The muffler acts as an acoustic filter in the exhaust system, also reducing the amount of harmful substances in the exhaust gas. It minimizes the amount of noise generated while driving, which makes the car socially acceptable, since the days when vehicles made loud noise on the street are long gone. Minimal damage to the muffler can make the exhaust sound louder - this is what allows you to find out about a malfunction. Driving a car with a broken exhaust system is prohibited, so drivers resort to using a sealant that allows them to make repairs:

- Fast;

- With your own hands;

- Without the use of welding or other complex tools.

Exhaust system overview

The exhaust system is an essential element of a healthy and safe car. It removes gases generated during fuel combustion. Without an acoustic filter, which is served by a muffler, the car is incredibly loud, which disturbs others.

If any crack appears, you need to either contact a specialist or carry out the repair yourself, using sealants designed specifically for the exhaust system of a car.

So, to understand the intricacies of working with the exhaust system, you need to know its components:

- Exhaust manifold connecting 1 or 2 gas flows.

- A receiving pipe that combines several flows.

- A catalyst that reduces the toxicity of gases by oxidizing them.

- A resonator that reduces sound volume.

- Directly the muffler.

The problem can affect any element, but the exhaust manifold and muffler are most often affected. It is for them that special sealants are developed that can withstand high temperatures and not be affected by external factors.

Composition of the exhaust system

Any exhaust system consists of the following elements:

- Collector

- Downpipe

- Corrugation

- Catalyst

- Resonator

- Middle pipe

- Muffler

The exhaust system works as follows. During the combustion of fuel, a large amount of toxic gases are released, which enter the manifold under high pressure. Its main task is to connect all exhaust outlets into one. The standard manifold creates high resistance to exhaust gases.

The gases then move into the exhaust pipe, where their temperature can reach over +1000 °C. After this, they enter the catalyst through the corrugation, where toxic gases are converted into harmless ones. In many cars, the catalytic converter also reduces noise levels and makes the exhaust sound pleasant to the ear.

Next, relatively harmless gases enter the resonator, which further reduces the noise level, and from it into the middle pipe. After it, the gases enter the muffler, which also serves to reduce the noise level.

When to use sealant

Defects that have arisen can be sealed only if they are located on the outside. If the breakdown occurs within the system, you will have to perform a complete unpacking. But this activity is not cheap and very labor-intensive, so it is more profitable to purchase a new part. But there are a number of problems that can be easily solved using sealant.

Typically, system breakdowns are associated with the following aggressive factors:

- Temperatures up to 1300 degrees, which gives the possibility of burnout.

- Constant vibration exposure, which accelerates wear.

- Environment with electrochemical components.

- Potholes on the roads, various mechanical damages.

Exhaust elements suffer significantly from previously performed repairs. Their condition will largely depend on this. A system that has undergone repairs is more susceptible to damage and will require inspection and minor repairs more often.

To understand that there is something wrong with the system, you should listen to the exhaust of a running car. If there are defects, you won’t be able to miss it, because the sound will be many times louder than usual. Immediately after identifying a problem, you can fix it with a sealant, but you should understand that not all damage can be removed in this way.

If a defect is identified, you need to conduct a thorough inspection of the exhaust parts to determine what caused it. When the damage is localized and can be repaired with sealant, it’s time to get started. Small cracks, gaskets, burnouts are problems that can be solved with the help of a hermetic composition. But it is important to remember that this will be a temporary measure and the exhaust pipe will need to be replaced soon.

Operating temperatures

All components of the intake system are exposed to high temperatures every day. The collector heats up the most - up to +1300 degrees. Other components and parts heat up less - from +250 to +1000 degrees. That is why to repair the system you need to use only heat-resistant sealant that can withstand up to +1500 degrees. The ideal option is sealants based on sodium silicate or liquid glass.

Choosing muffler paste

The sealants for working with the muffler consist of ceramic and metal components. Acrylic and silicone are often used in everyday life and in production, there are many of them, they are convenient to work with, but their wear resistance and heat resistance are rather weak. Ceramic sealant is more reliable; the presence of components such as metal and ceramics increases resistance to extreme temperatures and the influence of mechanical factors.

Repairing a car can be carried out using different types of compounds in the form of cement, glue, paste. They are most suitable for repairing rounded elements. Having paste and a basic set of tools, repairs can be carried out in the event of a breakdown on the road.

Drivers should take note - what else can the muffler repair composition be used for:

- Sealing of any automotive elements that are exposed to high temperatures (and not only automotive ones, sealants are actively used in everyday life).

- Prevention of breakdowns due to significant wear of exhaust elements.

- As a spacer, for the purpose of gluing parts that do not fit the parameters.

- As a connector for stronger fixation of elements.

- To prevent sticking of aggregates.

- Creating sound insulation, which is extremely necessary when working with a muffler.

Heat-resistant, high-temperature sealant can be purchased in packages of 200 grams, which will be enough to fix minor damage to the muffler. Of course, there are smaller and larger tubes.

Done Deal

The sealant from Done Deal, a little-known company in Russia but popular abroad, is well suited for working with any elements of the exhaust system. It is resistant to temperatures up to 1400 degrees, which means it is sure to fulfill its sealing task. It tolerates mechanical factors well and can be used for a long time in aggressive conditions. The composition is resistant to moisture, does not melt, and hardens within 2 hours after application.

Permatex

Permatex automotive heat-resistant compound has a limited range of applications, but is not inferior in quality to its analogues. The sealant from this company copes with sealing and insulation from noise, minimizing the likelihood of repeated failure.

The composition has minimal shrinkage, which is not visually determined; there is no need to additionally calculate the volume of application. The product dries within 24 hours, so after repair the car will have to be left in the garage for 24 hours.

Liqui Moly

High-quality ceramic mixture from a proven German manufacturer. Used for many jobs in case of breakdowns of the exhaust system, ignition, pads. The composition is universal and can be a leader among all listed.

The advantages of Liqui Moly sealant for exhaust parts will be:

- Prevention of corrosion and sticking.

- Complete sealing of elements.

- Improving the quality of sound insulation.

- Reducing the negative impact of an aggressive environment.

- Increasing the strength of connections.

- Simplification of disassembly of parts.

This composition, like many ceramic ones, can withstand up to 1400 degrees. But it is distinguished by the absence of toxic emissions. It can be used with most seals.

Abro

American Abro sealant is quite common in Russian construction stores. It is inexpensive, but this is because its range of applications is limited. It can be used to isolate from loud sounds, eliminate breakdowns of the catalyst, muffler, pipe, resonator.

It can withstand up to 1100 degrees, which also doesn't put it among the best tools for fixing exhaust breakdowns. But regarding loads, it is durable, wear-resistant and lasts a long time. The paste is available in several shades. The most popular are black and gray.

Crc

The first thing to note about Crc exhaust system sealant is that it dries quickly. The composition hardens within 10 minutes of engine operation or 10 hours of inactivity. This is the best option for working on the road. The rest of the sealing compounds require at least two hours before the car can be used.

Crc sealant provides high-quality noise insulation. It contains no solvents and protects against moisture penetration, corrosion and melting. What's also important is that it can be used on every part of the exhaust system, be it parts that heat up to 1000 degrees or connecting elements that at times endure up to 1300 degrees.

Tips for using automotive sealant

Experienced craftsmen give several recommendations that will help when working with automotive sealant and during its storage:

- Before applying sealant, it is recommended to thoroughly clean and degrease the surface.

- The surface to be applied must be completely dry.

- To ensure that the sealant is applied in an even layer, it is recommended to use a special pneumatic gun.

- Use a regular rubber spatula to trim the edges and remove any remaining sealant.

- If you need to remove the sealant, you should first warm it up well with a hair dryer and remove it in small pieces before it cools down.

DIY muffler repair

How to use sealant correctly:

- All elements of the exhaust system are preliminarily inspected. You need to localize the defects to fix them in one go, if possible.

- Before applying the paste, the surface is cleaned of old materials.

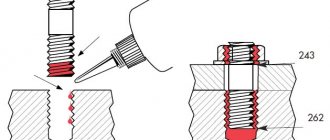

- After puncturing the sealant foil, the nozzle that comes with the kit is put on the tube.

- The composition is applied smoothly along the entire perimeter, a 2-3 mm seam is formed.

- Before assembly, the parts dry for at least 10 minutes, but complete hardening will take longer, depending on the type of sealant.

For repair work, a 0.8 mm steel clamp is used. The load-bearing parts of the body of most cars are made of elements of this thickness. Do not forget that repairing a crack with a sealant is only a temporary measure. Sealing will allow you to temporarily restore the normal functions of the exhaust system, but then it will be completely replaced.

On video: Quick repair of the exhaust system using sealant.

Making a patch and drilling holes

To do this, a rectangular section is cut out of a piece of rolled steel about a millimeter thick. Its area should be approximately half the size of the segment covered by the burnout.

Holes are made along the edges of such a plug into which fasteners intended for fixing metal products will be screwed.

Selecting a sealant

To correct muffler defects, different compounds can be used. These are pastes, adhesives, cements, high-temperature agents, restoration kits. Manufacturers usually offer a choice of several sealants.

Using the example of different companies, let’s look at what repair compositions are available:

- Crc glue for sealing minor damage in the form of cracks. It dries quickly and contains additives that make it heat-resistant and resistant to high-intensity mechanical loads.

- Crc paste for connecting individual elements. Hardening occurs quickly under the influence of temperatures. It is characterized by good resistance to loads, moisture and other factors aggressive to exhaust parts.

- Permatex sealant in the form of a paste for sealing the joints of resonator pipes and mufflers. Withstands up to 700 degrees, resistant to humid environments. Hardens within a day.

- Permatex kit including tape and wire. The tape is treated with a special compound (sodium silicate), which allows it to be in an environment at temperatures up to 1095 degrees.

- Permatex high temperature cement for repairing muffler and resonator failures. Also suitable for sealing various seams.

- Permatex high-temperature composition for metal parts is used to join elements. The sealant includes ceramic components and auxiliary substances that prevent corrosion.

Recommendations from the master

Not so long ago, the happy owners of Zhiguli and Moskvich cars, who today seem to be true Kulibins, knew and used a wide range of quite effective methods for restoring the performance of the muffler.

Due to the fact that in those days it was almost impossible to get its new analogue due to the shortage and considerable cost, Soviet car enthusiasts used the following methods:

- Installation of various types of iron hoops;

- Filling with cement and clay fillings that are resistant to strong heat;

- Wrapping with fiberglass;

- Preventive making of grooves to remove condensate;

- Coating the muffler with moisture-repellent chemical compounds created somewhere in closed military-industrial complex laboratories.

Sealant or welding

Comparing the two repair options, it follows that each option has disadvantages and advantages. The welding is strong, but the sealant does not require specific skills and allows you to carry out repairs as quickly as possible. When you can’t waste time using equipment and visiting services, exhaust system sealant is an ideal option.

When considering cold welding, you can turn to products from VersaChem. The company produces products for quickly repairing minor breakdowns. Cold welding forms a reliable adhesion to metal elements, eliminating all kinds of holes. What’s good is that the composition can be applied to rusted parts. It takes up to 12 hours to completely harden at a temperature of 15-20 degrees.

High-quality sealing with the choice of the most suitable sealant can last about a year. You shouldn’t use it anymore, because repeated breakdowns will be inevitable, and it’s better to install a new exhaust system in a timely manner, otherwise you may encounter a problem at the most unexpected moment.

Only ceramic compounds with the addition of auxiliary substances are suitable for repairing the exhaust system. All the variety of silicone products will not withstand the temperatures observed during the operation of exhaust parts; such a composition will immediately burn out. Working with sealant is simple, but do not forget about personal safety measures and if you have questions, contact professionals, which in some cases does not take time, but helps to carry out repairs faster and at minimal cost.

DIY muffler repair (2 videos)

Types of sealants for the exhaust system (20 photos)

Wide selection of modern auto sealants

Naturally, any prudent and economical car enthusiast will not rush to spend his hard-earned savings on buying a new unit just because of a few almost invisible fistulas found on the “original” muffler.

To successfully and permanently seal defects in the exhaust pipe without resorting to a labor-intensive welding procedure, you no longer have to look for or invent some clever method.

It is enough to use advanced devices produced today specifically for such repairs. Modern auto sealants allow you to quickly and efficiently eliminate holes of any diameter and cracks of any length.

Sealing the muffler with an iron patch

The distance between the holes is about 2.5 centimeters. Next, the plug with a layer of autosealant is screwed with a cordless screwdriver or drill onto the damaged area of the muffler, previously cleaned with an iron brush.

Heat-resistant substances in the sealant composition

Automotive muffler sealant contains heat-resistant additives that can withstand temperatures up to almost one and a half thousand degrees.

Such additives are:

- Sodium silicate;

- Clay;

- Steel powder;

- Artificial fiber.

The period for 100% curing of ceramic sealant in normal weather is about a day. To speed up polymerization somewhat, you can start warming up the engine three hours after installation.

Bosal 258-502

The company is known for high-quality mufflers and auxiliary installation equipment for the exhaust system as a whole. Obviously, the manufacturer also develops sealants to service its own products. Universal modifications include composition 258-502. It works best in sealing joint areas when two elements are connected. Bosal car exhaust system sealant can also be used as a restorative agent. The thick and stretchable mass corrects small defects in the form of cracks and holes. From the point of view of compatibility, of course, it is recommended to purchase this sealant for mufflers from the same company.

Express repairs on the way

Despite the fact that, according to the instructions, the repair site using DoneDeal DD6789 high-temperature tape must first be thoroughly cleaned, and ideally even degreased, in field conditions the DD6789 kit can be used directly as is - without additional tools, materials and an inspection hole. A fistula that suddenly appears on the road can be repaired even by simply driving the wheel onto a high curb to provide access to the bottom of the car!

The DD6789 kit includes a roll of tape and disposable protective gloves, but first you need to prepare the tape - fill the bag with water and lightly knead the contents for better impregnation. The strip, which has acquired elasticity and stickiness, is simply wound turn by turn onto the damaged section of the exhaust pipe or can. At a temperature of about 25 degrees, hardening occurs in 30–40 minutes, and subsequently the repair site can withstand heating up to 1400 degrees.

ABRO ES-332

A composition intended for domestic use, which is suitable for repairing exhaust pipes and sealing joints. In terms of performance, this product is even more effective than the analogue from Liqui Moly. The maximum temperature range, in particular, is 1100 °C, meaning the ES-332 can be used in the most severe operating conditions for high-performance internal combustion engines. You can use this sealant not only in situations where obvious processes of destruction are observed. The manufacturer also recommends it as a preventive measure during the installation of a muffler. For example, in new systems, it is advisable to apply ABRO car exhaust system sealant at the mounting points. Such treatment initially minimizes the risk of cracks and holes in the structure. Also in resonators with catalytic converters, the composition works well as a high-temperature adhesive base.

Sealing the muffler away from the workshop

However, it is not always possible to repair a muffler in a workshop where all the necessary tools are available. If fistulas and cracks make themselves felt on the road, then it will be almost impossible to carry out such repairs.

To do this, you will have to constantly carry a whole car service arsenal with you.

- Far from your home garage cooperative, you can repair the muffler using a special repair tape.

- It is a heat-resistant bandage for mufflers and is produced by the same brand as the ceramic sealant.

- This insulating tape is designed to instantly eliminate burnouts on mufflers and other gas lines heated to high temperatures.

How to choose the best option?

Each of the listed compositions is good in its own way. The emphasis in choosing one or another characteristic should be based on the problem being solved. Sometimes the heat resistance of the sealant, its protection from reagents and other active chemicals come to the fore. This applies to cases where it is planned to operate the train in aggressive conditions. Other selection criteria relate to physical reliability. To strengthen the joint, it is advisable to use a restorative sealant for the car exhaust system. Reviews show that the effect of cementitious bonding is most preferable when it comes to bringing two structural components together. Polymer products and compositions containing metallized particles have these qualities.

CRC Exhaust Repair Gum

This sealant is presented on the market as a black putty based on inorganic compounds and modifying additives. Bonding adhesive power is a key feature of Exhaust Repair Gum, which allows cracks and holes to be sealed even without dismantling the system. As practice shows, the composition acquires sufficient hardness for operation in less than a day, without requiring special crystallization conditions. With the engine running (idling), the coating hardens in just 10 minutes. The final effect of using this sealant for a car exhaust system can be expected to increase structural strength, restore surfaces with defects and reduce noise. In terms of protective properties, the shell protects the target area from moisture, thermal influences and vibrations (damping effect).

Reviews from motorists

Most motorists speak well of almost all sealants for repairing exhaust systems. These sealants are usually used in two cases: installation of individual exhaust tract elements with additional insulation of connections, or repair of minor damage.

The lifespan of a sealant depends on a large number of factors. Therefore, it is impossible to name any exact time interval during which the composition will not collapse. But in general, if the installation conditions are met, the sealant placed in the joint will last until the next system repair, and patches in some cases last up to 5 years.

Negative reviews are usually associated with improper use of products. For example, if you prepare the connection poorly (do not remove rust, soot and oily deposits), then the sealant will not adhere well to the surfaces, and eventually, after a short period of time, it will begin to crumble and fall off. Also, before starting full operation of the car, it is imperative to give the composition time for complete polymerization.

It is not recommended to use sealants for exhaust systems to repair cracks in potentially stressed areas and burnouts in heavily corroded and burnt-out elements with a critically thin metal thickness.

The muffler is an important part of the exhaust system, which plays the role of an acoustic filter. Thanks to it, the car drives on the street without making much noise, so if a part breaks, the exhaust sounds are too loud. If it is broken, you cannot drive: the driver will inevitably face a fine. The sealant for the muffler allows you to carry out repairs quickly, without welding and the involvement of specialists.

How to weld a muffler in the garage?

If the muffler is burnt out and the damage site is large, more comprehensive repairs may be required.

It is not difficult to recognize serious damage - first a “whistling” sound appears, which only intensifies if left unattended.

Smoke from the exhaust pipe enters the cabin, making it impossible to drive the car.

The most reliable method of repair is welding the damaged element. There are two ways here - entrust the work to a master or do it yourself.

In the second case you will need:

- Welding machine (it is better to choose a semi-automatic type device);

- Tool set (hammer, wrenches, screwdrivers, etc.);

- Brushes with metal bristles, as well as sanding paper;

- Grinder with attachments;

- Heat-resistant paint;

- Pieces of metal sheets having a thickness of 1-2 mm.

Muffler repairs are carried out exclusively in the damaged area (in the place where the unit burned out). If there are rusted areas, it is advisable to remove them completely.

Then proceed like this:

- Cut out a fragment of the resonator or muffler;

- Remove rusted areas;

- Pay attention to the condition of the internal components. If the partitions and tubes inside the muffler are damaged, restore them or replace the unit as a whole.

For welding, it is better to use a semi-automatic welding machine, which carefully patches the damage.

This is due to the fact that carbon dioxide used in the welding process prevents the metal from overheating and changing its structure. During the repair process it is worth making continuous seams.

Read more about welding machines in the article - how to properly weld a car body.

If rust has reached the junction of the pipe and the casing, you need to cut out the corroded area that has become unusable, then replace the damaged unit and weld the muffler back into place.

At the final stage, it is worth painting the surface, because at the factory this work is performed only formally. This stage should not be skipped, because with its help it is possible to extend the service life of the muffler (we will talk about this below).

Simple and quick repair

Despite the fact that the instructions for such heat-resistant tape require complete cleaning of the area of its installation and even thorough degreasing, in reality it can be used without any preparatory procedures.

To successfully repair the muffler in this case, you don’t even have to go down into the inspection hole.

It will be enough to lift one edge of the car, driving onto a wide and strong curb, and for greater safety, jack up the bottom. You can then look for the fistula and quickly seal it with high-temperature ceramic tape.

Auspuff Reparatur by Liqui Moly

Autochemical compositions of this brand rightfully occupy leading positions in various categories. In this case, the company offers a comprehensive solution for protecting the exhaust pipe, eliminating the risk of the formation and development of existing cracks with small holes on the surfaces of the structure. The sealing paste is resistant to elevated temperatures, does not require complex installation operations such as welding, and does not contain harmful chemical ingredients. In particular, the applied coating retains its performance at 700 °C. Treatment with Liqui Moly car exhaust system sealant can be carried out in typical garage conditions without connecting special equipment, which is also an attractive advantage when choosing.