What is anaerobic sealant

To understand the essence of the action of an anaerobic type sealant, you need to know its meaning. These products are acrylic elements that are placed in special containers where air ingress is excluded. In this form, without loss of characteristics, the composition can be stored for approximately 12 months.

When the sealant is applied to the metal, the curing process begins in the narrow crevices of the material. As a result, the layer obtains high strength properties.

These products are acrylic elements that are placed in special containers where air ingress is excluded.

A little about Loctite

The author of this product is considered to be chemist Vernon Krible from Connecticut, USA. This substance was first put into production and sale in the middle of the last century.

The material immediately received many positive reviews due to its positive qualities and performance characteristics.

It is worth noting that before the substance reached the consumer in its final form, it went through many changes.

Initially, it was in the form of an anaerobic glue, as the scientist planned to achieve by polymerizing esters and curing them in a space without air. Next, through trial and error, a material called “liquid locknut” was created. With its help, high-quality and long-lasting fastening was ensured.

Experiments continued, with their help a super glue with similar characteristics to Loctite appeared.

Also, many varieties of sealant have appeared with different compositions based on epoxy, silicone and acrylic.

They had one thing in common - the polymerization of one-component compositions, which made it possible to use them in various fields of activity.

After the world famous Henkel acquired the Loclite brand in the late 90s, the qualities of the material changed and became even more reliable, durable and affordable.

general description

Loctite sealant usually serves as a gasket between various components in auto repair. This helps create reliable protection against leaks; load-bearing parts receive uniform load distribution on the mechanisms and components of the machine. The sealant in the syringe is easy to apply; it is produced using modern technologies. Completely fills the required areas. Professionals note better efficiency from the use of sealant compared to standard compression gaskets, the use of welds, etc.

Loctite sealant usually serves as a gasket between various components in auto repair.

Assembly and dismantling

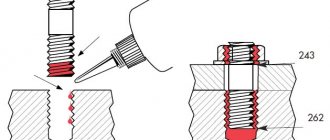

Loctite anaerobic sealants can be applied manually or using automatic or semi-automatic equipment. Excess Loctite product can be easily wiped off or washed off the surface. Traditional pipe compounds are difficult to assemble due to their slow action, inability to ensure clean installation, and the need for a specific tightening force to ensure optimal contact stress. Applying PTFE tape requires skill to avoid overstressing in threaded pipe connections and body castings. Loctite thread sealants provide quick, clean assembly and are easy to apply directly from original containers or dispensers. When assembling cylindrical or tapered threaded connections, sealant must be applied to both external and internal threads. Anaerobic products fill threaded gaps, making the tightening force of connections less critical. Loctite sealants also allow easy removal for subsequent repairs due to the absence of corrosion and galling in the threads. This connection cannot be penetrated by moisture or corrosive chemicals. Although Loctite sealants also have locking properties, they all allow threaded connections to be removed using conventional tools.

Brand Features

Loctite sealant is produced in a syringe by the famous brand Henkel, which has long established itself in the construction market as producing highly effective products. The company began production of this product in 1997; over time, it tried to make the composition more durable and reliable. And the result is a high-quality product that optimally copes with car repair work.

A high-quality product that optimally copes with car repair work.

Advantages and disadvantages

To understand why Loctite sealant is so popular, you should study its positive properties. Among the advantages of the composition, the following points are noted:

- A variety of compositions for different tasks;

- High-quality result;

- Increases the durability of processed parts;

- High degree of adhesion to various metals;

- Quick drying;

- Fast complete polymerization;

- Ease of application;

- Permissibility of operation at high temperatures; special types are selected for this purpose;

- High-quality protection against rust formation.

There are not many disadvantages:

- Cannot be used in oxygen and oxidized environments;

- It is undesirable to use them for sealing joints with a diameter larger than M80.

Increases the durability of processed parts.

Typical Applications

Loctite is suitable for joining parts. But we can highlight the area of application that is chosen most often. It is typical to apply sealant for sealing work with metal threaded connections. Separately note the use for stainless steel without the need for surface activation.

Loctite is suitable for joining parts.

Popular materials

The line of these products is very diverse, as is the price range. This allows you to choose the right product for each task or find a universal composition with a wide spectrum of action. For convenience and easy orientation, it is worth considering several of the most well-known models.

Loctite 5900

Popular one-component black sealant. Hardens at room temperature. Known for its increased resistance to motor oils. Among the advantages it is worth highlighting:

- no shrinkage and corrosion;

- wide temperature range - from –55 to +200 degrees Celsius;

- hardening at room temperature.

The sealant is intended for hydraulic and pneumatic connections. Suitable for filling metal threads that have small gaps.

Loctite 290

Well-known threadlocker with low viscosity and good strength. It has a smaller temperature range than Loctite 5900, but prevents loosening of the alignment of elements and the formation of leaks in the assembly. This sealant is suitable for M6 type connections and is actively used in carburetor screws, as well as in instrumentation.

Teroson MS 9220

Another equally popular remedy that deserves attention. The structural MS-polymer sealant has a one-component composition (cures upon contact with a moist environment). It has a characteristic black color and is used in the production of:

- automotive technology;

- railway cars;

- semi-trailers;

- sea vessels.

Teroson MS 9220 has excellent adhesion to galvanized steels, Teflon, glass, aluminum and other materials. Withstands short-term exposure to +120 degrees Celsius.

Types of compositions

The brand produces a variety of types called Loctite, they are suitable for almost all components in the car. The line includes adhesives and sealants. Can be used as a processing material for fastening joints and a gap sealer.

The brand produces a variety of types called Loctite, they are suitable for almost all components in the car.

Threaded fasteners

Their purpose is to fix fasteners and prevent the hardware from unscrewing itself. Their consistency is viscous and semi-solid, they penetrate well into the material, closing the gaps between the bases. Hardening occurs at temperatures of +20-25 degrees, suitable for metals. This is a one-component type, withstands vibration loads and does not allow leaks.

Their purpose is to fix fasteners and prevent the hardware from unscrewing itself.

Thread sealants

Necessary to create a seal on threaded connections, this avoids the penetration of liquid solutions and gases. The dried layer copes with increased loads. The following properties are distinguished:

- Ease of use;

- Does not shrink;

- Replaces gaskets;

- High degree of resistance to mechanical and vibration loads;

- High level of rust protection.

The ability of Loctite products to complete polymerization in an airless environment is noted.

Necessary to create a seal on threaded connections, this avoids the penetration of liquid solutions and gases.

Flange sealants

Used instead of cushioning materials. They are distinguished by their uniform closing of gaps, resistance to aggressive influences, and a completely sealed coating is created. It compacts quickly and does not shrink after shrinkage; it has a good level of resistance to high pressure.

You can choose different forms of sealants - paste or gel.

Used instead of cushioning materials.

Shaft-sleeve clamps

Suitable for working with the fitting of car parts in the form of cylinders: bearings, bushings and shafts. In order for the part to shrink correctly and reliably, a compound must be applied to it, this helps balance the load. Manual or semi-automatic tools can be used for distribution.

Suitable for working with the fitting of car parts in the form of cylinders: bearings, bushings and shafts.

Available types of sealants

The corporation produces several types of sealants; they can be used to repair almost any automotive component and element. The main types of Loctite sealants are sealing compounds and quick-drying adhesive solutions. The products of this manufacturer can be used both for sealing gaps and for application to fastening joints.

Thread sealants

These clamps reliably connect different fasteners and prevent hardware and bolts from unscrewing on their own. These Loctite thread sealants are semi-solid, viscous solutions that fill thread slots while eliminating gaps between bolts and where they are threaded.

Thread sealants polymerize at normal temperatures and can be applied to any metal products. These compositions are often produced as one-component, ready-to-use, they are resistant to vibrations, and completely eliminate leaks. The line of thread sealing products includes more than 20 products, the most popular are Loctite 243, 270, and others.

Threaded anaerobic compounds

These thread sealants are used to create sealing layers on all kinds of joints where there are threads, so that after sealing, automotive gases and liquids are not able to pass through the sealed elements. Anaerobic sealant Loctite can withstand very low pressure after application, and after polymerization is complete it can withstand maximum impact. Here are the main features of anaerobic sealants:

- easy and quick to apply;

- do not shrink, there is no displacement;

- are an excellent replacement for various gaskets;

- resistant to vibration loads and shocks;

- provide effective protection to metal from rust and corrosion.

Anaerobic sealants have the ability to set in an environment without air; thanks to this unique property, the technician who applies the sealant can check how accurately and evenly the composition is applied, only then install the part in place. These Loctite sealants should only be applied to thoroughly cleaned and degreased surfaces; the application process can be carried out using a semi-automatic tool.

Anaerobic sealants also include Loctite silicone thread sealants. These materials are universal and are suitable not only for metal, but also for different types of plastic parts and products. The following Loctite products, produced in the form of gels, are widely used: 577, 586, 5776, 5400, these products are used for medium and large thread pitches.

Flange sealants

This product is used instead of conventional gaskets. These sealants create an impermeable barrier between the flanges, eliminating any leakage of gases or liquids. Here are the main properties of Loctite flange sealants:

- fill any gaps in an even layer;

- are highly resistant to any aggressive substances;

- 100% tight;

- do not shrink;

- instantly seal flange connections;

- They can withstand high pressure without damage.

Loctite flange sealing products are much better than conventional gaskets, since the material after polymerization does not deform under the influence of loads, in addition, it is not squeezed out, has high tear resistance, cracks do not appear on it, and the sealant does not wear off. Anaerobic agents, the so-called rigid flange, and silicone compounds are manufactured to create a non-rigid seal.

The most popular flange sealing materials are Loctite 574, 518, 5188, they can operate at temperatures from -55 to +150 degrees. These products can be applied to steel, aluminum and cast iron surfaces of automotive parts. The most popular among car owners is the material in the form of Loctite 518 gel; it comes in a syringe and is red in color. This universal product is suitable for any parts and is very easy to apply.

Shaft-sleeve sealants

These materials are used for the purpose of rigidly fitting shafts, bushings and bearings of automobiles. The sealing compound is applied to the part, which fits neatly into its seat and does not move. Thanks to this, the load-bearing capacity of the part is significantly increased, and the load is evenly distributed over the entire surface.

These sealing products quickly fill any gaps, and they also provide reliable protection to metal surfaces from wear and corrosion. These fixatives, in the form of gels, are applied either manually or using semi-automatic instruments. The line of this product includes several products that form a layer with a maximum thickness of 0.5 mm. The composition acquires its technological strength after 15 minutes.

Application rules

Before you start applying the composition, you will need to prepare the surface. It is cleaned of grease stains, old solutions, and carbon deposits. For this purpose, you can choose products from the same series, but they are degreasers. It is advisable to work at positive temperatures above +5 degrees.

Before you start applying the composition, you will need to prepare the surface.

Instructions for use

To obtain the results specified by the manufacturers, it is necessary to correctly apply the sealant to the surface. Therefore, instructions for work will be given below.

To obtain the results specified by the manufacturers, it is necessary to correctly apply the sealant to the surface.

Loctite 574

Loctite 574 instructions for use include the following steps:

- Cleansing stage.

- The cartridge is inserted into the gun.

- The gel is evenly applied to the base.

- The parts are pressed tightly together.

- Excess sealant is wiped off.

When the syringe option is selected, it can be dispensed immediately. Guns are usually used in auto repair shops; in a regular garage, you can get by with the manual method.

When the syringe option is selected, it can be dispensed immediately.

Some useful storage tips

Products can be of different shades - red or orange. Storage should be in sealed packaging, room temperatures should be kept from +8 to +28 degrees. Do not pour the unused composition back into the container.

Temperatures in the room range from +8 to +28 degrees.

The article described the sealant in a syringe of red Loctite, which is an effective way to repair parts in engines and other areas of the car. They note its ease of use, which is suitable for self-repair.

Types of Loctite compounds

Loclite is a very affordable and at the same time high-quality material. It can be used in various fields of activity, both for industrial purposes and for personal purposes.

The range of materials is quite wide, since the substance has a universal purpose and can be used to solve many problems.

In construction and hardware stores you can find material under the following bulleted lists:

- 5699;

- 577;

- 5910;

- 518;

- 574;

- 5900;

- 5920, etc.

Threaded fasteners

First of all, they are very easy to use and suitable for do-it-yourself use. Among the popular brands of this type are:

- 270;

- 2400;

- 243.

The positive properties of thread locks include:

- polymerization at room temperatures;

- high adhesion to metal materials;

- long service life;

- resistance to vibration vibrations;

- wide choice of desired temperature;

- practicality of connection;

- high-quality elimination of leaks at thread connections.

The advantage of these connections is that they fill the entire space around the thread with themselves, thereby preventing liquid or other flowing materials from being saturated outward.

They also help securely and quickly connect fastening materials, thereby preventing self-unscrewing of hardware.

Thread sealants

This type of sealant is produced, depending on the scope of application, in the following types:

- silicone - used in plastic products;

- sealing thread - for metal and plastic connections;

- anaerobic - for metal pipes.

Anaerobic sealant works on metal even in a space without air. Silicone does not work even at room temperature due to the presence of moisture. The simplest sealant is considered to be in the form of a sealing thread.

These are one of the most reliable and high-quality sealants. They provide complete sealing of the threads - even the most liquid materials or gas will not be able to leak through the slightest scratches and openings.

Simply apply this liquid sealant and no other additional equipment will be needed.

Among the advantages are:

- preservation of low pressure after application;

- resistance to heavy loads;

- even at high temperatures its properties are preserved.

Flange sealants

The environment for their application is water and gas pipelines and other communication connections. The name says that the area of application is flange connections.

Among the advantages are:

- smooth filling of the surface with sealant after application;

- tightness of the coating;

- resistance to high pressures on highways;

- high-quality compaction without shrinkage;

- resistance to aggressive environments;

They serve for a very long time and there is no need to replace them. In addition, flange sealants are more effective than gaskets; they do not deform even under heavy loads and do not come out even under high pressure.

This type of sealant is very resistant to tearing, abrasion and cracking. They operate at temperatures from -55° to +150°.

Sealant 518 acts as a reliable barrier between metal flanges and acts as a gasket. It, like 5188, 574, is more suitable for flanges made of cast iron, steel and aluminum.

The release form can be in a red syringe, which is ideal for connections in the car.

Industrial sealants

The scope of application of these types of substances is very wide. They are used in connecting nodes of varying complexity, sealing nodes. They are able to withstand the movement of several parts without losing density.

They are also characterized by high adhesion and durability, which is very useful in industrial environments.

Thanks to these compounds, it is impossible for water, gases and other small particles to penetrate inside.

Such sealants provide excellent adhesion, are resistant to aggressive environmental influences, have a long service life, and are impervious to chemicals.

For industrial needs, such sealants are available in the form:

- butyl - excellent adhesion even to glass, ceramic and other glossy surfaces;

- silane-modified.

Thanks to such sealants, it is possible to assemble different structures together, thereby reducing the cost of additional fasteners that are not needed.

Shaft/sleeve retainers

They have good binding properties, which in turn ensures reliable fixation in cylindrical automotive parts. This is due to the correct distribution of material throughout the entire assembly, which ensures safety and avoids premature wear.

Sealants containing methacrylate have the following positive properties:

- completely fill the space;

- protect against moisture penetration and corrosion;

- increase the service life of the unit.

Among the popular and widely used is sealant 660, as it acts quickly - after 15 minutes of application, forming a layer 0.5 mm thick.