Sunday continues! Things are not getting any less, so I continue to change the cylinder head gasket.

To begin with, what sealant should be used on VAZ 16 valves under the camshaft bed and valve cover? That's right, the manufacturer recommends Loctite 574. The thing is not cheap (50 grams costs about 1,100 rubles, and much less is needed for the engine), so finding it on sale is a big problem. In stores - “Oh, why do you need it, take a silicone gasket. It holds up to 300 degrees!”... As I remember, I still laugh))))

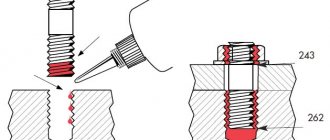

I really want to show them this picture:

And then the forums are filled with questions: I changed the gasket, and now the hydraulic compensators are making a clicking sound... How can they work when the oil channels are clogged with dried silicone sealant? Not to mention the oil starvation of the camshaft journals? Will we save or not? Or not)))

Now, in theory, you can assemble the head! But just a minute, the mileage of the engine is 180,000, let’s remember the Talmuds, which say that a working spring should be:

Installing weakened springs is fraught with uneven idle and “hanging” valves at maximum speed.

www.motortehn.ru/Main/Technology/ORS51UQ.html tells us: “On the other hand, when the elasticity of the springs decreases, engines lose power while simultaneously overusing fuel. For example, if the elasticity of the springs decreases by 20...25%, the loss of engine power reaches 17%, and the specific fuel consumption increases by up to 20%. According to the technical requirements for engine overhauls, the elasticity values of the valve springs, i.e. compression forces to a length corresponding to the position of the “open” and “closed valve” are strictly regulated.”

I immediately remember my neighbor “Yes, this is a VAZ, why measure it!”))))

So if you don’t measure anything and assemble everything by eye, then it will work like a TAZ...

so I quickly assemble a stand for checking valve springs on my knee)

Just kidding, a little simpler)))

As usual, you need to take something from Volga!

Namely - the drive rod of the clutch master cylinder with a nut for the pedal Well, and one original plate and a channel (reliably fastened) with a hole for the rod

And at a minimum - a calibrated load weighing 24.5 kg))))

And then - everything is simple, I hang the load, the spring compresses - I measure the height with a caliper, subtract the thickness of the plate,

It can be seen that the length of all the springs met the standard (requirements 38.19 and the difference from the value established in the technical requirements by no more than 1.5 mm)

But in the “closed valve” state - the load is 24.5 ± 1 kgf. length 32 mm, essentially all springs are weakened. You don’t have to measure further - tomorrow I’ll go for a set of new springs and choose the stiffest ones with the minimum difference in force.

Well, at the end of the day, should I get the valve stem seals?

You can’t do it with a screwdriver or pliers, but a couple of drops of welding and ordinary pliers turn into...

Into pliers for removing valve stem seals) in a couple of minutes they are all free!

Lada 2111 2004 - do it yourself

Cars for sale

Lada 2111, 2008

Lada 2111, 2012

Lada 2111, 2004

Lada 2111, 2007

Comments 49

This Loctite will not withstand 300 degrees. He only holds 150.

what's the point of 300? There has never been such a temperature in bed, unless you ride without antifreeze. Is Loctite expensive? take permabond, but never silicone shit!

I'm talking about the need for another Loctite

Don't Reinz or Elring have an anaerobic sealant?

OIL SWIPPER PULLER +++ OTHERWISE I JUST SHARPENED THE PLATES)

Did the new springs meet the specifications under load?

Science doesn’t know this, especially after looking at the new ones they sell here, I realized that it’s better to leave the old ones

Great report! Bookmark it!)

Photo with the remains of red sealant - definitely some kind of hand-assed mechanic whose motto is “A large amount will not hurt!” I assemble the cylinder head on an “ABRO” series 999, gray. The main thing is not to rush in time. Using a regular medical syringe, I apply the sealant where it is needed, run it with my finger, and remove the residue. Consistent assembly after applying the sealant in 25-40 minutes. After assembly, the sealant does not stick out from anywhere, much less bulge. I give a guarantee to customers for a mileage of 50 thousand km. No one has yet returned with any claims of oil leaks or full spark plug wells. I met with Lactite once. I had to redo it with sealant after using it. After two months, it still hadn't dried out and oil began to ooze through the cracks. I am not against factory standards, but if such a product were transported to the buyer in accordance with technical requirements, observing temperature, humidity, etc. then perhaps it would be of high quality, but frozen and spoiled. So a simple sealant is a 100% alternative to Lactite.

Advantages and disadvantages

Softness when exposed to oxygen is both an advantage and a disadvantage of anaerobic sealants. On the one hand, you can work without haste. However, if after joining the parts there is at least minimal access to oxygen, then there will be no hardening. The material will remain soft. It should also be noted that uneven application of anaerobic engine sealant to the surface will only result in partial hardening. If the pressure is excessive, there is a risk of destruction of the seal. Therefore, when working with these compounds, a certain skill is required.

Instructions for use

To obtain the results specified by the manufacturers, it is necessary to correctly apply the sealant to the surface. Therefore, instructions for work will be given below.

To obtain the results specified by the manufacturers, it is necessary to correctly apply the sealant to the surface.

Loctite 574

Loctite 574 instructions for use include the following steps:

- Cleansing stage.

- The cartridge is inserted into the gun.

- The gel is evenly applied to the base.

- The parts are pressed tightly together.

- Excess sealant is wiped off.

When the syringe option is selected, it can be dispensed immediately. Guns are usually used in auto repair shops; in a regular garage, you can get by with the manual method.

When the syringe option is selected, it can be dispensed immediately.

The choice of professionals

There is a large selection of similar adhesive-sealants, but not all of them are of equal quality. Also, not all are suitable for specific models. You need to find out about compatibility in advance. You can find out which sealant is best for a car engine in the operating instructions. Manufacturers usually indicate such information. Professional auto mechanics recommend time-tested products. These are compositions from the line from GOZETTE and Loctite. These are anaerobic compounds with excellent characteristics - say the reviews.

Application rules

Before using sealants, the contacting surfaces must be cleaned of oily sediment, carbon deposits, and remnants of old seals. To achieve ideal surface cleanliness, you can use Loctite 7063, 7200 cleaners and degreasers. If the temperature in the box is not higher than +5 degrees, you need to additionally treat the parts with Loctite 7240, 7471 or 7649 to prepare the surfaces.

Application instructions:

- Cleaning the parts to be joined.

- Refilling the cartridge into the gun.

- Uniform squeezing of the gel.

- Firm pressing of products.

- Removing excess sealant.

If a syringe sealant is used, it is immediately ready for use. Semi-automatic guns are recommended for use in professional service stations; in garage conditions, Loctite sealant can be applied manually.

Products manufactured by the famous Henkel brand have undoubted advantages for vehicle maintenance and repair. An extensive range makes it easy to select a sealant to solve a specific problem. Sealing products are expensive, but the price for quality products is quite justified.

Application of Loctite sealant (2 videos)

Sealant Loctite (15 photos)

Loctite 577

Key Visual Loctite 243 50 ml March 2012

"Permatex"

Permatex anaerobic engine sealant has similar characteristics. It is a thixotropic, fast-curing product. It also dries out when there is no air in the gap. The parts must be pressed tightly against each other. An elastic connection will be formed if the gap size is no more than 0.3 millimeters. Reviews say that the material can withstand temperatures well and also protects the metal from corrosion. Can be used not only for engine components.

Sealant "Forch-K161"

This product is also suitable for joining metal surfaces in internal combustion engines. It allows you to achieve high-quality sealing. It is an anaerobic product that is resistant to high pressure and withstands the effects of chemicals. Reviews say that after hardening, a fairly strong and rigid gasket is formed. In terms of quality and density, it is in no way inferior to factory ones. The advantage of this anaerobic engine sealant is the price. It is lower than the cost of Henkel products (700 rubles versus 1350). Although both products are made in Germany.

A little about Loctite

The sealant went on sale in the middle of the last century and quickly gained the trust of people. Consumers highly appreciated its quality and performance characteristics.

The creator of this product, chemist Vernon Krible from Harford (Connecticut, USA), experimented with ester polymerization inhibitors. He wanted to cure in an airless space, which led to the creation of anaerobic glue.

Further work led to the creation of a material called a “liquid locknut.” It eliminated the problem of unscrewing and provided high-quality and durable fastening. This was an excellent solution for securely securing threaded connections.

This is how Loctite was born. During subsequent experiments, the range of sealants expanded significantly, and additional products with similar or different performance appeared. An example is the world famous superglue. The compositions were created on a diverse basis:

- epoxy,

- acrylic,

- silicone.

The world saw cyanoacrytal and anaerobic agents with a wide spectrum of action. An important achievement was the polymerization of one-component compositions, which expanded the range of applications.

Another development spiral was set in 1997, when the Loctite company was acquired by the world-famous Henkel concern. The corporation retained the original name of the sealant, but made it even more reliable, practical, durable and affordable.

Loctite 574 anaerobic sealant is the best sealant for rigid flanges

Anaerobic sealant Loctite “Loctite” 574 is a one-component, medium-strength sealant, consisting of thixotropic anaerobic mixtures. Loctite sealant polymerizes (a complex molecular process of material hardening) in the absence of air, between gap-free metal surfaces (used in gearboxes, in all connections of an internal combustion engine, automatic transmission).

Many craftsmen (motorists) have tested this sealant in practice and now use Loctite sealant in their workshops and thereby improve the quality of their work.

To reduce the cost of Loctite sealant, it is packaged from large containers into medical syringes, packaged in 20 ml.

Retail store at Uralmash, Baku Commissars St., 113. 8 (343) 221-35-35

02. By courier for orders over 2000 rubles, in Yekaterinburg from 20:00 to 22:00

Delivery only to the entrance. Additional +100 rubles to the apartment.

02.2. By courier for orders less than 2000 rubles, by EKB from 19:00 to 22:00

Delivery to the entrance or to the gate. To the door +100 rubles for the courier.

02.3. By courier outside the EKAD, up to 20 km, from 20 to 22 h

The manager will calculate the cost of delivery and notify you by phone or mail if your phone number is not available.

After sending, we will definitely send the TRACK NUMBER of the parcel.

On the official websites of the largest manufacturers of spare parts: SS20, Tehnoressor, Demfi, SEVI, online store illva.ru – IP Koroleva, recommended as a reliable supplier of original spare parts.

07. TC SDEK - careful and fast delivery

Recommended for light parcels! Inexpensive up to 10 kg and without queues, many delivery points in all large, medium and small cities, select the closest one to you on Yandex maps by entering SDEK in the search. After sending, we send you a tracking number. Fill in your full name in the Name field. Long distance payment upon receipt. Shipping is free.

05. TC "KIT" - a lot of branches

We recommend! delivery to more than 300 cities of Russia and the EAEU (Kazakhstan, Kyrgyzstan, Armenia, Belarus, Crimea). The delivery price can be checked with our manager or on the TK KIT website. After sending, we send you a tracking number. Delivery to TK KIT is FREE!

Low prices. We recommend for northern and eastern directions and Kazakhstan.

Delivery throughout Russia and the countries of Belarus, Kazakhstan, and China.

Fill in your full name and indicate the series and passport number in the comments to the order below. Delivery to TC Energia is FREE!

06. TC "Business Lines"

Prices are high with lots of markups! Attention!! TC DelLinii automatically includes services in the invoice - Insurance and Delivery by courier - but you may not be able to afford these services upon receipt, otherwise delivery with them will be twice as expensive! It is not profitable for her to carry small and inexpensive cargo. After sending the goods, we send you a tracking number. Please fill in your full name when ordering. In the comments to the order below, indicate the series and passport number. Payment for delivery upon receipt - the cost of sending this shopping center is indicated below.

09. TC “PEK” (series and passport number required)

Choose PEC only if there are no other options. The cost of PEC is relatively more expensive, and cargo in PEC is subject to inspection with violation of packaging, after which it is packed somehow, PEC charges various additional fees and, in general, delivery is more expensive. After sending, we send you a tracking number. Fill in your full name and indicate the series and passport number in the comments to the order. Below is the cost of the courier to the PEC branch.

12. I can’t choose! Offer the cheapest one.

To calculate delivery, please provide your full Address and Full Name; zip code, city, street, house, apt. And for foreign orders Country and exact address.

TK Luch - economical delivery to cities in the Chelyabinsk region, but shipments are not tracked and there will be problems if lost. cities: (Snezhinsk, Verkhny-Ufaley, Kasli, Ozersk, Kyshtym, Kusa, Zlatoust, Ust-katav, Yuryuzan, Katav-ivanosk, Trekhgorny, Satka, Mias, Chebarkul, Kopeisk, Korkino, Yemanzhelinsk, Yuzhnouralsk, Plast, Troitsk, Chesma , Magnitogorsk, Varna, Sibay, Kartaly, Bredy)), as well as Berezniki, Perm, Kurgan, Nizhny Tagil, Yekaterinburg, Surgut, Tobolsk, Tyumen, Shadrinsk, Shumikha, Petropavlovsk, Kostanay, Rudny, Astana, Ufa, Uchaly. Delivery costs from 100 rubles to 30 kg and from 200 rubles for 30-60 kg, between terminals. Check prices on the website of TC Luch - in some cities there are double tariffs.

general description

Henkel began producing adhesives and sealants in 1997. The manufacturer's products cover the entire range of production processes and are widely used in the automotive industry. Over the years, innovative sealant formulas and advanced production technologies have been developed. Product advantages:

- A large selection of Loctite products for sealing automotive components and parts.

- High efficiency of the compositions relative to traditional cushioning materials.

- Increasing the service life of surfaces treated with sealants.

- Quick setting and good adhesion to metal (steel, cast iron, aluminum) and plastic parts.

- High speed of complete polymerization, convenient application and wide range of operating temperatures.

The use of Loctite sealants instead of gaskets provides effective protection against leaks and helps to evenly distribute the load-bearing load on components and mechanisms. Thanks to the unique formulas of the compositions, pastes and gels come into contact with treated surfaces at every point of contact. Loctite products are more effective than compression gaskets, the use of welded and soldered joints, and pressing of cylindrical parts.