Decorating the walls in the bedroom with imitation timber from coniferous trees

Any specialist without hesitation will list the areas where such a simple, affordable, but also reliable, safe and beautiful material as imitation timber is used: interior decoration of wooden houses and cladding of their facades. Indeed, wood is predominantly associated with country and country interiors, but it is increasingly found in the most ordinary apartments. Imitation timber is unique in its own way; with its help it is easy to create a warm atmosphere typical of wooden houses, while being limited to a modest budget. This material contains enormous potential, which will appeal to both supporters of eco-friendly or traditional styles, as well as lovers of modern design solutions.

Entrance hall finished with raised timber in warm tones

Open apartment terrace with wooden floors and partitions

A narrow, small-sized kitchen will be visually expanded by a wide imitation of timber, designed horizontally

Imitation of timber in finishing a bedroom with light wood

Relaxation area in a private house. Block house cladding

Execution of internal cladding

There are many types of finishes, among which it is sometimes difficult to choose.

It is usually used for ceilings and walls. There are two types of cladding used in the house - monolithic and combined. In the first case, the entire area of the ceiling and walls is covered with panels in compliance with all technologies. In the second option, partial processing of wood is carried out, a combination of imitation timber with textiles, wallpaper, and glass.

Bright and beautiful dining area

Wall decoration

Before finishing the walls with imitation timber, you need to wait for shrinkage (when covering a new house). At the preliminary stage, preparation is carried out with antiseptic treatment, vapor barrier, and laying of sheathing. After this, the panels are installed.

Using this material you can create original, unique interiors in rooms of different functionality. Panels up to 100 mm wide are suitable for narrow rooms, which will visually expand the space.

Tip The panels themselves are mounted horizontally. For larger rooms with low ceilings, it is better to mount the planks vertically.

Bathroom finishing

Ceiling

The ceiling surface must be sheathed after finishing the walls. In this case, narrower panels are purchased, attached to the sheathing in increments of 50-60 cm, placed along the length of the room. They start working from the window.

To calculate the area of the ceiling surface, multiply its width by its length. The resulting figure is divided by the area of one beam. The result is the number of panels required for the cladding. It is not difficult to calculate the fastenings: the total number of planks is multiplied by the number of parts needed to fasten one board.

Living room in Provence style

Before attaching to the surface, the panels need to be kept indoors for 4-6 days and adapted to the microclimate. First remove dirt and unnecessary parts from the walls and ceiling, cover them with impregnations and antiseptic solutions. Then the vapor barrier and sheathing are attached with a construction stapler (self-tapping screws are used at a distance of 70 cm).

When performing complex cladding of a ceiling with walls, first the walls are finished and the planks are secured with clamps. To fix the plastic to the ceiling, use self-tapping screws or small nails. Connections in corners are made with internal and external corners. At the final stage, sanding, tinting or painting is carried out. Processing imitation timber increases the wear resistance of the boards.

The best manufacturers

When deciding whether to purchase such material, you need to study the list of trusted manufacturers, including:

- Russian manufacturer WoodStockHouse.

- Russian manufacturer Derevo-Lesprom.

- Russian manufacturer Lenwood.

- Russian manufacturer Grand Forest.

- Russian manufacturer Real Wood.

Varieties

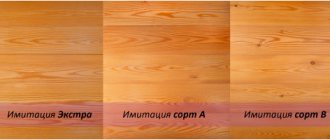

The class of imitation timber largely affects the cost of this type of lumber. The product range includes 3 main categories, each of which must meet certain standards.

"Extra"

High quality material, virtually free from defects. Imitation timber of the “Extra” grade is suitable for finishing the interior and facade of buildings, has an aesthetic appearance, and can also be used to form a rafter system and cover cornices. Among the acceptable defects, the standard indicates the presence of small cracks in the end part, resin pockets with a diameter of up to 2 mm each.

"A/AB"

The middle class of false timber is characterized by the presence of acceptable defects, including knots, on an area of no more than 10% of the surface. This material is most often used in the outer cladding of buildings.

"BC"

Imitation timber of this class is made from inexpensive raw materials, abundantly covered with knots and resin pockets. The presence of traces of rot in the form of black spots and stripes is acceptable. The volume of permissible defects can reach 70% of the entire board area. This greatly influences her choice. But if the affected areas are not too densely located, such false beams are suitable for exterior cladding of a house or finishing functional areas inside it.

The sequence of do-it-yourself work

The technology of facade finishing may vary slightly depending on the finishing coating used. But the sequence of work is the same in all cases.

First, the walls are leveled and treated with special protective compounds. Next, the building is insulated. The last stage is the actual installation of the decorative coating.

Thermal insulation and sealing

Insulating materials are fixed to wall surfaces using mounting adhesive. For wet facades, compositions made from polymers are often used. They have good adhesion to any surface.

Base layer

After installation, the thermal insulation material must be covered with a hard layer. This is necessary to prevent mechanical damage.

Most often, a fiberglass reinforcing mesh is used for this, additionally impregnated with various protective compounds.

Final decorative coating

The final stage of cladding the cottage is the installation of the selected finishing coating. For wet facades, decorative plaster is often used.

But if tile material or panels are chosen, then the sheathing is installed.

Characteristics of false timber

Lumber manufacturers are constantly developing new technologies that make it possible to make new finishing materials from wood. More recently, their range was represented by only a few types of lining.

Wide range of modern lumberSource thewalls.ru

Today on the market you can see various decorative panels, planken and decking, and decorative bars for walls. But the most popular is false timber - carefully dried boards, sanded on the outside. The width of the boards can be different, and the length ranges from 2 to 6 meters.

What false timber looks likeSource homify.com.mx

When assembled, the finish looks great. A tenon and groove system is formed on the side parts of the planed boards, so installation of the finishing occurs quickly. It has a number of advantages.

Wood is a natural material, it is completely harmless to human health, conifers are known for their bactericidal properties.

Wooden trim makes a home more comfortableSource www.interiorexplorer.ru

- Unlike standard timber, sawn boards are easier and faster to dry. During the production process, they undergo additional processing; they are impregnated with antiseptics and solutions that do not allow fungi and mold to develop and moisture from the air to be absorbed into the structure of the wood.

- Decorative timber in the interior of a country house looks natural, it is 100% similar to wooden beams, and at the same time costs much less.

Finishing with false beams looks naturalSource bs-ru.com

- The material is not afraid of temperature changes or exposure to ultraviolet radiation, so the finish will not fade over time.

- After assembly, the cladding does not shrink, it is not afraid of temperature fluctuations, so it is well suited for finishing attics, loggias, balconies, verandas, and any other “cold” rooms.

Residential veranda trimmed with woodSource pingru.ru

Using imitation timber, you can level any curved walls without carrying out labor-intensive wet work. Its installation is carried out by installing the sheathing. Guides are first attached to vertical surfaces. They are set to the building level, after which timber is placed on them.

Installation is carried out on the lathingSource ko.decorexpro.com

Special clamps are used for fasteningSource yourgreenhouse.ru

Any wall made of cold brick or silicate block will look more impressive if the inside is lined with natural wood. Insulation can be installed in the frame. This will help improve the heat capacity of the cottage. After finishing, the house will be much quieter. This is another additional bonus of choosing the described type of finish.

After installing false beams, the climate in the house becomes warmerSource epidemz.com.ru

What is used as raw material

Practice shows that false beams look very different in the interior. This is because it is made from different types of trees. Each has its own texture, its own color, its own pattern. This must be taken into account when purchasing material.

Light false beams make the room visually more spacious Source ttrofimov.ru

If the bars are made from pine, they will be light yellow in color. Over time it will darken a little, but its golden shine will remain. Designers recommend choosing this material for wall decoration in the kitchen and hallway. Pine looks good in the decoration of the attic. There, its light shades help to visually expand the space and fill it with air.

Imitation of pine timber in the bedroom interior Source pilomaterial-stroi.ru

In the interior, bars made of cedar always look royally luxurious. They are used to decorate living rooms, offices, and large reading rooms. This wood has a unique pattern, very beautiful and embossed, it adds restraint to any design.

After processing, the tree drawing is completely preserved Source fcld.access.ly

Therefore, when it is necessary to emphasize the severity of the chosen style, preference is given to wooden finishes made of cedar. It has its own smell, cedar is known for its healing properties, so interiors with cedar cladding have a beneficial effect on human health.

Cedar in the living room interior Source glenoakspathology.com

Larch is a material that perfectly resists moisture. Under its influence, it swells slowly, so wooden trim made from larch is suitable for decorating kitchens, baths, saunas, and saunas.

False beams in sauna decoration Source stroyservis-74.ru

Pricing Policy

Despite the fact that imitation timber is a specific name of the product, the price of its different options may vary significantly. The reason for this is not only the volume of packaging, but also the parameters of the boards, as well as their grade:

- “Extra” is made from wood, which may contain defects such as minor cracks at the ends, resin pockets, with dimensions not exceeding 2 cm in diameter and one point. The cost of imitation timber of this class is the highest. Most often, this material is used for interior or exterior decoration, as well as for the installation of cornice and rafter systems;

- “A/AB” is made from wood with a large number of the defects described above, as well as the presence of knots. In this case, external damage should be no more than 10% of the total surface of the element;

- “BC”, here defects such as cracks, knots and rot are allowed on the surface of the boards. Damage can cover 70% of the board surface. This material is the cheapest, but its use greatly affects the appearance of the surface being finished.

Differences between classes of boardsSource nts-sk.ru

Exterior paneling

It must be remembered that imitation timber is used for a ventilated facade and there must be a gap between the cladding and the thermal insulation layer. The panels can even be attached to objects made of logs or natural timber. This technology is convenient because it allows you to preserve the original appearance of the building for a long time. Therefore, it is profitable and rational.

Open plan in a country house

When purchasing material, you should consider the main nuances:

- Humidity level up to 15% (to prevent facade distortion during operation).

- Availability of grooves. The original appearance of the panels will remain longer.

- Width about 100 mm. The siding will look like timber. With a smaller width, the panels will look cheap, and wider ones will look sloppy.

- Quality of the locking connection.

- Smoothness, evenness, absence of damage and defects.

The material and components are preliminarily calculated, walls, window and door openings are measured.

Stylish kitchen

High-quality panels are not difficult to install. But the work is carried out in strict order:

- Prepare the surface by cleaning the walls from dirt. They can be treated with an antiseptic against pathogenic microflora.

- The sheathing is placed vertically to the base and secured with dowels or self-tapping screws.

- High-quality vapor and heat insulation is installed. The insulation is attached to a vapor barrier film and covered with it, the joints are taped.

- Panels with decorative elements are attached.

- The facade is secured with nails or screws.

- Cover with antiseptics and varnishes.

Rustic style

The panels need to be fastened in the direction from bottom to top, the grooves are located in the lower part. This will prevent moisture from entering. The first bar is placed with a level, since the evenness of the surface will depend on its correct installation. The fasteners are screwed in at a 45 degree angle.

Work is carried out at a temperature of at least -15°C, in dry weather. Panels should only be painted in dry and warm weather.

To extend the life of a façade covered with slats, you should properly care for the surface. It is necessary to periodically coat them with varnish and check for rot, fungus and defects.

How to install indoors?

Raised timber is well suited for interior decoration of eco-style premises. It gives the interior a fresh look and has good heat and sound insulation properties.

You can sheathe imitation timber not only on the walls of rooms, but also on floors and ceilings and even on balconies. It is recommended to use materials with dimensions of at least 20-25 mm in thickness and 100-120 mm in width. You should not use thicker planks, as they will visually reduce the usable space of the room. The length is selected depending on the size of the wall and the method of laying the timber.

The interior decoration of the room can be made using various materials or exclusively imitation timber. The first method is called combined, the second - monolithic. In case of combined finishing of premises, the laying of timber is limited to a separate wall or part of it, combined with plaster, tiles, and stone.

In the case of monolithic finishing, the walls, floor and ceiling are completely covered with wooden planks. They must fit closely to each other, all joints and grooves must be smooth and, if possible, hidden by interior elements. Installation consists of several stages.

Before the main work, it is necessary to prepare the surface. It must be smooth and clean, without chips, cracks or other defects. It is necessary to thoroughly treat it with antiseptics and solutions that prevent rotting and the growth of mold fungi.

Lathing

To assemble and install the sheathing frame, standard medium-sized bars are used, but not less than 20 mm in one plane. Since imitation of a smaller thickness is used for the internal cladding, the pitch between the sheathing bars can be up to 600-900 mm.

Insulation

The next step is vapor and heat insulation of the room. Before laying the false timber, a vapor barrier film is attached to the sheathing to prevent moisture from penetrating inside. All joints are carefully fixed. The next layer is insulation: mineral wool, polystyrene foam, polyurethane foam or any other materials of your choice, the use of which will reduce the heat transfer of the building and maintain the optimal temperature inside the room.

Wall mount

The panels are usually installed horizontally, starting from the ceiling, and in such a way that the tenons face up and the grooves face down. The parts of the structure must fit tightly, the joints must be aligned.

It is better to fasten the first panels at the corner between the ceiling and the wall, as well as the last ones between the wall and the floor, “through the body” and cover them with baseboards. Fastening of subsequent structural elements is carried out using clamps “through the groove” or self-tapping screws with nails “through the tenon”.

Another way to lay imitation timber is using “duet” fasteners. Professional builders recommend using it for beginners who are afraid of installing the structure weakly or leaving random gaps. The fastener is first connected to the false beam in its upper part; the limiter on the part will not allow it to go above or below its intended place. Then the plank is installed in its place with the tenon facing up, and the protruding parts of the fasteners are connected with self-tapping screws to the sheathing.

This method leaves space between the sheathing and the wall made of false timber, which improves ventilation. It is invisible and suitable for interior cladding. In this case, it is better to start installing panels from the floor to the ceiling.

Headlining

This is the most difficult part of the work due to its danger and inconvenience. You should not try to cover the ceiling with false beams alone; such work requires at least 3-4 people. Before laying, it is necessary to prepare the sheathing with a batten pitch of no more than 400-500 mm. In this case, ideal fastening will be provided by a clamp or “duet”. With them, installing imitation timber on the ceiling is much easier than using a hammer and nails.

Types of paints

All paints intended for processing imitation panels are divided into transparent and opaque compositions. The former are indispensable where it is necessary to protect wooden panels from harmful environmental influences, while preserving the original texture of the false beams. For these purposes, varnishes or glazes are purchased that have good protective properties and light decorative effects.

Varnishes, in turn, are divided into:

- Acrylic.

- Water-based.

- Polyurethane.

- Epoxy.

Varnishes can be completely transparent or with a moderate shade; after application, they form a film on the imitation timber finish. Liquid-flowing glazes with protective components penetrate deeply into the wood and leave a beautiful matte shine and the desired shade on its surface.

Painting imitation timber with varnishSource qrepaer64.ru

Opaque coatings include:

- Acrylic paints.

- Alkyd emulsions – oil and enamel.

- Water-dispersion paints.

If you apply opaque paint to the imitation timber, the real wood pattern will be completely painted over with pigments.

Opaque paint in the design of imitation timberSource antiseptik.com.ua

Paints for interior decoration

The primary function of painting imitation timber indoors is for decorative purposes. Interior wall decoration usually does not have any special requirements for protection. The exception is rooms with high humidity - sauna, bathhouse, bathtub, kitchen. It is advisable to treat such rooms with stronger paints. In other cases, the emphasis is on the decorative properties of the compositions, for which opaque coatings are selected that create the necessary textural effect.

The range of painting compositions for interior walls consists of the following items:

- Oil paint.

- Enamels.

- Acrylic paint.

- Alkyd paint – for baths, saunas and swimming pools.

Painting imitation timber inside the houseSource suporteimoveis.com

Before painting imitation timber inside the house, you must follow the basic rule: when buying paint for a living space, you need to rely on the safety of the coating

When selecting materials, you should pay attention to a trusted manufacturer. Low-quality paint is toxic and releases harmful substances into the air during the entire period of use.

Knowing how to properly coat imitation timber inside a house, a person will protect himself and his loved ones from the negative consequences of painting. The best paint option for interior decoration is water-based compositions.

Choosing a paint material for exterior finishing

External cladding boards can be damaged by sudden temperature changes, precipitation, and scorching sun. The main criterion for painting imitation timber on the outside of a house is the protective properties of the coating. Changing the appearance of the panel comes second here.

Assortment of facade paints for timber:

- Professional – applied using special technology.

- Alkyd.

- Acrylic.

- Silicone.

Painting imitation timber outsideSource lt.decoratex.biz

Form of false beam

Unlike a convex blockhouse, with which false beams are often compared, it has a flat surface. Chamfers are cut along the edges at an angle of 45°. After connecting adjacent planks, barely noticeable seams remain, but not the same as with eurolining. Rather, they resemble “calm” lining.

Block house on the cut

From the back side, 1 to 3 ventilation ducts are cut out, which run along the entire length of the beam.

The false block has the same lock as other types of lining

The edges of the lamellas have a spike on one side and a groove on the other. These are the connecting elements of the timber. The tongue-and-groove lock solves several problems at once:

- makes the cladding windproof;

- increases sound insulation properties;

- strengthens the skin.

Disadvantages of imitation

The disadvantages of such material will be significantly noticeable if the manufacturers were unknown or the production requirements were not met. Some sellers begin to sell material that is not quite ready yet: not completely dried or not processed as needed. Such material will become covered with cracks in a month and may also become a fire hazard.

You should not buy cheap material from an unknown manufacturer. You won't be able to save money on this material. The choice of material must be approached responsibly.

Installation of false beams

Installation begins with the installation of guide bars with a pitch of 600 mm. Bars with a side width of 50 mm are leveled using a construction cord or a laser level. The bars are attached to the wall with metal corners and screws.

False beams can be mounted both from bottom to top and from top to bottom.

When installed externally, the lining is placed with the groove at the bottom to prevent moisture from entering, and in the interior of the premises with the groove at the top, which makes it possible to more effectively hide the joints.

It is important to install the first board exactly horizontally using a level, the subsequent ones are inserted into it and attached to the bars with nails, self-tapping screws or special fasteners called clamps - these are brackets made of metal

Kleimers

Clamps are special metal brackets for hidden installation of lining. The clamps have numbers and are matched to the size of the board groove. Claypers are used when finishing only interior spaces, since the position of the board is obtained from above.

False beam protection

After installation, you need to protect the false timber from moisture, dust, mold and dirt. There are many types of protection: special primers, stains, varnishes and waxes. You can also paint the boards with water-based paint.

The main advantage of installing false beams is that it can be done by one person who does not have construction experience.

A copy is as good as the original

Finishing with imitation timber creates the complete illusion of classic wooden masonry (as the photo clearly demonstrates), but the result will be much cheaper, which is why the material is actively used in construction.

Imitation timber in a modern bedroom

Imitation timber or false timber is used for internal and external cladding of buildings. Such cladding ideally hides the “gloomy” base: walls made of concrete or foam concrete blocks, sand-lime brick, unsightly frame, insulation boards. Imitation of timber looks impressive, noble, adds light and warmth, it can be used when finishing new buildings or repairing old ones.

Panel imitation timber for finishing the entire room

Cladding facades with imitation timber is extremely popular in suburban construction.

Modern house covered with timber block house

However, interior decoration using this material can also easily be done not only in a private house, but also in a city apartment, especially if you want to create a unique, original interior filled with soft shades and the warmth of natural wood.

Advice! False timber for external and internal work differs in size. Wide, thick lamellas are suitable for cladding facades, and thinner and narrower ones are suitable for finishing inside the building.

Narrow slats look great at the head of the bed

Safety precautions

Decorating the inside of a house with imitation timber requires compliance with the rules: “Safety in Construction”. All work related to cladding is performed in special clothing, gloves and safety glasses.

Safety in using jigsaws and other similar cutting tools is observed based on their operating instructions, which must be carefully studied before starting work.

The safety glasses presented are required to protect against splinters getting into your eyes and soft tissues. This brand and form is just one of the options that you can use

False timber as a finishing material

It is worth noting that this material only partially lives up to its name. It is not so easy to obtain a surface that would match the appearance of a wall made of profiled timber. In most cases, the same effect is obtained as when finishing with eurolining. If you want a different result, you will have to carefully pore over the choice of sizes of false beams. The key parameters here are two: thickness and width - the larger they are, the higher the likelihood of the “scam” being successful.

False beams are distinguished by the type of wood used as raw material in production: pine, spruce, larch, cedar, etc. In this case, the dimensions of the material can vary within fairly wide limits, for example, width - from 90 to 200 mm, thickness - from 16 to 45 mm. As for the length, panels from 1 to 6 m can be found on sale. The larger the last indicator, the higher the likelihood that such false timber belongs to a mixed grade. Regarding the grade, which largely determines the aesthetic characteristics of the material, imitation timber can be of 5 grades: Extra, A, AB, B, C.

Advantages and disadvantages

Advantages of false timber:

- material from environmentally friendly raw materials. Hence all the advantages: pleasant smell, original texture, etc.;

- with the right approach, you can really create the illusion of walls made of corrugated timber;

- finishing with imitation timber is quite simple and, if desired, can be carried out by the developer

Many disadvantages are associated with the naturalness of this finishing material:

- false timber for exterior finishing needs high-quality protection from mold, insects, etc.: impregnation with antiseptics, coating with paints and varnish, etc.;

- the color of the finish changes under the influence of ultraviolet rays;

- the cost depends on the variety, and can be quite impressive;

- the cost of work carried out by third-party specialists is approximately equal to the cost of the material

Attaching false beams to the base

You can handle the installation work yourself and save a lot of money. Finishing work can be divided into two stages:

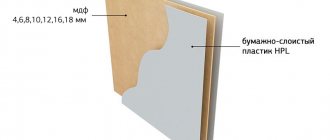

- lathing device. The lathing is an intermediate structure - a frame made of wooden bars or galvanized profiles, which is attached to the wall. Its main task is to achieve a perfectly level base, to which the false timber will subsequently be attached;

- installation of finishing panels. Imitation timber is mounted horizontally to the sheathing elements using nails, screws, self-tapping screws or clamps

How much does false timber cost?

Prices for false beams, when calculating the area of the surface to be finished, are determined by the thickness of the boards and their grade.

Of course, the type of wood also affects the cost: the budget option is pine or spruce imitation timber; products made from linden, larch or cedar will cost more. Approximately estimate the cost of 1 sq. m. false timber you can by reading the data in the table below. Approximate prices for false beams

| Wood type | Thickness, mm | Approximate prices for 1 m2 of finished surface |

| Pine or spruce | 16, 22 | 250-450 rub. |

| 28, 35 | 370-800 rub. | |

| Larch | 20 | 400-1500 rub. |

| Cedar | 12, 16 | 800-1400 rub. |

| 18, 20 | 900-1800 rub. | |

| Linden | 12, 15 | 300-800 rub. |

| 18, 20 | 1100-1900 rub. |

conclusions

Affordable prices for false timber, relatively simple installation of finishing panels, good results at the end of the work - all this makes imitation timber a worthy competitor to other modern finishing materials. Just before purchasing, do not forget to make sure that the walls finished with wooden boards really correspond to your ideas about comfort and coziness.

Size selection

This type of finishing material does not have strictly regulated dimensions. The most common products are those whose width ranges from 110 to 190 mm, and thickness from 18 to 34 mm (although there are modifications with the same thickness as lining: 14 and 16 mm).

The most popular panel thickness for interior decoration is 18-22 mm and width up to 110 mm.

If we talk about the standard version of ordinary or profiled timber, from which houses for permanent residence are built, then it has a cross-section of 150x150 mm. Therefore, the interior decoration of a house made of timber (in terms of cladding frame interior partitions) should be carried out using panels of the same width as the dimensions of the main building material.

With the choice of length, not everything is clear. There is no point in purchasing the entire batch with the same length, especially in the maximum size of six meters. Considering the length of the partitions, when covering walls inside a house, the most common panel sizes are up to four meters. It is better to calculate and select the dimensions of the molded lumber so that there are as few scraps as possible.

If the length is not enough for the entire wall, then the joints can be hidden behind furniture or hidden with a fillet.

To finish the ceiling, you need to use whole panels, if possible without splicing them along the length. And they should be located in the direction from the window (if the room is corner, then in accordance with the laying of the floorboard).

Calculation of the amount of imitation timber must be carried out not only for each room, but also for each type of surface. This will allow you to optimize the cost of materials and the cost of work in general for the interior decoration of the house.

Installation features

Installation of imitation timber during interior finishing work can be done independently if you have basic skills. The whole process consists of the following steps:

Calculation of the required quantity based on the size of the room and the layout of each panel. To avoid deformations after installation, the false timber after purchase should lie for 2 days at room temperature. Before starting work, the walls should be thoroughly cleaned and then treated with an antiseptic composition at least 24 hours before installation. A layer of vapor barrier is attached to the prepared surface. The sheathing is installed. It should be positioned perpendicular to the lamellas and have a pitch of 60-70 cm. The heavier the panels, the more frequent the pitch. For ceiling cladding, the distance can be reduced to 40 cm. In places where it is planned to install any equipment or hanging furniture, bars should be installed for subsequent fastening. The false timber is installed along the sheathing from the bottom up in a horizontal position. When finishing, the length of the lamellas should be selected as close as possible to the width of the room to reduce the amount of waste. The first plank is attached to the base with self-tapping screws, all subsequent ones are attached to each other and fixed with clamps.

Wooden panels of imitation timber on the kitchen apron, protected by glass

The finished surface is coated with protective compounds, sanded, after which a primer and finishing coating (varnish, stain, paint) are applied. The tinting composition can be applied to the slats before installation, so that unpainted areas do not appear in the seams over time.

Classic bedroom with a dark ceiling covered with imitation timber

Advice! The corners can be decorated with a special decorative beam, which will make the result more neat and aesthetic.

Exterior decoration of a mountain house with false timber

Two-level studio apartment with partial finishing with imitation timber

Imitation of timber will allow you to create a cozy atmosphere inside any room, characteristic only of finishing with natural wood. This material will allow you to fully enjoy the unique wood structure and natural shades, integrating them into both traditional and modern interior design.

Care Tips

In order for imitation timber to last for decades, you need to properly care for it. Treatment with antiseptic agents alone is not enough. After installation, the surface of the wood is opened with varnish or wax. It is necessary to maintain a sufficient level of humidity in the room so that the material does not dry out and begin to rot.

The imitation does not require special care. It is enough to periodically remove dust from it with a vacuum cleaner. Any stains that appear are removed using special products designed for wood.

Imitation timber is used for external and internal cladding of buildings. Thanks to its excellent technical characteristics, the wood will last a long time. It provides a beautiful interior, and installation is easy to do yourself. This coating allows you to realize your wildest design fantasies.

Varieties

Depending on what type of wood is used in the manufacture of false beams, the finish may have a different appearance. From round timber, boards for its base are cut to the required size. Further processing of the wooden surface depends on the characteristics of the texture. In some cases, the material is additionally aged or fired to achieve unusual visual effects. For example, from inexpensive types of wood it is quite possible to create an imitation of oak or wenge.

It’s worth talking in more detail about what false beams look like depending on the type or finish. There are several types of material.

Made from larch. Usually Karelian or Angara wood is used, which has a uniform color of a pleasant creamy salmon shade. It is worth considering that larch wood is very hard and dense, it practically does not absorb moisture, but it protects well from heat loss. The material will provide good thermal insulation of the facade.

Russian hut or rustic style

The main symbol of Russia is the hut. Nowadays, wealthy families are not averse to having a log house.

False timber is an excellent assistant for simulating wooden walls in the style of a Russian village. Being in such a hut gives you a feeling of unity with nature, connection with your roots.

It is quite possible to reproduce a cozy room for eating and welcoming guests. It will, of course, look in a new style, but it will still convey the old atmosphere. In such a room, everything should be made of wood: floors, ceilings, walls, furniture.

Ideally, the false beams will be an imitation of bulky matte boards with an antique effect. A massive wooden table with chairs or a bench should be installed in the center.

How to choose false timber?

When choosing false beams, pay attention to the following characteristics:

- size;

- type of wood;

- variety.

Raised beams are classified according to grades, sizes, wood species

Dimensions

The timber is produced in different sizes, which allows you to choose the most suitable option for your purposes:

- length - 2.5–6 m;

- width - 1.10–18.5 cm;

- thickness - 1.6–3.5 cm.

For exterior finishing, wider boards are used.

Which tree species are better?

False beams are made from different types of trees.

The timber is produced in different sizes

Conifers

This is one of the most popular tree species in home decoration. The most accessible products are made from pine. Spruce is also used, but the tree is quite knotty, which is a disadvantage, although it is more resistant to moisture. The advantage of the latter is its uniform color. Therefore, on spliced beams, the seams are hardly noticeable. Pine, unlike spruce, turns yellow over time.

However, Angara pine is already a premium type of wood. It has a high density and almost no knots. The same can be said about Altai cedar. The timber made from it has a beautiful pattern. But a much more significant plus is strength and weather resistance.

Photo 9. False timber made of pine

Larch remains the leader in wear resistance and consumer characteristics. It is especially often used for external cladding. After all, its resin contains natural antiseptic substances. Because of them, the wood is not susceptible to rotting.

Hardwood

Linden, oak - a couple of trees from which false beams are most often made. However, their uses are different. Linden is most often used to decorate saunas and baths, since it does not have the necessary strength. In addition, when exposed to sunlight, it acquires a yellowish tint.

Oak has the best performance characteristics. In terms of hardness, it is second only to ebony. In addition, it is resistant to all atmospheric influences.

Aspen is used to imitate timber, but quite rarely. Its core is susceptible to rotting. Therefore, they only make thin lining out of it. It is used for covering steam rooms.

Linden and aspen are often used for baths and saunas

An analogue of false beams is a block house - an imitation of rounded logs.

When choosing false timber, you need to consider where exactly it will be used. Larch and cedar are not suitable for bedrooms and children's rooms. They give off a rather pungent odor. This can cause headaches and worsen asthma. In summer cottages you can use inexpensive pine and spruce. Panels made from these materials are also suitable for the bedroom. In the living room it is better to use oak and cedar.

The lighting of the room also matters. If the lighting is dim, then light types of wood are suitable - pine, linden. For southern rooms choose darker oak and alder.

Variety

Table 1. Types of false beams

| Variety | Characteristics |

| Extra | Smooth surface, no growth, rot, or wormholes. Knots are only embryos, no more than one per linear. m. End cracks of 30x0.5 mm, tar cracks of up to 20x3 mm, as well as wane and non-string, which are not visible during assembly, are allowed. |

| A | There are no falling knots, no signs of rotting or damage to the wood by insects. Healthy knots - no more than 35 mm. There may be growth, tar marks, cracks at the end, chips on the ridge and bottom of the groove, blue, but not more than 10% of the surface and 10% of the batch. It may be difficult on the reverse side |

| B | There should be no rot, dead knots up to 10 mm. No more than 3 wormholes per panel (no more than 5% in the party). Porosity, tar patches, and wane hidden after installation are not considered critical. Blueness and fading (up to 10% coverage), as well as poor color underneath, are not considered defective. |

| C | There may not only be dead knots, but also holes. Longitudinal cracks up to 30x3 mm are acceptable. Boards with wormholes, sprouts, resin pockets, and rot, which do not affect the hardness of the board, are not rejected. The category does not exclude planing defects in any part and invisible wane. Used only under opaque coatings. |

Products of the AB category

Masters distinguish another intermediate class - AB, although they do not set standards for this category. Boards of this class are opened with varnish, wax, and paint.

Which is better

Lining for interior decoration is represented on the construction market in a huge assortment, so each type is distinguished not only by its unique design, but also by its technical characteristics.

To make the right choice and determine which material is the best, you need to take into account many nuances. Currently, manufacturers produce lining from both hardwood and softwood. Boards made of pine and other conifers contain many essential oils and resins, which protect them from the formation of mold and mildew. In addition, this lining lasts a long time, is easy to process and has an unusual texture. Also, products made from coniferous trees have high thermal insulation and fill the space with a pleasant smell. Therefore, if you need to beautifully decorate the interior of a house or apartment, then there is no better option.

If you plan to decorate a sauna or bathhouse, then you can give preference to lining made from hardwood; it can also be used to line a toilet. After special treatment, such a board does not emit resins, can withstand high temperatures and is not afraid of humidity. Oak boards are in great demand among craftsmen: although they are expensive, the price is justified by the quality. In a private house, this material is perfect for decorating slopes and the second attic floor.

To cover the walls of a country house or cottage, you can also use lining made of birch or linden. The pleasant shade of these types of wood will not only create an interesting room design, but will also create a special atmosphere of homely warmth and comfort in the room. Decorative wall decoration with clapboard looks beautiful in the hallway, bedroom, bathroom, it is also suitable for the corridor, and doors finished in this way will become a real decoration.

Color solutions

Traditional color schemes for imitation timber are not at all mandatory. If you do not want to preserve the natural shade of wood, especially in the decoration of the facade, you can tint the surface of the material in one of the popular shades:

- pistachio;

- brown – from ocher to rich smoked oak;

- light beige;

- grey;

- peach;

- orange.

Tinting allows you to preserve the natural structure of the wood and ensures its clearer appearance. At the same time, you can always choose full painting if you want to make the facade brighter or better protect it from atmospheric influences.

Advantages

When compared with lining, imitation timber differs for the better in the following indicators:

- greater mechanical strength;

- better thermal insulation properties (as interior decoration of the facade);

- higher level of sound insulation (when covering interior partitions).

When compared with a block house, the advantages of interior finishing of a house with imitation timber are as follows:

- it is easier to design internal and external corners;

- it is easier to install door and window frames;

- if necessary, it is easier to join individual panels along the length.

There are also general advantages of interior wall cladding with wood panels:

- no leveling of surfaces made of bricks or building blocks is required;

- the possibility of hidden wiring of electrical networks in houses made of logs, timber or SIP panels.

In addition to the thickness, there is only one external difference between imitation timber and Shtil lining: a beveled, rather than rounded, edge along the long side of the front panel. Both imitation timber and “thick” modifications of the lining have longitudinal grooves on the inside, which are designed to relieve the internal tension of the wood.