The muffler sealant allows you to repair exhaust system elements without dismantling if they are damaged. These products are heat-resistant ceramic or elastic sealants that ensure the tightness of the system. When choosing a particular sealant for muffler repair, you need to pay attention to its operational characteristics - maximum operating temperature, physical condition, ease of use, durability, warranty period, etc.

Domestic and foreign car enthusiasts use a number of popular sealants for the car exhaust system. This material provides a brief overview of the most popular and effective sealants with a description of their operation, as well as an indication of the packaging volume and current price.

| The name of the most popular sealant from the line | Brief description and features | Volume of packaging sold, ml/mg | Price of one package as of summer 2022, Russian rubles |

| Liqui Moly Auspuff-Reparatur-Paste | Exhaust system repair paste-sealant. Maximum temperature - +700°C, odorless. Shows itself well in practice. | 200 | 420 |

| Ceramic sealant Done Deal | Excellent for both repair and installation work. Increases the service life of the exhaust system by 1.5...2 years. Very dense and thick. The only disadvantage we can note is rapid polymerization, which is not always convenient to work with. | 170 | 230 |

| CRC Exhaust Repair Gum | Adhesive-lubricant for repairing exhaust systems. Used to repair cracks and holes in the exhaust system. Maximum temperature - +1000°C. With the engine running, it hardens in 10 minutes. | 200 | 420 |

| Permatex Muffler Tailpipe Sealer | Sealant for muffler and exhaust system. Does not shrink after installation. Using the product you can repair mufflers, resonators, expansion tanks, and catalysts. Maximum temperature - +1093°C. Provides high tightness. | 87 | 200 |

| ABRO ES-332 | Repair cement for muffler, resonator, exhaust pipes and other similar elements. The maximum permissible temperature is +1100°C. With the engine running, it hardens in 20 minutes. | 170 | 270 |

| Bosal | Sealant cement for exhaust systems. Can be used as a repair and installation tool. It hardens very quickly, which is not always convenient. | 190 | 360 |

| Holts Gun Gum Paste | Sealant paste for repairing mufflers and exhaust pipes. Can be used on various equipment. | 200 | 170 |

We repair the muffler with our own hands

If you suddenly discover an exhaust gas leak through a gap (crack) that has formed on the system pipe, you should not nervously estimate the cost of repairs in workshops.

You can fix everything yourself. To do this, go to the overpass for a visual inspection and convenient access to the entire system. With the engine running, crawl under the bottom and look for streams coming out of cracks formed in the pipes.

To repair a crack, you will need a metal clamp ring. The desired thickness should be at least 0.8 mm. Allow the system to cool slightly so as not to burn your fingers. Apply a layer of sealant to the gap, clamp it with the previously prepared clamp. Proceed further according to the instructions on the sealant packaging.

Repairing cracks in the manifold

The exhaust system begins with the exhaust manifold, and this part, most often made of heat-resistant cast iron, often cracks. Cracks can appear either on their own, due to a not very successful design and iron casting procedure, or be purely “man-made”, arising from driving through deep puddles or from washing a hot engine with a high-pressure gun. Cracks in the manifold are a serious problem because exhaust gas leaking through them fills the cabin with toxic smoke and causes extraneous noise in the engine sound. Repairing cracks in a cast iron manifold is not an easy and expensive task, often requiring removal of the manifold and not always leading to success, since cast iron is difficult to weld and repairs do not help for long.

An alternative method is to use an ultra-high temperature composite to seal the crack. In the DoneDeal assortment it is called “Thermostal 1400” DD6799. This special sealant is designed to fill cracks in cast iron and steel parts that heat up to 1400 degrees and are subject to constant vibration loads. The crack in the metal is first cleaned with a metal brush and, if possible, drilled along the edges with a thin drill to prevent further spreading. After which the cavity is filled with the composition - as is for sizes up to 9 millimeters, and in two stages with reinforcement with steel mesh for larger sizes. Primary polymerization of the composition occurs within 3–4 hours, after which it finally hardens when the part is brought to operating temperature (if we are talking about the exhaust manifold, then when the engine is completely warmed up). Solidity, reminiscent of welding, is achieved due to the chemical reaction of DoneDeal DD6799 with iron-containing materials and the diffusion of iron ions from the composition into the metal structure.

All you need to make your own exhaust pipe repair using products from the American brand Done Deal easy and effective is to carefully study the instructions on the packages before starting work. Then you will save both time and money. After all, following the instructions, you will do everything quickly and efficiently, and you will not have to buy new expensive parts and install them at a car service center.

Source

Exhaust system repair methods

The whole process comes down to sealing holes in the muffler and cracks that have arisen due to metal corrosion or external damage. The following methods are distinguished:

- Welding. To accomplish this, the seams must be of a certain rigidity and tightness, and this cannot be achieved with large holes or cracks. Sometimes the right thing to do is not to weld, but to weld a new part onto the part. But all this work requires equipment, space and skills.

- Sealants. You can use sealants that are not sensitive to high temperatures. They cover very minor holes, and they also seal the exhaust system when replacing parts or assembling them.

- Bandage. Ceramic-based bands can also withstand high temperatures and are an easy way to repair a muffler. Most often, the bandage is used for small holes and at joints and welds.

- Cold welding. It is different from conventional welding. Connections occur without exposure to temperature, due to the penetration of the welding mass into the necessary parts.

Each of these methods has pros and cons, so the choice is not always easy. Due to the frequent use of cold welding, which does not require special equipment or preparation, but has a very effective effect, it is worth saying more about it.

Criterias of choice

When choosing a sealant, it is important to be guided not only by the manufacturer’s promises and reviews of other motorists, but also by what parts the composition is intended to repair, what temperatures it can withstand, and whether the part being repaired is subject to constant vibration or not. Based on this, the car owner selects a suitable composition, otherwise the exhaust system will require new repairs in a short time

Temperature operating range

The most important indicator depends on how long the sealant will perform its functions. The higher the operating temperature range, the better.

In order not to make a mistake when choosing a sealant, it is important to carefully read the information on the packaging and pay attention to how long the composition will remain stable at the specified temperatures.

State of aggregation

All high-temperature sealants are divided into silicone and ceramic; the product’s resistance to constant fluctuations and vibration depends on the composition.

Silicone

Used in gaskets between parts. After the composition has frozen, it remains slightly mobile, so it is not afraid of constant vibrations.

Ceramic

Used to correct cracks, holes and rusty parts. After complete drying, the composition becomes hard, which is why it cannot withstand constant vibrations. It is better to use such a sealant when repairing fixed parts of the exhaust system. Motorists more often use silicone-based sealants, since they do not crack on both moving and stationary parts of the exhaust system.

Type

All high-temperature sealants are divided into several types depending on their characteristics.

For car exhaust system repair

The base is fiberglass, to which manufacturers add additional substances. A distinctive feature of sealants is the hardening time; it rarely exceeds 10 minutes. The compositions tolerate high temperatures well, but crack under constant vibration and shock, and are designed to eliminate damage to the exhaust pipe

Mounting paste

The composition hardens quickly and does not lose its properties even due to high temperatures. Used when installing new or repaired elements.

Muffler sealant

It is often used as a preventative measure; it takes some time to completely harden. This is a universal product that can be used to repair any part of the exhaust system.

Cement for muffler

Such sealants form a hard layer on parts and are not afraid of high temperatures. The most durable composition that is used to repair fixed parts of the exhaust system.

Taking into account the above-described features, the craftsmen select the required type of composition based on the existing damage and operating conditions of a particular part.

Choosing muffler paste

Any means for repairing the exhaust system can be divided into two types. The first includes various tapes, bandages, fiberglass gaskets impregnated with heat-resistant adhesives and sealants. They are used to repair significant damage and large holes. The second type includes high-temperature sealants for sealing small defects and sealing joints and joints.

Sealants consist of metal and ceramic substances, which is why they are often called metal-ceramic. There are also silicone and acrylic compounds on sale, but they are not suitable for muffler repair due to their low service life and the inability to work in difficult conditions.

Sealants may look like paste, cement, or glue. They are often sold as “travel kits”, which also include patches and tools. Such kits are designed for repairs outside the garage if problems arise on the road. Among the most popular brands are Bosal, Abro and a number of others.

Done Deal

This is an excellent ceramic-based cement sealant that can be used to eliminate problems with the exhaust system (preventing gas leaks, eliminating burnouts and cracks), as well as when installing new spare parts. The heat resistance of the sealant reaches +1400 degrees, it perfectly withstands mechanical factors, the influence of an aggressive external environment, moisture, and temperature changes. The composition dries in 2 hours. It is not always possible to find it in stores by article number; in Russia and the CIS countries it is less popular than in the USA and Europe.

Permatex

This sealant is also of high quality and is considered universal. It has a lot of positive properties:

- elasticity;

- elasticity;

- resistance to oils;

- strength;

- good sound insulation;

- minimal shrinkage.

The product dries within a day, which is a minus. But with its help you can make a gasket up to 0.6 cm thick, which works better and longer than rubber.

Liqui Moly

The composition is produced in Germany, has been on the market for a long time, and has consistently excellent quality. Liqui Moly is a ceramic sealant that can withstand up to +1400 degrees, a universal tool for performing a huge range of work. Its advantages are:

- prevention of sticking;

- prevention of metal rusting;

- reliable sealing of joints;

- increasing the level of noise insulation;

- lack of response to negative external influences;

- ability to work in physically and chemically aggressive environments;

- absence of harmful components.

In addition to repairing the muffler and other parts of the exhaust system, the paste is used to eliminate problems with ignition and pads.

Abro

This brand of sealant is made in the USA. It is excellent for repairing the exhaust system, as it can withstand heating up to +1100 degrees and increases sound insulation. It is durable, can withstand heavy loads, and is wear-resistant, so it lasts for several years. Abro paste has a black and gray tint.

CRC

A distinctive feature of CRC sealant is its fast drying time, it only takes 10 minutes with the engine running to fully cure (this increases to 10 hours if left idle). This product is especially recommended for emergency repairs when the muffler breaks down on the road. Since the sealant contains no solvents, it is considered safe and non-toxic. The advantages of CRC are undoubted:

- good noise insulation properties;

- protection against melting and corrosion;

- reliable operation at +1000…+1300 degrees.

What affects the temperature of the engine?

The normal operation of the vehicle's power plant and its service life largely depend on factors such as the optimal temperature regime, which is provided by the cooling system.

Maintaining the required temperature is possible only under two conditions - proper operation of the components and elements of the system, as well as its tightness.

But it often happens that the cooling system leaks. But it’s one thing when a leak appears in rubber elements - pipes and pipes or at their connections, and quite another thing if the coolant leaks due to damage to the radiator or a crack in the cylinder head, the block itself or the gasket between them.

In the first case, fixing the problem will not be difficult - just tighten the clamps or replace the damaged tube. That is, such repairs are simple and not expensive.

But if one of the radiators (the main one, the stove) is leaking or traces of liquid constantly appear in a certain area of the engine (where the pipes do not go through) - everything is much more complicated.

And in this case, the best option would be to contact a service station or fix the leak yourself by sealing the crack (for radiator leaks) or replacing the cylinder head gasket. In general, repairing leaks on metal elements is quite troublesome and complicated.

At the same time, leaks often appear either on the way, or at a time when the car is really needed and there is simply no time for repairs.

Read on the topic: Repairing a car radiator on the road.

In such cases, you can do differently - leave everything as is, and simply constantly monitor the coolant level, or use a sealant for the cooling system, which is now widely represented on the auto chemical market.

Description and characteristics of silicone

As a result of the chemical synthesis of polymers, elastic silicone is obtained. There are several types of material - elastomers, liquids, resins. The most common is rubber-like silicone, which has been widely used since the middle of the last century.

The main characteristics of silicone include the following:

- Safety. The material contains no toxic substances, so it is harmless to humans, animals and the environment.

- Wide operating temperature range. The ability to maintain shape and quality at extreme temperatures expands the range of uses.

- High elasticity. Even with prolonged use, the material remains flexible and does not crumble or crack.

- Water resistance. Silicone products can be used in places where there is frequent contact with liquid, as well as directly in an aquatic environment.

- Inert to microbes. Exposure to parasites does not affect the structure and appearance of silicone. In addition, disinfection can be easily carried out if necessary.

Additional tips and tricks

To ensure that the heat sealant lasts longer and does not lose its properties, it is important to remember the following tricks:

the product can only be used as a temporary measure, since under the influence of constant vibration and high temperatures it will begin to quickly deteriorate; use is only possible if the cracks are outside and clearly visible, otherwise the system will have to be completely dismantled and replaced with a new one; It is important to remember that the sealant completely hardens within a few hours, the process can be accelerated with heat; the product is applied only in an even layer, the excess is removed or carefully smeared, thereby achieving even greater tightness.

Proper use of the composition will not only extend the life of parts, but will also help delay major repairs of exhaust pipes or muffler.

Flaws

Like any compositions, welding of this kind has the following disadvantages:

- This is a toxic material, so during use they wear PPE and the room is ventilated.

- Use after the expiration date is not allowed.

- It is necessary to select only those suitable for the welding plane, otherwise the process will be useless.

- Corrects minor damage to the exhaust structure. If the defect is large, it is better to resort to welding or contact special services.

TOP 5 best high-temperature sealants for your car

DoneDeaL gasket sealant. Made on the basis of silicone, it can withstand a maximum temperature of +345°C, which is quite enough for the needs of working with the engine. According to sellers, it qualitatively seals holes, is not afraid of vibration, and has excellent resistance to high and low temperatures. It is not destroyed due to contact with oil and other chemical impurities. Estimated cost (205 g tube) – $13.

Hi-Gear (HG2235). Excellent for engine repairs. American high-quality production allows the use of sealant in areas of constant contact with oil. Recommended for use on diesel and gasoline engines. According to manufacturers, it effectively eliminates oil leaks from the crankcase, cylinder block (cylinder head), and manual transmissions. The product restores the size and elasticity of gaskets and seals in one use. Estimated cost (444 g) – $10.

ABRO Gray 999 Gasket Maker. Works great with parts heated up to +343°. Universal sealant is suitable for sealing almost all car gaskets. Resistant to gasoline and oil. Dries completely in 24 hours. Price approximately (85 g tube) – $4.

ABRO Red Gasket Maker. Another product from ABRO (which produces sealants). High temperature engine sealant withstands up to +343°C. Has a red color. The price is (85 g) – $3.

Mannol Red Gasket Maker. Budget sealant for cars from Mannol. Has a red pigment. The manufacturer recommends using it on vehicle components with a maximum heating temperature of up to +300°C. A one-component silicone-based sealant turns into rubber (figuratively speaking, of course) at room temperatures. The gasket made from the product does not crack or shrink. Successfully performs the role of oil seals and gaskets (other seals). Can be used to repair the oil pan, thermostat housing, transmission, valve mechanism. Resistant to gasoline, lubricants, coolant, and alkalis. Easy to use and remains flexible. Before application, the surface must be degreased with soapy water. Drying time 24 hours. Operating temperature range from -50 to +300°C. Estimated cost (85 g) – $2.

DIY muffler repair

- carefully inspect all parts to find and localize the area of failure and exclude the presence of other defects;

- clean all elements from dirt, degrease with acetone, be sure to remove traces of old sealant, if it was used previously;

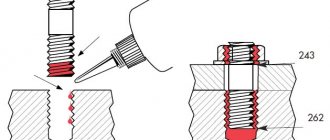

- open the package with the composition, put the nozzle on the spout (it is included in the kit);

- apply a seam 2-3 mm thick;

- if necessary, use clamps, overlays, patches;

- leave the sealant to dry for a couple of minutes, connect the parts, wait for the time specified in the instructions, and only then start operating the car.

Sealing the exhaust system is a temporary measure. In any case, if possible, you should contact a car service to replace or weld parts, because a glued muffler cannot last as long as a new one.

Restoring large-scale damage

Burnt-out sections of the muffler are restored by applying stainless steel patches with an overlap of 30 mm onto undamaged metal. The linings are drilled to the Ø of the self-tapping screw body. Sequence of operations:

- Remove burrs, shape the muffler, clean the trim from the inside, treat with solvent, and dry.

- Apply sealant to the edges of the holes and patches with excess.

- Fasten the screws, add a drop of cold welding under the caps, and tighten the screws.

Elimination of pipe burnout:

- The burnt area is cut out and removed, replaced with a larger diameter pipe.

- Prepare the surfaces, drill the overhead pipe for self-tapping screws on both sides.

- Apply cold welding to adjacent areas and connect.

- Secure evenly with self-tapping screws to seal the pipe caps and joints.

Features of repair of heat exchangers and heat-resistant pipes under pressure:

- Preparation of the repair site.

- Cut and bend the stainless steel plate along the diameter of the pipe with an overlap of 20 mm.

- The composition is applied to both parts.

- Secure the cover with tension clamps.

- It is recommended to reinforce small cracks with a dense steel wire bandage over glue.

When and why you might need a sealant

The exhaust system is operated under the most difficult conditions, so its service life cannot be too long. For example, the most durable filters made of stainless steel and aluminum last up to 10 years. Further, holes, burnouts, breakdowns, elements of chemical corrosion appear on the parts, and the effect of the system’s operation is sharply reduced. The cheapest mufflers may develop such problems within 1.5-2 years.

The following factors increase the risk of failure:

- overly intensive use;

- incorrect installation of system parts;

- use of low-quality spare parts during repairs;

- penetration of aggressive chemicals from the environment (for example, from road surfaces);

- too strong vibration load, driving through potholes.

In some cases, a complete replacement of the muffler, and sometimes the entire exhaust system, will be required. But often it is enough to use a sealant - a paste-like polymer-based material that reliably holds together various joints and ensures their strength.

An important condition for using sealant is that defects are located only on the outside. Internal problems are solved in a different way - by completely unpacking the structures

It is important to immediately inspect the exhaust parts to determine the cause of the breakdown.

Here are the main tasks that can be solved using sealant:

- installation of new exhaust system parts, strengthening of the annular surfaces of mating parts;

- sealing of connected, mounted elements, especially manifold flanges;

- Repairing a burnt-out muffler, sealing holes and cracks using patches (including metal ones).

Reviews from motorists

Most motorists speak well of almost all sealants for repairing exhaust systems. These sealants are usually used in two cases: installation of individual exhaust tract elements with additional insulation of connections, or repair of minor damage.

The lifespan of a sealant depends on a large number of factors. Therefore, it is impossible to name any exact time interval during which the composition will not collapse. But in general, if the installation conditions are met, the sealant placed in the joint will last until the next system repair, and patches in some cases last up to 5 years.

Negative reviews are usually associated with improper use of products. For example, if you prepare the connection poorly (do not remove rust, soot and oily deposits), then the sealant will not adhere well to the surfaces, and eventually, after a short period of time, it will begin to crumble and fall off. Also, before starting full operation of the car, it is imperative to give the composition time for complete polymerization.

It is not recommended to use sealants for exhaust systems to repair cracks in potentially stressed areas and burnouts in heavily corroded and burnt-out elements with a critically thin metal thickness.

Source

Sealant or welding

To repair mufflers, both methods can be used - sealing with pastes and other compounds or welding. Each of them has pros and cons. The use of welding is possible only in a repair shop, and it is impossible to carry it out without skills and expensive equipment. But such repairs will be no less reliable than replacing the part with a new one, because the exhaust system element will serve faithfully for many years.

Sealant is an indispensable thing in “camping conditions”, when repairs need to be carried out quickly and efficiently. Every car enthusiast who knows where the muffler is located can use the sealing method; no special skills are required. The cost of gluing the part will be minimal, as will the time spent working with it. But with the help of sealant it is impossible to fasten the internal components of the system, and the reliability of the repair will be less than after welding. Conclusion: the sealant is ideal when there is no time or money to visit a service center; it will help solve the problem of a broken exhaust system as quickly as possible, but for a limited period of time.

Manufacturers

Reviews (besides Abro) note several companies that produce high-quality tape for muffler repair:

- CRC.

- Done Deal.

- K2.

In addition to the tape itself, the kit may include a set of square or round patches, protective gloves, and wire for more reliable fixation. With the help of the latter, the material is rigidly fixed on the pipe until it completely hardens.

Then the wire can be safely removed. All parts repair work is carried out strictly wearing protective gloves.

Proper Use

Before work, you need to prepare the surface with which the sealant will come into contact. It needs to be cleaned of rust and degreased. The ambient air temperature at the time of work should be +5 degrees Celsius and above.

It is very important that the surface is dry because high-temperature putties cannot be used on wet surfaces. There are different methods for applying high-temperature sealants, but the most popular ones are using a mechanical gun or a regular spatula.

There are different methods for applying high-temperature sealants, but the most popular ones are using a mechanical gun or a regular spatula.

CRC Exhaust Repair Gum

This sealant is presented on the market as a black putty based on inorganic compounds and modifying additives. Bonding adhesive power is a key feature of Exhaust Repair Gum, which allows cracks and holes to be sealed even without dismantling the system. As practice shows, the composition acquires sufficient hardness for operation in less than a day, without requiring special crystallization conditions. With the engine running (idling), the coating hardens in just 10 minutes. The final effect of using this sealant for a car exhaust system can be expected to increase structural strength, restore surfaces with defects and reduce noise. In terms of protective properties, the shell protects the target area from moisture, thermal influences and vibrations (damping effect).

Brief overview of popular products on the market

Let's look at several popular muffler sealants in Russia.

There are quite a few other exhaust sealants on the market. They all have good efficiency. And in general, the rule works: the higher the price, the stronger and better the connection will be insulated or the damage will be closed.

Properties of sealant

What does muffler sealant do? This is a composition that, after application, takes on a solid form and prevents gases from leaking out. It is a kind of liquid patch that is usually used as a temporary repair. The sealant differs from conventional glue not only in consistency, but also in characteristics. Yes, it is very heat resistant. Silicone sealant is capable of maintaining its structure at 1300 °C or more. Can be used both at joints to repair cracks and in burnout areas. The sealant is resistant to moisture and water, and is not afraid of sound vibrations.

Can also be used as an analogue to metal gaskets. The latter wear out quickly and cause backlash. The sealant gives a firm shrinkage to the part and does not change its properties for a long time.

What are the criteria for choosing a muffler sealant?

Despite all the variety of car muffler sealants available in stores, you shouldn’t buy the first one you see! First you need to carefully read its description, and only then make a purchasing decision.

So, when choosing a sealant, you need to pay attention to the following factors

Temperature operating range

This is one of the most important indicators. Theoretically, the higher the maximum permissible operating temperature, the better. This means that the sealant, even with prolonged use and high temperatures, will not lose its properties for a long time. However, in reality this is not entirely true. Many manufacturers deliberately mislead consumers by indicating the maximum permissible temperature that the sealant can cope with only for a short time. Naturally, this value will be higher. Therefore, you need to look not only at the maximum permissible temperature value, but also at the time that the sealant is designed at this temperature.

State of aggregation

In particular, heat-resistant muffler and exhaust pipe sealants are divided into silicone and ceramic.

After hardening, silicone sealant remains slightly mobile, and does not lose its properties during vibration or small shifts of the processed parts. These are used on gaskets when connecting exhaust system elements.

Ceramic sealants (also called pastes or cements) become completely immobile (stone-like) after hardening. This is why it is used to cover up cracks or rusted holes. Accordingly, when vibrations occur, they can crack.

There are always small shifts and vibrations between the elements of a car's exhaust system. Moreover, even when driving, the car constantly vibrates on its own. Accordingly, it is advisable to use a silicone-based muffler sealant paste. Cement for a muffler is only suitable for directly processing the body of the muffler itself.

Sealant type

Sealing materials used to repair exhaust system elements are divided into several types, differing in their performance characteristics.

- Exhaust system repair adhesive. Such compounds are intended for sealing small holes and/or cracks in the exhaust pipe and other parts. As a rule, it is created on the basis of glass fiber and additional additives. It differs in that it hardens quickly (in about 10 minutes). It is resistant to thermal loads, but can also crack under strong mechanical loads.

- Mounting paste. Typically used for machining flange and hose connections. As a rule, it is used when installing new parts or when repairing and installing repaired ones. When exposed to high temperatures, it hardens quickly and retains its properties for a long time.

- Muffler sealant. This is one of the most common options. It is made on the basis of silicone with thermal additives. Can be used both as a preventive and repair agent. Silicone sealant can be used directly in the muffler, pipes, resonator, exhaust manifold. Doesn't freeze right away.

- Cement for muffler. These compounds have very high hardness and can withstand the highest temperatures. However, they can be used to repair only fixed parts - muffler housings, resonator, as well as for processing joints. Cement dries very quickly when exposed to high temperatures.

Muffler repair by cold welding

To understand how to seal a muffler using cold welding, you should start by defining what it is. This is a 2-part adhesive with wide application. It has many advantages, including:

- Resistance to water, reagents, high temperatures (up to 150 degrees).

- Resistance to shock loads (up to 120 kgf/cm²) and vibrations.

- Easy to use, so anyone can handle cold welding.

- The cost is not great.

- The weld dries easily, but it usually takes a day to fully set.

- Can be used in any conditions.

Of course, there are also disadvantages. Among them:

It should be used with caution due to the toxicity of the material. Cold welding is not suitable for large-scale holes. It is necessary to choose the right composition. Use only before the expiration date.

Of course, there are more advantages than disadvantages, which is why this method of repair has gained such popularity. Among the positives is ease of use, and this is easy to prove by looking at the algorithm for repairing a muffler using cold welding:

- A cloth, a tourniquet or a clamp will be useful for fixation.

- Before work, the surface is cleaned, degreased and sanded with sandpaper.

- Wear gloves to avoid damaging your hands with reagents.

- The mixture is mixed according to the instructions. If it is in a syringe, you should mix it again.

- To avoid the risk of poisoning, repairs are carried out outdoors. Glue is quickly applied to the surfaces to be glued; for high bond strength, you need to hold the parts together.

- Everything is fixed with a tourniquet.

- After an hour, you can clean the glued area from any remaining glue. Drying speeds up to 20 minutes if the temperature is 20-30 degrees.

- The mixture will get stronger in a day and will be ready for new loads.

Repairing a muffler burnout using cold welding

Many people are puzzled by whether it is possible to weld a muffler using cold welding. And the answer, of course, is positive. After all, this is an effective and fairly quick way to eliminate all defects, and this is the most important thing.

How to choose cold welding

When choosing cold welding to repair a muffler, you need to pay attention to the following parameters:

- Time of initial and complete hardening. The latter usually does not differ and is 24 hours, but the first varies from different manufacturers.

- Time of plasticity. Shows how long it will take to adjust the parts until the glue sets.

- Use temperature. On average it will be from -20 to +15.

- Heat resistance. On average, this value is somewhere up to +260 degrees Celsius. If you need something more resistant, then there is a limit of +1300 degrees Celsius.

- Glue consumption. Depends on the density of the parts to be joined and the experience of the user. For a seam 25-30 mm long, a regular tube of 60 ml of paste glue is enough.

On the one hand, so many criteria for selecting cold welding for a muffler complicate the choice. However, on the other hand, thanks to such a wide selection, everyone will choose the right material for themselves.

Advantages

- The material has a relatively low cost, which makes it the most affordable of the repair methods;

- The composition gives the compound high qualities of strength and temperature resistance, which is indispensable when used for a car;

- Cold welding for metal, which is widely used on the market, is suitable for such purposes;

- The repair time is relatively short, as it only takes a few minutes of the process itself and about an hour of waiting until everything dries;

- Can also be used for other metal parts in the car;

- Supplied in packages in which the quantity of material is presented with a reserve.

Flaws

- There is a risk of choosing the wrong composition or deteriorating it through improper storage;

- The reliability of the connection is inferior to welding, which may be fundamentally important for some use cases;

- Not suitable for large-scale repair procedures;

- Toxic in use, so requires the use of special personal protective equipment.

Suitable brands

When wondering whether it is possible to cold weld a muffler, first of all you need to pay attention to which one, because there are many different brands that are more or less suitable for this matter. One of these is the cold welding for the Abro Stell muffler, which is manufactured in the USA. It has the following technical characteristics:

| Parameter | Meaning |

| Shear test | 257 N |

| Pull voltage | 5.9 MPa |

| Initial hardening time | 1 hour |

| Time to maintain the plastic state | 7 minutes |

| Complete hardening time | 24 hours |

| Maximum joint shear force | 1050 N |

| Average shear stress | 2.39 MPa |

In addition, there is also a domestic analogue, which even surpasses this well-known brand in its characteristics. This is a cold welded Titanium, which is produced by Elf Filling. It comes as two separate components. The cold welding characteristics for this brand of muffler are as follows:

Heat-resistant sealant for muffler (exhaust system)

The exhaust system is an important component of any car, greatly reducing the sound produced by the internal combustion engine (ICE). Without this acoustic filtration system, using cars would become an almost unbearable experience.

Today on the market you can buy for every car (be it a foreign car or a domestic one) several types of muffler “original - factory” and “not original”.

In the first case, you will pay a lot of money, but you will also receive a high-quality exhaust system that will last from 5 years or more (depending on many factors, including, for example, road surface, use in winter, rain, outside asphalt, etc.) .

In other cases, you can buy a non-original exhaust system, made it is not clear where, which costs half as much (usually the cost differs by half), but such a part will last half as long (according to reviews, sometimes after 1 year it already rusts due to condensation ).

In any of the options, you need to install a high-quality exhaust system (muffler) on the car. A heat-resistant sealant that can withstand up to +1500 degrees Celsius will help with this work.

Why such a high threshold? Did you know that the muffler can heat up to +1300 degrees during intense driving? Therefore, it is very important to choose for the muffler not a high-temperature sealant where use is limited to +300/350 degrees, but rather a heat-resistant one with an upper mark of up to +1500 Celsius

Operating temperatures

All components of the intake system are exposed to high temperatures every day. The collector heats up the most - up to +1300 degrees. Other components and parts heat up less - from +250 to +1000 degrees. That is why to repair the system you need to use only heat-resistant sealant that can withstand up to +1500 degrees. The ideal option is sealants based on sodium silicate or liquid glass.

Glue selection

Several types of glue are suitable for the restoration of silicone products. To choose the right composition, it is recommended to familiarize yourself with the characteristics of the available options and settle on the appropriate one, taking into account the characteristics of the product. As a rule, silicone sealant or cyanoacrylate glue is used to connect parts. Such solutions reliably eliminate defects and firmly join surfaces.

A good gluing result is ensured by an adhesive that meets the following requirements:

- elasticity and strength - the composition forms a seam that is not damaged by external influences and vibration loads;

- optimal consistency - the thickness of the mixture to penetrate hard-to-reach areas and fill small cracks;

- ability to withstand high temperatures - just like silicone itself, the glue must withstand heat without loss of properties;

- ease of use - convenience is affected by the packaging of the substance and the method of application;

- rapid polymerization - a high-quality solution can harden in a couple of hours.

Silicone adhesive sealants

Elastic silicone sealant is made from silicon, which is found in the form of quartz or sand. First, polymers are created from the material, which act as the base for the sealant. The source material determines the key parameters of the sealant. The main characteristic is its high tensile capacity, which allows the sealant to be used to work with moving joints. The material compensates for deformation at the joints and does not collapse under external influence.

Special types of sealants with increased heat resistance can be heated up to 300 degrees. Also, the possibility of widespread use is associated with the resistance of the sealant to the negative effects of ultraviolet rays, cleaning agents and humidity.

Cyanoacrylate adhesives

The basis of cyanoacrylate solutions are esters of alpha-cyanoacrylic acid. Plasticizers necessary to regulate viscosity and stabilizers to improve adhesion are used as additional components. Depending on the brand of cyanoacrylate solution, it may contain modifying components that are responsible for the resistance of the resulting seam to moisture and heat.

Cyanoacrylate compounds demonstrate immunity to organic solvents and electrical insulating properties. To dissolve the applied adhesive after hardening, treatment with specialized substances will be required.

Causes of muffler failure

Since the muffler has virtually no protection from the influence of the external environment, it is made of durable materials so that its service life is longer. The quality of the roads, obstacles and even simple stone bounces lead to damage to the muffler.

However, mechanical influence is not the most common reason leading to breakdowns. Mostly, chemical corrosion causes breakdowns. The environment in which the muffler operates can be called aggressive. Because its body is exposed to water, snow, and various reagents to protect roads from icing. All this sticks to the surface and leads to muffler burnout.

Ultimately, a hole appears in the muffler, which is made by rust, or due to those very obstacles on the roads. If the damage is serious, the muffler is usually replaced. But if the damage is minor, then one of the methods for repairing it is used.

Faulty muffler