What is anaerobic sealant

To understand the essence of the action of an anaerobic type sealant, you need to know its meaning. These products are acrylic elements that are placed in special containers where air ingress is excluded. In this form, without loss of characteristics, the composition can be stored for approximately 12 months.

When the sealant is applied to the metal, the curing process begins in the narrow crevices of the material. As a result, the layer obtains high strength properties.

These products are acrylic elements that are placed in special containers where air ingress is excluded.

general description

Loctite sealant usually serves as a gasket between various components in auto repair. This helps create reliable protection against leaks; load-bearing parts receive uniform load distribution on the mechanisms and components of the machine. The sealant in the syringe is easy to apply; it is produced using modern technologies. Completely fills the required areas. Professionals note better efficiency from the use of sealant compared to standard compression gaskets, the use of welds, etc.

Loctite sealant usually serves as a gasket between various components in auto repair.

Chemical resistance:

The tests consisted of holding the polymerized product at the specified temperatures and then testing it at 22°C.

| Excerpt in: | Holding temperature: | % of original strength, measured through: | ||

| 100 hours | 500 hours | 1000 h | ||

| Engine oil | 125°C | 100 | 100 | 100 |

| Petrol | 22°C | 75 | 75 | 75 |

| Water/Glycol (50%/50%) | 87°C | 85 | 85 | 85 |

It is not advisable to use Loctite 574 in pure oxygen environments or in oxygen-rich systems. Loctite 574 should not be used as a sealant for chlorine and other strong oxidizing agents. Loctite 574 is generally not recommended for use on plastics (especially thermoplastic materials where stress cracking of the plastic may occur).

Brand Features

Loctite sealant is produced in a syringe by the famous brand Henkel, which has long established itself in the construction market as producing highly effective products. The company began production of this product in 1997; over time, it tried to make the composition more durable and reliable. And the result is a high-quality product that optimally copes with car repair work.

A high-quality product that optimally copes with car repair work.

Advantages and disadvantages

To understand why Loctite sealant is so popular, you should study its positive properties. Among the advantages of the composition, the following points are noted:

- A variety of compositions for different tasks;

- High-quality result;

- Increases the durability of processed parts;

- High degree of adhesion to various metals;

- Quick drying;

- Fast complete polymerization;

- Ease of application;

- Permissibility of operation at high temperatures; special types are selected for this purpose;

- High-quality protection against rust formation.

There are not many disadvantages:

- Cannot be used in oxygen and oxidized environments;

- It is undesirable to use them for sealing joints with a diameter larger than M80.

Increases the durability of processed parts.

Loctite 574 - Durable Metal Flange Seal - Universal 50 ml

Application: Sealing tightly fitted metal surfaces and flanges. Forming gaskets in place. Withstands slight pressure immediately after the connection is assembled. Loctite 574 fills micro-irregularities and gaps up to 0.5 mm and cures quickly.Operating temperature: up to +150°C

Conditions of applicability: Anaerobe = polymerizes in the absence of air in small gaps between active metal surfaces (or in the presence of the loctite7649 activator). For polymerization, 2 factors are required: absence of air + active surface (or loctite7649 activator). For polymerization, a small (up to 0.25 mm) gap between the parts being connected is required (decent thread quality) + an active metal surface, or the liquid loctite7649 activator. Active surfaces include carbon steel, cast iron, brass, bronze, copper.

Chemical Resistance: Tests consisted of exposing the polymerized product to the specified temperatures and then testing it at 22°C.

Excerpt in:

| Holding temperature: | % of original strength, measured through: | |||

| 100 hours | 500 hours | 1000 h | ||

| Engine oil | 125°C | 100 | 100 | 100 |

| Petrol | 22°C | 75 | 75 | 75 |

| Water/Glycol (50%/50%) | 87°C | 85 | 85 | 85 |

Loctite 574 is not recommended for use in pure oxygen environments and/or oxygen rich systems.

Loctite 574 should not be selected as a sealant for chlorine and other strong oxidizing agents. Loctite 574 is generally not recommended for use on plastics (especially thermoplastic materials where stress cracking of the plastic may occur). Instructions for use:

- To achieve optimal performance, the surfaces to be joined must be clean and free of grease.

- Loctite 574 is designed for tight fitting flange connections with close clearance.

- Loctite 574 is applied to the flange surface in an even layer or through a stencil

- To test the tightness immediately after assembly, the connection can be subjected to low pressure (less than 0.05 MPa).

- Flanges must be tightened immediately after assembly to avoid movement.

- The rate of polymerization depends on the ambient temperature and the size of the gap between the mating parts.

Storage: Loctite 574 Anaerobic Flange Seal Gasket should be stored in a dry place in closed containers at a temperature of 8 - 21°C unless otherwise stated on the packaging. Storage at temperatures below 8°C or above 28°C may adversely affect the properties of the sealant. To prevent deterioration of unused product, do not return it to the original packaging.

Typical Applications

Loctite is suitable for joining parts. But we can highlight the area of application that is chosen most often. It is typical to apply sealant for sealing work with metal threaded connections. Separately note the use for stainless steel without the need for surface activation.

Loctite is suitable for joining parts.

Types of compositions

The brand produces a variety of types called Loctite, they are suitable for almost all components in the car. The line includes adhesives and sealants. Can be used as a processing material for fastening joints and a gap sealer.

The brand produces a variety of types called Loctite, they are suitable for almost all components in the car.

Threaded fasteners

Their purpose is to fix fasteners and prevent the hardware from unscrewing itself. Their consistency is viscous and semi-solid, they penetrate well into the material, closing the gaps between the bases. Hardening occurs at temperatures of +20-25 degrees, suitable for metals. This is a one-component type, withstands vibration loads and does not allow leaks.

Their purpose is to fix fasteners and prevent the hardware from unscrewing itself.

Thread sealants

Necessary to create a seal on threaded connections, this avoids the penetration of liquid solutions and gases. The dried layer copes with increased loads. The following properties are distinguished:

- Ease of use;

- Does not shrink;

- Replaces gaskets;

- High degree of resistance to mechanical and vibration loads;

- High level of rust protection.

The ability of Loctite products to complete polymerization in an airless environment is noted.

Necessary to create a seal on threaded connections, this avoids the penetration of liquid solutions and gases.

Flange sealants

Used instead of cushioning materials. They are distinguished by their uniform closing of gaps, resistance to aggressive influences, and a completely sealed coating is created. It compacts quickly and does not shrink after shrinkage; it has a good level of resistance to high pressure.

You can choose different forms of sealants - paste or gel.

Used instead of cushioning materials.

Shaft-sleeve clamps

Suitable for working with the fitting of car parts in the form of cylinders: bearings, bushings and shafts. In order for the part to shrink correctly and reliably, a compound must be applied to it, this helps balance the load. Manual or semi-automatic tools can be used for distribution.

Suitable for working with the fitting of car parts in the form of cylinders: bearings, bushings and shafts.

LKMFLOT

Code: 100969623

Category:

Sealants

Brand:

Loctite

Packing:

0.05, 0.25, 2

Packing:

1

Sealant for sealing flanges Loctite 574 (Loctite)

DESCRIPTION: Loctite 574 is a one-component, anaerobic, thixotropic, fast-curing, medium strength sealant. The product polymerizes in the absence of air in small gaps between metal surfaces.

APPLICATION: Sealing small gaps between adjacent hard metal surfaces and flanges. In this case, the assembled unit can withstand slight pressure immediately after assembly. Typical applications include the sealing of rigid flange connections, including transmission and engine castings.

TECHNICAL CHARACTERISTICS: Color: orange Operating temperature range: -50°C - +150°C Strength: average Polymerization method: anaerobic

GENERAL INFORMATION This product is not recommended for use in pure oxygen and/or oxygen rich systems. It should not be selected as a sealant for chlorine and other oxidizing agents. For handling information, see the Material Safety Data Sheet (MSDS). When using special surface cleaning systems, before using the product, it is necessary to check its compatibility with cleaning solutions. In some cases, cleaning solutions may have a negative impact on the properties of the product. The product is not recommended for use on plastics, especially thermoplastics, due to the possibility of their destruction. If such use is necessary, it is necessary to first check the compatibility of the product with the material of the contacting surfaces.

DIRECTIONS FOR USE: To obtain the best results, the surfaces to be bonded must be clean and free of grease. The product is designed to seal flanges with a gap of up to 0.1 mm. The product is applied manually in a continuous bead or through a stencil onto one surface. To check for complete sealing immediately after assembling the connection, you can apply a little pressure to it (

STORAGE: The product must be stored in a cool, dry place in closed containers at a temperature of 8 - 28? C, unless otherwise indicated on the packaging. The optimal storage temperature is the lower half of the above temperature range. To prevent deterioration of unused product, do not pour it back into the original packaging. More detailed information on storage can be obtained from your local Loctite representative.

NOTES The data contained in this sheet is for information only and is believed to be correct. We cannot accept responsibility for results obtained by other organizations whose methods we do not control. It is the customer's responsibility to determine the suitability of any production methods mentioned herein and to take such precautions as may be necessary to protect property and personnel from any hazard that may arise from the handling and use of these methods. In light of the foregoing, Loctite Corporation disclaims all warranties of merchantability or fitness for any particular purpose arising from the sale or use of Loctite Corporation products. Loctite Corporation disclaims any liability for consequential or incidental damages of any kind, including lost profits. The descriptions in this sheet of various processes or compositions should not be taken to indicate that they are not covered by any patents or licenses of Loctite Corporation covering such processes or compositions. We recommend testing our products before repeated use and using the data provided here as a guide. There may be one or more patents or patent applications covering this product.

PACKING: 50 ml, 250 ml, 2 l

Application rules

Before you start applying the composition, you will need to prepare the surface. It is cleaned of grease stains, old solutions, and carbon deposits. For this purpose, you can choose products from the same series, but they are degreasers. It is advisable to work at positive temperatures above +5 degrees.

Before you start applying the composition, you will need to prepare the surface.

Instructions for use

To obtain the results specified by the manufacturers, it is necessary to correctly apply the sealant to the surface. Therefore, instructions for work will be given below.

To obtain the results specified by the manufacturers, it is necessary to correctly apply the sealant to the surface.

Loctite 574

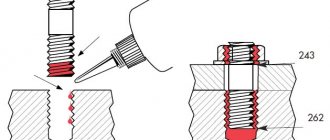

Loctite 574 instructions for use include the following steps:

- Cleansing stage.

- The cartridge is inserted into the gun.

- The gel is evenly applied to the base.

- The parts are pressed tightly together.

- Excess sealant is wiped off.

When the syringe option is selected, it can be dispensed immediately. Guns are usually used in auto repair shops; in a regular garage, you can get by with the manual method.

When the syringe option is selected, it can be dispensed immediately.

Application: Sealing tightly fitted metal surfaces and flanges. Forming gaskets in place. Withstands slight pressure immediately after the connection is assembled. Loctite 574 fills micro-irregularities and gaps up to 0.5 mm and cures quickly.

Operating temperature: up to +150°C

Conditions of application: Anaerobe = polymerizes in the absence of air in small gaps between active metal surfaces (or in the presence of an activator). For polymerization, 2 factors are required: absence of air + active surface (or activator). For polymerization, a small (up to 0.25 mm) gap between the parts to be joined is required (decent thread quality) + an active metal surface, or a liquid activator. Active surfaces include carbon steel, cast iron, brass, bronze, copper.

Chemical Resistance: Tests consisted of exposing the polymerized product to the specified temperatures and then testing it at 22°C.

Excerpt in:

| Holding temperature: | % of original strength, measured through: | |||

| 100 hours | 500 hours | 1000 h | ||

| Engine oil | 125°C | 100 | 100 | 100 |

| Petrol | 22°C | 75 | 75 | 75 |

| Water/Glycol (50%/50%) | 87°C | 85 | 85 | 85 |

Loctite 574 is not recommended for use in pure oxygen environments and/or oxygen rich systems.

Loctite 574 should not be selected as a sealant for chlorine and other strong oxidizing agents. Loctite 574 is generally not recommended for use on plastics (especially thermoplastic materials where stress cracking of the plastic may occur). Instructions for use:

- To achieve optimal performance, the surfaces to be joined must be clean and free of grease.

- Loctite 574 is designed for tight fitting flange connections with close clearance.

- Loctite 574 is applied to the flange surface in an even layer or through a stencil

- To test the tightness immediately after assembly, the connection can be subjected to low pressure (less than 0.05 MPa).

- Flanges must be tightened immediately after assembly to avoid movement.

- The rate of polymerization depends on the ambient temperature and the size of the gap between the mating parts.

Storage: Loctite 574 Anaerobic Flange Seal Gasket should be stored in a dry place in closed containers at a temperature of 8 - 21°C unless otherwise stated on the packaging. Storage at temperatures below 8°C or above 28°C may adversely affect the properties of the sealant. To prevent deterioration of unused product, do not return it to the original packaging.

Some useful storage tips

Products can be of different shades - red or orange. Storage should be in sealed packaging, room temperatures should be kept from +8 to +28 degrees. Do not pour the unused composition back into the container.

Temperatures in the room range from +8 to +28 degrees.

The article described the sealant in a syringe of red Loctite, which is an effective way to repair parts in engines and other areas of the car. They note its ease of use, which is suitable for self-repair.

Conditions of applicability:

Anaerobe - polymerizes in the absence of air in small gaps between active metal surfaces (or in the presence of an activator). For polymerization, 2 factors are required: absence of air + active surface (or activator). For polymerization, a small (up to 0.25 mm) gap between the parts to be joined is required (decent thread quality) + an active metal surface, or a liquid activator. Active surfaces include carbon steel, cast iron, brass, bronze, copper.