Using Akmigran ceilings in the interior of a room is considered a good way to increase the level of comfort, make it safer and at the same time quieter. Behind such an unusual name lie suspended ceiling tiles, which in appearance are practically no different from the more familiar plasterboard, mineral wool and fiberglass sheets.

What are Akmigran slabs

Akmigran slabs, used for finishing ceilings, are panels made of granulated or glass wool. During the production process, cotton wool and starch are added to the main components, thanks to which the final product acquires a high level of sound insulation properties.

Akmigran is produced using the pressing method. The production process is as follows:

- Initially, mineral wool is granulated, after which the raw material is processed, resulting in particles ranging in size from 2 to 15 mm.

- When the main raw materials are ready, begin preparing the binding solution. To do this, use cold water, starch and white clay.

- All components are thoroughly mixed until smooth and heated until the temperature reaches 85-90 degrees.

- Then stabilizers – borax or boric acid – are added to the binding solution.

- Mix everything thoroughly and add mineral wool in granules.

- The next stage is the formation of Akmigran panels.

- For 16-18 hours, the slabs are processed at a temperature of +140 degrees.

- The final stage is the final grinding of the finished material and cutting of the slabs. On sale you can find Akmigran in the following sizes: 30*25 cm, 30*30 cm, 60*60 cm, 80*25 cm, while the thickness remains the same - 2 cm.

The finished material has a white tint and a porous surface. The texture can be in the form of grooves, cracks or relief. As a rule, this type of facing material is used for finishing ceilings in rooms where the noise level is quite high.

Read also: What is a computer keyboard

Attention! Initially, the slabs are covered with small cracks

It is important to note that this is not a defect. These cracks help to increase the soundproofing properties of Akmigran.

These cracks help to increase the soundproofing properties of Akmigran.

Principle of operation

The operating principle of the pumping station can be divided into 4 stages:

- The pump pumps water into the storage tank (hydraulic accumulator), after which the pressure switch turns off the pump.

The unit goes into standby mode, in which the pressure in the second part of the accumulator reaches the set value.

Ready mode - taps can be opened, water can be used.

Reducing the water pressure in the tank restarts the station pump and so on.

The design of the hydraulic accumulator and the operating principle of the automation

Essentially, a hydraulic accumulator, or as it is also called a hydraulic tank, is a container consisting of two parts. One is hollow and is designed to store water, and the second is made in the form of a rubber bulb filled with air. Water entering the accumulative part of the hydraulic tank under pressure compresses the bulb with air. Having reached the required pressure, the automation (pressure switch) turns off the water supply. When the tap is opened, the air in the bulb displaces the accumulated water, and the check valve will prevent water from returning to the hydraulic tank. When the water pressure drops to the level assigned to the automation, the pumping station turns on again.

Automation also monitors temperature. If the NS overheats, it turns off, and the water serves as a natural coolant.

Need to know!

The advantage of a pumping station over a conventional submersible pump for a well or borehole is that even in the event of a temporary lack of electricity, you always have a small supply of water. Moreover, considering that tanks can be 24, 50 or more liters, this is a significant convenience, and as described above, it significantly reduces the number of pump on/off cycles. This way, washing your hands or a liter or two of water for the kettle will not start the pump every time.

- To water the garden or supply water to the pool, a pump station with a tank will turn on and off frequently (compared to a simple pump).

The pressure may drop slightly if hot water is consumed when connected to the autonomous heating system - this will cause the boiler to turn on or off unscheduled.

Such pumping stations are used if the suction depth (water surface) does not exceed 9 meters. If the water lies deeper, then you should choose deep-well pumps or pumps for wells.

Acoustic tiles

MVP, or acoustic mineral wool tiles, is a type of mineral tile that is made from mineral wool and a synthetic binder using vacuum. MVP is used as a thermal insulation material. The water absorption of such tiles is only 1.5%, so they can be used in rooms with high humidity levels. MVP is resistant to high temperatures, and tiles based on natural rocks, even when exposed to a temperature of 1000 °C, gradually begin to melt only after 2 hours. MVP is able to withstand even heavy loads and not deform. The service life of such tiles is about 25 years.

Thanks to a more uniform distribution of the binding components, the MVP is more durable in bending.

The surface texture of MVP is the same as that of acmigran.

Specifications

Before using linear panels for facade cladding, it would be useful to familiarize yourself with their main characteristics. The technical characteristics of the lamellas can vary significantly depending on the material used (steel or aluminum) and the thickness of the lamellas, but there are characteristics common to all linear panels:

- operating temperature range of the cladding from -50 to +50C;

- the service life is on average 25-30 years, depending on the thickness of the sheet and the type of protective and decorative coating;

- the length of the lamellas can vary from 0.9 to 6 m, width - from 140 to 400 mm. The thickness of the lamella can be from 0.45 to 1 mm;

- the weight depends on the thickness of the rolled metal and the type of protective coating, but rarely exceeds 7 kg/m2;

- according to the flammability class, all linear panels belong to the category of non-combustible materials;

- the material is resistant to sudden temperature changes, ultraviolet radiation and mechanical stress;

Thanks to these technical characteristics, the material is widely used in industrial and civil construction.

Advantages of finishing with Akmigran type slabs

Before you start choosing a facing material, you should first study all its advantages, disadvantages and design features. If we consider the advantages of tiles for Akmigran type ceilings, then it is worth highlighting the following points:

- Many users prioritize the high level of sound insulation and increased fire resistance of the material used, since Akmigran slabs contain asbestos fibers, the products are not subject to fire, and thanks to the structure of the slabs, the acoustic comfort in the room remains invariably at the highest level;

- if necessary, the structure can be installed independently, without the help of specialists in this field; it is also worth noting that facing work using Akmigran slabs is carried out quite quickly; installing a ceiling in one room will be enough in one day, maximum two if the installation work is carried out by a person for the first time in my life;

- if at the time of attaching the facing parts it is necessary to give a certain shape or the size is too large, then you can easily saw off the excess part using a hacksaw;

- the material that is used as the basis for fastening Akmigran slabs tolerates moisture, which is why this material can be used in rooms for any purpose, but it is important to understand that such ceiling tiles are not recommended for use in bathrooms and other rooms where there is a high level of humidity ;

- Since during the production of Akmigran they are coated with a white coloring composition, this is undoubtedly an advantage, due to the fact that white color is universal, as a result of which such a facing material can be used for finishing any premises, regardless of style and design.

It is worth noting that, if necessary, the manufacturer can give the slabs any shade.

Advice! During construction work, it is recommended to use a respirator to prevent dust from entering the respiratory system.

Advantages of the solution

One of the advantages of using such finishing is increasing the soundproofing characteristics of the ceiling structure, as well as increasing its fire resistance. Asbestos fibers have excellent fire resistance, and the structure of the products improves the acoustic comfort in the room.

Simplicity of installation makes it possible to install the structure on your own, without the involvement of outside specialists. At the same time, covering the ceiling with acmigran-type slabs is carried out very quickly - one day or even less is enough to install the covering in one room.

In addition, when installing the covering parts, you can give them the desired shape by simply sawing off the excess parts. To do this you will need a regular hacksaw for metal. When working, it is necessary to use a standard respirator to prevent dust and sawdust from entering the respiratory tract.

The material that serves as the basis for the manufacture of such parts perfectly withstands moisture. Therefore, acmigran coatings can be used in any type of premises. Naturally, for specific rooms, which include bathrooms and similar places in the house, it is better to use other materials that are more resistant to moisture.

The white color of the coating will be both an advantage and a disadvantage. The advantages include the versatility of the color - it is perfect for any interior, but the disadvantages include the fact that white is practically the only possible color. Upon individual order, the panels can be painted in any shade.

Akmigran

Akmigran - tiles made of granulated or glass wool with the addition of starch and cotton wool, which are characterized by high sound-absorbing ability. Akmigran is produced by pressing. Mineral wool is granulated and processed into particles with a diameter of 2–15 mm. Then a binding solution is prepared from cold water, starch and white clay. All components are thoroughly mixed and heated to a temperature of 85 – 90 °C.

A stabilizer, borax or boric acid, is added to the binding solution. Granulated mineral wool is added to the resulting mixture. After molding, tiles are obtained. They are covered with microcracks. However, this is not a defect. On the contrary, cracks increase the soundproofing properties of acmigran. The slabs are dried for 16–18 hours at a temperature of 140 °C. At the final stage, the acmigran is polished and cut into tiles measuring 300 × 250 mm, 300 × 300 mm, 600 × 600 mm, 800 × 250 mm and 20 mm thick. The tiles are painted white. The surface of acmigran is porous. The texture of the tile can be corrugated, with grooves or cracks. Akmigran is used for cladding rooms with high noise levels.

Akminit

Acminite is very similar in characteristics to acmigran. However, the production technologies of these plates have significant differences. For acminite, a wetter mixture is used. The plates are made in a more complex way. Press rollers compact the acminite mixture by squeezing out excess liquid. As a result, akminite slabs are stronger than akmigran, and their ability to absorb sound is higher. In addition, they consume less raw materials, the drying process is faster, and the tiles themselves warp less during use. After drying, the akminite slabs are treated with abrasive materials, dents are made using special blunt teeth, and holes are drilled. All this is needed to give the surface of the slabs a certain texture. Natural stone tiles, which are designed for laying using Western technologies, are thinner than domestic products. The thickness of foreign granite tiles for interior decoration is 10-15 mm, marble tiles - 10 mm.

Useful tips

- Take the time to draw up a plan and double-check everything carefully at this stage. An error noticed on paper is corrected instantly. If you discover it during the installation process, you will waste extra effort and time, and if you don’t notice it, the entire ceiling may sag or crack, and you will have to start all over again.

- Carefully approach the choice of a helper: so that you don’t get under your feet again, it’s a pleasure to spend time with him and his help is tangible.

- Before attaching the drywall to the frame, let it lie flat on the floor to level it out.

Now you know how to make a suspended ceiling with your own hands and save on hiring builders, but this amount can be half or even the full cost of all materials.

Types of tile ceiling

Let's first figure out what tiled ceilings are based on the installation method.

Under the sticker

These ceilings were very popular in our country about 15-20 years ago.

- Adhesive PVC ceiling tiles are the easiest way to correct minor surface defects from the ceiling without major repairs. After treating the surface with a primer, the tiles can even be glued to whitewash.

- The cheapness of such repairs is second only to whitewashing with lime.

- Repairs using adhesive ceiling tiles can be done by a novice without any construction experience.

How to put this tile on the ceiling:

- The ceiling is cleaned of whitewash (see How to clean a ceiling from whitewash: effective options) and peeling plaster or treated with a penetrating primer.

- Polystyrene foam or polystyrene tiles are glued to the surface using universal adhesive. Typically white. The edges of the tiles can be parallel to the walls or located diagonally.

- If necessary, the joints of tiles for the ceiling and walls are used ceiling plinth - also made of polystyrene foam or polystyrene.

Safety precautions

Installation of suspended ceilings should be carried out in compliance with the requirements of TKP 45-1.03-44-2006.

Persons at least 18 years of age who have a certificate for the right to carry out work and have undergone safety training at the workplace are allowed to work on the installation of suspended ceilings.

Work on installing ceilings at a height of up to 4 m should be carried out using mobile tables. Before starting work, it is necessary to check the condition of the mobile tables: their width must be at least 2 m, the distance between the table and the wall should not exceed 150 mm. The load on the table should not be more than 2.0 kN/m2.

Lifting workers onto scaffolding is allowed only on ladders with handrails. The slope of the stairs should not exceed 1: 3. To prevent the stairs from moving, they are firmly fixed to supports. The scaffolding must be fenced in places where it breaks with walls and partitions.

Installation work is carried out using hand and mechanized tools. Hand tools must be durable, reliable and convenient. The tool should only be used for its intended purpose.

Cutting of facial elements should be done in specially designated areas with exhaust ventilation, access to which is prohibited for persons not participating in the work. When cutting slabs, you need to use gloves, goggles, and respirators.

When installing luminaires in suspended ceilings, the terminals of the electrical wires must be reliably insulated to avoid electric shock to workers involved in installing suspended ceilings.

In accordance with the requirements of current regulatory documents, the lighting of the workplace when installing suspended ceilings must be at least 25 lux.

When attaching hangers to ceilings using dowels, the operator working with the PTs-52-1 piston mounting gun must comply with safety regulations.

Persons who know their structure and have experience working with them, who have been instructed, who have passed a medical examination and who have a certificate for the right to work with this mechanism or tool are allowed to work with electric tools and other means of mechanization.

Before starting and after finishing work, the serviceability of all mechanisms or tools is checked in the presence of a foreman. At the end of the work, the installer must disconnect electrical tools from the electrical network, inspect and, if necessary, correct the small mechanization equipment assigned to him, then hand them over together with the remaining materials for storage, and clean the workplace.

If artificial lighting of premises is necessary, portable lamps equipped with protective glass caps and metal mesh should be used. For these lamps and other portable (mobile) electrical equipment, flexible cables with copper conductors in rubber insulation that are resistant to environmental influences should be used.

714

Practical use of Akmigran slabs

For the installation of ceilings, the industry produces several standard sizes of slabs. Most often, Akmigran panels have dimensions of 30x30 cm, or in a lightweight version 30x25 cm, the thickness of the slab in both cases is 20 mm. Before laying the ceiling, the panels are sorted into size groups. High quality tiles, as a rule, have an error in linear dimensions of no more than 1 mm, but in any case, heavier elements are laid out on the peripheral sections of the ceiling, while lighter ones are used to finish the central zone of the suspension system.

Popularity of coverage

Why are ceiling tiles in demand by consumers? What are their advantages? For what reason should you choose this coating over alternative options?

What will you gain by choosing slabs for ceiling repair? Advantages:

save time (there is no need to level, putty, or even plaster the base); reduce costs (the types of work listed above require the purchase of many materials and tools); achieve a perfectly smooth ceiling; you can do the installation yourself (this process is easy and understandable); do not turn your home into a dump, as would be the case with a traditional ceiling renovation; insulate your home, which is very important in the current conditions; protect the apartment from neighbor or street noise (there are special soundproofing tiles for the ceiling on sale); you will achieve the desired color, relief and appearance of the ceiling, since you see the result immediately (even at the time of purchasing the products), and are not afraid that the workers will present you with a “surprise” when making a traditional coating; You will save your nerves, and, consequently, your health. Manufacturers continue to pamper us with new materials that make the repair process easier.

Manufacturers continue to pamper us with new materials that make the repair process easier.

When should you choose drywall?

Suspended ceilings made of plasterboard sheets will be the right choice if:

- the work needs to be done quickly and with a minimum of effort - installing a plasterboard ceiling is much easier for a beginner than plastering, and besides, you don’t have to wait for each layer of mortar to dry;

- it is necessary to hide wires and communications;

- you want to use spotlights;

- it is necessary to make sound or thermal insulation - it is convenient to hide any insulating material behind the plasterboard on the ceiling;

- there is a need for a perfectly flat ceiling surface in the absence of skills in working with plaster.

If you are already seriously thinking about how to make a plasterboard ceiling, take into account some of its disadvantages:

- Like any suspended ceilings, it will reduce the height of the room.

- Covering the ceiling with plasterboard requires the use of tools such as a hammer drill, a screwdriver, and a laser or water level.

- Cracks may appear at the joints of gypsum boards over time.

- Leveling the ceiling with plasterboard cannot be done alone.

How to make ceiling cladding with Akmigran type slabs

Before you begin installation work on installing Akmigran ceiling tiles, you must first independently develop a diagram or drawing of the future ceiling. This stage is the most important, as a result of which it is worth paying special attention to, which in the future will allow you to avoid significant mistakes when assembling the structure.

Also, do not forget about lighting fixtures if you plan to mount them in the ceiling. A place should be allocated for them and appropriate notes should be made on the drawing; in addition, it is worth taking care of the electrical wiring in advance.

After the drawing is completely drawn up, they proceed to installation work on installing the base of the frame. As a rule, the frame includes two parts:

- power – is a load-bearing element for mechanical load;

- decorative - used for attaching external elements.

The load-bearing suspensions are attached to the ceilings using dowels, after which decorative profiles are mounted to them, to which Akmigran slabs will later be attached.

As you can see, you can do the work yourself, even without experience. After the flow is assembled, lighting fixtures and decorative elements provided for by the design are installed.

Important! The first step is to install the power part and only after that proceed to the installation of the decorative part.

Assembly of the structure

The main point of performing installation work will be the development of a diagram or drawing of the future ceiling. This is necessary to avoid annoying mistakes at the remaining stages of assembling the composition. All lamps should be provided and the exact locations of their installation should be determined, since electrical wires will need to be laid in advance to connect them.

After drawing up the diagram, installation of the frame base begins. It consists of two parts: a power part, which carries the entire mechanical load, and a decorative part, which serves to fix the external elements of the composition. The power part is installed first, followed by the decorative part.

Load-bearing parts in the form of hangers are attached to the ceiling with dowels, and decorative profiles are attached to them, serving as fastenings for the panels. In shape, these profiles resemble rails, between which covering elements are inserted.

Assembling the structure is very simple and even an inexperienced person can do it. The final stage of the work will be the installation of lamps and the necessary decorative details, if they are provided for in the design.

Features of installation of suspended tiled ceilings

What should you pay attention to when installing a ceiling (primarily its frame)?

- When installing suspended ceilings, either a special galvanized or aluminum profile or wooden lathing can be used. However, wood cannot be used in bathrooms and kitchens: fluctuations in humidity will inevitably lead to deformation.

- If you have a flat ceiling lined with boards or OSB, you can do without a profile at all. The tiles are simply fixed to the ceiling with a wide planed strip. Of course, replacing tiles in this case will be somewhat more difficult than in the classic version.

- If a frame is used, it is better to navigate when hanging it not by distance from the ceiling, but by level.

The ceiling may be uneven. Focus on the level.

- To fasten the frame, do not use screws with wooden heads. Use only plastic dowels: they are not afraid of fluctuations in temperature and humidity, and they will not fall out of the holes after a few years.

- It is advisable to fasten profiles with a distance between fastening points of no more than a meter.

Installation of a tiled ceiling is more than simple and can be done even by a person with minimal construction skills (see Ceiling tiles: types and features of installation). All you need is a set of basic tools and a little self-confidence. Good luck with the renovation!

Application area

1.1 The scope of application of suspended ceilings of the “Akmigran” type are buildings for various purposes: administrative, cultural and domestic, educational, industrial with a relative humidity in the premises of 60 - 70% and a temperature from 5 ° C to 30 ° C.

They are used both decorative and in the form of acoustic elements of premises, enclosing the above-ceiling space in which various engineering networks and communications for air conditioning, electric lighting and low-current devices, etc. are located, and increasing the comfort of the premises.

1.2 This technological map discusses the issues of installing decorative suspended ceilings on a metal frame with front elements made of Akmigran slabs

1.3 Decorative suspended ceiling slabs “Akmigran” with a finished front surface are made from granulated mineral wool, a starch binder with water-repellent, antiseptic and other additives. Overall dimensions of suspended ceiling slabs, mm: length - 300, width - 300 or 250, thickness - 18. Weight of each slab - 0.7 kg. The weight of one square meter of suspended ceiling made from Akmigran slabs, excluding outlets, is 10.3 kg.

1.4 The design of a suspended ceiling, consisting of a “black” and “clean” frame with front elements made of Akmigran type slabs, is shown in Figure 1. The distance from the horizontal rods of the steel frame to the level of the “clean” ceiling, depending on the design solution, is 160 - 320 mm or 80 - 150 mm.

The “black” frame is made of vertical outlets from the ceiling and horizontal steel rods or angle profile elements made of VSt3 steel, welded to each other. The outlets laid during the installation of floor slabs are made of round reinforcing steel. The length of the outlets depends on the height of the ceiling space.

The “clean” frame consists of hangers with fasteners and guide aluminum profiles into which the suspended ceiling slabs are inserted and moved to the design position.

1 - reinforced concrete floor slab; 2 - release of reinforcement from the ceiling; 3 - horizontal rod of the steel frame; 4 — connecting plate; 5 - guide; 6 - rider; 7 — suspension; 8 — suspension bracket; 9 - key; 10 - bolted connection; 11 — “Acmigran” plate; 12 - comb.

Picture 1

— Structural diagram of a suspended ceiling with front elements made of Akmigran slabs

The design of suspended ceilings made from Akmigran slabs was developed by the Mosproekt-2 Institute.

1.5 The aluminum profile guide is attached to the horizontal rods of the “black” frame using a hanger made of galvanized sheet steel in accordance with GOST 14918-80*.

1.6 Akmigran acoustic slabs are connected to each other during the installation process using fiber dowels. The slabs are supported along the contour of the room on a metal molding (corner).

1.7 The small masses and dimensions of the structural elements of suspended ceilings allow installation work to be carried out manually.

1.8 The design solution of the suspended ceiling allows the installation of slabs from below and the removal of individual elements on any section of the ceiling when repairing wiring, installing and replacing lamps.

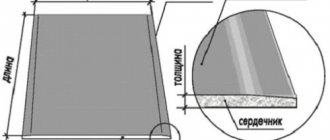

How Akmigran panels are arranged

The structure of the new ceiling finishing material is in many ways reminiscent of plasterboard or sandwich panels. Structurally, Akmigran slabs are a three-layer material with an inorganic filler:

- Inside the panel there is a filler made of granulated asbestos fiber impregnated with a binder. The result is a porous, non-flammable, lightweight and at the same time durable structure that absorbs and dissipates sound waves well;

- The front and back surfaces of the panel are sealed with a protective layer of cardboard based on pressed and glued organic and mineral fiber. This is done in order to form a smooth surface of Akmigran, to give it a more expressive appearance;

- Most ceiling panels are made with perforations over the entire surface area. Holes with a diameter of 2-5 mm are filled in increments of 5-10 mm.

The presence of perforations on ceiling cladding with Akmigran type slabs, photo, increases the decorative qualities of the material and at the same time contributes to better absorption of noise and sounds.

For your information! Panels without perforation are often covered with microcracks, but they do not affect the strength and absorption characteristics of the ceilings, so they are not considered defects.

At the ends of the slab material, grooves are formed with a paraffin layer applied. This makes it easier to slide when laying the panels and at the same time serves as protection against the penetration of water vapor. The surface of Akmigran must be sanded and most often painted with mineral paint.

According to the manufacturers, the ceilings can be used in the temperature range from 20 to 40

O

C, with air humidity up to 95%. In such conditions, Akmigran's asbestos matrix is capable of absorbing noise of any intensity with an efficiency of up to 95%.

This is interesting: Stretch ceiling: curtain rod in a niche

Scope of application

Based on the main characteristics of these panels, it can be assumed that they should be used where good sound insulation and absorption of extraneous noise are required. It is for such purposes that ceiling cladding with AGShT type slabs is used:

- In meeting rooms of enterprises or offices.

- To improve acoustics in office work areas.

- As finishing of floors of trading floors.

- In educational and medical institutions.

- For decoration of ceilings of entertainment centers, cafes and restaurants.

These materials are rarely used for decorating residential premises. However, if the desire arises, it will not be difficult to assemble such a ceiling - the installation process is very similar to the installation of conventional solutions from the Armstrong company and does not require special equipment or qualifications.

Armstrong ceiling tiles

The expressiveness of the design of the hanging decor, its style and the effect produced largely depend on how correctly Armstrong ceiling tiles were chosen. The frame and load-bearing elements of the ceiling are always hidden behind the decorative cladding, so the customer largely makes his choice based on the design of the tiles.

Types and models of Armstrong ceiling tiles

Several types of panels are used for frame suspended systems. Depending on the material and structure, Armstrong ceiling tiles can be used:

- For decorative design of ceiling surfaces in residential, entertainment and office spaces;

- Creating an acoustic barrier or noise damper for the ceiling. Used in medical, trade and banking institutions, in production and service premises;

- Equipment for false ceilings in swimming pools, laundries, washrooms and treatment rooms of medical institutions, where high resistance of ceiling tiles to water aerosols, water vapor and chemical reagents is required.

Depending on the dimensions and design of the Armstrong suspended ceiling, the size of the tile is also selected. The most common size is 600x600 mm; for high ceiling spans the size 600x1200 mm is chosen.

The thickness of the ceiling panel depends on the material and purpose of the decorative tiles. The thinnest are metal plates with a thickness of only 0.4 mm. The thickest Armstrong ceiling panels are made from pressed and granulated mineral and asbestos fiber. Their thickness can reach 20 mm or more.

Armstrong ceiling tiles for public buildings

The most difficult task is the selection of decorative panels for suspended ceilings for public areas and buildings, which would combine several useful qualities at once:

- Good thermal insulation;

- High acoustic impedance;

- Light weight;

- Chemical resistance;

- High decorative qualities.

Of course, no ceiling tile is perfect, but most modern decorative panels at least meet several of the criteria on this list, making them more attractive than conventional drywall or MDF.

Metal Ceiling Tiles

The most versatile are Armstrong ceiling tiles made of anodized metal, most often aluminum or galvanized steel. Decorative panels are made by hot stamping, painted with powder paints without gloss or pasted over with textured films to resemble mahogany or precious stones. Finished metal can be very beautiful.

The light weight of the material allows the use of double-sized Armstrong ceiling tiles. As a result, it becomes possible to make suspended ceilings that are delicately light, with long and thin spans.

Metal panels have one significant drawback - the material perfectly reflects sound waves, causing an echo. For a person standing under a metal ceiling, any high sound, even of low intensity, is perceived as very painful. Therefore, for noisy and crowded rooms, improved models of Armstrong suspended ceiling slabs are used. There is a through perforation on the surface, and a sound-absorbing cover is located on the back side.

In addition, the holes improve ventilation and dust absorption.

Fireproof boards

Huge rooms, which are periodically occupied by a large number of people, are equipped with non-combustible ceilings and cladding in accordance with fire safety standards. Therefore, for shopping centers, train stations and the foyers of sports palaces, special fire-resistant types of Armstrong ceiling slabs are used. The oldest and most famous - “Akmigran” or “Akminit” are made using granulated fiber sintering technology.

Thick and massive Armstrong sintered ceiling panels do not have the most expressive appearance, but they do not burn or emit toxic substances, like most foam and polyurethane insulation. In addition, the material perfectly absorbs high-frequency noise, which has made them popular for finishing premises in industry, retail and sports and entertainment facilities.

Office and special models of panels for Armstrong suspended ceilings

Panels made of metal and asbestos can be classified as highly specialized models; they work great in the most extreme conditions, but modern interiors require higher decorative qualities. New types of materials are increasingly being used to decorate ceiling surfaces of non-residential premises.

Universal ceiling panels

For small trading floors, offices and cafes, it has always been important to make the ceilings resistant to washing and periodic cleaning from dust and dirt. At the same time, it is important that the decorative qualities of Armstrong ceiling panels are high enough and do not change during maintenance.

In such conditions, Armstrong Ultima tiles are used to decorate the suspended ceiling. It has a well-thought-out decor, high strength and abrasion resistance, which allows it to be repeatedly dismantled, washed and returned to its place.

Special sound insulation

In many office spaces, one of the main working conditions is a low level of noise and sound. Especially if there are several dozen workplaces in one room. To ensure the maximum level of noise absorption, the Ultima DB model ceiling tiles are most often used. The surface of the Armstrong ceiling takes on a somewhat rough matte appearance, which is explained by the presence of a special fiberglass coating.

Thanks to this, the ceiling surface has an amazing ability to absorb even the strongest noises, reaching almost 100%. In a room with Armstrong-Ultima ceilings, there is not even background noise caused by poor wall insulation.

The Ultima variety, known under the brand Ultima OP, in addition to the highest sound insulation, has a smooth surface.

If you choose a different interior design scheme, for example, it is important that the ceiling tiles have the best decorative appearance, smooth surface and good sound insulation, then you can use the Optima or Neeva models.

Moisture-resistant and hygienic ceiling panels

One of the requirements for Armstrong slabs is resistance to moisture, water vapor and the ability to withstand wet cleaning of the surface. For regular office spaces, ceiling tile manufacturers recommend using the Frequence model. In addition to good sound insulation, ceiling tiles remain impervious to any damp environment.

For Armstrong ceiling systems in laundries, baths, swimming pools, washing rooms, and dining rooms, it is recommended to use tiles of the Ceramaguard or Newton models. The first can withstand even vapors of chlorine and other antiseptics, the second has high surface strength due to its silicate coating.

For medical institutions, it is recommended to use ceiling tiles with a special film coating. For example, for outpatient clinics, manipulation rooms and operating rooms, the manufacturer offers Armstrong ceiling tiles of the Bioguard model. The surface of the decor is coated with a material that kills pathogenic microflora and at the same time withstands the action of antiseptics and detergents.

For home false ceiling, you can use Mylar tiles. The surface made of polyester fibers is easy to clean, has high insulating properties and an excellent decorative appearance. Parafon Hygien is recommended for a children's room. Its antibacterial qualities and ability to withstand noise and mechanical stress are so great that this type of decor is the main one for ceilings in children's hospitals, kindergartens and hospitals.

Conclusion

Armstrong ceiling tiles are available in a very wide range of models, types and products. This allows you to choose your own type of decor for each specific room, which has special characteristics and properties. In essence, this is a new stage in the development of ceiling designs, more flexible and convenient for the consumer.

- Do-it-yourself whitewashing of the ceiling

- How to choose the right ceiling plinth

- Do-it-yourself stretch ceiling repair from flooding, cutting

- What types of ceiling panels are there?

The wisdom of choosing products

Let’s say you’ve decided what kind of material you want slabs from, how you plan to install them, taken into account the special requirements for the material, decided on the dimensions, found the most affordable option for you, calculated the ceiling area, purchased tools. We even took a master class on how to carry out such work. The time has come to make your planned purchase. It is better, of course, for you to do this yourself, carefully inspecting and checking each unit of goods.

By the way, you have the opportunity to become the author of a special project; do not be afraid to experiment with ceiling design

So what are your verification steps? Remember:

- the structure and density of the coating along the entire perimeter of the product must be uniform (no dents, bulges or waves should be present on the surface);

- any of the slabs must have smooth edges, that is, not deformed, not broken, not concave (don’t be too lazy to review each one, especially if the price of the product is “biting”);

- if there is a pattern on the products, check its clarity, because blurred lines or erased fragments will not decorate your home;

- the edges of the slabs must be perfect, since roundings and dents on materials of this format make their installation extremely difficult, if not completely impossible, in which case the product will simply have to be thrown away.

If you are primarily concerned about the shade of the ceiling, be careful: be sure to ask your consultant whether the material you have chosen can be coated with paint, and whether there are any nuances with this particular block of work.

Features of the material

AGShT panels are square parts with large perforations, mounted on a suspended base used in Armstrong-type ceilings. They are made from a gypsum mixture reinforced with fiberglass, covered on both sides with sheets of cardboard. Marking of AGShT parts indicates that the slabs are made with an underlying textile layer. Exactly the same parts, but without a textile backing, are marked with the designation AGSh.

Similar materials are used to improve the sound insulation of rooms. The main feature of AGShT panels is the ability to use them as a soundproofing structure without additional layers of soundproofing materials. To do this, the coating must be at some distance from the base ceiling. According to the standard, this distance should be 50 or 100 millimeters.

Characteristics

It is now almost impossible to find slabs on sale that have the original AGShT marking. The fact is that such materials were produced back in the days of the USSR and now only their analogues are produced. However, apart from the dimensions of the parts themselves, no other characteristics of the products have changed.

On the site of the plant that previously produced similar products, the production of materials offered under the Knauf brand is located. All characteristics of the soundproofing panels produced at this enterprise correspond to the original products marked AGShT. Therefore, except for size, modern analogues will not differ in any way from their predecessors.

- Length/width – 60 by 60 or 60 by 120 centimeters

- The thickness of the panels can be different - from 10 to 15 millimeters

- Sound absorption – from 0.55 aw to 0.80 aw

Common characteristics for all types of such parts will be good moisture resistance and fire safety. For the wettest rooms, such as bathrooms, such coatings are not suitable, but in other places they can be used without restrictions.