event of emergency fire situations.

So, before painting, the wood must be treated with special antiseptic agents.

When purchasing a solution for primary wood treatment, be sure to pay attention to the permissible area of application of the composition

When purchasing one of the protective solutions available for sale in a fairly wide range, you need to pay attention to the packaging label (label). It must indicate the area of its application, that is, a specific composition is intended for internal or external work.

Protective compounds can be transparent, preserving the completely open texture of the wood or giving it a glossy brightness or soft matte finish. However, there are also tinting solutions that make the material one or more shades darker.

There are several types of different solutions that can be intended to protect against various negative influences on wood - these are conventional and biomoisture-protective antiseptics, fire retardants, bleaching and primer compounds. To understand how they differ, it is advisable to consider each of them. This will make it easier to make the right choice.

Prices for wood antiseptic

antiseptic

- Antiseptic solutions are designed to combat fungus and mold that have appeared on wooden surfaces, as well as to prevent the formation of new formations. These compositions, in turn, are also divided according to different criteria.

An example of a high-quality antiseptic with a tinting effect.

So, you can find two types of antiseptics on sale - impregnations and coatings:

— Impregnations are designed to penetrate deeply into the wood structure. When purchasing this version of the solution, you need to carefully study its composition, since some of these treatment agents are very toxic;

— Coating solutions create a film on the surface of the wood and protect it from moisture. They are especially relevant for covering walls in rooms with high humidity, for example, in a bathroom or bathhouse.

Antiseptic solutions are produced on different bases, and according to this criterion they are divided into the following:

— Water-soluble compounds are environmentally friendly, so they are excellent for treating indoor walls. They are usually used under paints that are also water-based. A significant disadvantage of such antiseptics is that over time their protective qualities decrease.

— antiseptics made on an organic basis have high protective properties. However, they are more suitable for the facades of wooden houses, since they contain toxic components and are also unsafe in terms of flammability during application and before drying.

— Oil solutions of antiseptics are most often used for facade surfaces, wooden cladding of a balcony or loggia, especially if the house is located in a region with a harsh climate.

— Combined solutions consisting of oil and high-carbon components are used to treat both external and internal wooden surfaces. Moreover, they are also suitable for rooms with high humidity, providing their surfaces with high-quality protection.

The last option of antiseptics is the most expensive, since, in fact, it becomes a universal remedy used in any areas of construction and finishing.

- Biomoisture-protective antiseptics are used as an effective measure of protection against fungal growths, mold and insects harmful to wood. This type of antiseptic creates a protective barrier on the surface of the wood and also serves as a decorative coating. Therefore, the biomoisture-proof solution can be called universal, since it performs two functions at once.

One of the means for effective bio-moisture protection of wood - but it is more suitable for outdoor work.

Thanks to these properties of the antiseptic, not only money will be saved, but also time for painting. It is these solutions that are in high demand among owners of wooden houses.

- Fire retardants are used to make wood more resistant to fire, that is, material treated with such a composition is able to withstand exposure to open fire for a long time without igniting.

The main disadvantage of wood is its low resistance to fire, and treatment with fire retardants helps reduce the risk of fire.

Fire retardants are divided into two groups according to their reaction to fire:

— One group of solutions contains salts, due to which, when wood is exposed to high temperatures, gases are released that can prevent rapid combustion.

— The second group of fire retardants blocks flames by foaming, which occurs when wood is heated to elevated temperatures and creates a protective coating on it.

More effective fire retardants, according to experts, are those that contain sodium salts, as well as orthophosphoric, pyrophosphoric and tripolyphosphoric acids.

- Biopyrenes are impregnations that combine the functions of both a fire retardant and an antiseptic. Similar solutions can be used to treat walls from the inside and facade.

Binary action impregnation - provides both biological and fire protection for wood.

Due to the fact that this product is a complex consisting of all the components necessary to protect wood, using it you can save some money, time on work and on waiting for several different layers to dry out. solutions. So the costs are likely to be justified.

Biopyrene prices

biopyrene

- primer is another effective protective agent used for preparatory work before painting. These solutions are not only designed to prevent various manifestations and effects destructive to wood - they also create good adhesion between the surface of the wooden wall and the applied decorative layer. Water-based wood primers can be transparent, translucent or opaque. According to this criterion, they are selected depending on what effect is planned to be obtained as a result.

The use of primers greatly simplifies the subsequent process of applying paints and varnishes.

For example, if you plan to paint primed walls with a thick layer of paint, then it does not matter what kind of transparency primer to cover the wood with. In this case, rather, you only need to take into account that an opaque version of the soil will give a smoother surface. Transparent compounds work like impregnation, penetrating the structure of the material and filling its pores, but they do not have the property of creating a protective layer on the surface of the wood.

However, whatever primer is used, it creates a good base for the wood and paint to adhere to.

- Wood bleaching products are used to remove various manifestations from its surface that spoil the appearance of the entire wall - these can be blue, streaks or dark spots. Simultaneously with the removal of the above-mentioned flaws, these compositions also perform a protective function.

When using bleach, you must strictly follow the instructions provided by the manufacturer.

Bleaching solutions can be one- or two-component. The second version of the compositions is combined and mixed immediately before applying them to the wood. The formulation of some of the products provides for them to be washed off after a certain period indicated on the packaging, while others remain on the wood for painting as an antiseptic. Therefore, before purchasing one or another type of bleach, you need to pay attention to the packaging, which contains instructions for using the solution.

Varnish as a protective and decorative agent

As a protective agent for wooden walls, in addition to the above mentioned products, varnish solutions are used, which can also be made on various bases. To know which of the existing varnishes are suitable for indoor use, you need to consider each of them in more detail:

Varnishes are one of the best means for protecting and at the same time decorative coating of natural wood.

- Acrylic varnish consists of polyacrylates and is organic or water based. The solution is an environmentally friendly product without a pungent odor, and therefore it is often used to cover the surfaces of not only wooden walls from the inside, but also furniture.

Acrylic varnish - fits perfectly on the surface of wood, but, unfortunately, is not resistant to abrasive loads.

However, it must be taken into account that the layer formed by this type of varnish is not highly resistant to abrasion. This means that the coating will have to be updated quite often, and this is especially true for furniture accessories.

- Polyurethane varnish is made on a water basis, but despite this, it has high strength characteristics, including abrasion resistance. The composition of this protective agent is environmentally friendly and almost completely odorless after drying, so it is perfect for application to wooden walls inside the house.

Polyurethane varnish is highly resistant to abrasion - it is suitable even for wooden floors.

Some experienced craftsmen recommend adding hardening agents to the polyurethane solution to extend the life of the finish. Due to its high strength characteristics, this varnish is often used to cover wooden floors and parquet, so it is also fully suitable for walls. However, the price of these products is quite high, and this factor is the main disadvantage of this material.

- Alcohol varnishes and polishes can create a durable glossy layer on the surface of wood. However, despite their high strength, compositions based on this basis are not resistant to moisture, so they cannot be used to cover walls in bathhouses, loggias and balconies, as the coating layer will begin to peel off.

Varnishes are made based on natural resins, so their prices are quite high. This circumstance, coupled with low moisture resistance, determines that such compositions are not in high demand.

- Nitrocellulose varnishes consist of organic solvents and cellulose nitrate with the addition of synthetic resins to the solution.

Nitrocellulose varnishes are durable and quick-drying, but extremely flammable and have a strong odor until completely cured.

This type of varnish is divided into two varieties:

— One of them is intended for preparatory work, that is, it creates the basis for the outer layers.

— The second one is itself a decorative coating.

They are distinguished by the digital markings applied to the packaging. Typically, preparatory solutions have the property of drying quickly - this quality is provided by the manufacturer to avoid delays in the work. Therefore, when purchasing this composition, you need to pay attention to the instructions printed on the packaging with varnish.

Nitrocellulose solutions create a fairly durable coating layer on the surface of wooden walls, which is transparent and therefore does not change the natural color of the wood. Therefore, if you intend to preserve the beautiful textured pattern of the internal surfaces of wooden walls, then this type of varnish is well suited for this purpose. True, it is necessary to work with such compositions with special caution - they are extremely flammable in their uncured form (before the nitro solvent evaporates), and will emit a pungent odor before drying.

- Oil varnishes are made on the basis of artificial or natural resins; in addition, they also contain modified natural oil, driers and solvents. Varnishes of this type penetrate well into the wood and form a durable protective layer on its surface, giving the wood a warm ocher tint.

The solutions are well suited for interior finishing work; they cover wooden walls, floors, and furniture.

- Alkyd varnish is made on the basis of glyphthalic or pentaphthalic resins, to which driers are added. Since this type of varnish contains oils used as solvents, they are also often called oil-based. However, the alkyd version of varnish differs from oil varnish in its higher physical, technical and operational characteristics, so it is successfully used not only for interior but also for exterior decoration.

Some of the most popular and affordable varnishes are pentaphthalic-based alkyd varnishes.

In addition to alkyd varnishes, alkyd-urea solutions consisting of alkyd and amyl-formaldehyde resins are also available for sale. This type of varnish can be called two-component, since its drying is only possible when acidic hardeners are added to the mixture. This varnish is mixed immediately before applying it to the surface of the wood, since after preparation the solution remains suitable for a very limited time, and after it has hardened it will no longer be possible to dilute it.

This type of varnish is easy to apply and, after hardening, forms a durable protective layer on the surface that is highly wear-resistant. Thanks to this property of alkyd-urea varnish, it can be used not only for covering walls indoors, but also for covering parquet.

Paints for finishing wooden walls

In order to paint the inside of a wooden house, paints made on any base are suitable. Nowadays, various types of this material are presented in specialized stores in a very wide assortment. And one of the most important criteria when choosing a composition should be its safety, that is, the paint should not emit harmful toxic substances both during its application and during use of the premises.

Therefore, when purchasing any paint and varnish material, you need to pay attention to its characteristics, which should be presented on the packaging. In addition, it is recommended to obtain information from a sales consultant.

So, in specialized stores today you can find the following paints for finishing wooden surfaces:

- Water-based compositions are quite popular, since with their help you can cover the wood with a thick layer of paint, or you can make it translucent, thereby preserving the textured pattern of the wood. If the latter option is chosen, the paint must be diluted with water to the required consistency.

Water-based paints are attractive due to their low price and versatility, but are not durable - they cannot withstand abrasive loads.

Water-based solutions are distinguished by the absence of a sharp unpleasant odor and the fact that they do not emit toxic fumes harmful to humans. Therefore, they can be safely called an environmentally friendly material. The layers applied to the prepared surface set well and dry quickly, but are inferior to varnishes in their strength and wear resistance.

Prices for silicone paint

silicone paint

- Silicone paints are a solution of silicone resins, and thanks to them, they create a reliable and durable coating on the surface of wood. The paint composition has excellent technical characteristics, it is inert to mechanical stress and has good vapor permeability, that is, it allows wooden walls to “breathe”.

Some of the most durable and practical to use are silicone paints.

Moisture-resistant silicone film is resistant to abrasion and ultraviolet radiation. The applied coating is distinguished by enviable durability and is not only protection for the wood, but also a way to hide some flaws on its surface. The coating does not crack when the walls shrink, as it has good ductility.

- Silicate paint compositions are made from “liquid glass”, and therefore have a large number of positive characteristics. They are highly resistant to ultraviolet rays, high humidity, low and high temperatures, as well as open fire.

Silicate paints have a very beneficial effect on the atmosphere in the house, due to their environmental friendliness and high vapor permeability.

Silicate paint is an environmentally friendly product, since it does not contain substances harmful to humans and does not emit toxic fumes. Therefore, this type of material is excellent for covering internal surfaces, not only wooden ones, but also those made of other materials. Considering all the characteristics of this finishing material, we can conclude that it is well suited for rooms where conditions may arise that increase humidity, for example, an unheated balcony or veranda.

True, silicate compositions are completely incompatible with finishing solutions made on a different basis. That is, in case of repainting, it is necessary either to use silicate paint again, or to clean the surface to the very base.

- Acrylic paints are water-based, but have characteristics that exceed those of oil-based compositions, and therefore are able to provide reliable protection to wood and preserve its natural color. Due to their elasticity, paints have excellent adhesion to surfaces; they do not deform or crack.

High-quality acrylic paints are an excellent solution for interior decoration.

Paint can be used to paint both internal and external surfaces of a building.

- Alkyd enamel is used for painting both facades and interior wall surfaces. It creates a protective glossy or matte layer on the wood, making it smooth and aesthetically pleasing.

However, this composition also has its drawback - over time, alkyd white enamel turns yellow, and paint that has color fades, so to paint walls, for example, a balcony located on the sunny side, or that constantly receive a “portion” of sunlight, use it is not recommended.

- Oil paints have a considerable number of advantages over other compositions and are suitable for both internal and external coating of wooden surfaces. High-quality solutions are highly resistant to external mechanical influences and high humidity.

The obvious disadvantages of oil-based paint compositions include their long drying period, low resistance to ultraviolet radiation (over time, the coating begins to crack and peel) and air tightness. This type of paint is most often used to cover facade surfaces, but even then - with fairly frequent updating of the finish.

- Natural wax paints or liquid wax are made on a linen base and have been used to coat wood for decades, so they can be called a traditional material. Wax is well absorbed into the wood structure, making it waterproof.

Wax paints - create a pleasant matte wood surface, well protected from moisture penetration.

The solution can be transparent or tinted. If you plan to preserve the original color of the wood, then choose a transparent wax option, and if you need to darken the wooden walls, then you should use a tinted solution. Wax paint is easily applied to the surface, but acquires the chosen shade only after complete drying. Therefore, it is recommended to first apply a similar composition to a small area of the wall and wait for it to dry to make sure that the optimal paint tone is chosen.

Lucky

Varnishes leave the natural color of the timber, creating a glossy or matte effect. Serve as a protective option. There are many types of varnishes; the choice should be made based on operating conditions. Apply the same as paint.

Varnishes leave the natural color of the timber, creating a glossy or matte effect.

How to choose a color for a timber house

The color of the coating should be chosen to match the style of the room. It is not difficult to choose the appropriate option in order to get a good combination with other buildings and structures, because the range is huge. There are any colors from black, chocolate to green, red, gold. Classically, the natural color of the wood is left by applying transparent compounds.

The color of the coating should be chosen to match the style of the room.

Facade paints

Any paintwork material used for facade work must have a certain set of qualities. But in the situation with wood, this list increases, due to the natural vulnerability of the tree.

Characteristics that any façade material should have:

- resistance to precipitation of various temperatures;

- resistance to temperature changes;

- coating color stability;

- abrasion resistance;

- resistance to mechanical and physical influences;

- chemical inertness.

Facade paints can be successfully combined: wood protection and an interesting design solution

When it comes to painting a wooden facade, the paint requirements are supplemented by the following criteria:

- Plastic. Wood is a breathable, flexible material. Logs and boards can change volume depending on temperature and changes in humidity levels. Therefore, the decorative coating material must also be elastic and not crack.

- Vapor permeability. Decorative material should not create a barrier for moisture to escape from the body of the wall in order to prevent the onset of rotting.

- Fire safety. The material itself must not only protect the wood from burning, but also be non-flammable.

Most wood paints have a rich color palette

On a note! When choosing paint for painting a wooden facade, you should pay attention to the antistatic properties of the material. A paint coating with a high index will accumulate less dust and fine dirt, which means the façade will be much easier to maintain.

Prices for various types of paint for wooden facades

Paint for wooden facades

Classification of coatings for facades

Essentially, when choosing a paint, you select the type of future surface that will be obtained after applying the material to the wood. For exterior use, all paints are classified according to the type of solvent, the resulting texture and quality of gloss.

Gloss

Matte or shiny surface is not only beauty. Glossy coatings are more durable because they contain more resins. Matte surfaces are usually obtained from breathable decorative compounds. In addition, the glossy finish is more resistant to moisture and less susceptible to abrasion.

Manufacturers indicate the gloss level of the final coating on the can with a number ranging from 0 to 100. It is customary to divide the gloss level into 6 main groups.

Variety of colors for wooden facades

Table 1. Gloss levels.

| Digit range | Reflectivity |

| from 0 to 5 | matte without reflection effect |

| from 5 to 10 | matte with low reflection |

| from 10 to 30 | semi-matte have some shine |

| from 30 to 60 | semi-gloss with medium gloss level |

| from 60 to 90 | glossy with shine effect |

| from 90 to 100 | super shiny |

Solvent

All types of paints are diluted with 3 types of solvent:

- water, the compositions are called water-dispersed;

- organic chemistry, such as white spirit, acetone, solvent;

- inorganic compounds.

White Spirit

Paints diluted with inorganic compounds are rarely used in everyday life. For wooden facades, materials are usually used that are diluted to the desired consistency with water, as well as enamels, varnishes, alkyd and oil paints. The specificity of organic solvents is their unpleasant odor.

On a note! Water-dispersed materials can only be applied at positive temperatures. Paints diluted with organic compounds can be used even with a slight minus.

Texture

Facade paints come in textured (volumetric) and forming materials for smooth surfaces. Textured compositions are not used for wood processing, since wood initially has a rich texture and does not require additional decoration. Smooth compositions can be transparent, such as varnishes, or dense, like enamel.

Even covering with colored paint allows you to preserve the natural texture of the wood.

Technology of painting a house made of timber

The stages of painting indoors and outdoors are slightly different. Before painting the outside of a log house, you need to learn the rules of the job.

Outside

On the outside, they begin by preparing the surface, cleaning it and sanding it. The surface is primed to improve adhesion and save coloring agent. After the primer layer has dried, paint is applied. The process is carried out as standard, paying attention to the ends and seams.

The surface is primed to improve adhesion and save coloring agent.

Inside

They immediately begin by cleaning the surface, then eliminate surface defects, apply antiseptic compounds, and carry out grinding. When the surface is vacuumed, paint is applied. It is important that each layer dries.

It is important that each layer dries.

Color selection, recommendations

To choose the right paint color, you need to take into account the style of the interior - the color of the walls should be combined with the design and style of the room. If you want to decorate the inside of your house in a classic style, then painting should be done with transparent compounds to highlight the beauty and grain of the wood. The Scandinavian style is characterized by pastel and white colors. If you need to visually expand the space, then you should choose light-colored paint, and if you need to narrow it, then dark ones.

Pastel colors look harmonious in the interior of a house made of rounded logs and are combined with modern appliances

Painting a house made of profiled or laminated timber

Glued and profiled timber has a higher cost. The grinding stage will be easier to carry out, and the base will be of better quality. It is advisable to apply antiseptic impregnation to the timber itself, before construction. Priming is necessary; it is better to paint the surface with oil, acrylic paints or varnishes.

It is prohibited to use water-based dyes due to the poor resistance of the material to moisture.

It is advisable to apply antiseptic impregnation to the timber itself, before construction.

Painting the timber is necessary to obtain reliable protection from natural influences. It is better to choose high-quality compositions; saving will lead to the paint peeling off quickly. And the material will last less. Painting can only be done after preparing the base.

How to paint a wooden house decorated with dry materials from the inside?

Let's start with the fact that the floorboard, for example, must be painted: it is necessary to avoid contamination, wear and cracking. You can paint the inside with varnishes, or with paints. The varnish painting technology is more labor-intensive. First you need to decide: do you want to leave the natural color of the wood or do you want to tint it. If you want to add tone, then you: A) Take a special water-based stain and apply until you get the color that you need. Top coat it all with varnish. Under no circumstances should you use already colored varnish. Since it, unlike stain, does not penetrate the pores of the wood and simply hardens into a colored film and wears out quickly. The paint should be applied in the same way as the facade.

In the photo - a floor painted with stain

ATTENTION: do not use colored varnish to paint the floor! Give the floor color with stain, and then cover it with varnish.

As for the walls and ceilings: they also need to be treated, because dust and exposure to the sun have not been canceled. There are special one-component acrylic varnishes for interior work. Therefore, if you are satisfied with the natural look of the wood, you can use them - applied in 2 layers. If we want to paint it in color, then we can paint the same varnish. Before applying varnish, the wood must also be primed.

In the photo: a floor painted with stain and walls coated with a one-component varnish.

Choosing paint according to purpose

Paint for a living space is not always suitable for a kitchen. To figure out which option is right, you need to pay attention to the digital code in the labeling. Its first numbers indicate the special properties of the paint:

- 1 – weatherproof;

- 2 – intended for interior work only;

- 3 – used for metal structures, not suitable for lining or timber;

- 4 – resistant to hot water and steam, it is chosen for the bathroom and kitchen;

- 5 – special, for example, for leather;

- 6 – resistant to oil products and fats, rarely used in everyday life;

- 7 – insensitive to aggressive environments;

- 8 – withstands high temperatures, suitable for the kitchen;

- 9 – has electrical insulating properties;

- 0 – these are primers and enamels;

- 00 – putties.

Compositions that are resistant to steam or oil are more expensive than conventional ones. So you should buy them only for finishing special rooms.

Why do you need to paint?

Many owners do not paint the walls of their house. Logs look quite aesthetically pleasing, giving the premises a colorful look, but special processing of wooden structures is still necessary. This is done for a number of reasons:

- The use of specialized mixtures will help reduce the risk of fire.

- Preventing the process of rotting. By covering the wood with special solutions, you can preserve it in its original form for a long time.

- The paint coating prevents the appearance of various mechanical defects.

- Coloring will hide minor imperfections in the material.

- Applying a paint coating will prevent the appearance of various wood beetles and parasites in the wood.