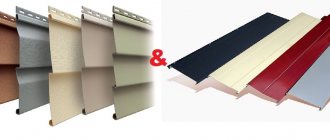

Exterior cladding of a house is a responsible undertaking that requires the purchase of suitable finishing materials. An excellent solution would be vinyl and acrylic siding. But these varieties have differences that must be taken into account in specific circumstances. Only an assessment of all properties and characteristics will allow you to make an accurate choice.

Advantages and disadvantages

Which siding is better: vinyl or acrylic? To make the right decision, you need to compare the pros and cons of materials.

Vinyl siding

Advantages of PVC products:

- Moisture resistance. The panels have a minimal level of water absorption, which prevents damage to the integrity of the structure.

- Frost resistance. The parts can withstand temperatures down to –50 degrees.

A temperature range of 100ºС is considered normal for polymer products - Wear resistance. The material is not subject to rotting and does not contribute to the spread of microorganisms. Does not deform when exposed to wind and hail.

- Safety. Although the products cannot be called absolutely environmentally friendly, they do not pose a threat to the life and health of others.

- Additional sound and heat protection. The surface prevents the penetration of noise, and when creating an air gap, it significantly reduces heat loss.

- Durability. Service life – at least 20–30 years.

- Easy to install. Due to the light weight of the panels, installation is carried out without the involvement of assistants.

You can install vinyl siding alone - There is a wide range of textures and colors to create appeal.

All these parameters are inherent in high-quality material that has the necessary certificates of conformity.

Vinyl also has its disadvantages:

- Discoloration. This is typical even for expensive varieties, although if they are used, the loss of the original color will take much longer.

The weak point of most vinyl siding models is fading in the sun. - Temperature expansion. This factor must be taken into account during installation. To level out its consequences, special compensation gaps are installed.

- Static. The coating attracts and accumulates dust, which leads to loss of decorativeness.

Attention! On the finishing materials market there is a large number of PVC products made in violation of technology or from low-quality components. This finish becomes unusable after one season of use.

Acrylic material

The advantages of acrylic products are similar to the previous option, but are supplemented by the following advantages:

- The coating holds its shape even at high ambient temperatures.

- Resistance to mechanical stress.

- Preservation of color under the influence of ultraviolet radiation.

- Easy to care for. The surface can even be washed with chemicals (provided you select the appropriate composition).

Acrylic coating is much easier to care for - Decorative. Externally, many varieties perfectly imitate the texture of natural materials.

The disadvantages include:

- It is mandatory to have expansion gaps to prevent the harmful effects of thermal expansion.

- There are many fakes, as well as products made in violation of technology or using outdated equipment.

- The acrylic variety has a higher cost, which affects the work budget.

Estimated prices for acrylic siding models

On a note! Both options have a base version, which allows finishing in difficult operating conditions.

Which is better to choose?

From all of the above, the conclusion suggests itself - metal siding is in many ways better than acrylic and vinyl. But this does not mean that you must choose it:

- Vinyl siding is better to choose for a summer house, country house and any other home in which you do not plan to invest a lot of money.

- Acrylic siding is better suited for regions where weather conditions change frequently, temperatures are critically low in winter and abnormally high in summer. It is also worth choosing if the walls of the house are not protected from direct sunlight.

- Metal siding looks better, is fireproof, and can be used for any building. But there is a significant “but”. It is harder to install. Particularly difficult is the finishing of round shapes, since the material does not bend, and additional elements are not always available. It is worth choosing if it is possible to hire specialists for installation.

What is the difference between vinyl siding and acrylic

Acrylic siding is a relatively new material for cladding wooden houses and cottages, but the popularity and demand for the product is steadily growing. What is its difference from the vinyl version?

Fundamental parameters of vinyl and acrylic finishes in comparison

The difference is in the following parameters:

- The production of acrylic panels is an improved technology that involves a more precise selection of all components and the use of brighter dyes.

- The composition contains components that reduce static electricity and reduce the likelihood of fire.

- A special polymer-based additive is used – Acrylnitril-Styrol-Acrylester (ASA).

Only a few companies in the world produce high-quality acrylic copolymer ACA.

Upon a more detailed analysis of products made from acrylic and vinyl, it turns out that the materials have almost the same base and the first variety is an improved variation of the second. The parameters are improved due to the ACA copolymer (acrylic), which is an external coating connected to the base using the co-extrusion method.

Expert opinion

Many professionals believe that it is simply impossible to choose one of the above types of siding, because each material has its own advantages and disadvantages. You must decide for yourself which factors are your priority. For example, acrylic-based siding is more durable than its vinyl counterpart. This is its main and undeniable advantage.

Characteristics of vinyl and acrylic

The features and characteristics of each material depend on the main components.

Polyvinyl chloride

PVC properties:

- Resistance to corrosion and rotting due to the fact that water has no harmful effects.

- Temperature resistance. The products can be used in conditions where temperatures exceed +50 degrees. The material begins to melt at temperatures above 150°C, and to burn at 500 degrees.

Low-quality PVC panels become deformed at the slightest overheating or severe frostsOn a note! Elimination of the source of exposure leads to self-extinguishing of the coating. But you should definitely use a special protective respirator, since the process of melting and burning releases harmful substances.

- Non-conductivity of electricity. If the wiring running through the frame system is damaged, the finish will not become a source of danger.

Good PVC siding consists of only 80% polyvinyl chloride, the rest is additives: calcium carbonate, butadiene, titanium dioxide, pigments, modifiers and antistatic agents.

All PVC panels are made from the same polymer

Important! High-quality panels cannot be glossy, since the technology involves adding matting substances to the top layer.

Acrylic

Material characteristics:

- High temperature resistance. Withstands temperatures up to 90 degrees. When heated briefly to 110 degrees, it does not deform. Brittleness appears at temperatures below –30°C.

- Safety. When melting, no harmful substances are released.

- Unaffected by ultraviolet radiation. The coating does not lose color saturation even after a considerable period of time.

Over time, the brightness of the color of the acrylic finish is not lost - Neutrality to moisture. Due to this, mold and mildew do not multiply.

- Resistance to chemical reagents. The panels can be washed with various means, and they are not destroyed when the house is located near a transport highway or enterprise.

Such parameters significantly increase the durability of the product.

Acrylic siding retains its original appearance for a long time

Which siding is best for cladding a house?

To choose the best option, take into account the following factors:

- Installation. Varieties have a similar installation process, which depends on the specific type of product. This type of cladding is great for wooden houses because it allows the use of wood sheathing.

- Price. The vinyl variety is inexpensive. Accordingly, the total cost, taking into account the purchase of components, will also be less.

- Resistant to sunlight. Here acrylic is superior to PVC, so for areas with long warm periods this is the best solution. But there are modern types of vinyl with special additives that significantly extend the fading period.

Comparison of sun-faded and new cladding - Lifetime. The leader in this indicator is acrylic siding.

- Care. Acrylic material requires less attention, because it has better antistatic properties. It can also be washed with different chemicals without fear of damage.

But a decision must be made based on the real situation and the availability of material at points of sale.

The main differences between the two types of panels

Acrylic or vinyl siding has its own characteristics. A comparative table of parameters will help in making the final decision on the purchase of material:

| Comparison characteristics | Type of panels | |

| vinyl | acrylic | |

| Mechanical strength (impact and directional impact) | high in the summer months, much lower in winter | high regardless of season |

| Guaranteed service life | at least 30 years old | at least 50 years old |

| Color retention ability | Over time there is a noticeable change in shade | do not fade with direct and prolonged exposure to ultraviolet radiation |

| Possibility of deformation when heated | change size when exposed to heat for a long time | don't heat up |

| Maximum temperature value | up to +50°С | up to +80°С – 85°С |

| Color palette and type of coating | mostly light, wood, brick, stone | dark, bright, glossy, wood effect |

| Appearance | do not have a clearly defined structure | full imitation of natural coatings |

From the characteristics comparison table, it becomes clear what the fundamental difference between the panels is. However, the higher performance properties of acrylic siding affect its cost - it is 40–50% more expensive than vinyl siding . As an example, a short overview of panel manufacturers:

| Manufacturer | Type of siding | Price, in rub. per piece |

| Alta Profile | Vinyl "Alaska" | from 140 |

| Acrylic siding "QuadroHouse" | from 200 | |

| Acrylic “Canada Plus” | from 250 | |

| FineBer | Vinyl country house | from 145 |

| Vinyl Standard | from 160 | |

| Docke | Vinyl Herringbone | from 170 |

| Vinyl Ship Timber | from 200 | |

| Acrylic Lux | from 250 | |

| Acrylic Wood Slide | from 310 |

It is important to note that the cost of additional elements and components for acrylic panels is also higher than those made of vinyl.