The formation of gaps and cracks after installing a PVC window is an inevitable result of the technology of installation and construction work.

They arise between the frame and the wall and require special sealing to prevent moisture from entering both the window structure and the interior of the room.

Often, when installing a window unit, installers only foam the installation seams; the rest of the PVC window sealing processes are carried out by the owners themselves. Therefore, even before installing the window unit, you need to select the sealing method and sealing materials in advance.

What are seams and gaps?

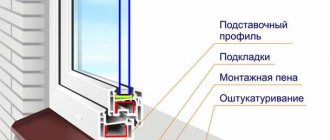

The gap between the wall and the frame appears due to the fact that the window design is slightly smaller in size than the technological opening in the wall. These are the requirements of the technological map and GOST for installing a PVC window block to provide space for thermal expansion of the window frame. Ideally, such seams are foamed, then waterproofed and sealed with putty and sealant.

Advantages of using foam to seal mounting gaps when installing PVC windows:

high level of free space filling;- ability to bear high loads;

- high characteristics of moisture, noise and thermal protection;

- low cost;

- high speed of work;

- simple application process;

The disadvantages of polyurethane foam for sealing installation joints include:

- Its high susceptibility to UV rays, therefore, after hardening and removal of excess, it must be covered with finishing and protective waterproofing materials.

- Foam at high temperatures can expand up to 10%, and at low temperatures, on the contrary, shrink.

Where exactly is sealing required after installation?

If the technical installation of PVC windows in the wall is carried out correctly, cracks will form :

- between the frame and the top and vertical walls;

- between the window sill and the frame.

If the installers follow the technology for installing the block, then such gaps do not exceed 2 cm, this is enough to ensure thermal expansion of the window frame. If the foam was applied correctly during installation work, then the completion of the sealing of the window block is carried out using putty solutions and sealant

Work progress

It’s worth noting right away that if you insulate plastic windows for the winter with your own hands, the warranty on them will automatically expire.

If the owner nevertheless decides to carry out the work himself, it is necessary to find a place for a draft. Sometimes it happens that it occurs due to depressurization of double-glazed windows. Unfortunately, in this case, it will not be possible to carry out high-quality insulation on your own. In most other cases this is quite possible.

Insulation of slopes

If voids appear under the facing of the slope, this means that it needs to be repaired. Finding them is quite simple: this is done by tapping on the surface. There is empty space where the sound would be louder.

The old insulation under the slope lining needs to be replaced

In this case, it is necessary to remove the facing material. There will be insulation underneath. In most cases, foam serves as insulation. If the problems are not too serious, it is enough to simply add material to the places where the voids form. When the insulation has already served its purpose, it must be replaced. The material can be very diverse: basalt wool, polystyrene foam, foam, etc.

After replacing the insulation, it is necessary to check the facing material. If the sheet has cracks or other serious damage, it must be replaced. It is better to use PVC or a plastic panel as cladding. Such materials not only look good, but also provide excellent thermal insulation.

Insulation of street slopes is carried out in the same way. However, if the apartment is located above the second floor, you need to contact professionals. It will not be possible to carry out the work without special equipment.

Replacing seals

In plastic windows, one of the fastest wearing parts is the rubber seal. After several years of use, it loses its properties and ceases to perform its functions. To increase the service life of the seals, you can use a special silicone grease (this is done twice a year). However, if the material has already worn out, it must be replaced.

To replace it, you need to pry off the glazing bead that holds the glass unit. After this it must be removed. Now the rubber is easily pulled out of its groove.

Replacing the sealing tape will increase the thermal insulation of the window

New material should be cut (it is better to leave a margin of 5-6 cm and cut it to the desired length after installation). Before assembly, you must ensure that the site is free of dirt. If necessary, the seal can be fixed with glue.

Setting the pressure

In modern plastic windows, the window sash pressure can be adjusted. This is done by rotating the eccentrics (located at the end of the sash). A 4 mm hex wrench is used for adjustment. There is a mark on the eccentric itself that helps determine the adjustment. If it is located on the street side, the pressure will be weaker.

Modern windows allow you to set summer and winter modes for pressing the sashes

Setting the position of the sash relative to the frame

There is another mechanism in the hinges of the sash, with which you can adjust the sash. Adjustment is carried out by tightening the screws.

Why do you need to seal and close knots?

Since the main material that can be used to seal mounting cracks in window openings is construction foam, which can be destroyed under the influence of precipitation and UV radiation, it requires protection. After the foam layer is leveled from sagging, it must be waterproofed and covered with finishing materials. If this is not done, the foam will collapse very quickly and through holes will be exposed.

Technology for sealing technological seams created when installing PVC windows:

- When installing the block, they try to ensure that the distance from the wall to the PVC frame does not exceed 2 cm. This is achieved by accurately measuring the wall opening before ordering the window block.

- Fill the seams with polyurethane foam, purchased according to the outside temperature in the area of installation work.

- Trim off excess foam after it dries

- Install a vapor barrier layer.

- Plastering.

- Paint the plaster layer.

After this, the window sill, drainage and slopes are installed. They seal small gaps up to 5 mm between the frame and the wall opening, as well as the frame, drainage and window sill.

How does installation work?

Installation of interior

When the doorway is ready for installation, we saw down the door frame and mill the grooves for the hinges. This is necessary if you use regular overhead loops.

Then we assemble the box using self-tapping screws and install it in the opening according to the level.

How to fasten the frame in the opening depends on the weight of the interior door. For inexpensive hollow interior doors, mounting foam is sufficient to keep the door securely in the opening during normal use.

Heavy wooden doors require more thorough fastening of the door frame with drilling of the opening.

How to clean floors in public catering establishments

It should be understood that installing a double-leaf door is one and a half times the price of a single-leaf door. And the installation of sliding compartment doors is 30% more expensive than swing doors.

Installation of metal entrance

Entrance doors are much easier to install in terms of the number of steps compared to interior doors. But not by its weight - after all, the weight of a good metal door can be more than 100 kilograms.

It is enough to align the entrance door, mark the holes and drill a hole in the wall for subsequent fastening with anchors or concrete screws in the opening.

After this, foam the gap between the box and the wall.

Installation of aluminum and plastic doors

We install PVC and aluminum doors in the same way as metal entrance doors. If the doors are glazed, we remove the double-glazed windows first.

When an aluminum or PVC door is fixed in the opening, we install double-glazed windows and then foam it.

What materials are best?

After the polyurethane foam is applied and the window sill, drainage and slopes are installed, even with the most careful execution there will still be small gaps that are sealed with sealants.

In the retail chain you can purchase several dozen very effective sealants for PVC windows. They contain various polymers that give them certain characteristics.

The form of implementation is tubes with a pasty and plastic mass, most often white. After the sealant is applied to the surface that has leaks, it gradually hardens, creating an airtight and moisture-resistant layer.

Let's look at the most popular types of sealants for sealing between structural seams of PVC windows.

Silicone

Available in the form of a universal paste of organosilicon compounds, intended for internal and external use. There are acidic and neutral types.

Advantages:

- high elasticity and good adhesive properties;

- ease of surface treatment and affordable cost;

- the resulting seam does not shrink;

- does not lose elasticity or color over time.

- For interiors, sanitary silicone sealant is used, which resists the formation of mold and other biological damage, so it always remains white.

To the disadvantages:

- the presence of the smell of vinegar in the room when applying acidic compounds;

- Over time, the smell dissipates.

Acrylic

The sealant is used for external work.

Advantages:

- increased elasticity;

- moisture resistance;

- resistance to UV rays;

- low cost.

The disadvantages include:

- high moisture absorption;

- in a liquid state it is easily washed away by water, in a solid state it absorbs room vapors, after which it darkens, so it is not recommended for indoor installation.

Liquid plastic

The material is produced on the basis of PVC from MS polymers.

Advantages:

- excellent adhesion and increased viscosity, as a result, after application with the base material, it forms an integral system;

- After the sealant has hardened, it can be coated with a layer of varnish or paint.

Flaws:

- high price;

- cannot bear the load.

Butyl or polyisobutylene sealant

It is produced on the basis of a rubber-like substance.

Advantages:

- high characteristics of elasticity and resilience, which are maintained at temperatures from -55 to +100 C;

- endurance of ultraviolet exposure;

- environmental and biological safety;

- high vapor permeability, therefore, in addition to sealing installation joints;

- additionally used for repairing double-glazed windows;

- is highly water resistant;

- does not swell.

The disadvantage is the low-strength composition.

Theocol sealant

Produced using polysulfide components.

Advantages:

- hardens at any air temperature and humidity;

- indispensable for external work;

- can be used in frost and precipitation.

The disadvantages of this type of sealant include:

- high price due to the large number of components that give it rubber-like characteristics;

- unpleasant smell.

Steez A

Acrylic sealant with a one-component composition, area of application for outdoor work.

Advantages:

highest adhesion to a variety of building materials;- resistant to ultraviolet radiation, natural precipitation and shrinkage deformation processes;

- can work at T=-20 C;

- high vapor permeability;

- can be painted in the desired color;

- resistance to mechanical loads;

- durability up to 20 years;

- minimal shrinkage and the presence of antibacterial components.

Flaws:

- insufficiently high elasticity lower than that of silicone analogues;

- porous structure;

- unpleasant odor;

- short shelf life of the prepared mass from 6 to 12 months.

Steez B

Acrylic one-component sealant for interior work.

Advantages:

- high adhesion to any type of wall;

- highest vapor barrier;

- wide range of application in temperature from -40 to +80 C;

- resistance to deformation;

- can be painted after drying;

- lower price than modification A.

Disadvantages: it is not able to remove moisture from the seam, so it can only be used for interior work in conjunction with Steez A.

Steam and waterproofing tapes

The materials must be used to create a warm seam system using PSUL - a vapor-permeable self-expanding sealing tape.

Advantages of PSUL Euroband:

- waterproofing and vapor barrier protection covers the internal seam and does not create mold;

- has a high level of elasticity;

- do not harden during operation;

- takes any shape, resistant to UV rays, 5-fold expansion coefficient;

- water resistance up to 600 Pa;

- fills various cracks;

- removes moisture from the wall structure;

- unable to support combustion;

- chemically neutral.

to be a disadvantage .

Properties of polyurethane foam

This chemical product is a polyurethane-based sealant containing isocyanate and polyol. This is the base, but different manufacturers may include various additives such as catalysts, stabilizers, blowing agents and the like. The foam has high adhesion and expandability, allowing it to fill the entire space. The materials with which this foam forms the strongest bonds are the following:

- Cement;

- Metal;

- Plaster.

At the same time, plastic or greasy materials, as well as wet surfaces, adhere to such foam to a much lesser extent. This in turn ensures that we don't put it in places where it shouldn't be. Although, it is still difficult to wipe off such foam from such surfaces.

TOP 5 funds

The popularity of a particular sealant is determined by the purchasing activity of large trading platforms. And also based on customer reviews. Among the sealants for sealing the seams of PVC windows, the following materials are the most popular.

Cosmofen 345

Liquid plastic from a German manufacturer. The place of sealing is between a quarter of the brick wall and the frame from the outside, option: PSUL + finishing + Cosmofen 345.

Advantages:

- excellent adhesion to all wall materials;

- increased resistance to ultraviolet radiation and atmospheric moisture;

- long service life of more than 20 years with preservation of original properties;

- efficiency and convenience of work;

- low shrinkage;

- capable of sealing seams up to 7 mm, ready in 24 hours.

The disadvantage is that it has a strong, toxic odor, so it can only be used outdoors.

The cost of a 310 g tube is 590 rubles.

Quelyd 007

Universal sealant for internal and external use from France. Installation location - outside side and top walls, option: PSUL + finishing + Quelyd 007, inside side walls, top wall and window sill, scheme: vapor barrier tape + finishing + Quelyd 007.

Advantages:

- multifunctionality;

- high moisture resistance;

- neutral smell;

- does not float;

- has minimal shrinkage.

There is only one drawback - high cost. The price of a 430 g tube is 650 rubles.

Soudal fix all high tack

Belgian universal sealant made of synthetic rubber. Installation location - outside side and top walls, option: PSUL + finishing + Soudal fix all high tack, inside side walls, top wall and window sill, scheme: vapor barrier tape + finishing + Soudal fix all high tack.

Advantages:

- high water resistance can glue even wet surfaces;

- instant gluing effect;

- high resistance to aggressive environments;

- wide range of operating temperatures;

- long service life.

The disadvantage is the high price, a 290 g tube costs 950 rubles.

MasterTeks ProfiMaster

Polish universal transparent acrylic sealant. Installation location - outside the side surfaces and the upper part of the opening, option: PSUL + finishing + MasterTeks ProfiMaster, inside the side walls, top wall and window sill, scheme: vapor barrier tape + finishing + MasterTeks ProfiMaster.

Advantages:

- high antibacterial resistance;

- highest adhesion;

- the widest range of permissible temperatures from -20 to +80 C;

- can be painted;

- reaches elasticity an hour after application;

- lends itself well to correction;

- relatively low price;

- long service life.

Flaws:

- turns from white to transparent when dried;

- painting required.

Price - 570 rub. for 1 tube.

Moment

White universal silicone sealant made in Russia. Installation location - outside side surfaces and upper part of the opening, option: PSUL + finishing + Moment, inside side walls, top wall and window sill, scheme: vapor barrier tape + finishing + Moment.

Advantages:

- high resistance to chemicals;

- high degree of protection up to T+150 C;

- good adhesion with all types of wall materials and PVC;

- does not provoke corrosion processes in contact with metal.

The disadvantage is the presence of an odor at the time of application, which later dissipates.

Price per tube - 350 rubles.

What are the benefits of heated windows?

- The glass is heated without visible heating elements that could block the view. Your guests will not suspect that there is an unusual double-glazed window in the window frame. No threads or spirals. Your secret will remain unsolved.

- The surface is heated evenly over the entire area. Therefore, thermal patterns will not form on the window.

- The protective coating returns 30% of the evaporated heat back into the room. This means that with the same heating costs, you can afford to add another third to your window. This will not only improve the view from the window, but will also enhance the natural light in your home.

- The specific power of heated glass reaches up to 3 kW per square meter. In this case, the operating temperature is reached in a matter of minutes. Therefore, even if there is no traditional radiator under the window, condensation will not have time to form on the glass.

- Warm glass is also compatible with heated glass units. A special glass surface that contains a liquid crystal layer, when connected to an electrical outlet, can make your window frosted or darkened. When the invisibility function is turned off, it returns to normal transparent glass. This is quite convenient with panoramic glazing. Such a window will take care of protecting your privacy and at the same time let in streams of light into the room and allow you to admire the surrounding landscape. At the same time, it blocks 99.5% of ultraviolet radiation.

- When it’s still too early to turn on the heating, and the house feels a little chilly, warm windows will help create comfort in your home. Even during frosts, the window surface will remain dry and clean. But with ordinary glass, you would have already turned on the heating, and condensation would form on the windows.

- Warm windows also help deal with snow and ice crust on the skylights. Just turn on the heating function and you can admire the sky again.

- When using conventional windows, constant air currents circulate in the room. There is a chill blowing from the windows, dripping from the window sills. With warm windows you won't feel this. Heated glass will give you warmth and comfort instead of cold. And the rooms will be evenly heated.

- Screens and panels made of warm glass can serve as a local heater.

- The Smart Home system can use heated double-glazed windows in its own way. Heated glass is connected to sensors that respond to changes in air temperature inside and outside the house, as well as to photocells that regulate the degree of transparency of smart glass.

- Among other things, heated glass can also serve as security sensors. After all, when the glass breaks, the contacts open, and the security unit receives an alarm. In order to use this function, there is no need to spoil the design with all kinds of tapes or conductors. It is enough to simply install the double-glazed window and turn it on to the power supply.

- In order to break a heated glass unit, you need to make a lot of effort. It can withstand the onslaught of vandals and can even protect against bullets fired from short-barreled weapons.

In the post-Soviet expanses, heated windows are presented by Saint-Gobain Glass.

Electrically heated glass has plenty of positive characteristics. All these qualities together make it possible to make even entire walls from this material, creating airy and transparent structures. Glass greatly expands the possibilities of design and architecture. Those projects that previously could not be realized in our climate can now be built for you.

And now the most interesting thing, the price of a heated window starts at $220 per square meter and this is only a double-glazed window. You still need to add automation here.

“Warm windows” are a modern technological solution that not only allows you to get rid of condensation and “frost patterns” in the winter, but also has a number of useful functions.

Rice. 1. Heated window

Tools

To seal seams and cracks, you will need a variety of tools, the list of which can be expanded depending on the width of the cracks and the selected processing technology.

If the frame is installed according to the project, then the gap between it and the wall opening should be about 20 mm, in this case the following tools, devices and consumables :

- Master OK.

- A set of spatulas, including an angular one.

- Mortar container.

- Construction level, plumb line.

- Soft wide brush.

- Construction float.

- Electric drill with a mixer attachment for preparing finishing slopes.

- Gun.

- Container with water.

- A towel or piece of clean cloth.

- Degreaser.

- Construction foam.

- PSUL.

- Vapor barrier tape.

- Sealant or liquid plastic.

- Primer composition.

- Reinforcing fiberglass mesh.

- Construction tape.

- Sponge and napkins.

Step-by-step instructions for sealing

The technology for sealing installation joints depends on the wall material, window design, selected consumables and scope of work. The main operations that the contractor must perform when sealing and sealing assembly seams and gaps between the surfaces of structures:

After fixing the frame and installing the window, all mounting cracks are foamed with construction foam.- PSUL is installed between the quarter and the frame.

- There is a diffusion tape between the frame and the ebb.

- Between the frame and the window sill there is a vapor barrier tape.

- Between the frame and the internal slopes there is a duplicate vapor barrier tape.

- Slopes are made with insulation and waterproofing.

- Next, they begin to seal the gaps between the PVC window frame, slopes, drainage and window sill board.

- Prepare a syringe for sealant and a vessel with water.

- Construction tape along the edge of the seam is used to protect all mating surfaces.

- Before starting work, clean the work area from dust.

- Window sealant is applied with a syringe at an acute angle, squeezing it into the cracks and at the same time using the spout to smooth out the seam.

- The protruding areas of the seam are smoothed with a wet finger, trying to evenly distribute the sealant along the entire length.

- Excess sealant is collected with a damp sponge, which must be constantly cleaned of glue in a container with water.

To ensure that the applied sealant does not harden, the work is carried out in sections. If the surface of the frame or window sill needs to be degreased first, acetone should not be used for this purpose.

Possible difficulties and errors

The first errors due to improper sealing will be detected by the owner of the window immediately when cold weather sets in; such a window begins to siphon from under the installation seams, and condensation appears abundantly outside and inside the structure, while the slopes turn black with mold.

If these signs were discovered by the owner on PVC windows, and their installation was carried out by a specialized organization, then their representatives urgently need to be invited to eliminate the defects.

If the work was carried out independently, then most likely the following gross mistakes :

- improper installation, excess thickness of the gap, for which the protective “pie” was incorrectly selected and installed;

- unprepared surfaces for sealing seams;

- Incorrectly selected polyurethane foam for temperature application;

- protective heat and waterproofing layers have not been installed before the external finishing of the mounting slots;

- the sealant was selected incorrectly, without taking into account the area of application: external or internal;

- the surface is not prepared for application of sealant;

- The sealant is placed unevenly on the protected surface with gaps.

Sandwich panel slopes

A PVC sandwich panel is two thin sheets of plastic with a layer of insulation (sheet thickness 1 cm).

Materials, tools for installing slopes of PVC sandwich panels on the front door:

Installing slopes from sandwich panels, or how to do it yourself:

If desired, the space between the PVC sandwich panel and the wall is filled with polyurethane foam. This is done after installing the sandwich panels.

For more information about installing slopes with your own hands after installing the front door, watch the video

Prices for services of masters

The cost of sealing seams depends on their size in width, total length in linear meters, the level of preparation of the treated surfaces, the number of floors the window is located and the protection technology adopted. The work can be carried out comprehensively, for example, during the installation of PVC windows or in individual technological operations.

Average prices for the service of sealing seams after installing a PVC window:

Comprehensive sealing of PVC windows after installation, RUB 2,000. per set.- Sealing of external seams - 600 rub./l.m.

- Sealing of internal seams - 300 rub./running meter.

- Sealing of seams between PVC frames and slopes 300 rub./l.m.

- Filling empty technological gaps between the frame, walls, ebb and window sill with foam - 150 rub./l.m.

- Installation of PSUL - 250 rub./p.m.

- Seam protection with steam and water protective tapes - 300 rub./l.m.

- Preparation of surfaces for sealing - 300 rub./l.m.