Drywall is the most versatile finishing material used for covering walls, installing partitions, creating multi-level ceilings, niches and various arched structures.

TOP 3 best products according to customers

Gypsum fiber sheet Knauf/Knauf Supersheet FC moisture resistant 2500x1200x10 mm

630.00 rub.

Product code 27

Knauf Superlist FC is a high-quality, environmentally friendly, moisture-resistant plasterboard for dry p.....

Gypsum fiber sheet Knauf/Knauf Superlist FC moisture resistant 2500x1200x12.5 mm

720.00 rub.

Product code 31

Knauf Superlist FC is a high-quality, environmentally friendly, moisture-resistant plasterboard for dry p.....

Gypsum fiber sheet Knauf/Knauf Superfloor moisture resistant 1200x600x20 mm

485.00 rub.

Product code 7

Knauf Superfloor is a factory-ready product for element-by-element assembly in...

The use of plasterboard eliminates wet finishing processes, increases labor productivity, and reduces construction costs by making the structures being built lighter.

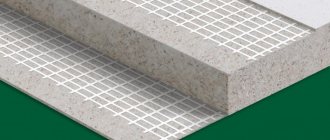

Gypsum boards are sandwiches of double-layer cardboard and a gypsum core.

Conventional drywall has a significant drawback - destruction under the influence of water.

Special hydrophobic additives help provide resistance to moisture:

- impregnated impregnations that reduce the rate of water absorption by the surface of sheets;

- antifungal compounds that protect sheets from mold, fungi and microorganisms that develop in a damp, poorly ventilated environment;

- waterproof solutions that prevent moisture from penetrating into the thickness of the sheet.

The recipe and composition of additives may vary depending on the manufacturer. Thanks to additives, moisture-resistant drywall (GKLV) absorbs 90% of water less than conventional gypsum board.

Figure 1. Structure of plasterboard sheets.

Types and sizes of moisture-resistant plasterboard sheets

Moisture-resistant drywall is available in two types:

- GKLV - moisture-resistant plasterboard;

- GKLVO - moisture- and fire-resistant plasterboard.

The edges of the sheets are also:

- straight;

- thinned;

- semicircular;

- thinned semicircular;

- rounded.

The edges of the sheets affect the quality of installation and the strength of the structure. The most popular semicircular edges with a thinned edge (PLUK) and thinned edges (UK)

Figure 2. The most popular types of edges.

A semicircular edge with a thinned edge allows you to create a higher quality and stronger seam, filled with putty to a depth of 8 millimeters, up to 11 millimeters wide.

Based on quality, plasterboard sheets are divided into 2 categories:

- Category “A” sheets are used for cladding visible surfaces.

- Sheets of category “B” are cheaper, for performing hidden work.

Moisture-resistant plasterboard sheets are produced in sizes from 600x2000 millimeters to 1200x4000 millimeters.

Thickness - from 6.5 millimeters to 24 millimeters.

Thinner sheets, up to 12.5 millimeters, are used to create multi-level ceilings, arched and shaped elements.

For cladding walls and installing partitions, sheets from 12.5 millimeters are taken.

The sheets are marked with a blue inscription, which includes the most important characteristics:

- view;

- edge type;

- sheet dimensions;

- GOST

Figure 3. Marking of plasterboard sheet.

TOP 3 best products according to customers

Plasterboard sheet Knauf/Knauf moisture resistant 2500x1200x12.5 mm

370.00 rub.

Product code 11

Knauf moisture-resistant is a rectangular material that consists of two layers of special.....

Plasterboard sheet Knauf/Knauf moisture resistant 2500x1200x9.5 mm

360.00 rub.

Product code 9

Knauf moisture-resistant is a rectangular material that consists of two layers of special.....

Plasterboard sheet Knauf/Knauf moisture resistant 3000x1200x12.5 mm

440.00 rub.

Product code 25

Knauf moisture-resistant is a rectangular material that consists of two layers of special.....

Flammability of drywall

Drywall is not a flammable material, and it can also withstand fire for a long time. As a matter of fact, any gypsum-containing materials can boast of such qualities.

- GOST 30244 determines flammability - it is for G1 plasterboard;

- GOST 30402 determines flammability, for plasterboard it is B2;

- GOST 12.1.044 determines the ability to generate smoke; according to this indicator, plasterboard belongs to group D1;

- GOST 12.1.044 defines toxicity; drywall belongs to group T1.

In the event of a fire, the characteristics of fire-resistant plasterboard allow it to withstand fire. The gypsum itself cannot burn, and after the cardboard is destroyed, the core simply crumbles. To increase fire resistance, partitions are made from two sheets of plasterboard. Thus, cardboard located between two sheets is able to withstand fire for a longer time.

Specifications

The differences between GKLV and conventional ones are as follows:

- GKLV has a cardboard layer of greenish color, in contrast to the usual one - gray;

- the weight of one moisture-resistant sheet is heavier than usual due to additives that impart water-repellent properties;

- the outer layer of moisture-resistant sheets is treated with special impregnated, antiseptic and water-repellent impregnations;

- GKLVO has a combination of properties of moisture-resistant and fire-retardant plasterboard;

- flammability group - G1, flammability degree - B2, toxicity level - T1;

- the weight of a standard sheet is about 10 kilograms;

- GKLV and GKLVO are more expensive than conventional plasterboard sheets.

Figure 4. View of the GKLV.

Important! Moisture resistance of moisture-resistant plasterboard is 90% higher than that of conventional plasterboard sheets.

Review of manufacturers

Moisture-resistant drywall is produced in Russia and abroad. The most popular manufacturer is Knauf (Germany). It has representative offices in 30 countries. In Russia it has 10 factories, which are known as Knauf.

Other foreign manufacturers of gypsum boards sold in Russia:

- Compagnie de Saint-Gobain SA (France);

- Lafarge Group (Poland);

- Gyproc (Scandinavia).

Moisture-resistant plasterboard of domestic production occupies only 20% of the entire Russian gypsum board market. The most popular manufacturers of this material in the Russian Federation:

- JSC Gips (produces GKLV Volma);

- OJSC Sverdlovsk Gypsum Products Plant (produces GKLV Gifas);

- Arakchinsky Gypsum LLC (manufactures Abdullingips sheets).

Advantages and disadvantages

Moisture-resistant plasterboard, like regular plasterboard, has undeniable advantages over other leveling and facing materials:

- environmental cleanliness and safety;

- mechanical strength and durability;

- availability;

- Fire safety. Does not emit toxic or hazardous substances to humans when exposed to high temperatures;

- high heat and sound insulation properties;

- vapor barrier material allows the walls to breathe, creating optimal humidity and natural air exchange;

- reducing the cost and increasing the speed of finishing work due to the elimination of wet processes and the use of large sheets;

- ease of processing and installation, not requiring special skills.

Walls lined with moisture-resistant plasterboard sheets can be wet cleaned without fear that the decorative finish will be damaged.

Moisture-resistant drywall will help bring to life any design solutions for bathrooms, kitchens, swimming pools and basements.

Important! Despite the moisture resistance of GKLV, when using them in a humid environment, additional protection of the surface of the sheets with hydrophobic impregnations and paints, polyvinyl chloride coatings or ceramic tile cladding is required.

Water absorption and softening coefficient

For brands of drywall that are moisture resistant (including those that are also fire resistant), moisture absorption of no more than 10 percent is permissible. Drywall also has another important parameter - the softening coefficient Kp, which is calculated by dividing the tensile strength in a water-saturated state (Rн) by the tensile strength in a dry state (Rс).

If we talk about sheets of ordinary drywall, their strength is significantly reduced when they are heavily moistened. There are quite a lot of similar materials sold, and they all have a small softening coefficient of approximately 0.8. But gypsum board has a slightly different value for this parameter - 0.45. This means that after getting wet, the strength of this material will greatly decrease.

Application area

Due to their high technical and operational characteristics, moisture-resistant plasterboard sheets are widely used in repair and construction work both inside and outside buildings.

They can be used in unheated basements with high humidity.

The following are made from gypsum boards:

- internal walls and partitions;

- multi-level suspended ceilings;

- interior elements;

- arched structural elements.

Moisture-resistant plasterboard is widely used for leveling and covering the walls of saunas, swimming pools, showers, bathrooms, toilets, kitchens. GKLV can be used to level the walls of unheated basements, verandas, loggias and summer cottage buildings.

Moisture-resistant plasterboard with fire-retardant properties (GKLVO) is used for cladding walls in saunas, when creating fireplaces, and passive fire protection for structures in wet rooms.

About the thickness of sheets

Drywall, which is sold in stores and on the market, most often can be 6, 9, 12 mm thick. The thinnest gypsum boards, 6 mm thick, are used for the “wet method” - they are used to make complex curved products (arches, designer structures, niches). A thickness of 9 mm is well suited for bending sheets “dry” and creating the same arches - experienced craftsmen usually do this. Ceilings are also made from nine-millimeter gypsum boards in order to reduce the weight of the structure. The thickest sheets are used for cladding walls and creating partitions. Other sizes are extremely rare on sale, and therefore, as a rule, they are not of interest to the average buyer.

Installation features

The installation process of gypsum boards is practically no different from the installation of conventional drywall, but has a number of nuances associated with further use in rooms with high humidity:

- It is better to use a profile made of aluminum or galvanized steel as a frame. The wooden frame should be abandoned;

- the seams between plasterboard sheets must be carefully sealed;

- to create a more reliable moisture-resistant layer, you can install a second layer of gypsum board;

- It is better to fill the voids between the frame with hydrophobic heat and sound insulating materials;

- It is better to decorate moisture-resistant drywall with ceramic tiles, moisture-repellent wallpaper or hydrophobic paints.

It is important to know that plasterboard sheets are attached with their backs to the wall. The back side can be identified by the markings applied to it and the gray color.

The front layer is intended for applying putty and subsequent finishing, and is made of two layers of cardboard with a high content of cellulose fibers, which increases adhesion to decorative finishing materials.

Plasterboard boxes

There are many water lines concentrated in the bathroom. Their presence spoils the entire external image of the room. Therefore, it is advisable to hide such shortcomings. To give an aesthetic appearance that is spoiled by plumbing, it is good to use moisture-resistant plasterboard. This is a fairly practical and popular method. It is used to sew up risers, water and sewer pipes.

In order to hide the water supply wiring, you can make a box from plasterboard. In a bathroom or toilet, the construction of the structure should be planned taking into account access to pipeline channels and water meters. This will make it easy to prevent or fix the problem.

This article highlights the main advantages of moisture-resistant drywall, methods and areas of its application. We found out how it differs from the usual one. In the end, it is worth emphasizing that this material is widely used, the main feature of which is its moisture resistance, which helps prevent the appearance and proliferation of various types of mold and fungi.

Installation sequence

GKLV must be purchased taking into account the height of the premises in order to avoid unnecessary seams and a large amount of waste. When installing drywall, leave gaps between the sheets, floor and ceiling of at least 5-10 millimeters to avoid expansion deformations.

Important! Plasterboard sheets must be kept indoors on a level surface for at least 24 hours.

There are two options for attaching plasterboard sheets: with glue and with a metal profile.

Fastening with glue.

On perfectly equal walls or with minor unevenness, you can attach plasterboard sheets using putty, polyurethane foam, silicone sealants, liquid nails, and tile adhesive.

The advantages of this method are that the height of the premises does not decrease when gluing ceilings, the usable area is preserved when gluing the walls of small rooms, and the costs of installing a metal frame are eliminated.

Figure 7. Attaching drywall with glue.

Sequence of work:

- We clean the base from excess mortar and old finishing.

- We mark the installation locations of the sheets.

- We cover the wall with a primer to increase adhesion to the glue.

- On the back side of the sheets we lay out the adhesive mixture in small slides, up to 20-30 millimeters, in increments of about 30 centimeters.

- To maintain a gap below the sheet, we install linings made of wooden planks or scraps of material.

- We lift the sheet and press it against the wall or ceiling, aligning it in the vertical and horizontal plane.

- In the same way, we glue all the sheets sequentially, around the entire perimeter of the room and let the glue dry for two to three days.

- We glue reinforcing tape to the joints and putty. We fill the recesses from the screws with putty. We fill the gaps with sealant.

- We cover the surface of the sheets with a primer and putty with a continuous thin layer.

Mounting on a metal profile.

We install plasterboard on a metal frame in the following order:

- We install the first plasterboard sheet level, starting from the window or door. First, we glue a vibration-isolating strip of porous insulating material onto the metal profile.

Important! The joints between the gypsum boards should be no less than twenty centimeters from the edge of the opening. To do this, place the sheet in place, draw the perimeter of the opening from the inside and cut it out.

- We fasten the resulting sheet around the perimeter with self-tapping screws, in increments of 20-25 centimeters, into rack and transverse profiles. It is better to use a screwdriver with a limiter so that the heads of the screws are recessed into the sheet no more than 1 millimeter.

Figure 8. Wall cladding on a metal profile.

- We fill the voids of the frame with mineral slabs, and pre-lay utilities or electrical cables in corrugated pipes.

- We cut holes in the sheets for sockets or switches.

- We cover the joints between the plasterboard sheets with sickle tape and level them with putty. We fill in the recesses from the self-tapping screws.

Figure 9. Puttying joints between gypsum boards.

- We fill the gaps at the bottom and top with silicone sealants.

- Apply a waterproof primer to the surface of the sheet.

- After the primer has dried, we completely putty the surfaces with a thin layer of gypsum, silicone or latex putty.

Walls

0 votes

+

Vote for!

—

Vote against!

The German company Knauf is rightfully considered the standard among European manufacturers of building materials. One of the most popular areas of the company is the production of finishing materials, including drywall.

This article will discuss moisture-resistant Knauf drywall, its main characteristics and scope of application. We will describe the features of finishing walls with plasterboard sheets and provide step-by-step instructions for performing installation work.

Content

- Production and composition of moisture-resistant plasterboard Knauf

- Technical characteristics and properties of GKLV Knauf

- Scope of application of moisture-resistant plasterboard

- Methods for installing drywall sheets

- Installation technology for moisture-resistant plasterboard

- frame method

- installation of gypsum boards with glue

- Transportation and storage conditions

Production and composition of moisture-resistant plasterboard Knauf

The Knauf company has its representative offices in 40 countries around the world, and the number of enterprises of this corporation exceeds 200. The company has developed and produces four types of plasterboard sheets: regular (GKL), with increased fire resistance (GKLO), moisture-resistant (GKLV) and fire-resistant moisture resistant (GKLVO). Moisture-resistant drywall contains fungicidal and hydrophobic additives, which give the material the necessary stability and allow the material to be used in wet areas.

According to generally accepted markings, the color of cardboard on the back and front sides of gypsum boards is green.

As the name of the building material suggests, drywall is made from cardboard and gypsum. However, to form the sheet and give it additional functions, plasterboard includes glue and various additives that improve the technical characteristics of the material.

Knauf moisture-resistant plasterboard has the following composition:

- cardboard – sheets 1250 by 1180 mm wide;

- gypsum – powder 85%;

- starch – 70%;

- glue (polyvinyl acetate emulsion);

- foaming agent;

- hydroresistant, antifungal and impregnated solutions for treating plasterboard.

For the production of drywall, not one machine is used, but a specialized automatic line. It includes a number of machines that perform different functions: kneading, dosing and supplying components, forming gypsum boards, drying, cutting and packaging. A line for the production of plasterboard sheets costs from 120 thousand dollars.

The entire production process can be divided into several stages:

- Formation of gypsum mass, mixing with fillers and additives.

- The gypsum mixture is automatically placed between sheets of cardboard, which are fed by a separate installation.

- Gluing layers and folding edges.

- Drying and cutting pressed fabric.

- Packaging of finished products.

Moisture-resistant drywall undergoes additional processing. Antifungal compounds protect the material from the spread of mold, which can appear in a poorly ventilated or damp room. The waterproofing solution does not allow moisture to penetrate deep into the material, and impregnated impregnation reduces the rate of moisture absorption. This dispersion creates a kind of balance of moisture levels inside and outside the material.

Moisture-resistant drywall absorbs 90% less moisture than regular drywall

Technical characteristics and properties of GKLV Knauf

Let's look at the main technical characteristics of Knauf moisture-resistant plasterboard:

- Nominal dimensions of Knauf plasterboard:

- length – 2-4 m;

- width – 0.6-1.2 m;

- the thickness of a sheet 2 m long is 6.5; 8 or 9.5 mm;

- the thickness of a sheet up to 4 m long is 12.5; 14 or 16 mm;

- the main size of GKLV KNAUF is 2500/1200/12.5 (mm).

- The weight of Knauf plasterboard of standard size is 9.7 kg/m2.

- The color of the cardboard is green, the markings are blue.

- Edge type – semicircular thinned. This type of edge is considered the most technologically advanced.

- Fire technical characteristics:

- flammability group (GOST 30244) – G1;

- degree of flammability (GOST 30402) – B2;

- smoke-forming ability (GOST 12.1.044) – D1;

- toxicity level (GOST 12.1.044) – T1.

- The price of moisture-resistant Knauf drywall of standard size is about 200 rubles per sheet.

- The package contains 50 sheets with a total area of 50 m2.

Performance properties of moisture-resistant plasterboard:

- Environmentally safe material. When used, it does not emit toxic substances hazardous to the human body.

- Increases the sound and heat insulation of the room, making living conditions more comfortable.

- Able to maintain the natural level of humidity in the room - absorbs excess moisture or releases moisture in dry air.

- The acidity level of the finishing material corresponds to the acidity level of the human body - this balance ensures a favorable atmosphere in the room.

Based on the number of permissible defects per product area, moisture-resistant drywall is divided into two categories “A” and “B”. For cladding, it is better to choose sheets of group “A”; to perform hidden work, you can use cheaper material – sheets of category “B”.

Scope of application of moisture-resistant plasterboard

The characteristics of moisture-resistant Knauf plasterboard allow the material to be used in various repair and construction work. It can be used to create a lightweight interior partition, suspended ceiling, various functional and decorative designs, and used for cladding and leveling walls in rooms with high humidity levels: swimming pool, sauna, shower, bathroom, toilet and others.

Moisture-resistant plasterboard is suitable as passive fire protection for various structures located in “wet” rooms. GKLV can be used not only for internal, but also for external construction work. Moisture-resistant panels, unlike ordinary ones, can be washed.

When choosing between regular and moisture-resistant plasterboard, for example, for a kitchen, preference should be given to the second option. The difference in the cost of the material will be insignificant, and the service life of a structure made from moisture-resistant sheets will be longer

Methods for installing drywall sheets

Installation of Knauf drywall is carried out using one of the following methods.

The frame method is used on walls with significant unevenness to create a decorative structure or interior partition. In this case, plasterboard slabs are mounted on a metal sheathing made of galvanized profiles. The frame itself is attached to the wall with self-tapping screws and dowels.

Important! Moisture-resistant plasterboard cannot be mounted on a wooden sheathing if the structure will be used in a damp room

To create the sheathing, metal profiles of different sizes are used:

- W – a larger profile intended for the manufacture of a general wall frame;

- D – for creating internal sheathing with subsequent fastening of plasterboard panels.

Each standard size has a U-shaped guide profile with a smooth surface (UW, UD) and a support profile with ribbed walls (CW, CD).

When leveling walls, the second method of installing drywall is often used - on an adhesive base. It is much simpler and faster than the wireframe method. Glue is applied to the plasterboard sheets, and the slab is pressed tightly against the prepared wall surface.

On walls with unevenness up to 4 mm, plasterboard sheets can be mounted using putty, for example KNAUF Fugenfüller. If the walls have unevenness of 4-20 mm, then gypsum cortan must be “planted” with Perlfix type glue.

Installation technology for moisture-resistant plasterboard

Frame method

Let's consider the procedure for performing work when installing drywall on a frame:

- Apply markings to all parts of the frame.

- Glue sealing tape or apply a layer of sealant to the guide profile that will be adjacent to the ceiling and floor.

- Taking into account the markings, fix the guide profiles with self-tapping screws. The fastening step is no more than 100 cm.

- Using a plumb line, mark the location of the posts, taking into account that the distance between them should not be more than 60 cm. Secure the posts with special rivets.

- Thermal and noise insulation can be placed in the frame cavity. If necessary, install electrical wiring, which must be placed in a corrugated pipe, or lay water pipes.

- Secure all communication networks.

- Holes for switches and sockets must be provided in advance in the sheets of drywall.

- Place the plasterboard sheet tightly against the frame and attach it to the CD and UD profiles with self-tapping screws 25 mm long. You need to start fastening from the edges of the canvas, and then in the center. The distance between the screws should be about 25 cm.

- Fill the seams between the sheets with putty and apply a moisture-resistant primer to the surface.

- Mount switches, sockets and boxes into the wall.

- The surface is ready for finishing: painting, wallpapering or tiling.

Installation of gypsum boards with glue

Despite the simplicity of the technology, installation of drywall sheets with glue must be carried out following a certain algorithm:

- Conduct a foundation inspection. Using a level, rule and plumb line, determine unevenness over the entire area of the wall.

- Clean the wall surface from the previous finish and try to eliminate as much unevenness as possible. Large tubercles can be knocked down with a hammer drill or chisel.

- Mark the fastening of plasterboard sheets on the wall.

- Treating the wall with a primer will improve the adhesion of materials.

- Cut out sheets of drywall and make holes for sockets and switches. Trimming the canvases is done so that there is about 10 mm of free space between the wall sheathing and the floor. This gap is necessary for air access to the glue. Subsequently, this gap will need to be filled with sealant.

- Place sheets of drywall on wooden or metal slats.

- Glue, in small slides, is placed on drywall. The height of the slide is 25 mm, the diameter is 100 mm, the distance between the slides is 20-30 cm.

- To control the bottom gap, wooden wedges or scraps of material can be placed at the bottom of the wall.

- Lift the gypsum board sheet and attach it to the wall. Align the position of the canvas plane, vertically and horizontally. You can use a rubber mallet for this. It is better to start covering walls with plasterboard from the corner of the room and move along the perimeter of the room.

Advice. Drywall sheets must lie for at least two days on the floor in the room so that after installation the sheathing does not become deformed

After completing the work, you need to let the glue harden completely (2-3 days), glue the seams with reinforcing tape and putty them. Remove the wedges from the bottom gap and fill the space with silicone or acrylic-based sealant.

Transportation and storage conditions

Drywall is transported in packaged form. In vehicles, packages with material are installed on pads or pallets made of wood. For tying, you can use synthetic or steel tape.

If it is necessary to transport small volumes, drywall can be transported without special packaging. If the finishing material is transported in open transport, it must be covered with plastic film to protect it from rain or snow.

During unloading and loading operations, impacts on plasterboard sheets are not allowed.

It is advisable to store drywall in a dry room with normal humidity levels. Packages with material can be stacked on top of each other, but the total height of the stack should be no more than 3.5 meters.

Tips for choosing

It is better to buy drywall in specialized stores that comply with storage conditions and have reliable large suppliers.

When choosing, pay attention to the following points:

- compliance of the dimensions and thickness of the sheets with the declared ones;

- the color of the sheet covering, which should be green for moisture-resistant drywall;

- availability of certificates and other documents confirming the quality and safety of the material;

- integrity of sheets, absence of damage, dents, cracks, scratches;

- There should be no bends or chips on the edges.

Important! Buy the type of plasterboard sheets that you need. You should not overpay for moisture-resistant or fire-resistant drywall for use in normal conditions - this is a waste of money.

To level walls or install partitions, choose plasterboard with a thickness of at least 12.5 millimeters. For ceilings, thinner and lighter sheets are suitable.

Having purchased drywall, pay attention to the neatness of the movers. If the store provides delivery, accept the delivered goods, checking for mechanical defects and manufacturer's markings on each sheet.

TOP 3 best products according to customers

Magma moisture-resistant plasterboard sheet 2500x1200x9.5 mm

315.00 rub.

Product code 12258

Intended for finishing and installation of non-load-bearing walls and partitions in buildings with high humidity…..

Magma moisture-resistant plasterboard sheet 2500x1200x12.5 mm

350.00 rub.

Product code 12257

Magma moisture-resistant plasterboard sheet 2500x1200x12.5mm (Building board for dry plaster moisture…..

If you are not sure of the quality of the material, you should not buy a large volume at once. Buy a few sheets to try. Try cutting the purchased sheet. The cut should be uniform and even, and the cutter should move smoothly.

Don't be tempted by the too cheap price. Buy plasterboard sheets from well-known, trusted manufacturers.

Thermal conductivity of drywall

To begin with, it should be noted that drywall retains heat quite well. The thermal conductivity coefficient of plasterboard ranges from 0.22 to 0.35 W/ (m×K). This is not bad - after all, when carrying out repairs, you can immediately make the walls even and slightly improve their thermal insulation. It should be noted that this method of thermal insulation of walls is inexpensive, fast and effective. And if you make a gap from 3 to 10 mm, then an additional air layer will appear, which will help conserve heat even better.

To achieve a good result in terms of thermal conductivity, various insulation materials are placed in the cavity between the insulated wall and the plasterboard. This could be, for example, mineral wool or ordinary polystyrene foam. The further we move the plasterboard away from the wall, the thicker the additional thermal insulation layer can be made.

Brands and prices

Moisture-resistant sheets from different manufacturers can vary significantly in quality.

The most reliable and trusted manufacturers who have won the trust of builders and individuals:

Knauf

It is in greatest demand among Russian consumers due to its high quality and compliance with the declared water resistance. GKLV from the Knauf company easily tolerates soaking and direct contact with water. It features impeccable geometry, good fire resistance and environmental safety. Thanks to the wide size range of products, you can choose sheets for any purpose.

The cost of a sheet measuring 3000*1200*12.5 is 400 rubles.

Figure 11. Moisture-resistant sheets from Knauf.

Gyprok

A Scandinavian company that produces a lightweight version of moisture-resistant sheets has an official stamp confirming environmental friendliness and safety. In terms of the volume of plasterboard products produced, it surpasses all well-known manufacturers. The price for a standard sheet with an area of 3.6 m2 and a thickness of 12.5 millimeters is 420 rubles.

Lafarge

The Polish manufacturer of plasterboard sheets is distinguished by more affordable prices and the production of sheets with four edges processed and covered with cardboard. The assortment includes sheets of only standard sizes 1200*2500 and 1200*3000 millimeters, with a thickness of 9.5 and 12.5 millimeters.

The cost of a sheet measuring 3000*1200*12.5 millimeters is 380 rubles.

Volma

Plasterboard sheets from the Russian manufacturer Volgograd Gypsum Plant are distinguished by a budget price and standard sizes, with a width of 1200 millimeters, a length of 2500 and 3000 millimeters, and a thickness of 9.5 and 12.5 millimeters. Moisture-resistant and moisture-fire-resistant plasterboard meets European quality standards.

The cost of moisture-resistant sheet Volma 3000x1200x12.5 millimeters is 390 rubles.

Figure 14. Volma moisture-resistant plasterboard.

Production

The technological process for manufacturing gypsum boards involves the use of only clean and high-quality raw materials. Certain technical characteristics of the sheets depend on this.

The following raw materials are used in production:

- Gypsum mixture.

- Pressed cardboard.

- Various additives.

The latest ingredients are modern components that improve quality indicators.

These include the following:

- Waterproofing solution - it prevents moisture from penetrating the structure and destroying it.

- Antifungal mixtures – protect the surface from the appearance of fungal diseases and mold.

- Impregnated impregnation - slows down the process of moisture absorption.

Thanks to the use of natural raw materials and all additives, GKLV plasterboard can be used in poorly ventilated areas.

Moisture-resistant plasterboard is mainly used for finishing the bathroom or kitchen.

Modern specialized equipment is used in the production of the material. The production line has more than 10 machines. With their help, drywall is given certain parameters.

Particular attention is paid to storage technology. The invariability of technical characteristics depends on it.

GCR should be stored in a dry room with a constant temperature. The warehouse is equipped with additional ventilation systems so that dry and humid air masses do not affect the structure.

The structure of fireproof plasterboard and its characteristics

Drywall Knauf - brand features

There are many brands on the construction market that produce moisture-resistant drywall. The production technology is always approximately the same - but of course, gypsum board sheets from different manufacturers may differ in quality. Practical resistance to moisture depends on many aspects - on the quality of raw materials, on compliance with all rules during manufacturing, on the moisture-resistant impregnations used.

Which is better: heated floors or radiators?

Warm floorBatteries

The greatest demand in Russia is GKLV from the German company Knauf. KNAUF plasterboard has some features that set it apart from its competitors.

- The material retains all its properties at humidity levels up to 90%.

- The gypsum core and cardboard layers are treated with high-quality hydrophobic impregnations.

- Drywall is resistant to mechanical stress - you can not be afraid of being damaged by an accidental blow.

- GKLV easily tolerates accidental direct exposure to moisture.

- Knauf products are environmentally friendly materials, the manufacture of which does not use toxic chemicals. In particular, natural starch plays the role of a binding composition here.

- Moisture-resistant material from a German manufacturer has good fire-resistant properties. Such drywall does not burn at all, but only chars when exposed to high temperatures for a long time.

The Knauf company produces plasterboard sheets of all common dimensions, so for any purpose you can find a suitable material among the product line. If necessary, Knauf can be easily processed and brought to the desired size.

Knauf is a quality proven over the years. It is also worth noting that the German company produces many other building materials that combine perfectly with each other. Thus, if during repairs you use, for example, adhesives from Knauf, it would be wise to choose drywall from this brand - you can be sure that when working, the two materials will fit together and will not complicate the repair.

Drywall in a damp room

Here is an example of the marking of such a sheet from GYPROS: GF 15 - a sheet with a thickness of 12.5 mm can withstand an open flame for 20 minutes. Fire-resistant sheets can be either moisture-resistant or ordinary. Any work with drywall can only begin when all “wet work” - using water solutions, plastering, puttying, etc. - is completed. To avoid getting wet or excessive moisture absorption, it is necessary to establish an adequate atmosphere in the room, without excessive humidity.

structures or simply plasterboard come in two types: conventional, consisting of gypsum and cardboard, and moisture-resistant, the components of which contain special materials. additives that affect the removal of moisture and its absorption by gypsum. Before finishing and applying facing materials, it is necessary to carry out all preparatory steps for waterproofing. Moisture-resistant plasterboard for bathtubs, according to many experts, is ideally combined with Fugenfüller-Hydro joint putty, and the finishing treatment after the joints have dried should be done with Tiefengrund primer. In places where moisture will enter or where condensation will form, it is necessary to apply a layer of Flechendicht waterproofing.

Even before assembling the frame, it is necessary to think about the mounting locations for sinks, faucets, toilets and shower holders; this equipment is quite heavy and it is impossible to attach it directly to plasterboard. To do this, even at the stage of installation of the frame, it is necessary to provide embedded elements,

- Remove paint and any loose or loose coatings. Ideally, gypsum board is glued to bare brickwork: this way the connection will be the most durable;

The seams are filled with gypsum putty after reinforcement with sickle. Self-adhesive fiberglass mesh is glued along the seam, after which it is filled directly through its cells.

How to treat the surface → Room decoration → How to choose the right paint → Surface treatment technologies → Leveling and finishing the walls → Selecting and applying a primer → Removal from the surface → Stretch ceilings and technologies → Reviews and testimonials

How to make drywall moisture resistant

- color – green or gray with a greenish tint. Although sometimes some manufacturers make it pink, but with a special note about its moisture resistance;

- types of edges are similar to other variations of this product;

Note! The composition that is used by various manufacturers to give the material better water-repellent properties differs. This is a process secret and is not disclosed by manufacturers. Edge types

- resistance to moisture – high;

- the main parameters of the sheet (length, width and height) are similar to standard sizes;

- cardboard layers are treated with special antifungal and water-repellent compounds.

- primer. It must penetrate deeply into the leaf to create an excellent protective layer;

- antifungal and anti-mold solutions;

- water-repellent paint. It is necessary in a situation where the sheet will not be externally protected by ceramic tiles.

- the presence of a large amount of residue after finishing the covering of another room. Typically, this situation arises when the amount of material required for repairs is incorrectly calculated;

- small volumes of finishing with moisture-resistant boards. For example, in this way you can create a box that masks communications means (sewage and water pipes, gas pipes, ventilation and the pipe connecting the hood to the ventilation hole);