The disadvantage of wet rooms is the inability to use building materials for repairs that do not tolerate high humidity. Under its influence they quickly become unusable. This concerned primarily drywall. The problem was solved relatively recently. Additives are added to gypsum to make the sheets resistant to moisture. Therefore, today moisture-resistant plasterboard is used in the bathroom, toilet and kitchen without restrictions. But it gradually began to be replaced by another material - gypsum fiber boards (GVL), also known as gypsum fiber.

Advantages

GKLV is environmentally friendly: does not harm human health. This makes it possible to use it in the decoration of any premises. The structure of moisture-resistant plasterboard absorbs moisture 90% less than that of conventional drywall.

It is fireproof because it does not ignite when exposed to a direct source of fire. The sheets can be installed in rooms with high air humidity. They will not be deformed from such exposure. The size of moisture-resistant drywall can be any. This allows you to select its parameters for faster repair work.

GCRs of this type are not afraid of temperature changes. Quite often, moisture-resistant plasterboard is used for cladding the facade of a building. In this process, the most important thing is to correctly treat the drywall surface with protective agents.

In addition, GKLV is endowed with the following characteristics:

- Durability - its structure can withstand significant physical and mechanical impacts.

- Practicality - the material is quite easy to install on any base.

- Versatility - its surface can be decorated with water-based paints.

Moisture-resistant drywall is considered an excellent heat and sound insulator. You can clean its surface with a damp cloth, but without using abrasives or detergents.

Advantages of gypsum fiber

Cellulose gives gypsum fiber its technical and operational characteristics:

- High strength. It is difficult to bend, break or pierce gypsum fiber. It can even withstand loads from heavy furniture, which is why it is used to create floors using dry technology.

- Increased moisture resistance. GVL, like gypsum board, is divided into two groups - ordinary, moisture-resistant for bathrooms. If we compare the moisture-resistant options of the two types, then gypsum fiber will give odds to drywall. It not only withstands high humidity in bathrooms, but also long-term water load, under the influence of which it does not swell.

- Less susceptible to deformation. On the one hand, this is a plus. On the other hand, it is difficult to form shaped structures from gypsum fiber (ceilings, door and window openings in the form of arches).

- Increased thermal and sound insulation characteristics due to the presence of cellulose in the solution.

- High fire safety.

Gypsum fiber sheet

Production

The technological process for manufacturing gypsum boards involves the use of only clean and high-quality raw materials. Certain technical characteristics of the sheets depend on this.

The following raw materials are used in production:

- Gypsum mixture.

- Pressed cardboard.

- Various additives.

The latest ingredients are modern components that improve quality indicators.

These include the following:

- Waterproofing solution - it prevents moisture from penetrating the structure and destroying it.

- Antifungal mixtures – protect the surface from the appearance of fungal diseases and mold.

- Impregnated impregnation - slows down the process of moisture absorption.

Thanks to the use of natural raw materials and all additives, GKLV plasterboard can be used in poorly ventilated areas.

Modern specialized equipment is used in the production of the material. The production line has more than 10 machines. With their help, drywall is given certain parameters.

Particular attention is paid to storage technology. The invariability of technical characteristics depends on it.

GCR should be stored in a dry room with a constant temperature. The warehouse is equipped with additional ventilation systems so that dry and humid air masses do not affect the structure.

Types of GKLV

Today, drywall is considered the most popular material for finishing work.

Since it can be used for cladding surfaces in any room, manufacturers produce various types of gypsum boards.

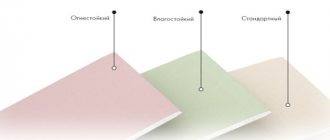

Moisture-resistant gypsum board can be of the standard type or moisture- and fire-resistant. The first type will become indispensable for tiling surfaces in the bathroom, the second - for decorating the kitchen area and fireplace room.

According to the scope of application, the material is divided into ceiling, arched and moisture-resistant wall plasterboard.

Their parameters differ significantly from each other. Wall is used to cover the surface of a wall. Ceiling is suitable for mounting simple and complex structures on the ceiling. Arches and other decorative elements are made from arched wood.

Is it possible to use GKLV in a bathhouse and outdoors?

If the use of moisture-resistant plasterboard in the bathroom is an issue that has no controversy, then in the case of using it to decorate a bathhouse, everything is not so clear. For example, it is allowed to use gypsum plasterboard for covering a washing room, since the conditions in such a room are similar to the conditions prevailing in the bathroom.

But for a steam room, some experts do not recommend using this material, justifying this by the fact that a steam room lined with plasterboard will have to be repaired every 5-10 years.

But even when finishing rooms such as bathrooms and washrooms, certain rules must be followed. In such cases, the joints between the sheets are sealed with waterproof putty, covered with fiberglass tape, on top of which another layer of putty mixture .

All this is worth doing even despite the standard recommendations that apply to a particular type of sheet edge.

It is also necessary to putty the screw caps to protect them from corrosion.

Read our article on how to putty drywall before painting.

As for whether it is possible to use gypsum boards on the street, the clear answer is no. Even if we are talking about the most moisture-resistant drywall in the world.

Specifications

During the production process, moisture-resistant drywall is given certain parameters. Also, with the help of additives and special substances, the material is endowed with quality indicators.

The size of a moisture-resistant plasterboard sheet depends on the established standards (GOSTs). The length of the gypsum board is 2 - 4 m. The width ranges between 60 - 120 cm. Such parameters allow you to calculate the exact amount of material for repair.

The weight of the sheet is not too large and is 9.7 kg/m2. This has a positive effect on the overall weight of the plasterboard structure. It does not create additional load on the rough foundation.

The thickness of moisture-resistant drywall depends on another parameter of the material. With a sheet length of 2 m it can be like this:

Which is better: heated floors or radiators?

Warm floorBatteries

The weight of the gypsum board also varies depending on this technical indicator.

If the sheet length reaches 4 m, then its thickness is 12.5 mm, 14 mm, 16 mm. These parameters do not affect the performance of facing work.

How to distinguish moisture-resistant drywall from regular drywall

When choosing finishing materials you need to be careful. You can often purchase counterfeit goods on the market that do not meet the standards. Its cost is quite low. It is this fact that attracts buyers.

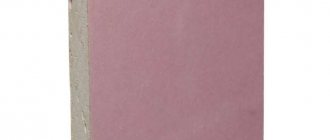

Moisture-resistant drywall, the thickness of which can vary depending on the length of the sheet, is quite easy to distinguish from ordinary plasterboard. In its production, special cardboard is used - it is painted green. The markings are applied in blue. A cardboard sheet of regular gypsum board is gray.

There are also differences in the shade of the structure. The gypsum composition of moisture-resistant plasterboard is darker. The edges of the sheet are protected by cardboard. This prevents moisture from affecting the structure.

Features of installation of gypsum boards

Moisture-resistant drywall is mounted using two methods: on a frame or with an adhesive solution. The first method involves constructing a sheathing of metal profiles on the rough surface.

It is not recommended to install a frame made of wood. This material absorbs moisture well, and the sheathing will begin to deform over time.

The use of an adhesive solution also has certain limitations. Do not use water-based formulations. In addition, the rough surface for mounting drywall sheets must be smooth and clean.

What is the difference between simple drywall and moisture-resistant one?

Moisture-resistant drywall - advantages and disadvantages of the material

Technologies for the production of building materials are constantly being improved. Manufacturers are trying to take into account all the needs of the market; external and internal cladding is acquiring more and more useful technical characteristics.

GCR has been used in interior decoration for no more than fifteen years, and companies annually offer us improved versions of this universal type of interior decoration. How does moisture-resistant drywall differ from conventional plasterboard, and what new properties and characteristics has it acquired?

Bathroom tiling

Specifications

Cut of gypsum plasterboard, resistant to moisture

The difference between moisture-resistant drywall and conventional plasterboard lies in the production technology and technical characteristics.

The production process consists of forming a flat continuous strip 1200 millimeters wide and various.

In recent years, finishing material such as plasterboard has gained a leading position in the construction market. It has become an almost irreplaceable material, without which not a single modern renovation can be done today.

At the same time, many people were faced with a situation where, after renovation, a lot of material remained in ordinary rooms that could be used in small rooms. For example, in the kitchen or bathroom. But there is a slight hitch here. Ordinary drywall is not suitable for finishing these rooms due to their specific microclimate (high humidity and temperature fluctuations). Therefore, many are interested in the possibility of converting ordinary drywall sheets into a moisture-resistant type. This article will tell you whether this can be done.

About the material

Today, manufacturers of building materials do not stand still and are constantly improving their products. Thanks to this, there are four types of drywall on the market.

GCL is one of the most versatile materials for interior decoration in residential and non-residential premises. It is used for cladding walls, erecting partitions, creating complex elements and multi-level ceilings. But the standard sheet has a drawback - destruction when exposed to large amounts of moisture. Therefore, moisture-resistant plasterboard is used for bathrooms and wall cladding around window openings. It is somewhat different in its structure and composition from regular gypsum board and is suitable for use in rooms with high humidity.

Technical characteristics of GKLV

Waterproof drywall consists of a gypsum core with hydrophobic additives and two layers of cardboard treated with special compounds. These components perform the functions of protection against moisture and fungus formation and may differ in their formulation depending on.

Based on resistance to high humidity and fire, plasterboard is divided into several types - regular, moisture-resistant and fire-resistant. There are no additional additives in the composition of ordinary drywall, and therefore it has standard properties. It is used for interior decoration of rooms with low temperature and humidity. The gypsum layer of moisture-resistant drywall contains a number of hydrophobic additives and antifungal agents. Prepregnated cardboard sheets are used, not ordinary ones. Therefore, such material can be used in conditions of high humidity, although its surface still needs additional protection.

Brief characteristics of moisture-resistant drywall

It is these systems that include, in addition to sheets of dry plaster, all the necessary elements for the quick installation of load-bearing frame structures, forms of any complexity, and allow you to easily carry out a full cycle of dry finishing technology, without the use of work associated with high humidity (plastering, etc.). A sheet of high-quality gypsum, covered on both sides with durable cardboard, has made a real revolution in construction finishing works.

The main advantages include high environmental friendliness, low weight, and ease of processing. GCR systems allow builders to put into practice the most fantastic solutions of architectural and design projects. High-quality material, including moisture-resistant plasterboard, standard sizes. This allows you to easily calculate the number of sheets, their weight, cost, etc. even at the design stage.

With two main standard sizes (9.5 and 12.5 mm) the thickness of the sheets produced.

GKLV is an inexpensive, high-quality material for finishing rooms with an unstable microclimate. To finish surfaces in a room with an unstable microclimate, appropriate materials should be used. One of them is moisture-resistant drywall, which differs significantly from its standard counterpart. The popularity of gypsum boards is easily explained - plasterboard itself is considered an inexpensive and high-quality material that craftsmen would like to use in various types of premises. With the advent of the GKLV, this opportunity appeared to them.

Despite the well-known versatility of drywall, there are still certain restrictions on its use. This fact required manufacturers to produce a new moisture-resistant material that could be installed not only in kitchens, but even in the bathroom. The presence of demand for a similar product led the Knauf company to release it.

Drywall can be called one of the most practical finishing materials of our time. Due to the speed and ease of installation, it quickly gained popularity among consumers, but due to its lack of moisture resistance, it could not be used in bathrooms, basements and other similar rooms for a long time.

This significant drawback was solved with the advent of special moisture-resistant drywall (GKLV). Now it can be easily purchased at the Komfort Bud store, but many still wonder: is it possible to impart moisture-resistant characteristics to ordinary drywall and, if so, how? In this article, you can find the answer.

The secret of moisture-resistant drywall

First of all, it is worth noting that branded gypsum plasterboard is endowed with moisture-resistant properties not only due to its external processing, but also internal:

Special reinforcing additives, as well as antifungal and hydrophobic components, are mixed with its main filler - gypsum. Double sheets.

Any building material has subtypes that differ from each other due to the presence of certain properties. Moisture-resistant plasterboard is often used in cladding walls, ceilings, creating arches and other works.

Material properties

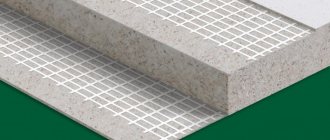

Gypsum plasterboard GOST 6266-97 is a building material that consists of several layers. In the middle there is a layer of gypsum, which is located between two cardboard sheets. In order to give the material greater strength, material reinforcement is used. The process is performed with fiberglass, metal mesh or other reinforcements.

Photo - moisture-resistant drywall

The main feature of the moisture-resistant material GKLV is that it can be used in conditions of variable microclimate. A non-moisture-resistant material, like a sponge, absorbs moisture, while a moisture-resistant material has high hydrophobic characteristics.

Before choosing the one you need.

There is a lot of information about drywall and it is difficult to tell about everything in one article, so this article will describe technical aspects and give practical advice on its use, cutting, storing and other important details. You can learn everything regarding the history of the origin of this material, its characteristics and its production from the article: “History of the appearance, production and characteristics of plasterboard sheets”

Now let's get down to business. In Ukraine, and not only, plasterboard of the main types is used. There are only six of them:

Ordinary wall plasterboard, this is what is meant when they say “standard sheet”. Ceiling plasterboard, which is most actively used for leveling simple ceilings and installing multi-level ones. Moisture-resistant plasterboard is simply irreplaceable when covering bathrooms. Fire-resistant drywall - its peculiarity is that it can resist being opened longer than others.

Tips for working with drywall

Everyone knows the saying: “repair is worse than a flood.” If you want to change the appearance of your apartment, but at the same time do not want to turn this into a problem that takes a lot of time, nerves, money and effort, then the easiest choice would be to work with drywall. A professional builder can create what is called a “masterpiece from plasterboard, but a beginner can independently transform his apartment using this material. And in order for the work to proceed smoothly, you can prepare in advance by studying some of the questions that arise for everyone for whom finishing with plasterboard is their first experience.

How to choose the right plasterboard?

Stacks of sheets of moisture-resistant plasterboard Knauf 12 mm

By type, all drywall is divided into ordinary, moisture-resistant, fire-resistant and fire-moisture-resistant. Drywall consists of 2 layers of cardboard and a layer of gypsum mixture. The composition of moisture-resistant and fire-resistant plasterboard includes special ones.

Drywall is a construction and finishing material that is very popular among craftsmen. It has found its application in the finishing of residential and non-residential premises.

GKLV is an environmentally friendly material, it is not afraid of moisture (unless it is flooding) and does not emit substances harmful to health. It consists of two layers of cardboard, between which is plaster. Unlike simple drywall, in the process of making moisture-resistant, additives are used that keep moisture from penetrating deep into the sheet, and impregnated cardboard.

Sheets with moisture protection in green shades

What is impregnated impregnation?

For such impregnation, polymer dispersions are used. They do not cause harm to humans. Impregnation is needed to prevent the rapid penetration of moisture into the material. As a result, a balance of humidity is formed outside and...

How to make standard drywall moisture resistant?

The desire to use the remainder of the wall plasterboard to decorate the kitchen, bathroom or basement can be realized by additional processing. The working properties of the resulting material and its resistance to high humidity have been questioned by many experts. How to make drywall partially or completely moisture resistant and how will the new material meet the stated requirements? Our experts will share their doubts.

Priming and waterproofing standard panels

Painting both sides of standard drywall with oil paint

First of all, let us remember that the water-repellent properties of branded moisture-resistant plasterboard are characteristic not only of the cover of the material, but also of its gypsum filler. The material is not only a successful combination of positive properties: cardboard, gypsum, and modifying additives.

Otherwise, drywall has undeniable advantages over other materials. It is safe for health, easy to install, affordable, does not require special care and makes it possible to implement any design solutions. For example, using moisture-resistant plasterboard of small thickness, you can decorate the bathroom with an interesting designer ceiling with marine-themed elements (waves). For maximum effect, it is recommended to use moisture-resistant plasterboard only in well-ventilated and ventilated areas.

In addition, you should pay attention to the labeling. Sheets are divided into two groups depending on the number of surface defects (A or B). It is known that the smoother the surface, the better the surface layer (putty) will adhere to it. Consequently, a similar design (type A) will be more durable, although less affordable.

The first option is thinner sheets (usually 9.5 mm ) and is used for finishing ceilings. Wall is the most commonly used option, which is used for cladding walls, constructing partitions, finishing slopes, niches, etc. Waterproof plasterboard consists of a gypsum core with hydrophobic additives and two layers of cardboard treated with special compounds. These components perform the functions of protection against moisture and fungus formation and may differ in their formulation depending on the manufacturer.

- Environmental friendliness. The substance is completely safe for humans, as it consists of pure components.

- Resistance to moisture and high temperatures. The sheets can be mounted both in the living room and in the bathroom.

- Easy to install. Working with drywall can be done even by beginners, as it is easy to cut and attach.

- Low cost.

- The surface can be covered with various materials, which makes the product universal.

Moisture-resistant and regular drywall have a lot in common. But at the same time, their technical properties and purpose may differ radically. You can distinguish moisture-resistant types by some product features: The main document regulating its production in the Russian Federation is GOST 6266-97.

For the convenience of the reader, I will present here the key requirements of the standard. After all, installation of moisture-resistant drywall is carried out on surfaces of different sizes. Therefore, it is advisable to calculate in advance the required number of sheets of different sizes to reduce waste. Drywall (gypsum board, i.e. plasterboard sheet) is an environmentally friendly material. A standard sheet of drywall is a “core” consisting of natural gypsum, covered on all sides with cardboard.

In gypsum plasterboard, 93% is gypsum, 6% is cardboard. The remaining one percent is starch and organic surfactant. Externally, GKLV and GKL differ from each other in the color of the cardboard surfaces.

Regular plasterboard sheets are gray in color, while moisture-resistant ones are green, which meets international requirements.

GKL or GVL, which is better: differences, what is the difference, what to choose?

Gypsum-based building materials are widely used by owners for comfortable furnishing of apartments. Gypsum fiber sheets (GVL) and plasterboard (GKL) are popular solutions that are used in construction and repair. We invite you to conduct a comparative analysis of these materials, which will allow you to understand the difference between them and determine whose set of properties - gypsum fiber board or gypsum plasterboard - is more preferable.

GKL - plasterboard sheets - do not need unnecessary popularization. This is a material that is one of the most in demand in repair and construction work. Its structure is:

Material advantages

Before purchasing GC sheets, you need to familiarize yourself with the pros and cons of the material:

- Thermal insulation. A leveled surface with material saves on heating costs. This is especially true if insulation is laid under the gypsum board.

- Flexibility. Drywall bends under a certain radius, this allows you to make decorative elements.

- Fire resistance. If a room catches fire, only the top layer that is not covered with a gypsum board finish will burn out - the gypsum does not burn.

- There are certain types of material used in the kitchen, bathroom, and balcony.

- When leveling the wall with material, communications, wiring and other cables are carried out behind the sheets.

With all the advantages of gypsum boards, there are disadvantages:

- fragility of the material. It breaks and crumbles, so installation work is carried out with caution;

- if you install the usual gray color in the kitchen or bathroom, it will absorb a lot of moisture and subsequently become deformed;

- before installing gypsum board on the surface, it is necessary to determine how thick it should be and whether the wall will be weighted;

The listed advantages show that the use of plasterboard is beneficial for leveling surfaces and creating other surfaces.

Before answering the question, it is necessary to list the external factors influencing the future design.

Gyproc Aqua Strong 2500x1200x15 mm - for the boiler room

This is the best fire-resistant plasterboard for arranging the walls of a boiler room, which will simultaneously give the surface insulating properties and protect it in the event of an open fire.

This material is produced in a light green cardboard covering. It has special strength to loads with an index of 870N. A slight bevel on the edge makes it easier to seal the joint without wasting putty.

Pros:

- does not support combustion and also retains its structure when exposed to direct fire;

- resists water and does not become covered with fungus;

- reliably protects the room from cooling due to low thermal conductivity of 0.21 W/(m*C);

- due to its high thickness of 15 mm, it insulates well from extraneous noise, which will not reach the living rooms from the boiler room (crackling firewood, popping noises);

- density 767 kg/m3 ensures resistance to mechanical damage to the surface.

Minuses:

- the cost is one of the highest - 470 rubles per sheet;

- weight 34.5 kg;

- does not bend well - a radius of 3500 mm is required in a dry state.

Minuses:

Material properties

Gypsum plasterboard GOST 6266-97 is a building material that consists of several layers. In the middle there is a layer of gypsum, which is located between two cardboard sheets. In order to give the material greater strength, material reinforcement is used. The process is performed with fiberglass, metal mesh or other reinforcements.

Photo - moisture-resistant drywall

The main feature of the moisture-resistant material GKLV is that it can be used in conditions of variable microclimate. A non-moisture-resistant material, like a sponge, absorbs moisture, while a moisture-resistant material has high hydrophobic characteristics.

Before choosing the desired plasterboard material, you need to study its parameters in detail. Technical characteristics of moisture-resistant plasterboard:

- The color of the sheets is most often light green - this is necessary so that you can visually distinguish ordinary cardboard from moisture-resistant one. Some companies also make it in pink;

- The gypsum layer is impregnated with special agents that provide water-repellent properties. All materials used for this are completely safe for human health;

- The cardboard manufacturing technology provides protection against mold and fungi, so the coating can be used even in basements;

- The material is used to cover the walls and ceilings of rooms with high levels of humidity;

- In addition, moisture-resistant cardboard is also fire-resistant;

- The dimensions of the drywall may depend on your needs. You can order sheets of any length and width, while the thickness remains constant. The minimum indicator is 7 mm, and the maximum is 24;

- Moisture-resistant Knauf plasterboard, the thickness of which is 12 mm or more, can be laid in an unheated room: in the bathroom, kitchen, country house or even outside.

It is worth noting that the fire-resistant and hydrophobic material is quite flexible. It can be used to decorate any premises, create shaped elements, niches, etc. It can be bent as needed without it breaking.

Photo - types of drywall

It is also necessary to distinguish between the types of drywall material. The easiest way to classify them by eye is by color; this is the classic marking:

- Fireproof material – red or gray;

- Moisture resistant – pink or green;

- Regular – gray or white.

In some cases, colors may vary depending on the manufacturer. The letter designation of the material is also used: GKL (plasterboard sheets), GKLV (moisture-resistant), GKLO (fire-resistant).

Video: how to choose drywall

- Surface preparation;

- Installation of the frame or application of adhesive;

- Finishing work.

Material markings and dimensions

This type of cladding allows you to create a wide variety of geometric designs

According to GOST 6266-97, moisture-resistant plasterboard sheets are divided into two groups according to the number of permissible defects per certain length - “A” and “B”. Of course, it is better to purchase gypsum plasterboard of group “A”; this cladding is of better quality, but is slightly more expensive.

Many buyers ask the question - how to distinguish moisture-resistant gypsum plasterboard from regular one? Of course, you need to study the technical documentation. But you can also determine by coloring which gypsum board is resistant to moisture.

Moisture-resistant wall plasterboard is always painted green or light green; some manufacturers offer plasterboard painted pink. It depends on the manufacturer.

Moisture-resistant plasterboard sheets are marked with the following abbreviations:

- GKLV is a moisture-resistant finishing option used in rooms with high air humidity, provided with an exhaust ventilation system;

- GKLVO is a finishing material that is resistant to high humidity and has increased resistance to open flame.

Sheet sizes depend on the surface being coated

Facing gypsum board is available in the following standard sizes:

- Length from 2000 mm to 4000 mm in increments of 50 millimeters;

- Width – 600 and 1200 millimeters;

- The thickness of moisture-resistant gypsum board depends on the manufacturer and can have the following dimensions - 6.5 - 8.0 - 12.5 - 14.0 - 16.0 - 18.0 - 29.0 - 24.0 millimeters. It is worth noting that the optimal thickness of gypsum plasterboard for finishing residential premises is 12 mm and above;

- Also, in agreement with the customer, the manufacturer can form the cladding of the required size, for example, small-format plasterboard. This type of gypsum board is very often used for finishing small bathrooms and bathrooms.

Cladding with tiles on a gypsum plasterboard box

Important. Before purchasing finishing materials, you need to calculate in advance the consumption of finishing and the dimensions of the surfaces to be coated. This will help reduce the cost of repairs.

After all, installation of moisture-resistant drywall is carried out on surfaces of different sizes. Therefore, it is advisable to calculate in advance the required number of sheets of different sizes to reduce waste.

For example, the Leroy Merlin supermarket offers a wide selection of finishing materials of all sizes, so you can always choose the ones you need.

- Length from 2000 mm to 4000 mm in increments of 50 millimeters;

- Width – 600 and 1200 millimeters;

- The thickness of moisture-resistant gypsum board depends on the manufacturer and can have the following dimensions - 6.5 - 8.0 - 12.5 - 14.0 - 16.0 - 18.0 - 29.0 - 24.0 millimeters. It is worth noting that the optimal thickness of gypsum plasterboard for finishing residential premises is 12 mm and above;

- Also, in agreement with the customer, the manufacturer can form the cladding of the required size, for example, small-format plasterboard. This type of gypsum board is very often used for finishing small bathrooms and bathrooms.

Differences between gypsum fiber and drywall

Unlike drywall, gypsum fiber does not have a layered structure. GVL is a mixture of cellulose fibers and gypsum, which is then pressed. To obtain a smooth and even surface, after pressing the material is cut and ground.

Any gypsum fiber has high fire resistance, since the structure of the gypsum fiber board itself prevents ignition.

Gypsum fiber sheets can be of two types :

- ordinary GVL

- moisture resistant GVL.

Both are gray with blue markings. The type - regular or moisture resistant - is indicated on the back of the product. The dimensions are also indicated there.

Any gypsum fiber has high fire resistance, since the structure of the gypsum fiber board itself prevents ignition.

Moisture-resistant plasterboard for the bathroom: types and characteristics

UK (AK) is a thinned edge that tapers towards the edge from the outside of the sheet. The joints between the sheets are covered with serpyanka and puttied. Thus, to process cardboard, impregnated impregnation, which is a polymer dispersion, is used. It not only prevents the rapid absorption of moisture into the material , but also ensures its release from inside the drywall. A – group for size accuracy.

There are only two groups of drywall - A and B, where A is a sample with high-precision dimensions. If we consider the sizes of specific brands, then the parameters may differ slightly and have narrower or wider standards. For example, you can take popular samples from foreign and domestic manufacturers - “Knauf and Volma” . PLUK (HRAK) is a semicircular edge that is thinned from the outside of the drywall. The joints are covered with mesh and putty.

It must be said that in the above list the rules for sealing seams are mostly theoretical, whereas in practice it is better to follow other instructions. But this will be mentioned below.

What is the difference between moisture-resistant drywall and regular drywall?

The Knauf company produces plasterboard sheets of all common dimensions, so for any purpose you can find a suitable material among the product line. If necessary, Knauf can be easily processed and brought to the desired size. Important. Before purchasing finishing materials, you need to calculate in advance the consumption of finishing and the dimensions of the surfaces to be coated. This will help reduce the cost of repairs. Important.

Moisture-resistant plasterboard sheet is used for finishing rooms with high humidity, which are provided with constant exhaust ventilation. The manufacturer guarantees moisture resistance when protecting the surface with waterproof primers or moisture-resistant polyvinyl chloride coatings.

- GKLV is a moisture-resistant finishing option used in rooms with high air humidity, provided with an exhaust ventilation system;

- GKLVO is a finishing material that is resistant to high humidity and has increased resistance to open flame.

The greatest demand in Russia is GKLV from the German company Knauf. KNAUF plasterboard has some features that set it apart from its competitors.

How to make moisture resistant from ordinary drywall?

To make regular plasterboard more resistant to moisture, it should be treated with special compounds, which include:

- Deep penetration primer. Apply the first layer, preferably several times.

- Antifungal and anti-mold solutions.

- Water-repellent paint. Necessary if the surface will not be finished with ceramic tiles.

- Also, instead of a primer, you can use a water repellent, which will serve as both a primer and waterproofing. The sheets are processed on both sides using a brush or roller.

It is worth saying that all these procedures, although they will improve the moisture-resistant qualities of drywall, will not make it absolutely identical to factory-produced plasterboard. In terms of performance characteristics and service life, homemade material will be significantly inferior to its branded counterpart.

Therefore, it is best to use real moisture-resistant sheets whenever possible.

Is drywall moisture resistant?

If we consider the sizes of specific brands, then the parameters may differ slightly and have narrower or wider standards. For example, you can take popular samples of foreign and domestic manufacturers - “Knauf and Volma”

. It is visually very easy to distinguish moisture-resistant material from non-moisture-resistant material - gypsum board sheets are green, and ordinary drywall is gray. The information on the packaging (labeling) will also tell you about the features.

The difference is also noticeable in price - moisture-resistant materials will cost more than usual. All these measures of additional protection for plasterboard sheets will work effectively only if a high-quality ventilation system is installed in the room. If this is not possible, it is not recommended to use drywall in a damp room. Natural ventilation will not cope with the task of airing. The finishing material must meet the requirements of the state standard, according to which VLGK has the following characteristics.

In the bathroom, kitchen, glazed balcony - in all rooms with inherent dampness, moisture-resistant plasterboard is provided (its price is slightly higher than usual). With the availability of the material, a number of advantages of its use have appeared: no plastering process; the ability to hide communications and defects in load-bearing walls and ceilings; the emergence of new design solutions and the ease of their implementation (columns, niches, figured ceilings).

Features of use

Before upholstering a bathroom, you need to remember one fact: even the highest quality material does not have a moisture resistance higher than 80-85%. Therefore, treating with moisture-resistant paint or laying tiles on the surface of the sheet will not be superfluous.

Otherwise, drywall has undeniable advantages over other materials. It is safe for health, easy to install, affordable, does not require special care and makes it possible to implement any design solutions. For example, using moisture-resistant plasterboard of small thickness, you can decorate the bathroom with an interesting designer ceiling with marine-themed elements (waves).

In addition to moisture-resistant and fire-resistant sheets, builders often use gypsum fiber sheets. In terms of its characteristics, it surpasses standard materials due to its special structure. Gypsum fiber can also be moisture resistant, while it has high mechanical strength and thermal insulation, and does not crumble when cut. Therefore, it is advisable to level the walls using gypsum boards, but for creating shaped elements and arches, gypsum boards are the best option.

Back to contents↑

Drywall moisture resistant

Modern gypsum board is produced in the form of rectangular sheets, which consist of a gypsum core covered on both sides with cardboard. On the front part they are painted green, which distinguishes them externally from other types of gypsum boards. There is also another type of drywall - moisture- and fire-resistant. In addition to being resistant to high humidity, it also has higher fire resistance and is able to withstand the effects of open flames longer (within 35-40 minutes) compared to other types of material. It should not be forgotten that waterproof plasterboard, despite all its positive qualities, it is made on the basis of gypsum, and with prolonged contact with moisture it will gradually deteriorate.

This can only be prevented by limiting the direct effect of moisture on the material using additional finishing with tiles, vinyl wallpaper, moisture-resistant paint, etc. GKLV is produced in several types according to purpose, types of edges and dimensions. The standard size of moisture-resistant plasterboard is 2500x1200 mm (length and width). Such products are the most popular among both ordinary consumers and experienced builders.

This is due to their ease of use and the minimum number of seams that are formed during installation between adjacent sheets. There is a lot of controversy regarding the possibility and feasibility of using plasterboard sheets for finishing rooms with high levels of humidity. Some home craftsmen even manage to use ordinary plasterboard to level walls in kitchens and bathrooms.

However, this is fundamentally wrong and the service life of such structures will definitely not please you. The optimal solution for rough finishing work in conditions of unstable temperature and humidity conditions is moisture-resistant plasterboard (GKLV).

How to treat the surface → Room decoration → How to choose the right paint → Surface treatment technologies → Leveling and finishing the walls → Selecting and applying a primer → Removal from the surface → Stretch ceilings and technologies → Reviews and testimonials

Properties and installation features of moisture-resistant plasterboard

Bathroom tiled with moisture-resistant plasterboard

Since the use of moisture-resistant plasterboard most often takes place in bathrooms, bathrooms and kitchens, it has the following properties:

- Environmental safety. The manufacturer must indicate in the technical documentation that no chemical components harmful to human health were used during the production process;

- Manufacturers are constantly improving production technologies and introducing know-how, solving the problem of how to make drywall one hundred percent moisture resistant. But so far, unfortunately, the moisture resistance of this type of finish does not exceed eighty-five percent;

Kitchen tiling

Important. Even if you trust trusted large manufacturers, it is advisable to additionally treat the cladding with water-repellent paint or a special water-resistant plaster mixture.

Is it possible to glue tiles to this type of finish? Of course yes. This will additionally protect the cladding from dampness and mold.

- Has high strength and wear resistance;

- The cladding is easy to install and can easily be done by hand;

- The material makes it possible to create structures of various shapes;

- The smooth surface allows you to decorate the finish with a variety of finishing materials;

- Increases heat and sound insulation in the room;

- Since this finishing material is able to “breathe,” this creates a favorable microclimate in the living space.

Related article: Country cabins: a great idea for a garden house

On our website you can see photo and video materials on the design of bathrooms, toilets and kitchens using moisture-resistant gypsum board, made in different stylistic solutions. We hope that viewing will help you make the right choice.

- Which side to mount drywall