When designing large-scale heating systems (in particular, calculating the adjustment of the heating system of an apartment building and its full functioning), especially close attention is paid to the external and internal factors of equipment operation. Several heating schemes for central heating have been developed and are successfully used in practice, differing from each other in structure, working fluid parameters and pipe routing patterns in apartment buildings.

Types of heating systems

To understand how heating works in apartment buildings, it is important to navigate the variety of types of heating systems. They are classified according to several criteria, in particular:

- structure and device;

- wiring system;

- location of boilers;

- characteristics of coolants.

Let's take a closer look at the most common classification criteria.

According to the placement of heating equipment

Depending on the location of the sources generating heat, the following types of heating systems in an apartment building are distinguished:

- Apartment heating. This system involves placing a heating boiler in each apartment, usually in the kitchen, in a specially designated room or in the corridor. The system is typical for two-story houses built in the 50s.

- Central heating. The most common heat supply system in a typical structure. The principle of operation is to transfer the generated heat from the central thermal power plant to local heating points and boiler houses, which distribute it to homes.

- Individual heating. It is typical for a separate high-rise building to have its own boiler house, serving one or more nearby houses. It is maintained by the management organization (housing and communal services company), but is the common property of the residents, who independently decide on its launch.

According to the properties of the heat carrier

Depending on the coolant used in the systems, the following types of heating are distinguished:

- Vodyanoe. The most common coolant is heated water, transmitted to the premises through pipes and radiators. In this system, water circulation can be natural (gravity flow) or artificial (using a pump). The system is characterized by large radiators and significant heat losses when transferring heat over distances.

- Steam. The heat carrier is water vapor. The system is characterized by small radiators, low-cost heat production and the absence of losses in heat exchangers. At the same time, due to the high temperatures of the carrier, according to modern building codes, steam is considered dangerous and is prohibited for use in residential premises. It is often combined with a water system, when heat from the boiler room to the building is transferred by steam and then transferred to a liquid carrier.

- Air. Air as a coolant is successfully used in individual residential buildings, industrial buildings, and retail spaces. Its essence is to generate hot air and forcefully blow over the area. The advantage is the ability to control temperature and air flow in real time depending on needs.

According to the method of system wiring

The layout of the heating system in high-rise buildings is traditionally divided into horizontal and vertical.

Depending on the method of placing pipes in the premises, the wiring can also be:

- top,

- bottom,

- combined.

Horizontal wiring method

Horizontal distribution of the heating system presupposes the presence of one thermal riser on the territory of the house, from which the floor-by-floor distribution of internal heating mains is carried out.

Such a system has a number of undeniable advantages:

- installation of metering devices in each apartment;

- the ability to disconnect individual residential premises;

- individual design of heating in an apartment.

As a rule, such a system is used for low-rise apartment buildings. This is due to the fact that its effective operation is possible only by ensuring the necessary coolant circulation and maintaining high pressure in the line.

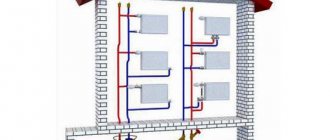

This is what the horizontal wiring diagram looks like.

Vertical wiring method

Vertical wiring has been used in the design of heating systems since Soviet times. It is characterized by the presence of several thermal risers on the territory of the apartment building, to which radiators are connected.

This method allows you to minimize heat loss and independently regulate the temperature in each battery, which is why it is widely used in apartment buildings of standard construction above 5 floors.

In addition, the vertical system allows for both upper and lower pipeline routing, and installation of lines under the ceiling or under the floor. At the same time, it has a number of features:

- allows you to install a thermostat or weather regulator on each individual battery to maintain a comfortable microclimate in the room;

- a used heat meter is installed on each riser, since it is impossible to install individual meters for all apartments;

- In the event of a breakdown, it is easy to disconnect any radiator from the system.

Vertical and horizontal wiring have their own advantages for a separate layout.

Both heating system schemes for apartment buildings can be single-pipe or double-pipe.

According to the method of connecting devices

The choice between single-pipe and two-pipe heating systems depends on the method of connecting the water riser to the radiators.

Single-pipe main

As the name suggests, a single-pipe system involves connecting heating devices along one circuit and connecting them with a single pipe. It is characterized by a sequential arrangement of batteries and a gradual flow of coolant from one to another. Because of this, the single-pipe heating system of a multi-storey building has a negative feature: each subsequent radiator in the chain is colder than the previous one.

This drawback can only be compensated for by installing batteries with a large number of sections - the higher the floor, the larger the heated radiator area should be.

There are other disadvantages:

- It is not recommended to change the system configuration so as not to affect its performance;

- It is impossible to install thermostats and other control devices.

Given the relatively short length of the system, a small number of pipes are needed, so the user saves on installation.

Two-pipe main

A two-pipe heating system involves the installation of a riser consisting of two elements: a supply pipe and a “return” pipe. The supply pipe is separately supplied to each radiator along the main line, providing them with coolant of the same temperature, regardless of the floor and place in the circuit. After this, water at a lower temperature passes into the return line, through which it leaves for the next heating.

This scheme allows you to maintain the temperature of the carrier anywhere in the line, but its installation requires a pipeline twice as long.

The advantages include:

- the ability to change the backbone configuration without loss of performance;

- the ability to install control devices;

- saving the surface of heat transfer devices.

It is not surprising that the two-pipe scheme is so common in residential construction.

Finally, about the scope of application

To avoid problems during operation, use single-pipe heating networks in suitable conditions:

- “Leningradka” works well in one-story dachas and small houses with an area of up to 150 m². If the quadrature does not exceed 70 m², one common ring for all batteries is sufficient, otherwise the system is divided into 2 circuits or a pipeline of a larger cross-section is laid.

- In a 2-story building, you can assemble an open-type gravity single-pipe circuit or a closed version with bottom wiring - your choice. In case of power outages, it is preferable to organize gravity flow and place the circulation pump on the bypass.

- Gravity flow with an accelerating manifold, used in one-story buildings, is characterized by inertia. Radiators warm up slowly, the water cools down greatly due to the low flow rate, and the boiler operates in extreme mode. It is better not to use this circuit at all; it is outdated and will not work normally without a pump.

- Feel free to divide the Leningradka into 2-3 separate floor loops with the optimal number of batteries on each. Do not combine the radiators of all floors into a single circulation circuit - the last devices will remain cold.

- The single-pipe Leningrad system is a suitable option for installing autonomous heating for a 2-3-room apartment.

Experts who prove the indispensability of single-pipe heating systems often refer to Soviet-built multi-story buildings, saying that they have 20 radiators per riser. But they forget to mention the pressure and performance of pumps from a centralized network, which is unattainable in private homes. Do not listen to would-be specialists and use the best system options - two-pipe, collector or associated.

How does the MKD heating system work?

To see how the heating system works, you need to go down to the basement of a multi-story building. But we will help you understand the structure of the heating main without this.

The system begins with a valve, which cuts off the intra-house fragment from the heating main of the central heating supply. The valve is a line of division of responsibility: before this element, the heating network bears responsibility for the main line, after that - the management company.

The centralized heating circuit of an apartment building located behind this valve looks like this:

Elevator unit: mud traps, hot water valves, elevator, heating circuit valves, water discharges from the system → filling pipe → risers and jumpers → heating devices → return riser and so on.

All these key nodes have their own characteristics. We propose to dwell on each of the elements of the system in more detail - without this it is difficult to understand how heating works in an apartment building.

Elevator unit

The elevator unit begins immediately after the inlet valves. Next to them are:

- Mud traps are devices that trap persistent mechanical particles in water, such as scale or rust.

- Hot water taps on the supply and return pipes. It is practiced to place one or more taps, which ensures a round-the-clock supply of hot water to the system.

- Heat metering unit, which is usually mounted between the hot water supply point and the elevator.

- The elevator is the key device of the elevator unit. Thanks to it, we get water at the required temperature in the system. The fact is that water heated to 110-150˚C circulates along the heating mains. The design of the elevator allows the supply liquid to be mixed with cooled return water, releasing coolant into the system at a temperature of 90-95˚C. Using this design, the heating system is adjusted: the wider the hole in the nozzle for supplying water to the elevator, the higher the temperature in the batteries.

- Heating circuit valves are valves that repeatedly disconnect the house from the central main and heat supply.

- Reset valves are taps for draining the system in case of repair or replacement of hot water with cold water in the summer.

Filling pipes, risers and circulation direction

Immediately after the discharge valve on the supply, a pipeline begins that goes into the risers. It's called a "fill pipe". Heating risers in an apartment building diverge from it.

The principle of installing risers is always the same - it is a system that delivers coolant to radiators on floors. Depending on the construction and design of the house, the direction of water supply and circulation may differ.

The designs of risers are different. Taking into account the direction of water circulation, systems with top and bottom filling are distinguished.

Top filling system

Heating with top pouring is a standard scheme for mass multi-storey Soviet residential buildings.

Although all the key elements are located in the basement, the bottling pipe leads to the attic of the house, where the entrances to the risers are mounted. The first tap is located here, allowing you to disconnect the riser from the system, expansion tanks and air valves. The second tap is placed in the basement, at the end of the riser.

The return line is located in the basement. It is mounted parallel to the supply filling pipe in such a way that each riser acts as a jumper for the supply and return pipes.

The upper heating distribution of a high-rise building has a significant disadvantage - a linear drop in the temperature of the coolant to the lower floors. Such losses are compensated by increasing the area of heating devices, the number of their sections or the number of radiators.

Top filling has other characteristic features:

- starting the system is simple - just open both supply valves and air valves for circulation to begin by itself;

- disconnecting/connecting individual risers, on the contrary, causes problems, because the valves are located both in the attic and in the basement;

- With proper design, discharging media from the riser takes a few seconds.

Bottom filling system

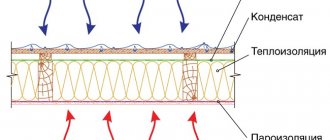

Houses with bottom pouring can be either five or nine storeys. Heating according to this scheme involves the installation of supply and return pipes in the basement with alternate pairwise connection of risers to them.

At the top of the system, paired risers are connected to each other by jumpers. This happens either in the attic or in an apartment on the top floor. There is an air valve on the jumper, which creates certain problems for mechanics:

- if the jumper is placed in the attic, this is fraught with freezing of the system even with a short stop in circulation - the lack of thermal insulation affects it;

- when the jumper is in the apartment, access to it is limited, which creates difficulties when starting the system during the heating season.

Radiators

Since large-scale construction was carried out on the territory of the Russian Federation during the Soviet period, in most houses there are three types of radiators:

- Cast iron. They are characterized by impressive weight, poor heat transfer (up to 150 W per section), regular leaks and unaesthetic appearance. Because of this, apartment owners are trying to get rid of them, replacing them with more modern models.

- Steel (convectors). This type of radiator became widespread in the 90s. Its design consists of a tube wrapped in coils, with welded steel plates that increase heat transfer.

- Bimetallic. The most modern type of heating equipment is MKD, which was installed en masse in the 2000s. Modern design and high-tech materials (steel and aluminum or copper and aluminum) ensure the strength of the radiators and high heat output (about 200 W per section).

Since heat in apartments becomes more expensive every year, residents of houses are increasingly replacing old heating devices. There are several important points to consider:

- The diameter of the heating pipe in the apartment. When replacing radiators, you should not change the pipes themselves. This can affect performance and cause the system to become unbalanced. If replacing, use pipes of the same diameter (usually 20-30 mm).

- When installing a device in front of the radiator that regulates the flow of coolant, be sure to place a jumper between it and the riser. Without it, the regulator will affect the flow not only in the radiator, but throughout the riser.

- Replace appliances during the warm season. For those who are interested in whether water is drained from the heating system in the summer, we answer: the liquid is constantly in the radiators. However, it is in the summer that replacing radiators creates minimal discomfort for the owner and other residents. In addition, restarting the water system allows you to ensure that there are no leaks before the heating season begins.

Payment

Finally, we will answer several questions, one way or another related to the growing tariffs for heat and hot water every year.

How are payments for heating and hot water supply calculated?

The key parameter in charging for heating is the amount of heat spent to maintain a comfortable temperature in the apartment or to heat water. The cost of thermal energy for 2017 is 1000 - 1800 rubles per gigacalorie, depending on the region.

Utility tariffs for 2022 for the city of Berdsk

However, not all apartments have heat meters, so the following appear on receipts much more often:

- Fixed payment for heating a square meter (it is calculated as the product of the heat consumption standard for a given region and the price of a unit of thermal energy);

Simplified diagram: heating costs are calculated based on the square footage of the heated area

- The cost of a cubic meter of hot water, including the meter (90-170 rubles per cubic meter).

How can you save on heating?

To reduce costs you need to:

- Install heat metering devices on each radiator;

- Install chokes or thermal heads on the connections to limit the flow of coolant through the heating device.

The photo shows a sectional radiator with a heat meter and a throttling thermostatic head

Is it possible to use hot water supply to heat an apartment?

Technically yes. To do this, it is enough to form a closed heating circuit (for example, the simplest one-pipe Leningrad) and connect it to the gap in the hot water riser. Since there are no metering devices on the riser, the heat obtained in this way will be absolutely free for you.

The simplest heating system - Leningradka

However:

- Any change in the configuration of public utility networks requires approval from the housing organization and, in the case of hot water supply and heating, from the relevant service providers. It is clear that none of the organizations will give permission for such a change in the heat supply scheme;

- Uncoordinated redevelopment of communications is an administrative offense and is punishable by a fine with an order to restore the original configuration at your own expense;

The Housing Code regards uncoordinated redevelopment of communications as an administrative offense

- Finally, the main thing: you can disconnect from the central heating system only at your entrance or home, providing a plan for an alternative heating scheme and agreeing with electricity or gas suppliers (alternative heat sources). Without an official termination of the heating service, you will continue to receive bills that you want to get rid of.

To stop paying for central heating services, you need to cut off the heating devices from the heating risers and draw up a disconnection certificate with representatives of the housing residents

Starting heating in a high-rise building

The performance of the heating system depends not only on its design features, but also on the correct start-up. Uneven heating of individual floors or risers, air vents, and massive leaks are common consequences of a mechanic’s inattention to starting rules.

To properly start heating in an apartment building, you need to adhere to the following order:

- Pre-pressure testing is a hydraulic test of the system for its tightness and integrity.

- Carry out a smooth launch of the coolant through the intra-house pipeline. The circulation pumps are started at minimum speed so that water slowly fills the system.

- Fill the pipeline through the return line to reduce the unnecessary load on old radiators and displace air from the system.

- Release the remaining air at the highest points of the system through the air valves.

- When heating is supplied to apartments, you should check the degree of heating and the functionality of all radiators in the house. If the residents do not complain, the radiators warm up, there are no leaks, the heating and circulation pumps are started at the required power.

Methods of obtaining and types of hot water supply

According to the method of production, DHW systems are divided into two types:

- open,

- closed.

Hot water supply for an apartment building comes in two versions:

- with single-pipe risers,

- with two-pipe risers.

The two-pipe system consists of two risers:

- server,

- circulation.

The heated water flows through the supply riser to the apartments, and through the circulation riser into the central main. Both pipelines are nearby. Heated towel rails are placed on the circulation riser in bathrooms - curved pipes that not only heat the rooms, but also compensate for temperature changes in the length of the pipe. The water in them will no longer be disassembled by consumers, but will be returned through the central pipeline back to the boiler room.

In a single-pipe scheme, each consumer has one riser - supply, and all circulation pipes are combined into one “idler”. It has no consumers, and the water through it returns to the main line.

Heated towel rails with this design:

- placed on the supply pipe,

- electric ones are installed,

- connect to the heating bed.

In the latter case, heated towel rails only operate during the heating season.

With any wiring scheme, the hot water supply system of an apartment building must be able to drain periodically occurring air pockets. With the top wiring, automatic relief valves are installed for such purposes; with the bottom, air can be removed through the top water intake valve.

Installing a heating meter

Many are not satisfied with paying for heat at an average tariff based on consumption standards. In this regard, some people prefer to install a heat meter and pay only for the heat received.

The design features of heating systems, in particular, the widespread vertical distribution, do not allow apartment-by-apartment accounting of consumed heat, be it an open or a closed heating system of a high-rise building.

The only way out is door-to-door accounting. In this case, the procedure will be as follows:

- The management organization develops technical specifications for the installation.

- Housing departments or residents purchase a heat meter on their own.

- Based on the documents for the meter, a project for its installation is developed and agreed upon with the heat supply organization.

- The metering device is installed, the heat supply representative seals the meter and draws up the corresponding report.

Find out how a common house heat meter is installed in an apartment building.

Supply from city networks

We inherited centralized heat supply to multi-storey residential buildings as a legacy of planned management since the existence of the Soviet Union. Today, this method of providing housing with thermal energy is still the most common.

The main advantage of central heating is that residents of houses do not have to deal with issues related to the operation and repair of equipment and pipelines. The annual launch and necessary overhaul of networks is the responsibility of the city heat supply organization. With centralized and autonomous heating, individual elements can be repaired or altered only in agreement with the heat supply organization.

The design supply temperature in urban networks can be in the range of 90-115˚C, and existing standards for the safe operation of equipment prohibit heating accessible hot surfaces above 60˚C to prevent possible burns.

Therefore, a special elevator unit was installed at the pipe entry into the building. It mixes the hot coolant from the supply with cooled water from the return, returning from the consumer, changing the temperature to an acceptable one. Calculation of elements, maintenance of elements and change of the elevator control nozzle are carried out only by employees of the heat supply organization.

Temperature standards

It is quite difficult to regulate heating in a residential apartment building. Even if residents have access to the system and the ability to increase/decrease the heat supply, it is not always possible to find a common language with their neighbors. In this case, it is worth focusing on the current regulations.

Temperature standards are regulated in accordance with GOST R 51617-2000, approved. . According to this document, the minimum temperature in apartments during the heating season should be:

- in living rooms, toilets, and kitchens - at least 18˚С;

- in the bathroom - not lower than 25˚С;

- in corner rooms, regardless of purpose, as well as for families where disabled people live - 2˚C above the established norm.

If the readings in your apartment are lower, you can safely demand an increase in temperature.

Read more about what temperature standards are set in the apartment.

Traditional approach or full automation

If we consider heating options for an apartment building with several floors, a single-pipe system will ultimately create more problems. In the future, we can expect uneven heating and additional costs to increase the efficiency of the heating structure.

If you still choose a single-pipe system, then the most difficult part of it will be a carefully calculated professional project.

There are many supporters of this option; they are inspired by the low cost of work and old houses in which such a system has been successfully operating for many decades.

A more flexible option is a combination of two-pipe and one-pipe systems. It will allow you to save money and take advantage of the advantages of both systems.

What to do if the batteries are cold

What could be worse than cold radiators in winter? This is not only discomfort and violation of temperature norms, but also the threat of getting sick.

It is important to know what limits the timing of a possible emergency heat shutdown. They should not collectively exceed 24 hours per month, and last no more than 16, 8 and 4 hours in a row, if the temperature is not lower than 12, 10, and 8˚C, respectively.

If the radiators remain cold during the heating season, you need to contact:

- To the heating network dispatch service. If they do not know the reasons, they are required to check for the lack of heat.

- To the management organization (or others). Perhaps they are the ones carrying out the repair work.

- To the city housing inspectorate with a complaint about violation of housing standards.

- To law enforcement agencies (Rospotrebnadzor, prosecutor's office), if the heat is not restored on time and the problem is not solved.

If the heating network does not see a problem, an independent heating expert may be required.

We recommend that you find out in more detail what to do if there are cold radiators in the apartment.

Grade

Advantages

Why is a radiant heating system better than a sequential one? Here is a typical list of arguments of its supporters:

- Minimum temperature spread between heating devices. They are powered from a common collector and are fed from one supply thread;

- Ease of management. From the manifold cabinet you can change the temperature of any part of the heating system;

The manifold cabinet is the heating control unit for the entire house.

- Independent temperature control of devices. If you cover or completely turn off any of them, this will not affect the operation of the remaining batteries;

- Hidden liner routing. When laid in a screed or grooves, they will not spoil the design of the living space.

The heating connections will be hidden by the floor laid over the joists.

Flaws

First, a few critical comments on the properties of collector wiring that I mentioned among its advantages.

- In a two-pipe series system, it is also possible to obtain the same temperature of the batteries. With dead-end wiring, it is achieved by balancing the system (that is, throttling the connections of the batteries closest to the boiler); with parallel wiring, the temperature on all heating devices will be the same without balancing;

Tichelman loop, or a two-pipe system with associated coolant movement. The temperature of all radiators is the same without balancing.

- It is most convenient to control the air temperature in the room directly from it. If you need to go through the whole house to the collector cabinet in order to reduce the heating of the battery, this, you see, does not look like an advantage at all;

- Independent temperature control of radiators is possible in any two-pipe system. With single-pipe wiring, this is also achievable: it is enough to connect the batteries not into the filling gap, but parallel to it.

Connecting a radiator parallel to the filling in a single-pipe Leningrad tank. Taps on the inlet allow you to reduce the heating of the battery without affecting the operation of other heating devices.

And the actual disadvantages:

- Expensive. The total length of the heating connections in the case of radial pipe distribution will be several times greater than when the batteries are connected in series;

- Difficult. Grooving walls or pouring screed with collector wiring is possible only at the stage of major renovation of a private house or apartment. Meanwhile, it is possible to sequentially separate the batteries even after finishing the final repairs: the only dirty work to be done is drilling the walls for bottling;

Heating with serial connection of radiators can be installed after finishing finishing.

Unreliable. The heating system requires a circulation pump to operate, which makes it energy-dependent. When circulation stops (for example, in the event of a long power outage), the water in the pipes will freeze. It is much more difficult to warm up connections hidden in the floor or walls than openly laid outlets.

The line below the connection to the radiator is filled with water. It is impossible to drain it completely.

conclusions

In my opinion, radiant wiring is justified only in one case: if you are installing water-heated floors.

Arguments? At your service:

- The length of one heated floor circuit cannot exceed 120 meters due to the high hydraulic resistance of the pipes, so in any case there will be several parallel circuits in the house;

- It is most convenient to connect parallel circuits to the terminals of the distribution manifold. Alternative installation methods involve open laying of bottlings and open installation of chokes or thermal heads, which, as you understand, goes against aesthetics.

Water heated floor: collector wiring is completely justified.

A high-temperature radiator heating system is cheaper, easier and smarter to install in series.

Is it possible to install an individual boiler in an apartment?

Many Russians would like to switch to individual heating. Today this is more real than 10 years ago, but it is still associated with a considerable number of obstacles.

Since installing an individual boiler involves rebuilding the heating system in an apartment building, the apartment owner needs:

- obtain the consent of neighbors;

- obtain permission from the heating network to disconnect central heating and dismantle heating devices;

- if a gas boiler is being installed, obtain specifications for its installation from the local city gas company;

- draw up a VDPO conclusion on the presence and serviceability of the chimney;

- agree on a new heating project in the heating network, if the reconstruction is technically possible, and pay for installation work.

And these are not all the problems that await the owner.

Find out more about how to install individual heating in an apartment.

Switchgears

The elevator unit with all its piping can be thought of as a pressure circulation pump, which supplies coolant to the heating system under a certain pressure.

If the facility has several floors and consumers, then the most correct solution is to distribute the total coolant flow to each consumer.

To solve such problems, a comb is designed for the heating system, which has another name - a collector. This device can be represented as a container. The coolant flows into the container from the elevator outlet, which then flows out through several outlets, with the same pressure.

Consequently, the distribution comb of the heating system allows the shutdown, adjustment, and repair of individual consumers of the facility without stopping the operation of the heating circuit. The presence of a collector eliminates the mutual influence of the heating system branches. In this case, the pressure in the heating radiators corresponds to the pressure at the elevator outlet.

Failure and cut-off of heating in the apartment

Refusal of central heating is the most difficult stage of installing an individual boiler. However, not wanting to put up with the policy of local heating networks, some decide to completely cut off the central heating supply to an apartment in an apartment building, without installing their own boiler.

Whatever the reasons for this, the initiator of such a decision will face stiff resistance from representatives of the heating network, housing departments and, probably, other residents of the apartment building.

According to clause 6 of the Rules, approved. , the heating system (risers, heating elements, any other equipment on the main line), even if it passes through a specific apartment, is the common property of the residents.

This single system is designed to heat the entire house, not just one apartment. Therefore, intervention in public communications is possible only with the consent of all owners of residential premises. In practice, few neighbors will agree to such pruning, because this can cause imbalance and disruption of the entire system.

The house is designed for uniform heating. If one of the apartments is not heated, a temperature difference will arise, which will lead to the slow destruction of the house.

The only chance to cut off the radiators is to obtain a court decision that the in-house heating system is not the common property of the residents.

What documents are required for trimming?

In order for the court to allow pruning and reconstruction of the system, in addition to the statement of claim and other standard papers, the initiator must provide:

- registration certificate and title documents for housing;

- consent of the residents of the entire house to interfere with the heating system or proof that it is not the common property of the residents;

- conclusion of a specialized expert organization on the technical feasibility of rebuilding the heating system;

- house heating project, taking into account changes that will be made after pruning;

- calculation of residual heating from risers and sunbeds.

Shutdown procedure

If the court makes a positive decision, the pruning procedure will look like this:

- trimming radiators with welding and cutting off all connections;

- inserting lintels into risers;

- if this is an apartment on the top floor, move the jumper between the paired risers to the neighbors below;

- thorough insulation of the riser along its entire length in the apartment;

- drawing up by a heating network employee a certificate of disconnection from central heating and termination of the contract for the provision of heat.

Even in the case of cutting batteries, the homeowner is obliged to provide mechanics with access to the risers.

Which scheme is better to choose?

The selection of wiring is carried out taking into account many factors - the area and number of floors of a private house, the allocated budget, the presence of additional systems, the reliability of power supply, and so on. We will give a number of general recommendations for choosing:

- If you plan to assemble the heating yourself, it is better to opt for a two-pipe shoulder system. It forgives beginners many mistakes and will work despite the mistakes made.

- If you have high requirements for the interior of rooms, take the collector type of wiring as a basis. Hide the comb in the closet, and route the lines under the screed. In a two- or three-story mansion, it is advisable to install several combs - one per floor.

- Frequent power outages leave no choice - you need to assemble a circuit with natural circulation (gravity flow).

- The Tichelman system is suitable for buildings with a large area and a large number of heating panels. It is not financially feasible to install a loop in small buildings.

- For a small country house or bathhouse, a dead-end wiring option with open piping is perfect.

If the cottage is planned to be heated with radiators, heated floors and water heaters, it is worth adopting a dead-end or collector wiring option.

The two indicated schemes can be easily combined with other heating equipment. Date: September 25, 2022

Autonomous boiler room for one building

Heat sources serving only one city house began to be built in the last two decades. Boilers are installed in a special room on the roof, in an extension or in a separate building near a residential building. The level of automation of such a boiler house does not require the constant presence of maintenance personnel and can provide central dispatch control over the operation of the equipment.

The absence of large distribution networks makes it possible to avoid the use of overheated water, which reduces heat losses and increases the level of comfort. The coolant is supplied to the apartments through the main risers located in each entrance or directly through the upper distribution pipes if the boiler room is installed on the roof.

Classification according to the direction of movement of the coolant

Depending on the direction of movement of the supply and return coolant relative to each other, heating systems are designed in the three most common schemes: dead-end, with the associated movement of the coolant, and collector (radiant).

Dead-end coolant flow patterns

In dead-end (standard) heating systems, coolants move in countercurrent; the branch of radiators furthest from the boiler has greater resistance than the one that is closer. Therefore, a situation may arise where uneven heating of nearby radiators occurs. In order to avoid this, it is necessary to create additional resistance in shorter circulation rings, that is, install balancing valves.

Associated coolant flow schemes

When the coolant moves parallelly in the supply and return pipes of the heating system, all circulation rings, that is, branches with radiators, are in the same conditions. That is, both pipelines and risers or radiators are hydraulically balanced with each other. However, such systems are the most metal-intensive compared to standard ones, and also require laying much longer pipelines. This is reflected, first of all, in the cost of the system and the price of installation work. Therefore, associated schemes in housing construction are used most rarely.

Collector heating circuits

The ideal option for cottage and residential construction in general is to use a collector circuit for the heating system.

Such a system is a manifold cabinet installed on the floor or in the boiler room, in which, in addition to shut-off and balancing valves, manifolds with outputs either to the radiator branch or to each heating device are installed. Such a system is also hydraulically stable and easily adjustable for individual, most remote branches or those loaded with thermal power. When planning a radial heating system circuit, you can connect each radiator separately to each collector output, and lay the pipelines in a hidden way. In this case, the pipeline section must be made from a single piece of pipe.

General requirements for installation of beam distribution

When using collector-beam wiring, a common method is to lay pipes in the floor in a screed, the thickness of which is 50-80 mm. Plywood is laid on top, covered with a finishing floor covering (parquet, linoleum). This thickness of the screed is quite sufficient for free “monolithization” of the intra-apartment (intra-house) radial wiring of the heating system. It is possible to lay pipes externally along the walls under decorative skirting boards, which entails an inevitable increase in the length of the pipelines. There are known options for laying radial distribution pipes in the space of a suspended (suspended) ceiling, in grooves.

Connecting radiators with a collector-beam circuit.

Metal-plastic or cross-linked polyethylene pipes (PEX pipes) are used, laid in a corrugated pipe or in thermal insulation. PEX pipes have an undoubted advantage here. According to SNiP, only unbreakable connections can be “mortared” into concrete. PEX pipes are connected using tension fittings, which are permanent connections. Metal-plastic pipes use compression fittings with union nuts. “Monoliquing” them means violating SNiP. Each detachable pipe connection must be accessible for maintenance (tightening).

Even without fittings, not every metal-plastic pipe is uniquely suitable for laying in a floor screed. Manufacturers' products suffer from a serious defect: layers of aluminum and polyethylene delaminate under the influence of repeatedly changing coolant temperature. After all, metal and plastic have different coefficients of volumetric expansion. Therefore, the glue connecting them should be:

- internally strong (cohesive);

- adhesive to aluminum and polyethylene;

- flexible;

- elastic;

- heat resistant.

These requirements are not met by all adhesive compositions even from well-known European manufacturers of metal-plastic pipes, which delaminate over time; the inner layer of polyethylene in such a pipe “collapses,” reducing its cross-section. The normal operation of the system is disrupted, and the location of the malfunction is almost impossible to find - usually the “sin” is due to malfunctions of thermostats, pumps and other products with moving parts.

In light of the above, we recommend that readers pay attention to metal-plastic pipes from VALTEC, which uses American adhesive from the DSM concern, which ensures the strength of the metal/plastic connection, adhesion and the complete absence of delamination