Carrying out painting work involves not only preparing paint and varnish, but also preparing the correct composition for this procedure.

The overall result depends on the physical properties of the painting material.

If the work will be carried out using a spray gun, then the composition should be liquid, this way it will be possible to avoid smudges. But when holding brushes in your hands, you should use viscous paint. As a rule, all manufacturers indicate how to dilute their product, but sometimes the instructions can be an excellent advertising event that promotes a related product of the same brand, and it can be expensive.

To minimize costs and obtain high-quality components for painting a car, you should know the criteria for choosing paint, solvent, their interaction conditions, and much more.

When carrying out high-quality grinding work on the body, some cracks still remain on it. To fill all micro cracks, it is worth applying less thick paint.

Otherwise, minor deformations may appear on the painted surface of the car.

It is also not worth diluting the paint too much, because this is fraught with the appearance of shagreen, and the surface will take a long time to dry and worse, and who knows what may happen during this time.

This result directly depends on the paint, but the varnish plays an equally important role in the result; it is responsible for the gloss and strength of the coating that was previously applied.

But still, the solvent is added to the paint so that it adheres more easily to the surface; the only question remains in proportion, which depends on all the conditions where painting is carried out, taking into account technologies, volumes and many other points.

The quality of the applied coating determines the protection of the body from corrosion and other physical damage.

Solvents are divided depending on the temperature and time it takes for the paint to dry, but first of all you need to decide on the paint, how to choose it?

Painting MOBIHEL with metallic base and MOBIHEL with metallic base enamel

5.6.3.1. Preliminary surface preparation. primed only using 2K technology, must be degreased with MOBIHEL anti-silicone cleaning agent, and then the remaining dust must be removed from it using an antistatic cloth.

5.6.3.2. Preparing MOBIHEL metallic base enamel for application. It is necessary to thoroughly stir the enamel in the jar. For partial painting, check the shade by test spraying onto a test card and varnishing.

It should be remembered that the true color of the base should only be seen under the varnish . The color of the metallic base also depends on the amount of thinner added, working viscosity, nozzle diameter, air pressure, angle of application to the surface to be painted, application technology (“wet on wet” or dry).

Check the viscosity with a viscometer and bring it to 15² by adding up to 60% MOBIHEL metallic thinner. Strain the prepared mixture through a disposable funnel - filter (pore diameter 150 - 200 microns).

1st layer. When applying a metallic base, you must maintain a distance between the gun and the surface to be painted equal to 12 - 14 cm (up to 16 cm is acceptable). Before applying the second coat, the surface to be painted should be matte, but not dry.

2nd layer. The application technology is the same as the first layer.

The 3rd layer is sprayed quickly and at a greater distance from the gun to the surface to be painted.

The 4th layer (in the case of light, low-opaque colors) is applied in the same way as the third.

The thickness of the dry layer of topcoat enamel should be 15 - 20 microns.

After 15-20 minutes. to the matte surface.

Recommendations

The most common solvent to paint ratio is 1/1. Those. you need to add the same amount of thinner as paint. However, the correctness of painting directly depends on the method of applying the composition to the surface.

It is recommended to make the first layer “dry”. For such a layer, you need to dilute 2 parts of paint and 1 part of solvent. This way you will ensure the structure is protected from defects. The surface will become smoother, allowing for more uniform application.

After waiting 15-20 minutes, the second layer is applied. Apply a basic 1/1 ratio and coat the surface of the piece thickly with the spray gun. It will not cover the primer and will have a matte finish. After complete drying, the last layer is applied with the same ratio, but more thinly.

After painting, it is necessary to coat the surface with varnish with the addition of a solvent to achieve shine. When the composition has dried, polish the surface and you will achieve the desired effect.

Tips and tricks for proper paint dilution

There are a huge number of paints and varnishes, but only some of their representatives are used to paint a car:

All of them differ from each other in performance characteristics, but at the same time they are effectively used by car owners. For a 100% high-quality result, these products are diluted with solvents. What solvent should you use to dilute car paint?

Acrylic paints

This is a two-component liquid, which contains a thinner and a hardener. The desired color is achieved by applying a certain number of layers of material.

For acrylic paints, a specialized automotive solvent is used, which is more expensive than conventional organic solvents (646, 647), but it is worth it. If such a product could not be found, then you can use its analogue - solvent 651 or P 12.

Alkyd paints

Such products are rarely used for painting car bodies, only because they require a more careful approach. The resulting surface should be varnished and polished, but the finished products are distinguished by high performance characteristics and good appearance. The coating prevents the formation of corrosion and performs well in adverse conditions.

For dissolution, white spirit, gasoline, solvent, turpentine and its mixtures are used. There is a universal solvent P 4, but it is better to choose according to the product labeling.

Nitro enamels

They have a mirror effect, for which they have received wide appreciation from car enthusiasts. The body, painted with nitro enamel, differs from other cars in its gloss and metallic sheen. The only significant drawback is toxic fumes during painting work, which are harmful to human health.

Before application, the body surface must be perfectly cleaned and prepared for painting. Nitroenamel dries quickly and lasts quite a long time. It is diluted with organic products, for example, transparent 646.

Advice. This solvent is highly flammable and belongs to the category of aggressive solvents, so it must be handled with extreme caution. To play it safe, you can use the universal product P 4.

Water-based paints

This type of paint is considered the most suitable for painting a car, although it requires expensive equipment to achieve maximum effect. Such products are environmentally friendly and have a number of advantages:

What kind of paint is suitable for a spray bottle?

The following paint compositions are ideal for this purpose:

- alkyd;

- acrylic;

- water-based;

- oil;

- nitro enamels.

Interesting materials:

Is it possible to feed petunia with ammonia? Is it possible to feed tomatoes? Is it possible to connect pilot to pilot? Can I connect AirPods to PlayStation 4? Is it possible to connect an analog camera to a TV? Is it possible to connect an Android console to a monitor? Can I connect Apple TV to my TV? Can I connect wireless headphones to PS4? Is it possible to connect wireless headphones to a smart TV? Is it possible to connect a bluetooth speaker to a TV?

Painting with 1K (one-component) alkyd enamels MOBIHEL

MOBIHEL offers MOBIHEL car enamel, made on the basis of high-quality alkyd resin, light-resistant and weather-resistant pigments, solvents and auxiliaries. This auto enamel is used for repair painting of passenger cars, final painting of truck bodies, buses and other metal objects. MOBIHEL alkyd auto enamel is not used for painting plastic products .

5.6.1.1. Preliminary surface preparation. The surface to be painted, primed using 1K or 2K technologies, must be degreased with MOBIHEL anti-silicone cleaning agent, and then the remaining dust must be removed from it using an antistatic cloth.

5.6.1.2. Alkyd car enamel is prepared for application by diluting it with MOBIHEL ZS thinner or MOBIHEL ISO hardener to the desired viscosity (about 20%) .

. Apply 2 – 3 layers using the “wet on wet” system with an intermediate exposure between layers of 5-15 minutes. The thickness of the auto enamel film should be approximately 50 microns.

When painting a car completely, first the left half of the roof is painted, then the right, then the rear hood, then the front, then the right side, then the left.

At different temperatures, it is recommended to apply car enamel as follows:

Option A. At high temperatures (about 35°C and above), the first and second layers are applied with a thickness of 25 - 30 microns. The enamel should be applied “wet on wet”.

Option B. At low temperatures, the first layer is made thin, and subsequent layers are applied at normal thickness. Waiting time between coats should be longer.

5.6.1.4. Drying. If the car enamel was diluted with MOBIHEL ZS thinner, then at 20°C the drying time is 16 hours, and at 60°C – 60 minutes. If MOBIHEL ISO hardener was used, then at 20°C the drying time is 10 hours, and at 60°C – 60 minutes.

5.6.1.5. Elimination of painting defects. If necessary, eliminate paint defects by polishing or repainting after complete drying within 3 days when diluting MOBIHEL ISO with hardener or after 7 days when diluting MOBIHEL ZS with thinner.

Avoid contact of moisture, gasoline, oil and other substances on the surface of a painted car for a week.

When painting, use personal protective equipment and take precautions when working with flammable materials.

Your opinion is important to us! Was the published material useful? Yes | No

Source

Features of metallic paint dilution

Metallic is considered a complex paintwork and requires precise application technology. The product is widely used for painting vehicles (cars and motorcycles). The surface has a metallic reflective sheen. This effect is explained by the presence of special aluminum powder in the material. The finished coating is not affected by corrosion, and the result will please the eye for a long time. However, mechanical stress and disruption of the integrity of the coating will ultimately lead to its destruction. The paint does not fade under the influence of ultraviolet rays of the sun.

The quality of the coating depends on the degree of viscosity of the material, so the solvent for such paint is carefully selected. A product that is too thick can harm the result because it will not be able to completely fill the rough surface of the car body. Modern metallic paints and varnishes are diluted directly by the manufacturer and are ready for application. The cost of such materials is much higher than others, however, the quality of the coating will amaze with its splendor and beauty.

Source

Types and features of the choice of solvents and thinners for automotive paints

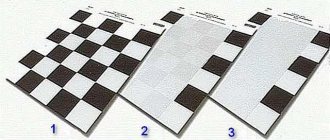

All existing types of solvents can be divided into several groups, each of which differs from each other in the rate of evaporation. The solvent that will be added to the car paint is selected depending on climatic conditions. There are 3 types of funds:

Paint diluted with a solvent is applied using a spray gun. In order for the coating to be smooth and uniform, the degree of thickness of the product should also be selected so that the equipment can work effectively.

Important! When working with paints, it is necessary to take into account the outside air temperature. This is the main parameter on which the quality of the future coating depends.

Manufacturers of paints and varnishes produce several types of special thinners, which differ significantly from solvents in their effectiveness. And this difference is significant. The diluent is simply added to the product, thereby diluting it to the required concentration.

Choosing paint for painting a car

Depending on the concentration of components, all enamels are divided into: highly filled, filled to the middle, low filled.

In the first case, such paint is marked with the abbreviation VHS, but low-fill paints are designated as LS.

“Fullness” is a property that is responsible for the viscosity and volatility of a material. Knowing this criterion, you can determine how much solvent and other components are added to the paint so that it does not dry out.

Before applying paint, you should always read the instructions for it.

How much paint will it take to completely decorate a car? This question interests not only beginners in this matter, but also more experienced car enthusiasts who have already encountered this issue.

This issue must be approached individually. The amount of paint used is also affected by the previously selected solvent.

They are also polar and non-polar . To avoid possible compatibility problems, many experts recommend using products from one manufacturer, because this is the only way to avoid all sorts of defects.

Paint made from polar components is mixed with the same solvent, which contains hydroxyl group substances - ketones, alcohols, etc. Non-polar substances include other substances, for example, white spirit, kerosene.

Trying to make a replacement is strictly prohibited. In order to change the viscosity of the consistency, you can use a special device, a viscometer.

Such a device will not be as expensive as you think, but its role is irreplaceable. The holes in this container are calibrated.

When working, you can use viscometers of different volumes and diameters. How many seconds will the material flow out of this device, these are the indicators of its viscosity.

To obtain the most accurate data, all work with the device must be carried out in a certain temperature regime.

To correctly determine the type of composition, you should understand what type of solvent is specified in the instructions for the paint.

For example, if the composition contains acetone, then it comes into contact only with polar compounds. Many people consider xylene and benzene to be universal solvents; they are not so tied to the components of the paint.

Paint and varnish compositions have their own numbers, which allows you not to get confused in the presented options:

- No. 646 is a very aggressive solvent that dilutes the paint and can make real changes to its composition.

- No. 647 is also a very aggressive composition, dilutes nitro enamel and nitro varnish, requires increased safety;

- No. 650 – softer action, used with many paints and varnishes;

- R-4 - for paint containing chlorinated polymers.