MesterulManole

17721 0 4

MesterulManole October 17, 2016Specialization: many years of experience in finishing works of residential and office premises, dachas, country cottages, etc. Hobby: cycling in all its forms

Modest but aesthetically attractive design of an opening in a country house

Greetings. Today you will learn about how to lay window openings from facing bricks. The topic is not easy, since cladding through finishing masonry is carried out by highly qualified specialists. Our task is for you to carefully familiarize yourself with the technology, look at photo reports and get a general idea of how this work is done.

Why are windows framed?

When erecting the walls of the designed building, all masonry work is carried out according to the drawings.

Surely, there will be no disproportions in such a structure, which cannot be said about houses that are built “by eye.” Those who are engaged in construction themselves should keep in mind that the appearance of the facade largely depends on the size and symmetry of the openings, and this is what you need to pay the main attention to

The role of openings in the aesthetics of the facade

The dimensions of windows, the width of the walls between them, the height of the window sill area - all this is regulated by standards. But even if the dimensions of the openings do not correspond to them, there is no big problem in this - any company today will manufacture window blocks according to individual sizes.

The key to the harmony of the facade is that the windows are located symmetrically on the walls and are themselves proportional. To understand what we are talking about, just look at the photo below. In our opinion, the shapes and sizes of the windows here are extremely poor, as well as their location on the wall, which is why the façade is not at all pleasing to the eye.

- In such situations, decorative lining of the opening with brick will only aggravate the dissonance, and the asymmetry will be even more striking. In any case, finishing of openings is carried out not during the process of laying the wall, but after it has already been completely raised to the designed height.

- It happens that the frame of the house was built earlier, and other work, including the design of brick window openings, is carried out after the house has settled. If this is exactly the situation you have, then before you begin this work, you need to check whether the window openings are located symmetrically in the brickwork.

Decorating a house with panels: pros and cons

The appearance of the facade is an important aspect of the design of a residential building.

For this purpose, there are many types of materials, differing in properties, cost and other features. Plastic facade panels are a popular solution for decorating the facade of a residential building. They have a varied appearance and have high technical characteristics.

Externally, PVC does not differ from other panel options

Plastic products differ from metal and other options at a lower cost. In many cases this factor plays an important role. At the same time, PVC panels have the following advantages:

- the light weight of the material allows you to avoid additional load on the foundation and load-bearing elements of the building; the resistance of PVC to precipitation and temperature changes ensures their durability; a variety of colors makes it easy to find a specific option; simple installation is carried out without a large number of fasteners; to clean the panels, just wipe them with a damp cloth; damaged elements can be easily replaced with new ones without completely dismantling the wall cladding.

PVC panels are available in all hardware stores.

When choosing, it is worth considering the disadvantages of the material.

An important property of plastic is that the panels are not sufficiently resistant to ultraviolet radiation. In order to avoid damage to the skin, you need to choose panels with a good protective layer. And it is also worth considering that low-quality elements are more prone to deformation and cracks than thick and durable panels

All about the material, its advantages and types

Thanks to the use of facing bricks, the external defects of the building are hidden. If facade brick is used for old buildings, then it perfectly hides the presence of cracks on the walls of the house that appear due to load. But not only old houses require finishing - the brick facade of a new house looks even more impressive. Previously, many buildings were erected using brick, but now it is customary to use facing bricks specifically as a finishing element for the facade.

Facade bricks are:

Thanks to the use of facing bricks, external defects of the building are hidden

Both are used to decorate the exterior walls of the house and give it a beautiful appearance. The use of clinker is necessary for houses that are made using three-layer wall technology. Of course, the expenses for such a facade will be greater, but the benefits will also increase. A favorable microclimate is created inside houses with three-layer walls, and all thanks to the fact that the thermal insulation is distributed as evenly as possible between the load-bearing and outer walls.

The use of clinker bricks has a number of advantages:

- The material has high mechanical strength

- Frost-resistant and non-flammable, and also serves as a barrier to fire

- Not afraid of corrosion and pollution

- A huge selection of clinker facing material allows you to perform a variety of finishes, which allows you to make your house beautiful and attractive

Clinker brick facade

In addition to a large selection of shades, the facing material is also available in black and white. And if you take advantage of this and make the facade of your house from facing bricks of different colors, you can achieve incredible effects and show everyone that you have taste and imagination. The shapes of clinker bricks are varied; they can have rounded edges or chamfered edges. Clinker facing bricks can be perfectly combined with wood, stone and metal, so various combinations of clinker material and other facade elements will give an original appearance.

Nowadays it is customary to use facing bricks as a finishing element for the facade.

Repairing the brick façade is a major challenge. The cause of cracks on the wall can be not only time, but also shrinkage of the house or improper design. Sometimes it is possible to use overlays and metal belts - they strengthen the wall of the house and prevent further destruction.

Important! Outwardly, it can be difficult to understand whether a crack is growing or not. In order to understand this, glue a sheet of paper onto the damaged brick - if after time the sheet remains intact, then the crack does not increase and you can begin to carry out repair work and restoration

When it is impossible or you do not want to use such a finishing element as brick, you can use other options. For example, brick siding will be a cost-effective solution that you can implement yourself. Siding is lightweight, and thanks to this there is no unnecessary load on the house. Siding can be easily processed, and it is applicable for a curtain wall.

Brick siding panels: original and inexpensive facade design

Of all the advantages of using, the following can be highlighted:

- Brick siding is so similar to natural material that from afar it can be very difficult to understand whether a building is built of brick or lined with siding

- The ideal appearance is obtained by making a mold based on a cast of masonry from natural material

- A brick wall requires restoration, and facing siding just needs to be washed with water

- The service life of the finish reaches 30 years or even more - it is not afraid of precipitation and does not fade in the sun

- Light siding panels can be used to cover not only the walls of a house, but also its individual elements.

- A wide selection of colors, along with the lightness and low price of the panel, made it one of the most popular cladding elements

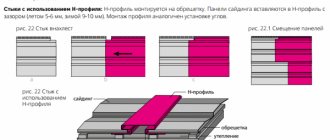

A hinged ventilated facade is used to cover the house with siding. The panels are fastened to the sheathing after the thermal insulation layer is laid. The ability to decorate your home yourself using such panels is a huge advantage. And the fact that this work is clean and dry, unlike “wet” facades, makes it even more pleasing and enticing to do it yourself.

Siding panels imitating brickwork

Construction of an opening using formwork

If the masonry of the window opening is made from blocks and the width of the opening is quite large, lintels are made from boards 4-5 cm thick. Formwork is placed on top and concrete is poured directly at the opening site with mandatory preliminary reinforcement. Usually, for these purposes, 12 reinforcement is used, which must extend onto both sides of the opening. A mortar is laid over the formwork, into which reinforcement bars are embedded. They will be located under the bottom row of brickwork, which will go above the window opening. The ends of the reinforcement should be anchored. After the solution hardens, the formwork is disassembled and a concrete lintel is formed connecting both walls. This way we get the window opening we need. It is also possible to construct a lintel using boards that rest on the walls of the opening by at least 25 cm. The wood must be pre-tarred or treated with a water-repellent solution to avoid the onset of rotting processes. The window opening is laid directly along them; preliminary reinforcement is required. Arched vaults are quite complex in masonry. But they are also arranged using formwork of a certain shape with mandatory reinforcement.

A lot of thermal energy escapes from the room through windows. New buildings currently being built are already equipped with heat-saving windows. Proper installation will help create a warm and comfortable environment in the room. It is necessary to calculate and think about the size and location of window openings in a brick wall in advance. All parameters must be indicated in the design documentation for the house.

Installation of windows in a brick wall should be done very carefully, observing the entire technological process. To carry out the work, it is worth preparing the necessary tools in advance: a container for mixing the solution, a square, a straightening rod, a scraper, a tape measure, a water level, a rule, a jointer, a cord, a plumb line, a hammer and a trowel.

It is not uncommon for a team of builders to begin installing plastic windows in rooms on the ground floors of a building while other workers have not yet finished creating window openings in a brick wall on the top floors. In this situation, it is impossible to reduce or increase the opening by 1 cm.

In order for the window opening to retain heat well, the cladding on the facade must be protruded by a quarter of the brick relative to the main masonry. Therefore, in order not to make a mistake in the dimensions, it is worth knowing the principles of installing plastic windows in the opening of a brick wall.

The window opening is created when the five-row masonry is laid twice. And under the future window, masonry was made with pokes. The opening begins approximately at the 14th row of brickwork. A mason who builds a wall with a window must know all the dimensions indicated in the design documentation. The cladding should begin in such a way that the edges of the opening and the vertical seam of the main wall coincide, or, in extreme cases, fall into the middle of the brick.

The opening should have a width slightly larger than indicated on the drawing. This value cannot be reduced even slightly. To obtain the desired height, the masonry is adjusted by changing the thickness of the seam

between the rows. You can block the opening using a metal corner, 12 cm wide. Its length is selected based on the size of the opening (width + 20 cm), and after sawing it is painted. The corner must be installed strictly level. This is only possible if the entire cladding has horizontal rows.

When constructing cottage buildings, the design specifies windows in the shape of an arch, a semicircle, or even a circle. Cladding with such geometry can only be done by a highly qualified mason. The opening is blocked using a steel corner, concrete lintels and a monolith.

What to do if the brickwork already exists, and a window needs to be installed in this place? Or did you want to organize an additional window between the rooms? You can also make a window opening in existing brickwork. To do this, you will need additional tools: a crowbar, a pick, a marker, a hammer drill, an angle grinder and a jackhammer.

Framing options

Homeowners and professional builders use a variety of window framing options.

Wooden elements

Framing windows on the façade of a building using wooden elements is a very common option today. Their use allows you to decorate windows in a unique Russian style. This method of framing has come down to us since time immemorial and is still very popular.

The disadvantages of such finishing include significant cost, difficulty in manufacturing design elements in the same style, fragility of wood and high requirements for finishing care.

Related article: Window insulation using Swedish technology

Brick

Very convenient material to use. It is most often used in brick buildings, since in this case the framing of the windows of the house can be done directly at the construction stage.

Stone

Decorating window openings with stone is quite a labor-intensive job, which requires the use of a significant number of elements. They can be represented by cornices, platbands, keystones, carved brackets, window and door slopes made of stone, and window sills.

Decorating window openings with stone is quite a labor-intensive job, during which a significant number of elements should be used

Plaster stucco

This option for finishing windows on the facade of a building is very expensive not only in terms of cost, but also in terms of labor intensity at the stage of installation work. In recent years, the popularity of gypsum stucco has declined significantly. It has been replaced by modern and more affordable materials.

Plastic profile panels

A very affordable option in terms of price and installation for finishing windows on a facade made of various materials, including brick, wood and others. The only, but quite noticeable, disadvantage of using profile panels is the low decorative effect of the resulting cladding.

Plastic profile panels are a very affordable option for finishing windows on the facade in terms of price and installation.

Wood-polymer composite

Recently, this material has received close attention. Its undoubted advantages are low cost, simple installation and guaranteed durability.

How to dismantle a window

First you need to get rid of the old window.

To do this, remove the sashes of this window, and then knock out the frame and window frame. You need to carefully inspect the box to find all the fasteners. Most often, the box will be screwed to the walls with long dowels, which must first be removed, after which dismantling the window will be much easier. However, dismantling the window is not difficult in any case. When the old window is dismantled, all surfaces are cleared of old materials and debris. Usually the slopes are covered with paint and a thick layer of plaster. All this must be beaten off with a chisel and hammer or using a hammer drill. Of course, working with a hammer drill will be faster and more convenient.

Material selection

First of all, you need to decide on the material that you want to use for finishing. Very often, in brick houses, windows are also framed with brick of the same or a different color. It’s not difficult to make simple brickwork, and this option will always look simple and stylish. The material is easy to use, beautiful and durable. Framing can be done both during the construction of your home and after its completion.

For a brick house, you can also use stonework around the windows. The decor of window frames with facing stones can be very diverse - sometimes the stone is laid evenly on the frame, and sometimes an interesting design or mosaic is created from several types of stones.

Metal framing looks interesting and is suitable for both modern and traditional home designs. The design of such structures can be extremely diverse. The advantage is their durability, but you need to remember that the metal quickly heats up in the sun and becomes extremely cold in the cold - in some cases this can cause discomfort.

Framing with wood is typical for both brick and wooden houses. You can make both laconic frames and carved versions in the Russian style. At the same time, it is very important to properly treat the wood from moisture and contamination so that the frame really lasts you a long time.

Concrete structures are also quite simple. Concrete can look quite interesting if the structures are covered with plaster and paint. This option looks good in a house with a painted facade, and it is most convenient to make such window framing during the construction stage.

For houses in a classic style, moldings with a wide variety of designs are often used. They are usually made from polyurethane. The molding is usually a white structure that imitates columns or stucco: this option can look very elegant, but it will only be appropriate if the design of the entire house is appropriate.

If you want to save money, you can use siding, plastic structures and even foam. If you choose an artificial material, you need to carefully consider its quality. The advantage is that from artificial materials you can create quite a few options for unusual design framing - this solution is suitable for modern cottages and country-style houses.

Types of bricks

There is a wide range of materials on sale that can be used to make practical and effective brickwork above the window.

- Hyper pressed rounded. The raw material for production is dolomite, limestone, granite and marble chips. The ingredients are mixed with stone dust and moistened. The mixture is placed into molds and then pressed under high pressure. In terms of strength, the finished products occupy a middle position between concrete and natural stone.

- Shaped single hollow. The products are distinguished by a variety of shapes and void configurations. The presence of beveled edges allows you to create a pleasant-looking surface from elements with rounded contours.

- Clinker relief. The material is quite expensive, as it is made from rare types of clay and requires a lot of energy. It has high thermal insulation characteristics. Texture is imparted during the molding process.

- Glazed. The front glossy surface protects the block from moisture and abrasives, as it is highly durable. Various models imitate substances such as wood, stone, fabric. The price is the highest among analogues.

- Sand-lime brick. The most budget material used in cladding. Rarely chosen due to its inconspicuousness and low strength.

When choosing, you should not put price at the forefront. The cladding is done for decades. It should be pleasing to the eye and perform its functions efficiently.

The nuances of facing a house with bricks

Finishing the facade with brick has features that must be taken into account to obtain a high-quality result.

Strengthening the foundation

If you intend to cover a structure that was erected quite a long time ago or is a frame structure, then it is necessary to obtain reliable and durable support for the cladding layer. The fact is that the brick puts a serious load on the building itself and on the area where it is located. In the absence of a strong base, the surface will sag and become deformed. To strengthen the foundation, a solution in the form of a reinforced tape is additionally poured over the entire area of the house.

If there is no space for external brickwork on the main foundation, then it is necessary to install a reinforced concrete frame nearby

Bunch

The lining needs to be securely connected to the main walls; for this purpose, metal mesh, anchors or wire are used. The bottom line is that there must be at least 4 points per 1 m2. The selected material is installed in load-bearing walls and located along the seams of the masonry, while the minimum depth should not be less than 8–9 cm.

When arranging decorative masonry during the construction of walls, the tie is carried out using a mesh; for finished buildings, anchors are used

Creating window openings

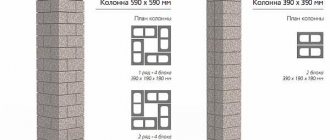

Window openings in brickwork require a very responsible approach. To install them, it is necessary to carry out markings in advance and draw up a layout diagram. That is why most often surfaces are covered in parallel with the construction of load-bearing structures. The laying of window openings is carried out as follows:

- Initially, the main part of the walls is erected according to the chosen method.

- The creation of the opening begins as soon as the height of the areas located nearby is equal to the height of the window. The main thing is to make sure that all openings have a uniform structure.

- The masonry is carried out using the end method; for this purpose, the brick is cut to length. First, the lower section of the opening is laid out, and then the vertical posts.

- The upper part needs strengthening. For this purpose, a metal corner of suitable thickness, treated with a protective anti-corrosion solution, is used.

- The corner is located exactly above the window; one of the corners of the brick is cut off. First, the elements are placed without mortar to ensure the accuracy of their location, and then they are mounted on the composition. The masonry can be made protruding or flush with the main walls. To avoid deformation, the corner is propped up with a wooden strip.

- If it is planned to line the opening without removing it, then the bricks are laid close to the frame with the elements trimmed to the required size.

Of course, if you lack experience, window design may require more time and effort, but the main thing is to install the parts exactly to the level. Doorways are created using a similar principle.

In the absence of experience, it is advisable to check each level of masonry with a template

Preparatory stage

If you decide to decorate your home yourself using brickwork, then you should first carry out a series of preparatory work. You should not neglect them if you want to achieve a good and sustainable result. Make sure that the foundation of the house, as well as its overall structure, is designed for the installation of brickwork. The foundation must be constructed in compliance with all building codes. It must withstand significant loads. Cheap and simple bases will not work in this case.

You should also make sure that the foundation of the house is made of raw materials such as monolithic concrete (concrete blocks are also acceptable). The foundation itself must be sufficiently wide

This requirement is especially important because it is on the foundation structure that the facing brick will rest. In some situations, bricks are placed on special steel corners, which are attached to the base using anchor bolts

In addition, it is allowed to organize an additional foundation if the quality of the main one leaves much to be desired. Another foundation must be poured along the perimeter of the building, retreating about 30 cm from the first foundation.

Next you should pay attention to the roof structure

It is very important to take a closer look at the roof. In most cases, in old houses, the cornice part does not protrude beyond the perimeter of the building by more than 25 cm

With such a structure, the bricks will become endlessly wet and may even be subject to destruction. After about 5 years of such use, the brickwork will become unusable. This problem can be solved in one sure way - you will need to coat the walls of your home every year with a special water-repellent compound, but keep in mind that such products are quite expensive

In most cases, in old houses, the cornice part does not protrude beyond the perimeter of the building by more than 25 cm. With such a structure, the bricks will become endlessly wet and may even be subject to destruction. After about 5 years of such use, the brickwork will become unusable. This problem can be solved in one sure way - you will need to coat the walls of your home every year with a special waterproofing compound, but keep in mind that such products are quite expensive.

If you plan to cover the main wooden walls with brickwork, then before starting work you will need to coat the wooden bases with antiseptic compounds. If you are decorating external walls, then you need to buy the appropriate product for them. For external work, you should not purchase internal impregnations - they will be of little use. In addition, it will be necessary to attach a vapor barrier material to the wooden walls using a construction stapler. These coverings should be laid with an overlap (minimum - 10 cm).

You will also need:

- carefully inspect the surface of the walls of the house, remove all unnecessary parts, such as lanterns, gutters and other similar objects;

- the previous paint layer, peeling elements, and shedding should be removed;

- all noticed defects must be covered with a layer of putty;

- if the damage to the walls is too serious, you will have to completely plaster them;

- In order to install the insulating layer, you need to put a layer of primer, which will be responsible for better adhesion of the wall and the adhesive.

In addition, it will be necessary to properly prepare the solution. A simple cement mixture is hardly suitable here, because facing bricks are resistant to water absorption. This problem is especially acute when it comes to the installation of clinker bricks, which simply require specialized additives to ensure more effective adhesion.

The correct solution consists of the following ingredients:

- cement grade M500 – 1 part;

- sand – 4 parts;

- water.

Some craftsmen add a little clay to the solution to achieve greater plasticity of the composition. However, here the opinions of different masons differ - some see this as only harmful due to the leaching of the clay component from the composition and a decrease in its strength, while others, on the contrary, believe that clay makes the joints of the brickwork more durable. In this matter, each user relies on his own opinion and experience.

Installation algorithm in an already finished wall

The second option for arranging a window opening involves performing work on an existing wall. The workflow looks like this:

- First the marking is done. This stage involves identifying zones for placing jumpers and technological holes. The working stage is carried out using the triangle method, the lintel is marked so that its top is in the lower masonry row;

- Having made such marks, fifteen centimeters are added for each edge of the jumper. This distance is necessary to install supports that secure the lintel made of metal structures or reinforced concrete;

- installation of the support begins. It is necessary to provide a distance of seventy to eighty centimeters between the load-bearing wall and the supporting element;

- as soon as the support is placed, a wooden beam is laid on it, which is necessary to redistribute the load effects;

- a mark is made along the outer surface of the wall corresponding to the placement of the beams;

- in order to place these marks on the inside of the wall, drill holes into which studs are installed, supporting them on each side with supporting elements;

- the next stage is fixing the support. This can be done with ordinary nails, driving them into boards and studs;

- Using a hammer and a sharp chisel, the plaster layer is removed from the surface of the wall. The cleared area should correspond to the size of the future window opening. An additional three centimeters are added on each side;

- Having removed the plaster material, we begin dismantling the brickwork section. It is best to move from the place where the jumper is located, after that all that remains is to install it;

- all protruding bricks are adjusted;

- Having finished installing the jumper, use a grinder to make a cut. This will help to level the edges of the brickwork of the opening area, remove irregularities above the window, and facilitate subsequent processing of the slopes;

- At this stage, the design is completed, it is allowed to proceed with the installation of the window structure.

DIY brickwork: tools, order and features

Now that you have an idea of how to lay bricks with your own hands, you need to talk about the procedure as well as some technical nuances.

Sample list of tools for bricklaying

Let's start with the tool. You will need:

- mason's trowels - apply and level the mortar onto the bricks;

- concrete mixer or container for mixing mortar;

- mortar shovel - for kneading and periodic mixing;

- two or three buckets for the solution;

- plumb line - check the verticality of walls and corners,

- building level - to check the horizontality of the row of masonry;

- cord-mooring - for beating rows;

- jointing (for molding seams);

- hammer-pick for breaking incomplete bricks (halves, 3/4 and checks - 1/4);

- The rule is a flat metal or wooden strip to check the plane of the wall.

Next we will talk about the features of the technology. First: it is advisable to soak the brick before use. This is especially true in hot, dry weather. Then it will “pull” less moisture from the solution. If there is not enough moisture, the cement will not be able to gain the required strength, which will affect the strength of the building.

First, two corners are driven out, then they are connected with several rows of brickwork

Second: the corners are driven out first. First the first two. They are connected with 2-3 rows of bricks according to the chosen masonry pattern. Then the third corner is kicked out. The second and third are also connected in several full rows. Afterwards the fourth corner is placed and the perimeter is closed. This is how walls should be built, going around them around the perimeter, and not pushing walls out one by one. This is one of the most common mistakes.

Third: there are two row control technologies. The first is that nails are inserted into the seams of the corners, to which strings are tied. It needs to be pulled so that it marks the top edge of the brick, and also limits the outer (and, if necessary, inner) surface of the wall.

Procedure for attaching the mooring cord

The second way is to use wooden or metal orders. This is a flat strip or corner on which marks are applied every 77 mm - marks on wood or cuts on metal. They mark the required row thickness: brick height + seam. They are installed using flat mounting brackets that are inserted into the seam. If necessary, they are then simply removed and rearranged higher.

There is another way - a mason's corner. It has a slot on one side, into which there is a solution at an angle.

Breaking out a row using a mason's corner

The disadvantage of this method is the same as just using a nail in the seam: the height of the row must be controlled “manually” when drawing out the corners. If you lack experience (and where can you get it if you are doing bricklaying with your own hands for the first time), this is difficult. Having (having done it yourself) everything is easier.

Fourth: preparation of incomplete bricks. As you have seen, when laying, they use halves, three-quarter bricks and checks - 1/4 parts. To ensure that the work does not slow down, it is necessary to prepare them before starting masonry. This is done using a hammer-pick. When preparing, high precision in size is required, otherwise the dressing will go wrong. To make it easier to control the length, marks of the appropriate length are made on the handle. By placing the pen on the brick, marks are made on both sides of the spoon. Then, placing a pickaxe blade on the mark, they hit the reverse side with a hammer, making notches. Having made notches on both spoons, they break the brick with a strong blow of the pick.

Peculiarities

Exterior window framing is a process that must be approached carefully. Framing is preceded by the installation of the windows themselves - wooden or plastic. If you have never encountered this, it is better to seek help from professionals

It is especially important that the work is carried out by specialists if you have a ventilated facade

Once the windows are installed, you can think about the exterior decor and take into account several nuances.

Modern finishing options are extremely diverse

At the same time, when choosing synthetic options, make sure that the material does not have any foreign odor when heated and does not deform - the quality of the material is important for your health and comfort

Before installing frames made of stone or other heavy materials on the facade of the house, calculate whether the weight of the structure is too large

In rare cases, particularly heavy structures lead to deformation of the walls. Pay attention to the rules for working with different materials and think about whether you will do the finishing yourself. While siding can be easily fixed with your own hands, stone framing will require special knowledge, and the work of specialists can be expensive. Consider what style of framing will suit your home

The finishing should be organically combined with both the exterior of the house and the decorative elements on your site.

Home wall decor

Also, with the help of interfloor molding, we visually reduce the not always proportional height of the house. And the final piece in the set of façade decorations for the walls of a private house is the plinth strip. This element is primarily a logical separator between the basement part of the structure and the main wall. The base profile can also perform technical functions - smoothing out the difference between the protrusions of the wall and the base, drip edge, etc.

Below are several examples of facade decoration on the corner of a house. You can see more ready-made design options for the entire house facade HERE.

Cladding methods

Varieties of finishing design

Laying window openings from facing bricks will not cause any particular difficulties if you initially plan everything correctly, use high-quality tools and materials, and maintain proportions and symmetry.

There are the following methods for lining window openings with brick:

- Chernova. It is used when masonry is carried out by an inexperienced worker, when using stones from an uneven surface or creating a complex figure with gaps. Once the solution has hardened, the structure is finished using decorative plaster.

- Finishing. Assumes precise work with high quality materials. The masonry is carried out with millimeter precision; no additional finishing is required upon completion.

The choice of method is determined by your own abilities and the configuration of the purchased brick.

The main functions of lining window openings with bricks

Facing window openings with brick improves the appearance of the building and adds strength.

Industrial and domestic construction is carried out according to uniform standards, which require the manufacture of window openings of square or rectangular shape. The dimensions are determined by the design strength of the supporting structures. Having received real estate at his disposal, the owner can rebuild and decorate it, but not at the expense of the reliability of the building. Laying bricks around windows is not included in the list of prohibited activities.

The technology has the following functions:

- closing boring-looking gray concrete slopes;

- giving the opening unusualness and originality;

- thermal insulation of the room by laying an additional layer of insulation;

- strengthening the structure.

If you do not touch the load-bearing walls, you can lay out a round, hexagonal or even ellipsoidal window in the brickwork, if the owners like it and it matches the interior. The most important thing here is not to get carried away by originality and maintain the harmony of the facade.

Homemade run

When designing window openings of non-standard sizes, the production of the lintel (its filling) is carried out at the location. To do this you will need to perform the following typical operations:

- first of all, the masonry surfaces on the sides of the window opening are cleaned of mortar residues;

- after this they are thoroughly primed;

- At the final stage of work, formwork is installed at the location of the lintel.

Formwork

Reinforcement

Upon completion of these procedures, a thin layer of pre-prepared concrete mixture is poured into the formwork, after which a reinforcing mesh is immediately placed there. After this, you can continue pouring the lintel, followed by placing another reinforcing fill in the concrete. When dismantling the formwork, it should be taken into account that it is not always possible to dismantle its lower part.

Supports for formwork

Lintel laying

When decorating window openings lined with facing bricks (the so-called facing brickwork), in order to preserve its decorative advantages, it is allowed to use channels (wide metal corners). In this case, the visible part of the purlin will be located only on the inside of the load-bearing wall.

Laying a figured window opening

At the same time, there should not be any noticeable traces of the presence of a lintel on its façade surface.

Bookmark methods

In practice, there are two ways to lay a window, suggesting a hollow and blind option. In the first case, it is laid with bricks in two rows. First, the outer row is laid, after which the constructed partition is insulated with polystyrene foam or mineral wool. After this, the laying of the inner row is done.

Thanks to the insulation through such a partition, heat loss will be significantly reduced and sound insulation will significantly increase.

When the opening is solidly filled with foam concrete or brick, such material forms a continuous monolithic partition corresponding to the thickness of the wall. When carrying out masonry, it is recommended to regularly check the verticality of the surface using a level and plumb line. The brick should not protrude beyond the surface of the wall, and rows of blocks should be laid parallel to each other to ensure sufficient strength for the partition.

To properly lay a window opening, you need to follow the sequence of work and follow all the recommendations of specialists.

Almost any brick can be used to fill such an opening. The entire window space must be completely covered, excluding the formation of gaps and open fragments. Otherwise, the thermal insulation of the external wall may be damaged, which will lead to the formation of condensation on the internal surface.

Style and design

It is very important that the design of the entire house looks like a single whole. For a harmonious style, not only the material is important - the color design is also of great importance, as well as the design itself

Depending on your preferred materials, consider tips for stylish exterior window treatments.

Very often, for the facades of houses in the Russian style, windows are framed from wood with traditional floral patterns. At the same time, more modern options can also look great: you can create a wooden frame with an asymmetrical streamlined shape, or make a strict geometric pattern on it. It will look very good to add a second wooden element of a different color - for example, light wood can be combined with wenge or red wood decor.

Stonework can be very diverse. Sometimes neat identical stones are used to lay out an even frame around the window in the same way as with bricks. Nevertheless, the material allows you to try more interesting designs. For example, you can make masonry that smoothly transitions into the masonry of a facade of a different color if your house is entirely trimmed with stone. You can use two or three stones to frame one window. Contrasting colors such as black and white can look good, or, on the contrary, options that are similar in tone: for example, shades of beige, brown and terracotta.

Often frames made of artificial materials also highlight windows in an interesting way. You can choose an unusual siding color or make a plastic structure of an interesting shape.

Construction of strip foundations on the ground

First, wooden pegs are installed around the perimeter of the construction and the length of the fence is measured to the nearest centimeter. After this, they begin to calculate the number of pillars, taking into account the size of the gates and gates. Depending on the filling of the fence body, the distance between the posts may vary. It ranges from 2.5 to 3 meters. If the soil allows you to avoid installing formwork, concrete is poured directly into the ground.

This is possible for clayey, rocky soils that may not crumble for several days in good weather without rain. If the ground is sandy, it is necessary to install formwork to the entire height of the base. For formwork, boards, plywood, and flat slate are used. If the house is located on a slope, then the fence foundation will have to be stepped.

Photo: foundation with pillars installed on a slope

Benefits of using buta

Foundations for a fence made of rubble stone with brick pillars are in no way inferior to concrete ones in terms of load-bearing capacity. To fill the trench, use any stone materials of suitable size. Large stones are split with a chisel or an old axe. To do this, they are placed on the ground and, with strong blows, first cut a long furrow in them, and then split them. The stones are tied together with a solution of at least M200 grade.

There should be no gaps or cavities between the elements that are not filled with cement mortar. If water gets into the cavity in winter and freezes, there is a risk that the foundation will rupture and the fence may tilt. If the bottom of the foundation tilts a few centimeters, the top of the fence will move 5-10 cm to the side and everything will have to be redone.

Photo: rubble laying

Foundation with glasses and reinforced concrete beam

This is the most cost-effective option for constructing foundations for brick fences. After laying out the plan, holes are dug under the fence and concrete cups are poured into the formwork. At the top of the glass a recess is left equal to the thickness of the beam. Reinforced concrete beams, which act as a plinth, can be cast in one place, and after hardening, transported to the fence and installed. An expansion joint should be provided between the beams and the glasses.

Foundation on screw piles

Steel screw pile supports can be used to construct foundations in soils with low bearing capacity. They have steel caps on which a concrete grillage is formed under the load-bearing beams

It should be taken into account that screw pile supports for houses have a closed contour and are a rectangle or square in plan

Fences can be longer, and in order to reduce the influence of positive or negative temperatures, expansion joints will have to be made at certain intervals. The advantage of screw steel supports is that there is no need to use earth-moving equipment during their construction. In fact, the body of the foundation is above the ground.

Adviсe:

- Choose welded piles for low-density soils or cast ones for heavier ones. However, keep in mind: cast piles are much more expensive, although more durable.

- The internal cavities of the piles are filled with concrete of a grade not lower than M200.

- For fences with a large windage, filled with corrugated sheets, you will have to make calculations for wind load.

Construction of strip-column foundations

This type of base is used for brick fences with continuous brick filling between the posts on unstable soils in climatic zones with a freezing depth of more than 1 meter or in areas with permafrost. A very expensive method of constructing such foundations. This requires the use of special machines and mechanisms: excavators, drilling rigs.

The pillars are concreted in special metal formwork and, after hardening, treated with bituminous compounds for waterproofing. Waterproofing serves as a lubricant for heaving soils when temperatures drop to -30° C and below. The entire body of the foundation with pillars is reinforced with steel reinforcement.

Peculiarities

Exterior window framing is a process that must be approached carefully. Framing is preceded by the installation of the windows themselves - wooden or plastic. If you have never encountered this, it is better to seek help from professionals

It is especially important that the work is carried out by specialists if you have a ventilated facade

Once the windows are installed, you can think about the exterior decor and take into account several nuances.

Modern finishing options are extremely diverse

At the same time, when choosing synthetic options, make sure that the material does not have any foreign odor when heated and does not deform - the quality of the material is important for your health and comfort

Before installing frames made of stone or other heavy materials on the facade of the house, calculate whether the weight of the structure is too large

In rare cases, particularly heavy structures lead to deformation of the walls. Pay attention to the rules for working with different materials and think about whether you will do the finishing yourself. While siding can be easily fixed with your own hands, stone framing will require special knowledge, and the work of specialists can be expensive. Consider what style of framing will suit your home

The finishing should be organically combined with both the exterior of the house and the decorative elements on your site.

In what cases is it worth sealing a window in a log house?

- an old house was purchased and the new owners decided to carry out a large-scale reconstruction;

- during the first years of operation, it turned out that real heat losses exceeded the calculated ones, and since windows are the main channel of heat loss, the owners decided to reduce the total glazing area (most often, a similar situation arises after the construction of a bathhouse);

- there was a need to change the internal layout of the rooms and, as a result, it was necessary to install one or more old windows;

- During the construction of the house, the requirements for the casing design were ignored, as a result of which the installed PVC double-glazed windows burst, and it was decided to install new windows with a reduction in the glazing area.

Please note that removing a window is a complex and expensive operation, so before deciding to start such work, we recommend weighing the pros and cons several times.

In addition, it should be taken into account that in order to completely hide the location of the sealed window, you will have to significantly modify the interior and exterior of the house.

Cladding brick windows

It emphasizes the contour, adds volume and highlights the windows on the façade of the building. Cladding a window with contrasting or relief brick allows you to almost completely change the facade. Facing brick gives the building a more neat and elegant look.

The surroundings of the windows must be carefully calculated and symmetrical in relation to the masonry of the main walls and the corners of the building. Original, beautiful windows will complete the look of the facade, provided that the cracks are carefully sealed using special masonry or using brick platbands.

The harmonious appearance of the facade directly depends on the size and shape of the windows, or more precisely, on how symmetrical they are relative to the corners of the building and the width of the partitions. It is necessary to comply with certain standards when constructing the walls of buildings, but in practice it is often possible to observe inconsistencies that it is advisable to eliminate before laying facing bricks.

General information

The construction industry is developing very rapidly, and the market for construction and finishing materials is regularly replenished with new high-tech materials, which allow expanding the field of activity of designers and architects.

New and modern finishing materials make it possible to make the framing of your home's windows stylish, original, attractive and durable. For decorative window framing, materials such as brick, natural stone, gypsum, polyurethane panels, wood and other materials can be successfully used. Most often you can see the framing of openings on the facade with brick and wood.

The choice of material directly depends on the goals that the home owner achieves. In addition, it should be remembered that framing with brick, wood, polyurethane slabs and other materials allows you to create an original style of window framing.

For decorative framing of windows, materials such as brick, natural stone, gypsum, wood and other materials can be successfully used.

Window frame made of polyurethane - advantages

The first (main) advantage is the original design.

Almost no other material for decorative framing of windows and doors has such variability and the ability to combine various components. Here you can create compositions from moldings and cornices, arches and rustications, rosettes, consoles and keystones; you can “play” with the length of elements, the distances between them, patterns of alternation, color and style.

The ability to cut any decorative elements in any place and at any angle without compromising quality, easy assembly of stucco molding allows you to create individual compositions from finished elements or their parts. For greater expressiveness, you can use individual stucco details with small patterns - bas-reliefs, rosettes, panels, door trims. The result is a truly exclusive frame for a door or window, one of a kind, since the designer’s imagination is limited solely by the size of the opening and the financial capabilities of the customer.

Related article: Do-it-yourself repair of plastic swing windows

The second advantage is the durability of polyurethane stucco molding and its ability to hold its shape even for small artistic detailing.

Indeed, the ease of care and durability of polyurethane products can hardly be overestimated. Facade decor made from it is not afraid of snow, rain, or frost; it can be washed with both ordinary water and detergents. Frames of windows and doors made of polyurethane on the facade of the house do not need to be restored, like wooden decor - it is enough to paint it and it will look like new. As for durability, the service life of polyurethane stucco is comparable to the service life of a building - more than 25 years.

The third advantage is ease of installation.

As you know, polyurethane stucco is very easy to process. It can be sawed, cut, drilled, and glued. Therefore, the installation of frames for openings is greatly simplified. Elements - door and window frames, sandstones, rusticated stones and so on can be put together almost like a mosaic; they just need to be fastened together and fixed to the load-bearing surface with glue and self-tapping screws: the decor will hold firmly.

Another advantage is the lightness of polyurethane stucco.

Due to its low weight, it can be attached to any flat surface, including plastered walls and houses of lightweight construction (for example, those made using frame technology). Stucco molding is also convenient to work with: even large decorative trims and moldings can be lifted by installers without the use of special equipment, and this is a direct reduction in the costs of construction work. Our website presents original architectural solutions for decorative framing of windows and doors with polyurethane stucco, developed by the FACADE PROJECT company.

Tying the exterior trim to the main wall

Without proper attachment of the finishing layer to the wall, rapid destruction of the structure, displacement of its elements, and cracks are possible. There are dozens of ways to tie designs together. If there are no rods, plaster mesh and other elements intended for tying, then fastening is carried out using dowels and flexible wire (knitting). A dowel with a diameter of 6 mm is driven into the wall, and a wire fastener is screwed to its head, the length being equal to the width of the brick. The ends of the wire are hidden inside the masonry. A high-quality binding is a wire fastening every four rows. In width - every 60-70 cm.

Tips for working with the material

Strength, durability and visual attractiveness of a brick facade can only be achieved by working in strict accordance with existing technologies:

Brick cladding is always a ventilated facade. It is better to use “breathable” mineral wool as insulation (if necessary). The use of polyurethane foam and polystyrene foam sheets is impractical, since in this case they cannot be avoided becoming damp, which means the materials will lose their thermal insulation properties. Their use is permissible only if there is no ventilation gap between the facade and the walls.

- The service life of mineral wool insulation can be increased by using a moisture-proof, vapor-permeable membrane.

- Brick cladding, especially a combined facade (when different materials are used for the walls and the façade) requires mandatory connection with load-bearing walls. Outdated “old-fashioned” methods of connection (reinforcement, steel mesh and other improvised materials) usually cause cracking of the facade in the area of connection.

- If it is necessary to cut brick, the only tool that will allow you to make an even cut without destroying the material is a grinder with a disk for cutting dry stone with a diameter of 230 mm.

- Before laying the facade, load-bearing walls must be cleaned, dried and coated with at least two layers of primer, and wooden buildings require additional treatment with antiseptics and fire retardants.

- Using products from several batches at once will help to avoid the effect of a striped facade, the appearance of which is due to differences in brick shades. To do this, you should take 3-5 pallets with bricks from different batches and use them alternately when laying rows.

- When using not special masonry mixtures, but self-made cement mortar, the bricks are soaked in water for several minutes before laying. This is done to prevent the material from taking moisture from the solution.

It is important to make vertical ventilation gaps every 3 rows of cladding. They are not filled with solution; when it gets there, it is immediately removed with a wooden stick.

You can also create ventilation gaps using plastic boxes. Their width is 10 mm, and their height corresponds to the height of the brick. Their use is much more convenient, especially since the boxes are inexpensive. At least 2 ventilation gaps must remain in the lower part of the windows when facing.

Work order

Proper use of masonry mortar.

As a rule, when sealing an unnecessary doorway with brick, a partition thickness of 12 cm (half a brick) is maintained, since this structure does not bear any load; the upper part of the existing wall is held by a lintel. A window in an external fence can also be laid in half a brick, provided that additional insulation is provided.

To ensure that a blocked door can bear the load from hanging cabinets or any household appliances, the usual method of laying stones is used - on spoons. In this case, it is necessary to bandage the seams by half or a third of the length of the brick. Sometimes another method of embedding is used - a one-and-a-half hollow stone 88 mm high is laid with a bandage on the edge. But it should be taken into account that such a partition will not be able to bear additional load.

The work is carried out in the following order:

- Prepare a simple cement-sand mortar of M50 grade, using 1 part M400 cement to 5 parts well-sifted sand. Another option is to purchase ready-made masonry mixture and mix it with water, following the instructions on the bag.

- Moisten the base and sides of the opening with water. Place 1 row of stones near the installation site, cut the last one to the required size.

- Carefully spread the mortar to the length of 2-3 stones and begin laying 1 row. After each laid brick, pull the mortar to its side with a trowel, and then press it with the next stone.

- Apply the mortar to the end of the last brick in advance and put it in place. To maintain the thickness of the seam, the stones must be tapped.

- Fill the entire opening in this way, focusing on the plane of the existing wall. Do not allow the masonry to bulge or cave in; to do this, constantly check the wall, applying an even plank to it. Another option is to pull the mooring line and navigate along it.

In a situation where it is necessary to pass heating pipes made of PPR, metal-plastic or metal through the gap being laid, steel sleeves (cases) are placed in the partition. Their diameter must be greater than the outer size of the pipe. The length of the case is selected so that its ends extend beyond the surface of the masonry by 2-3 cm.

After the mortar has hardened, the structure must be lined so that the door covered with bricks does not differ in appearance from the rest of the walls. Choose the appropriate type of finishing - plaster, drywall or other material.

Design of lintels during construction

Jumper diagram

The basis for forming an opening in a brick wall is a well-known structural element (the so-called purlin), resting its ends on the walls lined with brick. For the manufacture of purlins, such well-known building elements as:

- industrial concrete lintels (it is also possible to make them yourself);

- metal channels of one size or another;

- standard metal corners.

Using a channel

The choice of material for purlins (lintels) is made taking into account the expected loads on this part of the structure, as well as for reasons of ease of working with them. When choosing their linear dimensions, one should proceed from the requirements of SNiP, which specify the amount of masonry overlap within the range of 150–200 mm on each side.

Therefore, with a window opening 1200 mm wide, you will need to prepare or buy a purlin about 1500-1600 mm long.

Steel corner as a “hidden” jumper

Question asked:

Grigorash

In connection with the use of facing bricks, the question naturally arose about covering window and door openings so that the appearance of lintels would not spoil the cladding. Builders recommend using a corner, but opinions differ regarding its size. So what corner should be used for “secret” lintels for openings with a width of 700 mm, 900 mm, 1200 mm, 2200 mm, and one opening 3000 mm? There is a corner 75x75x7 and 80x80x8 available, is it possible to use it?