Drywall is moisture resistant from 2.5 to 3 meters. Manufacturer's warranty! Low prices! Delivery in Moscow and Moscow Region. Pickup on the day of order.

Not available

Drywall 2 meter gypsum board 2000x1200x12.5mm

190 ₽

Price for 1 sheet = 190 RUB From 104 pcs = 180 RUB From 936 pcs (truck) = 170 RUB 1 sheet - 2.4 m2 / 21 kg Pallet - 52 pcs / 1120 kg In stock - 764 pcs

More details

Plasterboard ceiling gypsum board 2500x1200x9.5mm

250 ₽

Price for 1 sheet = 250 RUB From 132 pcs = 245 RUB 1 sheet - 3 m2 / 21 kg Pallet - 66 pcs / 1380 kg In stock - 528 pcs

Buy on the website with delivery

Wall plasterboard gypsum board 2500x1200x12.5mm

280 ₽

Price for 1 sheet = 280 RUB From 104 pcs = 275 RUB 1 sheet - 3 m2 / 26 kg Pallet - 52 pcs / 1420 kg In stock - 1280 pcs

Buy on the website with delivery

Drywall 3 meter gypsum board 3000x1200x12.5mm

345 ₽

Price for 1 sheet = 345 RUB From 104 pcs = 340 RUB 1 sheet - 3.6 m2 / 33 kg Pallet - 52 pcs / 1800 kg In stock - 480 pcs

Buy on the website with delivery

Moisture-resistant plasterboard “MAGMA” (GKLV-9.5) 2500x1200x9.5 mm

380 ₽

Price per sheet = 380 RUR Price from 132 pcs = 375 RUR 330 pcs available in stock

Buy on the website with delivery

Moisture-resistant plasterboard “MAGMA” (GKLV-12.5) 2500x1200x12.5 (3 m2)

400 ₽

Price per sheet - 400 RUR Price from 104 pcs - 395 RUR Available in stock 624 pcs

Buy on the website with delivery

Moisture-resistant plasterboard sheet 3 meters “MAGMA” (GKLV 3-m) 3000x1200x12.5 (3.6 m2)

475 ₽

Price per sheet - 475 RUR Price from 104 pcs - 470 RUR Available in stock 364 pcs

Buy on the website with delivery

Fire-resistant drywall GKLO-12.5 MAGMA 2500x1200x12.5mm (3m2)

420 ₽

Price per sheet - 420 RUR Price from 104 pcs -415 RUR In a pallet 52 pcs (1500 kg)

Buy on the website with delivery

Only a few experts recommend the use of plasterboard in bathroom decoration. But moisture-resistant sheets are an exception, since they are characterized by numerous advantages and are not susceptible to moisture. They are easy and quick to install and are suitable for subsequent tiling and painting.

Moisture-resistant plasterboard is a building material that can be used for various purposes at high humidity (for leveling surfaces, constructing arches, walls or partitions). GKLV is treated with a special composition that serves as protection against moisture and water penetration. Our company sells plasterboard in the form of sheets with standard sizes, which allows you to calculate the required volume before carrying out repairs or construction.

Based on the level of quality, GKLV can be labeled A or B. The material is produced in many companies, the most popular of which are some manufacturers (Knauf, Gyproc and MAGMA). The cost of the product is slightly higher than the price of standard drywall, but its quality will be much higher. The sheets have a green or blue tint, but may have other markings.

The material consists of gypsum (93%) and cardboard (6%), the rest of the volume is occupied by moisture, starch and surfactants. Moisture-resistant sheets are pliable and, when wet, can take on a semicircular shape. Drywall is fastened to the sheathing (metal profiles) or using mastic.

Depending on the thickness of the moisture-resistant drywall, its use also differs. For example, for finishing the ceiling and walls, sheets with a thickness of 9.5 and 12.5 mm are used, and if it is necessary to change the shape of structures, arched material with a thickness of 6.5 mm is used.

The main characteristics of moisture-resistant drywall include:

- width 120 cm;

- thickness 9.5 and 12.5 mm;

- length (from 2 to 3 m).

The moisture-resistant plasterboard we offer from the manufacturer complies with GOST 6266–97 and has straight, thinned and semicircular edges. The material is treated with antifungal, waterproof and impregnated substances, which ensures high resistance in high humidity conditions.

To protect moisture-resistant drywall, it is advisable to use special water-repellent paints and primers. This task is successfully accomplished by moisture-proof films, PVC and ceramic tiles laid on top. As a result, over a certain time, the sheets absorb only 10% of moisture (compared to conventional material).

Characteristics

The main feature is to withstand exposure to fire and high temperatures for a certain period of time. For comparison, a plasterboard wall sheet is able to “ignore flames for 20 minutes, after which the structure of the sheet is destroyed. High temperatures also do not add strength, gradually reducing all properties. A fire-resistant sheet of material has a fire resistance limit of 40–45 minutes; the structure of the material is not damaged due to its characteristics. And such drywall is also not damaged under the influence of high temperature.

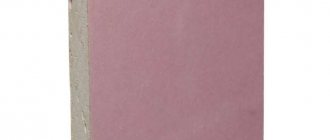

This is what sheets of fire-resistant plasterboard look like

To distinguish fire-resistant samples from wall and moisture-resistant analogues, you need to know some technical characteristics. The description is as follows.

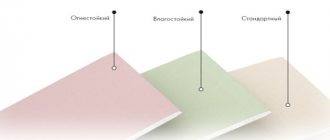

- marking on the sheet: red or pink outer cardboard (wall - white/gray, moisture-resistant - green);

- GKLO dimensions: length 2500 mm, width 1250 mm; Dimensions of fire-resistant plasterboard sheet

- thickness is only 12.5 mm, fire-resistant sheet cannot have other sizes and thickness;

- weight approximately 25 kg;

- gypsum filler + reinforcing fiber 3 – 30 mm long.

With these characteristics, such drywall is able to “breathe and is environmentally friendly.

Example of quality

An excellent example of the quality of such sheets is fire-resistant plasterboard “Knauf”. The Knauf company produces finishing materials, including those that are fire resistant. All products of this company have a quality certificate that meets the norms and rules of construction in terms of their properties. Knauf drywall has some of its own characteristics. In terms of size, this is a standard sheet with the same parameters.

The outer shell is a two-layer cardboard, a layer between the two shells, the so-called “gypsum dough”, to which reinforcing elements are added. The Knauf plasterboard has a semicircular edge, which is covered by rolled cardboard of the outer face layer.

Cardboard, a sheet from the Knauf company, performs the function of reinforcement, and can be used as a basis for further finishing with plaster. The gypsum filler and the outer layer are connected with a special glue.

There must be a “fire-resistant marking, GSP - DF and additional designations of the standard, type of edge, size. In addition, there are quality certificates. Watch a video about testing fire-resistant drywall.

Areas of use

When finishing walls with plasterboard, it is not advisable to purchase fire retardant. GKLO is more expensive in cost, and its area of use is more highly specialized. Heat-resistant material is used in rooms where fire protection is more important.

- air ducts are assembled from fireproof gypsum board;

- creation and finishing of ventilation shafts;

- assembly of various non-flammable plasterboard boxes where the wiring is located;

- creation and decoration of fireplaces;

- partitions with increased fire protection.

It can be used in the assembly of structures and other purposes where a heat-resistant option is needed, and a wall or moisture-resistant analogue is not suitable.

Sheets of fire-resistant plasterboard GKLO However, the specific fire-retardant area of use accordingly also implies the technique of working with fire-resistant plasterboard sheets.

Installation features

It is important to know that fire-resistant plasterboard samples are used only on frame structures made of metal profiles. Under no circumstances should wooden slats be used. This nuance is especially important when using drywall to create a fireplace. Despite the strength and fire-resistant properties of such drywall, there are a number of rules for its installation and assembly of structures.

- A prerequisite is to attach fire-resistant gypsum boards only to a metal frame.

- Fastening screws for plasterboard products are used with a length of 20–25 mm. But the attachment points are located much more often, no more than 120 mm (compared to the usual step of 250–300 mm).

- Foam plastic cannot be used as a heat insulator; if you need to make thermal insulation for drywall, use a non-flammable mineral insulator that does not ignite or smolder. Most often, foil insulation samples are used. Thermal insulation is laid between the frame posts, after which the plasterboard is sheathed.

- At the corner joints of plasterboard structures, installation must be done using an aluminum or steel perforated corner (not plastic!).

- If fire-resistant plasterboard is used in the finishing of wooden buildings, then frame racks and a special reinforced tape are mounted on the wall, and only then the sheet itself.

An example of finishing an attic with fire-resistant plasterboard - The finishing is completed with plasterboard putty. However, if a starting gypsum mixture is quite suitable for rough finishing on fire-resistant plasterboard, then a finishing putty is best suited on a polymer base.

- All decorative types of finishing on fire-resistant plasterboard structures are the same as when using conventional wall analogues of the material.

If you need to build structures with fire protection, you need to carefully select fire-resistant sheets of material.

Be sure to buy drywall with a quality certificate and appropriate markings on the surface indicating its purpose. You should not skimp on finishing in places that require increased fire-resistant qualities. You cannot use waterproof or ordinary wall types, such a plasterboard partition or box can lead to dangerous consequences. Installed structures made of gypsum plasterboard in compliance with the technology will withstand all the indicated impacts and will last the required warranty period.

Humidity is not a problem

This room requires a special finish that is resistant to moisture and temperature changes, and that is why tiling has long been the optimal solution for the bathroom and toilet.

However, the necessary leveling of walls and other components of major repairs is a troublesome, long and expensive process.

But with the invention of the strongest and lightest material made of gypsum, a standard ceiling, as an example of complex, masterly work with plaster and tiles, becomes not the only possible solution.

It was replaced by the quick installation of panels that can withstand tiles, hot fumes, and temperature fluctuations.

It’s not just the ceiling - any element of the load-bearing structure can be made from plasterboard in the bathroom using this universal material.

Moisture-resistant drywall - technical characteristics and sizes

With the advent of drywall, great changes have occurred in the construction and renovation industry. Many “dirty jobs” gradually disappeared by themselves. Sheet material began to be used to decorate the surfaces of premises, thereby creating a flat and smooth surface suitable for further finishing. In addition, it should be noted that drywall has a large number of advantages, which greatly distinguishes it from a wide variety of finishing materials.

Which is better: heated floors or radiators?

Warm floorBatteries

But, as is usually the case, even such a unique building material has some disadvantages. For example, low resistance to humidity. Gypsum, which is the basis of this material, is a hygroscopic substance, so it easily absorbs moisture. And this affects the quality and size of the sheet itself, so it was never used in wet rooms.

But scientific and technological progress does not stand still, and now moisture-resistant drywall is already appearing on the market. The Knauf company was the first to produce it. In principle, this was to be expected, because this company is the leader in the production of gypsum products.

What is the difference between moisture-resistant drywall and regular drywall?

- By appearance, or more precisely, by the color of the cardboard layer. For ordinary plasterboard, the color of the shell is grayish, while for moisture-resistant plasterboard it is greenish. So, when choosing GKLV, you can’t go wrong, that’s for sure.

- By marking. GKL – plasterboard sheets, GKLV – moisture-resistant plasterboard sheets. For information, let’s add one more type - GKLO - fire-resistant plasterboard (how far progress has come).

- According to the degree of processing of the cardboard layer. The moisture-resistant analogue is treated in several layers with various preparations. Which ones exactly? Antifungal, waterproof and impregnated compounds. It is these solutions that provide increased stability when using the material in wet areas.

- By weight. All additional protective compounds add a little weight to moisture-resistant drywall. True, not by much, but still there is such a difference. The approximate discrepancy in the mass of one sheet is two to three kilograms upward.

- Dimensions. Sheet thickness can vary from 6.0 to 22.0 millimeters. But companies mainly produce drywall in two thicknesses: 9 and 12.5 millimeters (other sizes can be ordered). The same applies to the length and thickness of the sheet: length - 2500-4800 millimeters, width 1200-1300 millimeters.

- Price. GKL is cheaper than GKLV.

- All other technical characteristics are identical to conventional gypsum boards.

Types and sizes of moisture-resistant plasterboard sheets

Moisture-resistant drywall is available in two types:

- GKLV - moisture-resistant plasterboard;

- GKLVO - moisture- and fire-resistant plasterboard.

The edges of the sheets are also:

- straight;

- thinned;

- semicircular;

- thinned semicircular;

- rounded.

The edges of the sheets affect the quality of installation and the strength of the structure. The most popular semicircular edges with a thinned edge (PLUK) and thinned edges (UK)

Figure 2. The most popular types of edges.

A semicircular edge with a thinned edge allows you to create a higher quality and stronger seam, filled with putty to a depth of 8 millimeters, up to 11 millimeters wide.

Based on quality, plasterboard sheets are divided into 2 categories:

- Category “A” sheets are used for cladding visible surfaces.

- Sheets of category “B” are cheaper, for performing hidden work.

Moisture-resistant plasterboard sheets are produced in sizes from 600x2000 millimeters to 1200x4000 millimeters.

Thickness - from 6.5 millimeters to 24 millimeters.

Thinner sheets, up to 12.5 millimeters, are used to create multi-level ceilings, arched and shaped elements.

For cladding walls and installing partitions, sheets from 12.5 millimeters are taken.

The sheets are marked with a blue inscription, which includes the most important characteristics:

- view;

- edge type;

- sheet dimensions;

- GOST

Figure 3. Marking of plasterboard sheet.

TOP 3 best products according to customers

Plasterboard sheet Knauf/Knauf moisture resistant 2500x1200x12.5 mm

370.00 rub.

Product code 11

Knauf moisture-resistant is a rectangular material that consists of two layers of special.....

Plasterboard sheet Knauf/Knauf moisture resistant 2500x1200x9.5 mm

360.00 rub.

Product code 9

Knauf moisture-resistant is a rectangular material that consists of two layers of special.....

Plasterboard sheet Knauf/Knauf moisture resistant 3000x1200x12.5 mm

440.00 rub.

Product code 25

Knauf moisture-resistant is a rectangular material that consists of two layers of special.....

What is impregnated impregnation

Everyone understands that antifungal compounds are intended to protect materials from the spread of colonies of microorganisms that unexpectedly appear in damp and poorly ventilated areas. Waterproof solutions are a barrier against the penetration of moisture into the material. But probably not everyone knows what impregnated impregnation is.

Firstly, we note that these are polymer dispersions that do not affect the human body. Secondly, they are designed to protect surfaces from rapid absorption of moisture. That is, a layer of dispersion applied to drywall creates conditions under which the internal moisture of the material does not leave it. There is a peculiar balance of humidity outside and inside the material.

It is very important. Having moisture inside the drywall body will prevent the material from absorbing more than it can accept. In addition, additional protection against moisture penetration is installed.

Important! Comparing the two types (simple and moisture-resistant), we note that the second absorbs moisture only 10% of the volume of moisture absorbed by the first type.

Where is moisture-resistant plasterboard used?

As mentioned above, this type is used in wet areas:

The most surprising thing is that the installation process of the two types is no different. That is, you can use technologies for the frame and glue. The joints of sheets are sealed in the same way using special reinforcing tapes, putty, etc. The only thing that can be noted is the ceramic tiles, which are installed in a moisture-resistant manner.

How to use GKLV

Anyone who constantly works with drywall knows that the light side of the sheet is its front side. The same goes for moisture resistant. But that's not the only distinguishing part.

Usually the chamfers of the panel are taken as a basis. Please note that the edges of the material may have different shapes. What is it for? It is no secret that drywall is sometimes combined with various finishing materials.

So, for each material, a specific sheet with different edges is used. What types of edges are there?

- Rectangular. If this type is chosen, then there is no need to seal the joints.

- Stepped. To seal the seams, you will need both a putty solution and reinforcing tape.

- Rounded. In this case, you can do without reinforcement, just putty.

Note! When sheet material is laid on a surface, its edge shaped part should face outward. This is the law.

Surprisingly, but not unfairly, the moisture-resistant type can be used in places where the usual one is used. But the opposite is not possible. Although, probably, no one will use gypsum plasterboard in the living room or bedroom. It's simply not economical.

Choosing moisture-resistant drywall: 6 main features

When choosing moisture-resistant drywall, you need to pay attention to whether the GOST quality certificate meets the requirements. It is he who guarantees the safety of the material for human health. Such drywall must necessarily have fire-resistant properties. Waterproof gypsum fiber board is suitable for finishing walls in unheated rooms.

The choice of material for finishing indoor surfaces largely depends on the microclimate in the room. Sometimes it can be difficult to choose a material that will not become unusable due to sudden changes in temperature, increase or decrease in humidity levels. One of the materials that is not afraid of water is moisture-resistant drywall.

- The slabs are light green or pink in color.

- The marking is applied to the back of the sheet using blue color.

- When producing sheets, a special impregnation is used, which performs a protective function against the penetration of moisture and fungi into the material.

Hydrophobic drywall is designed specifically for rooms with high humidity. It contains a layer impregnated with water-repellent agents. The material is easy to install.

You can finish the room yourself, after reading the instructions first. The material can be covered with a variety of decorative and finishing materials.

How to choose?

When choosing drywall, you need to look at its markings. Here's what the symbols on the packaging mean:

- A - standard size sheet;

- D - density depends on operating conditions;

- E - vapor permeable (for facade);

- F - fire resistant;

- H - moisture resistant;

- I - increased hardness;

- P - for tiles or plaster;

- R - increased bending strength.

For the manufacture of radius structures, choose flexible sheets with a thickness of 5–6.5 mm. For arches with slight curvature and flat planes, 9.5 mm sheets are suitable. For finishing bathroom walls and a single-level ceiling, the optimal thickness is 12.5 mm. For interior partitions - from 14 mm.

Types of drywall used in finishing

There are many types of drywall depending on the activity and where it will be installed. One of the important details that drywall offers is the presence of tapered edges on the long edges of the drywall sheets. These tapered edges, when joined together, create a shallow recess for the drywall and joint, allowing invisible finished joints to be seen. There are other options, but not as common as the previous ones. There is an ECO board made from recycled material using waste material to create drywall that looks like concrete. It can be made from 20 different by-products, and one of the most important benefits is that it prevents mold and termites due to its composition.

Green gypsum board is also known as moisture resistant drywall. It has a green coating that makes it more resistant to moisture than regular drywall. The cost is slightly more expensive than regular drywall, but keep in mind that it is not waterproof, so do not use it if it will come into contact with water. Also used as a finish in confined wet areas such as bathroom and basement walls, as well as kitchens, laundry and utility rooms. Blueboard drywall is also known as plaster baseboard. Blue board is used for plaster cladding, and the surface of the paper has special absorption qualities. It is waterproof and mildew resistant. Blue board drywall is resistant to dirt, tape and paint and works great in bathrooms or areas with a lot of moisture. In addition, this type helps reduce noise levels and ensures low emissions. Good choice for overall performance. Purple Drywall is an advanced moisture resistant product that offers the same benefits as regular moisture resistant drywall, but with superior moisture and mold characteristics. It can be installed in all wall and ceiling applications and is ideal where increased resistance to moisture and mold is required. If it will be in contact with water, this is the type to use.

Instructions for use

Basic rules for working with gypsum boards:

- Sheets can be secured not only with self-tapping screws, but also with glue. If they begin to bulge during drying, they can be straightened with a rubber hammer.

- There must be a gap of at least 1 mm between the floor and the gypsum board. A small gap should be left between adjacent sheets.

- Thin sheets are not suitable for installing partitions - they are deformed.

- To fold the sheet, mark the fold line with a needle roller, then wet it. Once wet, the material will bend easily.

Scratches on gypsum plasterboard are easily masked with putty. To maintain the strength of the finish, scratches should be covered with reinforcing tape before puttying.

Which side should I attach?

The front side is inside the room, the back side is towards the wall. The front surface is lighter than the back surface, which is also distinguished by the presence of markings.

Can it be used in the bathroom?

Yes. GKLV is an excellent material for finishing walls and ceilings in the bathroom. But there must be a finishing touch (tiles, plastic panels), since moisture-resistant drywall is only resistant to high humidity - it will collapse from direct exposure to water.

Is it possible to glue wallpaper?

Yes. Moisture-resistant plasterboard sheets are suitable for wallpapering, but only after puttying. Otherwise, the wallpaper will be painted in the color of the gypsum board, the joints will protrude, and stains from the markings will appear. Without putty, the wallpaper can only be torn off with a layer of cardboard.

What to cut with?

GKLV can be cut:

- sharp knife;

- jigsaw;

- hacksaw for metal.

Thin sheets can even be cut with a stationery knife.

Moisture-resistant drywall

A standard plasterboard sheet consists of three layers - a layer of gypsum is located in the core, and sheets of durable cardboard cover it on top and bottom. Gypsum is a material prone to crumbling, so cardboard protects it from mechanical destruction. Drywall is a durable and easy-to-use material that can be used, including in wet rooms. What features does moisture-resistant plasterboard have? Such plasterboard is recognized as one of the most versatile finishing materials: leveling walls, ceilings, partitions, arches, architectural elements - all this is within the capabilities of GLKV.

It is not difficult to distinguish the moisture-resistant version of plasterboard boards - according to the accepted standard, they are made in green color, so that there is less chance of confusion. However, both of these materials have low resistance to moisture. Therefore, for a long time, gypsum board was used only in rooms with normal humidity.

With its help, internal partitions and ceilings were made, floors and walls were strengthened. It was believed that it was pointless to use drywall in the kitchen, and especially in the bathroom, since constant contact with moist air and steam would quickly deteriorate the material.

Properties and installation features of moisture-resistant plasterboard

Bathroom tiled with moisture-resistant plasterboard

Since the use of moisture-resistant plasterboard most often takes place in bathrooms, bathrooms and kitchens, it has the following properties:

- Environmental safety. The manufacturer must indicate in the technical documentation that no chemical components harmful to human health were used during the production process;

- Manufacturers are constantly improving production technologies and introducing know-how, solving the problem of how to make drywall one hundred percent moisture resistant. But so far, unfortunately, the moisture resistance of this type of finish does not exceed eighty-five percent;

Kitchen tiling

Important. Even if you trust trusted large manufacturers, it is advisable to additionally treat the cladding with water-repellent paint or a special water-resistant plaster mixture.

Is it possible to glue tiles to this type of finish? Of course yes. This will additionally protect the cladding from dampness and mold.

- Has high strength and wear resistance;

- The cladding is easy to install and can easily be done by hand;

- The material makes it possible to create structures of various shapes;

- The smooth surface allows you to decorate the finish with a variety of finishing materials;

- Increases heat and sound insulation in the room;

- Since this finishing material is able to “breathe,” this creates a favorable microclimate in the living space.

Related article: How to seal a doorway with plasterboard - installation diagram

On our website you can see photo and video materials on the design of bathrooms, toilets and kitchens using moisture-resistant gypsum board, made in different stylistic solutions. We hope that viewing will help you make the right choice.

- Which side to mount drywall

The difference between moisture-resistant drywall and regular drywall

It is worth noting that there are abbreviations similar to GKLV, that is, GVL and GVLV. Despite the fact that these materials are also similar in their composition, there is still a big difference between them, which lies in the manufacturing technology . As for the external differences, ordinary drywall is gray in color, while the moisture-resistant analogue is always green sheets ( see photo above). The choice of material depends on where it will be used.

Moisture-resistant drywall (GKLV) is a material intended for finishing rooms with normal or high humidity. Drywall has long been associated with quick and relatively uncomplicated finishing of surfaces, which results in a perfectly smooth coating. But gypsum is far from a universal material, so in certain conditions the quality of such cladding can be seriously affected. This applies to wet areas. In addition to moisture-resistant and fire-resistant sheets, builders often use gypsum fiber sheets.

In terms of its characteristics, it surpasses standard materials due to its special structure. Gypsum fiber can also be moisture resistant, while it has high mechanical strength and thermal insulation, and does not crumble when cut. Therefore, it is advisable to level the walls using gypsum boards, but for creating shaped elements and arches, gypsum boards are the best option.

Specifications

The differences between GKLV and conventional ones are as follows:

- GKLV has a cardboard layer of greenish color, in contrast to the usual one - gray;

- the weight of one moisture-resistant sheet is heavier than usual due to additives that impart water-repellent properties;

- the outer layer of moisture-resistant sheets is treated with special impregnated, antiseptic and water-repellent impregnations;

- GKLVO has a combination of properties of moisture-resistant and fire-retardant plasterboard;

- flammability group - G1, flammability degree - B2, toxicity level - T1;

- the weight of a standard sheet is about 10 kilograms;

- GKLV and GKLVO are more expensive than conventional plasterboard sheets.

Figure 4. View of the GKLV.

Important! Moisture resistance of moisture-resistant plasterboard is 90% higher than that of conventional plasterboard sheets.

Types of drywall and their purpose

Studying the range of drywall from different brands, you can see that manufacturers are guided by general principles. They are based on the requirements for buildings and mounted structures that currently exist. Most manufacturers produce several main types of plasterboard sheets used in various areas. The most popular of them are gypsum boards and gypsum boards. Read more below.

Important:

The minimum thickness of wall cladding is 12.5 mm.

Smaller thicknesses: 6 and 9 mm are available for arched, curved, radius surfaces. And, if you need to make, for example, a radius partition, then you need to use 9 mm sheets in 2 layers. The common belief that 9 mm gypsum board is needed for ceilings is wrong; for ceilings it is also necessary to use 12.5 mm sheets. This is information provided by the manufacturer, and not by the seller in the store, who is unlikely to practice the use of gypsum plasterboard. The water absorption of gypsum plasterboard does not exceed 10%.

In addition, its core contains special additives that destroy fungi and prevent the formation of mold. Therefore, such sheets can be used for installing partitions, suspended ceilings and cladding the internal surfaces of walls in rooms with high humidity. So, despite the presence of shortcomings, this material has much more advantages, which has ensured its constantly growing demand. Depending on the scope of application and the composition of the gypsum layer, there are different types of plasterboard. Moisture-resistant drywall (VGKL). The cardboard is treated with a water-repellent and anti-fungal treatment, and the core is designed using additives that significantly reduce moisture absorption.

Suitable for wet rooms: bathrooms, kitchens, garages.

What kind of drywall is there?

- construction of interior partitions and false walls;

- installation of suspended ceilings;

- wall covering;

- production of various decorative structures: multi-level ceilings, niches, boxes, arches.

In the form in which we are accustomed to seeing and using (two sheets of cardboard with a layer of gypsum), drywall was patented a little later in the USA by Clarence Utsman. UK - thinned edge. Most often it can be seen on sheets of the manufacturer Gyproc. To seal the seam, it is necessary to use reinforcing tape.

GKLO - used for finishing rooms with a high fire hazard: kitchens, attics, boiler rooms, ventilation shafts. It differs from other types in that special reinforcing components (clay and fiberglass) are added to the gypsum core, which make it maximally insensitive to open flame for up to 55 minutes. The sheets are predominantly pink with red markings.

It turns out that the prototype of the current building material appeared back in 1894. The American Augustine Sackett developed and manufactured the “construction board”. It consisted of 10 layers of paper, greased with plaster and had a thickness of 15 mm.

The meaning of the abbreviation GKLV is a moisture-resistant plasterboard sheet. Like standard plasterboard, this material consists of two layers of durable cardboard and a gypsum layer between them, but all layers are treated with special impregnations that make it waterproof. The longitudinal edge of the plasterboard sheet can be different, for example, less thick than the main sheet, which will allow the joints to be puttied efficiently. A beveled or tapered edge is suitable for finishing, and when installing several layers of plasterboard, it is better to choose a standard straight edge .

The edge type is indicated on the packaging. Plasterboard sheets have been known for a long time and are successfully used for rough finishing. Since gypsum is characterized by low moisture resistance, the material is used mainly in residential areas with normal humidity. But this applies only to ordinary gypsum plasterboard; moisture-resistant plasterboard has improved technical and operational characteristics.

In addition to its main functional purpose, moisture-resistant plasterboard serves as passive fire protection, since it is a non-flammable and flame-retardant material. It is capable of restraining the spread of flame to other building structures within 15-20 minutes. The appearance of plasterboard in the arsenal of building materials has significantly facilitated the work of rough finishing of premises, the construction of structures and partitions, and expanded design possibilities. And the addition of a hydrophobic component to the gypsum layer ensured water resistance and made it possible to take the use of gypsum plasterboard to a new level. Moisture-resistant plasterboard is successfully used in conditions of high humidity when renovating bathrooms, kitchens, basements, balconies and loggias.

Note! You can visually distinguish waterproof plasterboard from standard panels by the green color of the front cardboard layer.

How to treat the surface → Room decoration → How to choose the right paint → Surface treatment technologies → Leveling and finishing the walls → Selecting and applying a primer → Removal from the surface → Stretch ceilings and technologies → Reviews and testimonials

Limitless material possibilities

It’s quite easy to design and implement plasterboard shelves in the bathroom yourself. The reason for this is the design features of industrial drywall, whose one of the most valuable characteristics, which makes it very easy to install, is the presence of beveled edges.

They provide a shallow recess for plasterboard tape and joint compound, allowing them to snap together easily to form invisible finished joints.

In a plastered or painted state, the joints will not be visible to the naked eye.

- When installing plasterboard walls in a bathroom, it is necessary to take into account the weight of the facing material - the load that it can withstand must be respected, otherwise the structure will not last long.

- For example, the decision to choose heavy porcelain tiles must be accompanied by an adequate assessment of the load that it will give to gypsum plasterboard panels, otherwise the collapse of the entire structure is inevitable.

- As for insulation, not many available materials can compare with gypsum plasterboard as insulation.

- It helps maintain the temperature in any room, be it cold or warm air.

- Improved insulation not only makes rooms comfortable to stay in, but also reduces heating costs throughout the year.

Since heaters don't have to work too hard to keep rooms with drywall warm, a DIY drywall bathtub that's made with the technology in mind will also keep whoever's in it from getting hypothermic.

By creating structures of various types and types from gypsum plasterboard, you can significantly save on materials, transform the room, and easily and quickly complete protracted repairs.