The bathhouse should be warm, cozy and clean. All this can be created using wooden finishing, the main thing is to follow the technology and choose high-quality materials. We have already written about the construction of a wooden bathhouse in this article. But we only talked about the building itself and the main nuances of the design; today we will talk in detail about the arrangement and decoration. The fact is that a bathhouse requires serious attention to materials, technology and details. Otherwise, the structure may become deformed, begin to rapidly deteriorate due to moisture and rot, and simply cause harm to your health.

List of requirements for finishing a bath

Thematic building is used for washing in moderately hot steam conditions.

For this reason, projects for finishing the inside of a bathhouse with your own hands or not with your own hands, but with the help of specialists, have special requirements:

- Use exclusively hardwood;

- Focus on non-flammable and natural insulation materials;

- Refusal from wood impregnated with paints and protective solutions;

- Application of rough tiles;

- Using drains for drainage;

- Organization of a protective screen and foundation around the heater;

- Use of fasteners made of wood and stainless steel.

Let's take care of the thermal insulation of the room

Before starting work, you must wait at least 6 months after installing the log house; this does not apply only to structures made of laminated veneer lumber. During this period, the building will undergo final shrinkage, with a clear demonstration of all deformations.

After this, you can safely begin the first stage of work - thermally insulating the steam room and relaxation room with your own hands. All that remains is to decide the question of the material - natural or synthetic.

Plasterboard walls or how to decorate the inside of a timber house

Natural

Finishing the inside of a bathhouse in past times was very often associated with caulking the cracks between the beams with flax or hemp rope, as well as moss. They were available to the vast majority of the village population. These materials, of course, helped get rid of drafts, thereby providing some thermal insulation, but that’s all (

Basic finishing methods

The construction of a bathhouse frame is permissible from wood, aerated concrete and foam blocks, and brick. If building standards are observed, the building will be functional. The choice of material depends on the personal considerations of the developer. In central Russia, preference is given to wood in 50% of cases. A log or beam. Another 25% falls on frame structures, the basis of which is also wood. The last quarter remains for other materials.

The interior decoration of a bathhouse built from logs, using frame technology or bricks and blocks, does not depend on the material of the box

It is important that it meets the specific requirements imposed by the functionality of the building. The most stressful conditions are in the steam room, where the humidity reaches 70% and the temperature reaches 90°C.

For the washing room and dressing room, a humidity of 40% at a temperature of 30 - 35°C and low humidity at 20 - 25°C are recommended, respectively. The given numerical values are indicative and justified from a medical point of view. In life, differences happen. When it comes to steam rooms, the rule of thumb is: higher the temperature, lower the humidity.

Tile installation technology

If we are talking about laying tiles on the floor, then the floor area is first filled with cement mortar at a slight slope towards the drainage system. The perimeter of the sauna is framed with construction twine. The tilting technology depends on the first tile from which the further floor angle is measured.

When laying, you can use a special tile adhesive, but a prerequisite for ensuring no subsidence is the addition of sand granules

If the tile is laid on a cement-sand mortar, then before laying it is immersed in water for 10 hours.

When installing ceramics on the screen around the furnace, heat-resistant thick glue is used. If the mastic is runny, it is better to make it thicker by adding sand. Wall tiles are laid in rows from bottom to top level.

Regardless of the purpose for which the bathhouse is being built - personal use or business, the task of properly equipping the steam room is considered the main one on the to-do list. Compliance with the necessary standards will guarantee a long, safe, pleasant use of the Russian bath.

The choice of materials for the interior decoration of the bath

When choosing building materials, it is important that they meet the following requirements:

- Resistant to high temperatures and sudden changes.

- Moisture resistance.

- Safety - a person should not have an allergic reaction or burns upon contact with the material.

- Environmental safety – absence of toxic substances.

- Hygienic - the material should be easy to maintain and clean.

- Long service life.

- High strength and reliability.

- Attractive appearance.

Steam room finishing

The best material for cladding a steam room is wood, but it is better to give preference to hardwood. The thing is that these types of wood do not heat up, you won’t get burned on them, there is no release of resins, and when ventilated, the material dries quickly, making the formation of fungus impossible.

Types of wood for finishing the steam room:

- Aspen is a classic option for the northern regions of Russia, since the material is low in cost, due to its high strength it is difficult to split, and in addition, the wood has bactericidal properties.

- Linden is an attractive material with a stable color and low heat capacity. Due to this, the tree quickly gains temperature and is safe to touch. Linden also creates a pleasant atmosphere due to its special aroma and has a low price.

- Abash is a material that is just becoming popular, since it is wood from the African tropics and we still don’t know enough about it. It is best to make shelves from abasha that are resistant to steam and high temperatures, since they hardly heat up.

- Alder is an attractive visually and tactile wood material that is resistant to steam room conditions. Easy to maintain and clean, low cost.

It must be remembered that wood should never be painted or varnished, since under the influence of high temperatures the coating will release harmful chemicals and odors. When finishing, nails and screws must be carefully hidden, as they heat up and can cause burns. Experts also recommend filling the lining vertically, because the water drains much faster this way.

Waterproof skirting boards will help protect the joint between the walls and the floor. For finishing the floor, it is best to use larch or tiles - the latter option is more preferable, as it is resistant to fungus and is easy to clean. If the tile seems cold, a wooden grate is placed on it, which can be easily removed if necessary.

Finishing the dressing room and sink

It is better not to use wood for lining the sink; preference is given to tiles, since in the shower there is constant contact with water. Ceramic tiles do not rot, they are easy to care for, and for an attractive appearance, you can choose special stylish tiles that imitate natural wood.

As for the dressing room, it is a warm and cozy place, but there are no high temperatures here, so it is allowed to use coniferous wood with a pleasant and healthy aroma.

Among the popular types of wood for finishing the dressing room are:

- Pine is an attractive and durable material that has a long service life and is the most popular. During use, the wood may change color, becoming a little redder. Also popular is Scandinavian pine, which has a pink tint and annual rings that create a decorative pattern on the walls.

- Spruce has a homogeneous structure; when dried, it remains solid and does not crack. The color scheme is slightly lighter than pine.

- Fir is a tree that has properties similar to spruce, but practically does not emit resin.

Advantages and disadvantages

Lining is an excellent option because it has a good appearance and has all the qualities that are necessary for the finishing material of a steam room. There are many options for how to process it without harming your health.

Due to the fact that there are many types of lining, you can decorate the steam room in the style that you like best. When choosing this or that tree, you should think carefully about what you would like the bathhouse to look like in the end. In addition, you need to calculate the price, since the cost is different for each type of wood. There are, of course, other types of finishing materials, but they are more expensive and require much more attention during installation. In addition, the lining is easier to dismantle in case of damage.

Typically, a bathhouse consists of a steam room, a shower and a dressing room. Each of these rooms has specific requirements. That is why the material that will serve as interior decoration must have specific technical characteristics and be of high quality.

The main advantages of lining over other materials include:

- value for money;

- high moisture resistance;

- resistance to high temperatures;

- variety of types in stores.

Lining can be called an environmentally friendly material that is safe for human health. Since the temperature in the steam room is quite high, the material with which the room will be decorated should under no circumstances be heated. In addition, in order to know how to choose the right material, you need to inquire about the characteristics of the wood species from which the lining can be made. Some types of wood can release resins when heated, which sometimes cause allergic reactions. The lining has no obvious shortcomings, so you can safely purchase this material for finishing.

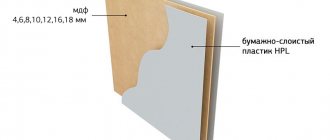

Finishing material

Not all finishing materials are suitable for covering walls, ceilings, and floors inside the washing room. This is due to the influence of destructive factors.

Wood paneling and panels

Wood panels and lining are popular, classic finishing materials for Russian baths. They help give the room its originality.

Lining can be made from different types of wood:

- conifers - spruce, cedar, pine;

- deciduous - alder, aspen, linden, oak.

Coniferous lining is suitable for finishing recreation areas. For the washing room it is better to choose finishing material made of hardwood.

Benefits of wood:

- durability, strength;

- environmental friendliness;

- attractive appearance;

- ease of processing.

Flaws:

- Conifers secrete resin.

- Wood is destroyed by moisture and deformed by temperature changes.

- Fungus and mold often form on the panels.

To level out the shortcomings, the wood must be treated with special antiseptics.

Lining (Photo: Instagram / tverles)

Tile

Tile is not suitable for a steam room, since its surfaces quickly heat up under the influence of high temperatures, but for a washing room it would be the best option.

Advantages:

- Durability, reliability.

- Resistance to mechanical stress.

- Large selection of drawings.

- Easy to care for. To clean the tiles from dirt, you can wipe the surfaces with a damp cloth.

- Resistant to moisture and temperature changes.

Flaws:

- High price compared to wood, paint, plastic panels.

- Fragility. Tiles can easily break if accidentally dropped or hit.

You can lay the floor with tiles, but we must not forget that this is a cold material that will be unpleasant to walk on barefoot. To correct this drawback, you can install a “Warm Floor” system.

Tile (Photo: Instagram / ivan__neverov)

Artificial and natural stone

Such materials are used if you want to get a non-standard surface design.

Advantages:

- attractive appearance;

- large selection of sizes;

- durability, mechanical resistance, strength, wear resistance;

- immunity to moisture and temperature changes.

Flaws:

- high price;

- heavy weight.

To reduce the risk of stone collapse when fastening to walls, masonry should not be made higher than 50 cm.

Natural stone (Photo: Instagram / zelenii_kamen_perm)

Plastic panels

A universal finishing material that is resistant to aggressive factors. The panels cannot be used in a steam room, but they are suitable for a washing room and dressing room.

Advantages:

- resistance to moisture, temperature changes, ultraviolet radiation, chemicals;

- strength, durability;

- large selection of colors and designs;

- low price.

Flaws:

- Mechanical stability is not as high as that of other finishing materials.

- When exposed to extreme heat, the plastic begins to deteriorate.

It is better to choose panels from well-known manufacturers. Poor quality products may emit harmful substances during operation.

Plastic panels (Photo: Instagram / stroysya_vl)

Dye

On sale you can find various painting compositions that are suitable for coating concrete walls in conditions of high humidity, but paint is considered a less popular finishing material because it does not look as attractive as its analogues and has low resistance to aggressive factors.

Types of suitable insulation materials

In our opinion, it makes sense to divide the types of thermal insulation materials for baths into sheet, roll and backfill. In addition, there are insulation materials that are applied to the walls in the form of foam or a moistened mass - these are polyurethane foam and ecowool, which are sprayed using special equipment.

Mineral wool can be purchased in rolls or sheets. It all depends on its density and the binders used.

BY THE WAY! We rarely name specific brands, but do you understand that the names Rockwool or Isover hide the same mineral wool produced by different companies?

Basalt wool is a type of mineral wool, a literal reference to the similar mineral used. There is practically no difference.

Basalt wool for baths

But you should not confuse mineral wool and glass wool - these are different insulation materials, made of different materials and with different properties.

Glass wool should no longer be used anywhere, because it is extremely unpleasant for humans - if it gets on the skin, it causes itching, and is hazardous to health if it gets into the eyes or respiratory organs. Yes, and fiberglass crumbles during operation, turns into dust, and it penetrates through the cracks, and you breathe it.

Does not like fiberglass insulation and elevated temperatures typical of a bathhouse.

Polystyrene foam and extruded polystyrene foam are good insulation materials, especially the latter, but using them in a bathhouse is dangerous. They are absolutely not suitable for a steam room, but could (theoretically) be used in other rooms, but we will not recommend them, since they are a fire hazard.

ADVICE! In the bathhouse, polystyrene foam and penoplex can be used in floors under concrete screed - there they do not pose any danger.

So, sheet insulation is mineral wool, foam glass (excellent, but expensive insulation), calcium silicate and magnesium silicate sheets, non-recommended polystyrene foam and extruded polystyrene.

Foam glass

Roll insulation is again mineral wool (lower density), glass wool. foamed polyethylene, with or without foil (penofol, isolon, etc.).

We have already spoken about fiberglass, now about foamed polyethylene. It is often used as additional insulation in residential buildings, but polyethylene does not tolerate high temperatures, so it should not be used instead of foil to insulate a steam room.

Foil insulation Penofol

IMPORTANT! Polyethylene already melts at a temperature of one hundred degrees. By the way, it supports combustion.. In general, it is quite possible to insulate other rooms of the bathhouse with it (as a second layer)

In general, it is quite possible to insulate other rooms of the bathhouse with it (as a second layer).

We will divide bulk insulation for baths into those that can be moistened and “glued” to the wall, and those that cannot. Expanded clay and vermiculite belong to the second category, ecowool - to the first.

Expanded clay and vermiculite can be used to insulate floors and ceilings, where they adhere perfectly and retain heat indoors. In order to insulate the walls of a bathhouse with them, it is necessary that between the two layers of the main wall material there is a gap, a cavity that can be filled with insulation.

Expanded clay

Ecowool is waste paper (cellulose) crushed into dust, impregnated with fire retardants so that it does not support combustion. And it really doesn’t support it - this is a good material for insulating baths where it is on sale. Ecowool is used in dry and wet form. In dry conditions - for insulating floors and ceilings, as well as for filling cavities. When wet - for application to walls.

Insulating the roof with ecowool using the wet method. Cromwell Photos

Also on our website you can read two articles that provide a more complete overview of insulation materials that can be used in a bathhouse:

- review of bath insulation;

- choosing the best of natural and artificial insulation for a bath.

The primary task is to insulate the walls

If the building is based on untreated logs, you need to caulk the cracks by going through the joints with a sealant. A hut made of timber will require the following actions:

- The wall is sheathed with lathing.

- Insulation is laid between the beams.

- A vapor barrier layer, represented by oilcloth or foil waterproofing, is placed on top.

- The final stage is upholstery with clapboard or natural boards.

The following is used as an insulating element:

- mineral wool;

- peat slabs;

- chipboard;

- Styrofoam;

- traffic jam

Organic variations are suitable for the dressing room, rest room, synthetic ones to avoid the appearance of mold - in the washing department, steam room. Polystyrene foam can ignite and, when heated, becomes a source of release of hazardous chemicals.

Finishing a bathhouse made of timber

- Interior decoration

- Lining

- Tile

- Exterior decoration

- Siding

- Block house

Finishing the steam room is necessary not only for the implementation of stylistic decisions. This process also includes insulation, steam and waterproofing. External and internal finishing of a bathhouse made of timber is not carried out immediately upon completion of construction. You need to wait until the structure has completely settled and then apply caulk. Sometimes about one or two years pass between the construction of a log house and its cladding. It is not advisable to cover the structure up to the caulk, since this process involves raising the bathhouse to a height of 8-10 cm. In this case, the finishing material will be damaged.

Methods for installing heated floors in a bathhouse

Modern construction requires maximum comfort for people, including when constructing bath complexes. After all, this is not only an opportunity to take a steam bath, but also to relax. The need to install heated floors arose when they began to be made of concrete, due to the fact that the service life is 3 times higher than that of wooden ones.

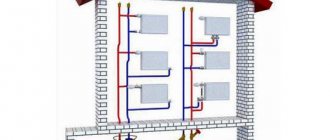

Both water and electric floors can be installed. Water ones require preliminary installation of pipes and connecting them to heating equipment. This is not always possible. Therefore, more often the choice is made in favor of the second system.

Electric floors are safe in the bath complex. The system is mounted in a screed. The concrete base must first be prepared.

It is important to avoid mistakes during installation that will later be impossible to correct. Therefore, the work must be transferred to specialists

You can make warm floors yourself by installing additional thermal insulation from the following materials:

- mineral wool;

- expanded clay;

- felt;

- polystyrene foam

To do this, you will need to pour 2 layers of concrete, between which thermal insulation should be laid.

Installation of a water floor in a bathhouse

Ceiling protection

Before finishing, you should protect the ceiling from hot steam. To do this, use aluminum foil or a construction membrane.

Important ! Do not use foil with mineral wool or polypropylene foam glued on it. When heated, these materials release toxic substances.

Protecting the ceiling in a bathhouse using aluminum foil Source ko.aviarydecor.com

Finishing the bathhouse inside: fixing the lining

Having completed the preparatory stage, they begin the process of finishing the bathhouse inside - the photo will help you navigate the order of actions. It is necessary to select suitable fasteners made of materials that are not susceptible to exposure to moisture and high temperatures. Immediately forget about traditional nails, as they will quickly corrode and the walls will be damaged by rust stains. And when the temperature in the steam room rises, touching the nails is dangerous - they can burn the skin.

The lining is cut immediately to size, focusing on the height of the bathhouse, then it is attached to a pre-prepared grate (or directly to the walls) with special brackets. If necessary, the width of the lining can be slightly trimmed at the corner joints.

The relaxation room in the bathhouse is the place where you spend the most time.

To finish the steam room, high-quality wood should be used that can withstand high temperatures and high humidity.

How to cover walls with clapboard: step-by-step instructions on how to do it yourself (read more)

All actions must be performed using a level to obtain a perfectly level structure. After making the frame, it is coated with an antiseptic. The lining should also be processed, but before installing it on the frame. Laying the material starts from the corner. Nails, staples and clamps are used as fasteners. The material that was used to decorate the surface of the walls can also be used to decorate the ceiling.

Light wood species are best suited for small rooms.

It is necessary to understand that the maximum temperature is located under the ceiling, which is why it is necessary to choose lining for this surface from rocks that contain a small amount of resins, otherwise their drops may burn the skin when falling. The finishing of the place where the stove will stand must be made of non-combustible materials - tiles, bricks.

On a note! It is not recommended to choose spruce or pine for the steam room. It is better to cover the dressing room with this material.

The floor in the bathhouse can be made of non-slip tiles.

Beginning of plating

A bathhouse is a room in which the temperature rises quickly and lasts a long time, so here you need to create the so-called thermos effect.

We insulate the bathhouse from the inside using any type of insulation. Then you need to install a hydrobarrier and a reflector that returns heat to the steam room.

The next stage of work: installation of sheathing under the lining. If you do not plan to attach shelves to the walls, then you can use ordinary slats for the sheathing. Otherwise, purchase beams for the sheathing that can support the weight of a human body. Of course, the slats must be installed horizontally.

Wall upholstery elements placed vertically on horizontal bases

When the sheathing is ready, we begin to cover the bathhouse with clapboard, and you need to start from the corner. Eurolining is becoming increasingly popular. To install it, use clamps that allow you to attach the lining to the sheathing without making holes.

Claimer functioning

Experts advise that when covering a bathhouse with clapboard, use only the vertical type of installation, which eliminates moisture retention on the wood.

Finishing a bathhouse inside with a block house: photos and features

Finishing a bathhouse with a block house allows you to decorate the interior in the same style. Work on the interior decoration of a bathhouse can be done independently without the involvement of specialists. The whole process is divided into stages:

- Preparation.

- Installation of vapor barrier. The system protects the material from the formation of rotting areas.

- Insulation (insulation is attached to a vapor barrier layer).

- Installation of the sheathing (wooden base on which the finishing material will be attached).

- Installation of a block house.

Important! A wooden bathhouse can be sheathed no earlier than a year after construction. This is due to the process of shrinkage of the structure

When performing finishing work with a block house in a bathhouse, special attention should be paid to the ventilation of the room. The only disadvantage of this material is the low vapor permeability

Lack of good ventilation leads to condensation.

Below are photos of the interior decoration of a bathhouse with a block house.

Preparatory work

Preparatory work for lining the interior of the bathhouse begins with the processing of wooden materials (if the work has not been completed in advance in production). For interior work, combined impregnations, antiseptics and moisture-repellent compounds are used as protection. It is not recommended to use varnish or stain. The coating will collapse under the influence of high temperature and humidity and will begin to release components harmful to human health, which is extremely undesirable in a bathhouse.

The technologies for covering wooden and brick baths are the same. But if the walls are uneven, the preparatory work may include the installation of additional sheathing. It is installed to level the surface. After installing the lathing, layers of thermal insulation and waterproofing are installed.

Specifics of finishing a bathhouse inside a block house

For interior decoration, panels with a width of 80 - 90 mm are used. The panels are fastened using nails or self-tapping screws. The resulting holes are masked with putty or a wooden dowel.

Advice! The use of staples is not recommended. They do not provide reliable fastening of the material.

Sheathing can be started both from the top and from the bottom. An important condition is the presence of gaps. They are designed for blowing out the casing. The tenon on the board should point upward. This prevents moisture from accumulating in the grooves.

Proper joining of corners in the room will prevent heat loss. To set the angles correctly, you need to make a cut at an angle of 45 degrees or use slats (internal or external).

Rules for visual inspection of boards and assessment of their condition

The following must be taken into account:

Pay attention to the quality of the chips. The boards must have a flat and smooth surface. This directly affects the economic benefits of finishing work. If the front side of the lining is rough, finishing will be complicated by the increased consumption of antiseptic and paint materials. The moisture content of the boards should not exceed 12-16% (GOST requirement). It is visually impossible to determine whether the material offered by the manufacturer meets this criterion. Therefore, it is necessary to request documents confirming compliance with GOST. If the wood is not dry enough, there is a high risk that it will suffer during the first years of operation of the finished premises. Pay attention to the depth and evenness of the groove. These indicators determine the quality of installation

And it doesn’t matter how it will be done: using clamps, nails or staples. If the groove is shallow, there will be nothing for the fasteners to grab onto.

An important characteristic of boards is width. Often there are lamellas on sale that are wider than standard ones (more than 88 mm) and managers assure that it is more profitable to buy such lining. This is not true, since such a finish will be less durable and there is a high risk of wide boards bending when exposed to moisture.

How to properly solder polypropylene pipes

Everything seems simple if you have experience, but soldering for the first time is scary.

It is necessary to mark the pipes before welding (see information below)

Step 1. Screw couplers to the front of the soldering iron to heat the internal or external surfaces of pipes and fittings. For showers, we recommend using Ø ¾″ pipes. The pipe is heated on the outer surfaces, the connecting elements (couplings, triangles, elbows, etc.) on the inner ones.

Preparing the soldering iron for work

Step 2. Connect the soldering iron to a 220 V network. On the body of the device there is a heating temperature regulator and two indicator lights. Green indicates that the soldering iron is ready for use, red indicates that the heating temperature is insufficient.

Turn on the soldering iron and wait until the green light comes on

Step 3. Set the temperature regulator to +250°C. Specific values do not play a big role; the degree of heating of the pipe is regulated by the holding time.

Step 4. Take the two elements to be connected and insert them each into their place in the soldering iron. Heat for approximately 5-9 seconds. The ends must fit into the heaters until they stop.

Inserting heated elements

We heat the couplings along the inner surface

This also explains why you should not use a soldering iron heating temperature table. We advise you to always set it to maximum - the pipe will warm up much faster.

Pipe heating table

Step 5. The surface of the heated plastic pipe should resemble thick sour cream. Once such softening is achieved, remove the elements simultaneously from both sides of the soldering iron.

Step 6. Connect the two heated planes together as quickly as possible, keeping them as level as possible. You need to hold it in the clamped state for 10÷15 seconds, the exact time depends on the heating temperature of the plastic. As you can see, almost all parameters and modes of pipe welding are determined not by instructions, but by the experience of the master. Experience will appear already on the second or third gluing, gain skills on unnecessary segments.

Sectional connection of PP pipes

Connecting heated elements

Material selection

Methods for finishing a timber bath:

- Monolithic. The walls in all rooms are covered with clapboard without adding any additional elements.

- Combined. Wood is combined with ceramic tiles, porcelain stoneware, artificial or natural stone.

For interior decoration of bath rooms, you need to choose a material that meets a number of requirements:

- high strength, durability, wear resistance;

- low thermal conductivity;

- environmental friendliness.

Popular types of materials:

- lining made of different types of wood;

- ceramic tiles, porcelain stoneware, clinker, mosaic;

- natural or artificial stone.

More often, owners of steam rooms choose lining - wooden panels for covering walls, ceilings, gables, and anemones. Advantages:

- natural look;

- ease of installation;

- good air microcirculation;

- environmental friendliness.

The best lining options for a bath:

- Linden. Boards made from this type of wood are easy to process. Surfaces heat up slightly. Linden lining is suitable for finishing steam rooms.

- Alder. Durable, durable, wear-resistant material. It has a beautiful color and does not absorb foreign odors.

- Aspen. A durable breed that is suitable for finishing washing rooms and steam rooms. Since the tree begins to rot while still growing, it is rare to find high-quality lumber.

- Larch. Durable material that has high strength and wear resistance. Withstands prolonged exposure to moisture and is resistant to temperature changes.

The wall behind the stove can be finished with stone. Various rock types are suitable. If you want to lay stone around the stove, it is better to choose soapstone.

You can combine ceramic and clinker tiles, porcelain tiles, and mosaics with clapboard or natural stone. More often, such materials are used to finish the floor and walls behind the stove.

If the bathhouse is used in winter, the tiles will be constantly cold. To avoid hypothermia, it is recommended to install a “warm floor” system.

Finish lining

In the first place is a wooden lining. Its installation in various rooms is described in detail in our previous articles on the site.

Attaching it to the walls of a timber bathhouse is no different, so the instructions will consist only of the main points:

- You should not choose coniferous boards for the steam room, as they contain a significant amount of resin, which, when heated, begins to come out and burn the body. This material is perfect for other rooms. It is best to use linden or its analogue - the African abashi tree. They practically do not heat up in the steam room, while saturating the atmosphere with their aroma.

- The lining should be fastened to a horizontal lathing made of timber with a cross-section of 50x50 mm. The sheathing pitch is 550 mm to conveniently insert the mineral wool mat.

- You can fasten the lining to the timber with nails, but it is best to use clamps.

Fastening wooden lining with a clamp

- There is no need to cover the boards on top with anything inside the steam room.

You can lay larch on the floor, although its price is high, but it does not rot, is durable and has a long service life. If you decide to make a concrete base for the floor, the best option would be non-slip ceramic tiles. Our website has a detailed description of the installation process.

Tip: To safely walk on wet tiles, make a removable wooden floor sheathing.

The construction of a bathhouse made of timber has been used for a very long time. Its positive aspects more than cover all the negative aspects associated with the finishing. When creating an interior, try not to deviate from natural motifs, place more emphasis on natural materials (see also the article “Finishing a bathhouse with clapboards with your own hands: creating a cozy atmosphere”).

Restroom

The decoration of the rest room in the bathhouse is usually done with pine lining. This type of wood is not used for steam rooms and washing rooms. When exposed to high temperatures, resin is released from pine boards. Its fumes can be harmful, and if it comes into contact with the skin, the molten resin causes burns.

Pine wood is relatively inexpensive and durable. Its advantages:

- resistance to external influences, despite the softness of the wood, the covering made of pine lining lasts a long time and retains its attractive appearance;

- ease of use - pine is easy to process and can be coated with a variety of paints and varnishes;

- low cost - the use of pine lumber for the rest room in the bathhouse will save money.

Along with pine lining, lumber from other coniferous species - for example, spruce, larch or cedar - is also used to perform finishing work in a rest room or small dressing room. The last two options are more expensive.

Wood processing

If the eurolining or slatted floor in the steam room is made of linden, cedar, or larch, they do not need additional processing . But if other species are used that are not so resistant to water and temperature, oils, impregnations and even paints can be used for protection.

- Waterproof yacht varnish – contains polyurethane, but can withstand the highest temperatures. The varnish protects the wood from mold and prevents the appearance of cracks. Rarely used for beauty.

- Oils – both solid, mixed with wax, and liquid. The option with wax is better, as it impregnates the top layer of finish and creates a denser protective film. Special oils are used, with appropriate markings.

- The lining can be treated with colored acrylic varnish . It is not as stable as yacht wood, but it prevents the wood from darkening.

Drying oil cannot be used for treating wood in a bathhouse.

DIY finishing process

A day before the start of work, it is recommended to bring into the bathhouse all the materials that will be used in the finishing process. This must be done so that the material “acclimatizes” to the room temperature.

Highlights of interior finishing step by step:

- Manufacturing of sheathing;

- Fastening steam and thermal insulation;

- Installation of wooden panels.

Requirements for installing sheathing

- The sheathing slats must be positioned strictly parallel to each other and the floor. To achieve this, a level is used.

- First, the upper and lower guides are attached, and then all the other slats.

- It is necessary to place the slats from each other at a distance of no more than fifty centimeters.

- The finished frame must be treated with an antiseptic.

Hydro- and thermal insulation of steam room walls

For vapor barriers, aluminum foil and foamed polymer materials (polypropylene) are most often used. The advantage of polymer materials is that they simultaneously have vapor and heat insulating qualities.

These materials, laminated with foil, not only help maintain a high temperature in the steam room, but also resist the accumulation of dampness and the appearance of fungus.

Sequencing:

- Attach insulation to the timber wall (mineral wool is best suited for this purpose).

- Attach a layer of foil to the insulation.

- Install the sheathing (it is necessary to create an air gap between the lining and the foil layer).

Installation of lining

- Before installation begins, the lining (as well as the sheathing) must be treated with an antiseptic.

- Installation of the lining should begin from the far corner of the steam room.

- For fastening, you can use nails (which is extremely undesirable due to their tendency to corrosion under the influence of high humidity).

A more suitable and more modern means are clamps - staples that, when installed, do not damage the surface of the lining, since they do not form holes in it. This is the so-called hidden fastener.

You should know that there are different types of clamps, depending on what materials they are intended for fastening.

- Walls should be sheathed vertically.

This is due to the fact that condensation that can form on the walls will flow down, rather than accumulating at the joints and gradually ruining their condition and appearance.

For a step-by-step guide on how to properly cover walls and ceilings with clapboard, watch the video instructions:

Cladding from the inside with clapboard from a to z

The interior lining of the bathhouse starts from the ceiling and ends with the walls.

We calculate the area of the internal lining. How to take measurements correctly?

To completely cover the lining in the bathhouse, it is necessary to calculate the total area of the walls and ceiling minus the window and door openings. Correct calculations will help you save your budget on the costs of basic and consumable materials:

- The ceiling area is calculated using the formula Spot = LxW, where L and W are the length and width of the room, m².

- The area of the walls is calculated using the formula Sst = 2x(L1xH1)+2x(L2xH2), where L1.2 and H1.2 are the length and height of the long (1) and short (2) walls, respectively, m².

- The obtained values are added to the total value Stotal = Spot + Sst, m².

- The area of the window and door is calculated: Sok = WokxHok; Sdv = WdvxHdv, where Wok, dv and Hok, dv are the width and height of the window and door, respectively, m².

- The net area for the cladding is calculated: Snet = (Stotal – Sok – Sdv), m².

Preparation of lining and beams. Treating wood with protective agents

It is recommended to first dry the room, then bring in lumber and open it for a day to allow it to warm up and get used to room temperature.

After a day, the lining can be coated with a water-based antiseptic, after which finishing work can begin.

Preparation of materials and tools

In order to sheathe the inside of the bathhouse, you will need:

- beams for sheathing with a cross section of 50x50 mm;

- fasteners (screws, clamps, dowel-nails);

- thermal insulation material;

- foil for vapor barrier;

- tape for fixing the foil;

- construction stapler;

- drill for working with concrete and brick surfaces;

- screwdriver;

- building level.

Conducting communications

Before you start fixing the lining in the bathhouse, you need to think through and mark the location of utilities on the walls and ceiling: power supplies, switches and lighting.

Installation of the frame under the lining

The lathing for the lining in the bathhouse must be durable and of high quality, since it is subject to such requirements as fixing the heat and vapor barrier layer, supporting the weight of lamps and shelves, as well as the finishing material itself. In addition, properly installed sheathing will allow the walls to “breathe”; condensation will not accumulate on the inner surface of the lining and the main wall and mold will not form.

If the lining is vertical?

Vertical markings are applied along the entire wall indicating the installation locations of the beams for the frame and the places of their fastening in increments of 0.5 m, then the beams are attached to the pre-waterproofed surface with self-tapping screws.

If you want to line the inside horizontally?

The technology for installing the frame is the same as for vertical cladding, with the difference that the main beams are attached vertically.

The same work is performed for mounting the frame on the ceiling.

Laying insulation and vapor barrier in a bathhouse

The insulation should be placed tightly into the cells of the sheathing, the vapor barrier should be secured with an overlap stapler, starting from the bottom row. Lining the inside of the bathhouse with foil is additionally accompanied by fastening the joints with tape. Then you need to stuff thin slats onto the frame - the lining will be fixed on them. The thickness of the slats is sufficient to form an air gap that prevents the formation of condensation.

The same work is done on the ceiling.

Installing lining on walls

With horizontal cladding, the lamellas are fastened with clamps to the sheathing from the bottom up, with the grooves down. In vertical finishing, fastening begins from the corner, evenness is also checked by level. Each panel is tightly packed into the previous one.

Lining the lining on the ceiling

The ceiling in the bathhouse should be covered with clapboard in the same way as the walls, but there are some nuances here:

- Installation of panels begins from the entrance, using only clamps.

- A hidden nail is used for the last board.

- The ends of the lining should be placed at a distance of 4-5 cm from the walls for air circulation and the possibility of panels moving due to temperature changes.

Decoration of doors and window slopes

Slopes for doors and windows are made of lining, cut to the required length, and covered with decorative corners and platbands. It should be remembered that it is not advisable to stick decorative elements. To fix them, finishing nails are used with final grinding of the installation sites to avoid accidental injury.

Selecting the necessary materials

For the bathhouse and dressing room, wood material is used - lining. The most inexpensive wood material is pine lining, however, due to its resin content, it is not suitable for a steam room. At high temperatures, the pine lining will begin to release resin and a pungent odor, because of this, there will be nothing to breathe in the steam room, plus you can get burned by streams of resin. Typically, hardwood is used for a steam room, and most often linden. Linden does not overheat at high temperatures, retains its light color, does not emit resin, has almost no noticeable odor, dries well and quickly, and is durable. In addition, linden creates a special microclimate in the bathhouse. The table below shows the materials for making the lining.

| Material | Description |

| Conifers | Coniferous species are characterized by high moisture resistance, however, it is better not to use such lining for finishing the steam room itself: the released resins can cause certain problems. It is believed that pine resins are beneficial for humans. When they are inhaled, the work of the cardiovascular system is stimulated, but in combination with high temperature, such a combination will be extremely dangerous. In view of this, it is better to leave the pine needles for finishing the rest room - they are ideal here. As for specific species: - pine. It has a high density, stands out with an attractive golden hue and interesting ornaments; — cedar is an expensive option with a pronounced pine smell. It has a long service life, excellent texture and antiseptic properties; - spruce. Well suited for interior decoration of a bathhouse. It has a neutral odor and an attractive appearance; - larch. Fills the air with substances beneficial to human health. The material is characterized by the highest resistance to moisture and similar density. |

| Hardwood | Most often, hardwood is used for the interior lining of bathhouses. This lining is characterized by higher thermal insulation properties, which is an additional advantage, and also helps to improve ventilation in the room and create the most healthy microclimate. Several types of wood are used to make lining: - oak. Expensive, durable and strong. Among other advantages, the material is characterized by an expressive structure and generally has an attractive appearance; - Linden. This lining has a beautiful light honey shade that does not change over many years of service; - alder. Hygroscopic and beautiful material with antimicrobial properties; - ash. Quite dense wood, resistant to deformation and has an expressive pattern. |

The following table shows the classes and their descriptions. It is worth knowing that wood with a large number of knots heats up faster and can burn. The markings are the same for all types of wooden lining.

| Class or variety | Description |

| Extra | Free from cracks, knots and other defects. The surface is perfectly smooth and even. |

| A or 1 | The surface is smooth or slightly rough. There is 1 healthy knot per 1 linear meter (knot diameter no more than 1.5 cm). There may be cracks: hairline cracks - no more than ½ panel long, non-through cracks - less than 9.5 cm long (the crack exit is directed towards the end of the panel) that appear when drying - no more than the width of the panel. There may be tars and resin pockets of 2 pcs. by 1 m.p. |

| B or 2 | There are many knots, of which no more than 2 can fall out. by 1 m.p. There may be through cracks up to 1 mm wide and up to 15-30 cm long; hairline cracks are allowed along the entire length of the board. The presence of wormholes (3 pieces per 1 m.p.) and rot (no more than 1/10 of the panel) is allowed. Grade B lining is suitable for painting. |

| C or 3 | The quality is low. Many different defects. This lining is suitable for upholstery of technical rooms or rough work. |

Lining marking