One of the important stages of construction work on insulation is puttying on foam plastic. However, few people think about why to do this and how such work is done. If everything is more or less clear with puttying walls, then with polystyrene foam it’s not so much. There are a number of nuances associated with this.

In this article we will look at why you need to putty foam, how to choose the right putty, what tools and materials are needed for this. And to consolidate the result, we will look at step-by-step instructions on how to putty polystyrene foam.

What does foam putty give?

We are all accustomed to the fact that any action must be thoughtful, logical and have its own reason. For example, we sweep to keep the room clean. Why do you need to putty foam? Thanks to this, the quality of the finish can be improved. But that's not all. Here are some more reasons:

- Everyone knows how fragile polystyrene foam is. It is very easy to damage it if you move it carelessly or hit it. A crack or hole forms in place. If you putty it, this will increase its mechanical strength.

- This allows you to preserve the thermal insulation qualities of the foam. Despite the fact that moisture does not affect the material in any way, since it easily absorbs and releases it, low vapor permeability prevents the rapid removal of moisture from the foam structure. This is why the ability to retain heat deteriorates.

- Thanks to the putty, the anti-feather properties are increased. Everyone knows how resistant polystyrene foam is to fire. Even with a slight increase in temperature it begins to melt. A layer of putty will help eliminate the risk of fire or damage to the material.

- The foam will also be protected from ultraviolet rays and wind. They negatively affect the performance characteristics of the foam. In the sun it turns yellow and loses its original properties. Putty is an additional protective layer.

- Thanks to the putty, it is easy to apply the next finishing layer. This is like a foundation that is easier to work with in the future.

But in order for the putty to really fulfill all its tasks, it is important to choose a high-quality option. How to make the right choice?

Choosing putty for foam plastic

The peculiarity of polystyrene foam is that it melts when exposed to solvents. This means that the putty for it should not contain chemical components that will destroy the structure of the material. Otherwise, choosing the composition is not difficult. There are special mixtures for polystyrene foam.

There are several nuances that need to be taken into account when choosing putty for foam:

- Place of work. This can be façade putty or putty intended for interior work. The conditions outside the house are more aggressive, so the composition is different.

- Date of manufacture of the putty. In order to save money, some people buy discounted putty, the so-called promotional product. Typically, such events are abandoned when the shelf life of the material comes to an end. It is important to monitor this so as not to buy a composition that has lost its original characteristics.

- Storage conditions for putty. You should also consider where the products are stored. It is important that this is not a damp room that is not heated. And if this is a shed on the street, then temperature changes, dampness and sun had a negative impact on the raw materials.

- Presence of glue. Polystyrene foam cannot be called a material with high adhesion. Therefore, without an adhesive, the putty will not adhere well to the surface.

If you take into account all the above requirements, then we can say with confidence that you will buy a quality product that will 100% fulfill its purpose. And now that everything is ready, you can consider how to putty the foam.

Preparation of materials and tools

Since foam insulation is most often carried out outside, first we will look at what and how to putty it on the street. Very often on the Internet you can find advice that you need to use simple tile adhesive or other mixtures. But why do this? If you have a vacuum cleaner, you won't sweep with a mop. Foam putty is commercially available specifically for this purpose. For example, an excellent option is Ceresit ST85 or Ceresit ST83.

This is a dry mixture that can be used for both external and internal work. The material is universal and has won the trust of many. In addition to the putty itself, the following materials are needed:

- polyurethane foam;

- primer;

- corners for reinforcement;

- fiberglass mounting mesh. It is important to understand that it can be for interior or exterior use.

Now let's look at the list of relevant tools:

- clean container (bucket, basin);

- drill mixer;

- roulette;

- rule;

- wide, narrow and medium spatulas;

- stationery knife;

- foam grater.

When the entire arsenal is assembled, you can start working.

How do you glue ceiling tiles and seal the seams?

There are seams between the ceiling tiles that need to be sealed. The finishing mixture is suitable for this - it is better applied, and as a result the surface becomes smooth. It comes in the form of a dry mixture for dilution or ready-to-use. Simply scoop the solution onto your finger and apply it to the joints, gently smoothing it out.

If the tiles need to be attached to the ceiling, acrylic putty is suitable. It has a viscous structure, so you won’t have to hold the glued tiles for a long time - they will be fixed after the first contact with the mixture.

Excess putty can be easily removed from the foam with a sponge soaked in water.

We mount the mesh on polystyrene foam

Thanks to the reinforcing mounting mesh, the putty will not crack, and the surface itself will become stronger. There is no way to skip this stage. The step-by-step instructions for gluing the mesh are as follows:

- The fiberglass mesh is prepared for gluing. Use a knife to cut it into pieces of the required size. When finishing the facade, the mesh is also prepared for the slope. It is important to note that the edges of the mesh should overlap each other by about 10 cm. The gap at the corners is also 10 cm.

- The mesh will be glued to the adhesive. It will have to be cooked. The packaging contains instructions on how to do this. Typically the process is as follows: the dry mixture is added to a clean container, after which water is poured into it. The contents are mixed. During the kneading process, additional water is added to obtain a homogeneous composition. It should resemble dough in consistency. All you have to do is wait 7-10 minutes and move the contents again.

- Gluing the mesh begins with the slopes. To do this, you need to scoop up the glue with a narrow spatula onto a wide one, and transfer it to the slope, maintaining a layer of 5 mm. Next, a piece of mesh is applied to the surface with the adhesive composition, leveled and embedded in the solution with a spatula. Everything should turn out smooth and even.

Already at this stage, you should ensure that the surface is leveled, maneuvering the spatula smoothly and evenly. When the slopes are processed, you can proceed to the entire surface of the wall. The task is the same: apply a 5 mm layer to the surface, apply the mounting mesh and embed it with a spatula. In this case, it is important to ensure that there is a 10 cm overlap at the joints and leave a 10 cm fold at the corners. How exactly to handle the corners can be seen in this photo. For this purpose you will need to have a coal spatula.

That's all, the mesh is glued and the surface is ready for the next stage. After all, the wall is still far from ideal. Now we will try to make it as it should be.

Preparation of putty

Prepare the adhesive mixture in the following order:

- The dry mixture is slowly poured into a clean container filled with water. In this case, the solution is stirred all the time. This is done with a wooden spatula or a drill with a screw attachment.

- If the mixture is prepared using a drill, then it is turned on at reduced speed. This guarantees a homogeneous mass without lumps.

- Under no circumstances should dry powder be added to the finished putty. This will cause hard lumps to form. This kind of putty cannot be used.

- After receiving the finished mixture, it should be allowed to stand for 5-10 minutes.

- Then the solution is finally mixed.

Puttying foam

According to the scheme described above, you need to prepare putty. But it is recommended to make it not dough-like, but more liquid. The consistency should resemble sour cream. When the putty is ready, you can begin to putty. To do this, you need to scoop the mixture onto a wide spatula and apply it to the wall in a thin and even layer. But it should be approximately 3 mm. Use the spatula correctly. You need to place your thumb under the handle and place your palm on the canvas.

Your task is to make quick and even movements with the spatula. The putty layer must be perfectly even. The process is repeated: using a narrow spatula, putty is scooped onto a large spatula, after which the composition is transferred to the surface. This is how the entire wall and slopes are finished. For clarity, you can watch a video on how to putty polystyrene foam with your own hands:

That's all, puttying the foam is considered complete. If the walls turn out to be even and smooth, then the job is done correctly. It is clear that such a surface cannot be called ideal. Moreover, as a finishing stage it is no good. To improve the appearance of the facade, it is recommended to cover the whole thing with decorative putty. Bark beetles, structural and textured mixtures are often used. This will help hide all the flaws and make the walls attractive.

To better navigate the work, you can watch this training video that will show how to perform decorative finishing of foam plastic.

What does puttying do?

Foam putty will not only improve the quality of the subsequent finishing, but will also provide the following:

- Strengthening. The material breaks easily under mechanical stress, for example, an unsightly hole can form upon impact. The putty protects against such influences.

- Preservation of thermal insulation qualities. Moisture is not dangerous for penoplex, but due to the low vapor permeability of the material, trapped moisture particles from the foam structure take a long time to be removed, which has a bad effect on the ability to retain heat.

- Increasing fire retardant qualities. Expanded polystyrene is very flammable, and the applied putty will serve as an additional way to reduce the risk of fire.

- Protection from wind and sun. Even if interior decoration is carried out, it is impossible to completely avoid exposure to sunlight on the material, and they have a destructive effect on the foam structure.

But how to choose a putty solution so that it has maximum protective qualities?

Selection rules

Choosing a suitable solution is not difficult, but only putty for expanded polystyrene should be purchased - other building mixtures may contain chemical components that destroy its structure. In addition, when choosing a mixture, you need to pay attention to the following:

- Place of work. Depending on whether you plan to putty in a room or on the street, you select a façade putty or a composition for interior work.

- Release date. Many people, wanting to save money, purchase putty mixtures at sales or special promotions. But the closer the expiration date is, the worse the strength and protective qualities of the composition will be.

- Storage conditions. You can buy cheaper putty in large construction warehouses, but there it is most often stored in damp, unheated rooms or under a canopy outside, which means that the mixture was exposed to temperature changes and moisture could get into it. Such compositions, even if they have a fairly long shelf life, will be of poor quality.

- Presence of glue. Polystyrene foam has low adhesion, and without glue, the adhesion of the putty to it will be weak.

By following the suggested recommendations, you can purchase a putty composition that will ensure durable and high-quality repairs. But it is important not only to determine how to putty the foam, but also to apply the chosen composition correctly.

Expert advice

In order to putty everything well and not have to redo the work again after a short time, you need to use the following expert advice:

- The putty must contain glue, otherwise the adhesion to the base material will be weak, and subsequently everything will fall off.

- Select the putty and type of reinforcing mesh based on the place of work (outdoors or indoors).

- A material with a suitable shelf life loses some of its properties, which means that adhesion to the foam will be poor.

- It is better to buy materials in a store where they were stored in a dry room at above-zero temperatures. At the market in open pavilions, everything freezes in winter and overheats in summer, and there is also a high probability of moisture getting in, which is why it spoils long before the expiration date.

- Instead of a special primer, the foam plastic can be coated with PVA glue in two layers.

- If there are several layers of putty, then between them you need to apply a layer of primer for better adhesion.

- You need to start laying the reinforcing mesh and puttying from the slopes.

- Putty must be purchased at the rate of 3 kg per 1 m2 to secure the mesh and 5 kg to level the surface.

Having studied the technology of working with putty on polystyrene foam, any owner who has any skills in construction will be able to do everything on his own. This will save on hired labor, and the money can be spent on better materials.

How to putty

Working with polystyrene foam is slightly different from puttingtying other materials due to the characteristics of polystyrene foam. The first difference is that before applying the putty, a reinforced mesh is glued to the foam surface.

Some craftsmen who do not want to deal with gluing the mesh are interested in whether it is possible to putty without it. It is possible to do it indoors, although it is not advisable, because the repairs will not be of very high quality. But outdoors it is impossible to do without reinforcement, otherwise under the influence of atmospheric conditions the putty will soon begin to peel off, and the finishing will crack or become deformed.

Surface preparation

How to putty polystyrene foam correctly? To do this, you need to follow several steps:

- Primary preparation depends on whether repeated finishing work is being carried out or whether insulation is being installed for the first time. If repeated puttying is carried out, the surface must be cleaned of dust, dirt and decorative finishes; the reinforced mesh does not need to be removed.

- The prepared surface is treated with primer. You can use any deep penetration primer that does not contain chemical compounds that are aggressive to polystyrene foam. Craftsmen recommend using PVA glue diluted with water in a 1:1 ratio for priming.

- After the primer has dried, the reinforced mesh is glued. To do this, neat strips are cut from the mesh along the length of the wall and carefully glued to the foam. You can use any tile adhesive for this.

Application

Next, putty is applied to the foam. This is done in several stages:

- With the first layer, the base putty only slightly hides the reinforced mesh, providing stronger adhesion to the base. It must be remembered: the thinner the layer of applied mortar, the higher the quality of the finish.

- After the first layer has dried, priming must be repeated. Many craftsmen neglect priming, believing that the putty mixture already contains glue, but this makes the result of less quality.

- The second and subsequent layers of base putty are applied in order to hide the mesh and level the surface as much as possible. It is recommended to apply primer between layers to increase strength.

Final finishing

After the last layer of the base putty has dried, you can proceed in two ways:

- If you plan to tile or stick other decorative elements, then you can begin finishing work.

- If the final stage is painting or wallpapering, then it is necessary to achieve maximum smoothness of the surfaces. To do this, the walls are leveled using finishing putty, and then painted or wallpapered.

Anyone who has ever puttyed penoplex can confirm that the work process is simple, and if you follow all the steps, you get a warm and beautiful home. Only when purchasing materials should you not try to save money - this will affect the durability of the finish.

Foam putty is used to make the surface of the insulating layer more resistant to external influences. In addition to putty, foam primer is also used for the same purposes. If these products are applied correctly, the material will retain its basic properties and gain additional properties that are valuable in construction terms.

A little about the features of penoplex

It is worth noting right away that it would be more correct to call penoplex extruded polystyrene foam, since the familiar word “penoplex” is the real name of the company that manufactures and sells this heat-insulating material. To some extent, this is reminiscent of the situation with copying machines, which in the CIS countries are still called “copier”.

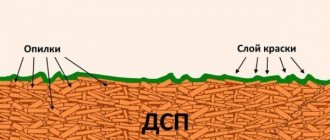

Extruded polystyrene foam is based on the simplest polystyrene foam, namely polystyrene foam.

But thanks to the processing of the material using a special thermal method, the material was able to obtain the following extremely valuable qualities:

- Strength, which is several times higher than the strength of standard polystyrene foam.

- Uniform structure and very smooth surface.

- Moisture absorption, which is practically zero.

- Higher level of vapor permeability.

In addition, a material such as penoplex has a low level of adhesion when compared with polystyrene foam. Because of this, it would be a grave mistake to putty such material using standard technology. This can lead to the putty starting to lag behind the insulation layer and reinforcing mesh. Although penoplex is not intended for wet cladding, plastering it is in fact possible. Construction specialists were able to develop finishing technology that makes it possible to obtain a high-quality result and also guarantees a high level of strength.

Why do you need to trim the foam?

Puttying polystyrene foam is a prerequisite in the process of insulating a room with this material. But, auxiliary finishing of polystyrene foam surfaces is not always used. It all depends on the method of attaching the insulation. If the foam is attached to the wall using construction umbrellas and glue, then puttying is used. Other fastening methods completely exclude this finishing method.

The foam itself is very fragile, so it needs additional protection, which can be achieved using special finishing mixtures - primers and putties.

Finishing materials in this direction are necessary for:

- reducing the risk of mechanical damage;

- minimizing exposure to moisture;

- hiding foam from exposure to direct ultraviolet rays;

- improving the aesthetic appearance of insulating material;

- formation of an adhesive base between all layers of finishing;

- smoothing out temperature differences.

The primer is the fastening link between the surface of the foam and further layers of the finishing coating. Puttying is necessary in order to eliminate defects in the surface of the foam and prepare it for painting or decorative plaster.

On video: how to insulate a house with polystyrene foam.

Technology of covering walls with polymer insulation

Before starting work, prepare the following tools and materials:

- insulation boards;

- umbrella dowels;

- metal, fiberglass or plastic reinforcing mesh;

- perforator;

- construction knife;

- roulette.

Installing foam sheets on vertical internal fences of a house does not cause any particular difficulties:

- mark the location of expanded polystyrene sheets on the wall;

- additional elements are made by cutting solid foam slabs;

- polymer sheets are secured with umbrella dowels in the corners and in the center of the plane.

It is optimal to use glue or umbrella dowels for installing panels.

Coating building facades with polymer slabs is somewhat different from cladding the walls of premises:

- The bases of the facades (monolithic concrete, brickwork or wooden frame) are coated with an adhesive primer.

- The insulation sheets are installed with special glue.

- For more reliable fastening, the foam is fixed with dowels - umbrellas.

- A reinforcing mesh is glued on top. The mesh can be metal, plastic or fiberglass.

Scheme of wall decoration inside and outside the building.

In some cases, it is possible to install facade insulation without glue on dowels, which ensure reliable fastening of the insulation. The surface of the insulation has weak adhesion, so the polymer coating of the walls must be puttied.

What kind of putty is needed?

How to putty foam? Success depends on choosing the right putty material. The composition of this mixture can be different: prepared independently or purchased ready-made. The store sells putty mixtures for polystyrene foam, which just need to be diluted with water in the appropriate proportion.

This product is of high quality if you use certain brands that have earned a reputation over the years. The manufacturing company Ceresit can boast of an optimal ratio of quality and price.

When choosing a material, you should pay attention to the following characteristics:

- Area of application of putty. It can be for external and internal use.

- Manufacturer's recommendations indicated on the packaging. Here are instructions for preparation and use. Some brands require special operating conditions, which relate to air humidity and temperature conditions.

- For exterior work, a regular sand-cement mixture is often used. A reinforced mesh holds this layer on the surface of the foam.

- For interior finishing work of this type, reinforcing mesh is not used; special glue is required.

In order for the choice of finishing material to be correct, you should carefully select the product: establish the correct storage conditions and service life. Under no circumstances should the mixture be used for outdoor use indoors and vice versa.

If you take into account all the quality conditions when choosing construction products, the mixture will serve as an ideal coating for many years. Otherwise, the putty will peel off and crack within a short time after application.

A PVA glue solution will improve adhesion to the glue

Finishing foam with putty

Before starting work, my friend and I laid out the slabs, diluted store-bought PVA glue with water, and went over all surfaces, including the ends, twice with long-nap rollers. The solution was applied generously. Then they left everything to dry.

The next day we continued insulating the façade. Vadik was interested in why we primed the slabs before installation.

When you cover loose material with PVA glue diluted in half with water, a protective film is formed. It strengthens the surface and increases adhesion. The glue will adhere better to the foam when attached to the wall.

The first composition penetrates into the material, strengthening the bond between the factions. The second layer creates a durable film that can bond with various materials and reduce their consumption.

Puttying the walls of a balcony covered with foam plastic

The slabs coated with soil are held more firmly by glue on the wall. How to properly plaster and putty walls before painting? Fiberglass mesh is easier to fix to the surface. If accidentally skewed, the sheet will not break.

The putty applies easily, in an even layer and does not slip.

Acrylic putty after such treatment can be applied without a reinforcing mesh. For interior work, PVA-based putty with chalk and CMC plasticizer is used. A layer of up to 2 mm of these materials is an exception and is maintained without a mesh.

Preparatory work

In addition to the correct choice of finishing material, it is necessary to make appropriate preparations for work: collect the necessary tools and prepare mixtures and products. Preliminary cleaning of the wall is also necessary.

First you need to collect all the necessary equipment:

- reinforcing mesh made of plastic or metal;

- dry putty;

- a certain type of primer;

- wide and narrow spatulas;

- construction mixer for preparing the mixture;

- roller and paint brushes;

- construction float with clamps.

First, the wall surface is prepared for attaching foam blocks or sheets. After installation of expanded polystyrene, a primary primer is performed. This procedure will eliminate the appearance of mold and mildew in the thickness of the finishing material and increase the adhesion of the finishing materials. Afterwards plastering is carried out using reinforcing mesh. And only after that they do the puttying.

Puttying process

Many inexperienced builders have a completely correct question: how to putty polystyrene foam? How to do it correctly, and most importantly, efficiently? The process consists of several main steps and processes that guarantee a good result. This is how façade putty is applied to polystyrene foam:

1. After the surface has been primed, plastering is carried out using an abrasive mesh. The mesh must be completely covered with plaster. When the finishing layer has dried, it should be sanded using a float. Sanding is best done about a day after applying the plaster.

2. Sanding (grouting) must be done efficiently so that no obvious defects or irregularities are visible. Putty is applied to such a base, which is considered the finishing base for painting.

3. Apply the prepared mixture onto a wide spatula with another small spatula, and rub the material over the surface of the wall with smooth circular movements. The layer should not exceed 3 millimeters. Puttying is carried out in separate sections.

4. At the end, the finishing finishing layer is grouted. A construction float is used for this. Such work should be carried out no earlier than every other day, but no later than 4 days. It is important not to overdry the final layer, since when grouting such material there may be a problem with individual parts breaking off.

After the work on strengthening the foam is completed, secondary priming and finishing with decorative plaster will be carried out. The secondary primer is chosen to be based on quartz grains, making it more suitable for strong adhesion. This is followed by finishing with decorative plaster and painting with facade paint.

If everything is done correctly, the reinforcing and decorative layers will last for a very long time - the service life is at least 5 years under optimal conditions. The main thing is to choose high-quality building materials and carry out preparatory and construction work correctly. In addition to aesthetic preferences, the technical side regarding putty is also determined.