Once the material is purchased and delivered to the desired facility, it must be given time to rest for about a day, to reach the desired temperature and humidity of the room. (PVC should be unpacked at a temperature not lower than plus 15°C.) The tiles can be laid on a concrete screed or plywood. The entire surface must be leveled and free of dust. All cracks on the floor must be sealed in advance with putty and primed (deep penetration primer to increase adhesion). It is worth buying tiles with a small margin, also according to the strength class: living rooms - 23 mm, public places - 33 mm, warehouses - 43 mm. When cutting PVC tiles, markings must be made from the front side.

NOT RECOMMENDED

Use PVC in rooms with intense mechanical impact, intense exposure to abrasive materials, fats, oils and water. Lay tiles on heated floors whose temperature exceeds plus 27°C.

Lay PVC on a previously laid floor covering, on a base painted with oil paint, on fibreboards (DFB) or plywood, which deform when the temperature and humidity changes.

RECOMMENDATIONS

To achieve the best result, it is recommended to use the services of professional installers. Our company can also offer services for professional stackers. You can read more on the services page (here) or call one of our stores for clarification (here).

When laying PVC, you should be guided by the Technical requirements and rules described in this section.

Before installation, the following operations must be performed:

- Measure the room to its greatest length and width, taking into account protrusions and doorways;

- Choose a laying scheme in accordance with the design solution.

- Calculate the required footage of PVC for installation, taking into account trimming.

Recommended styling tools

- To mark the room - a tape measure, a pencil.

- For cutting - a knife with a trapezoidal blade, a square with an angle of 900 (450).

- For installation - a notched glue trowel (insert A1-A2), a lapping board, a smooth roller weighing 50 kg (75 kg).

Recommended materials

Type of glue: Acrylic water-dispersion.

Existing types of PVC tiles

Before moving on to considering the technology of how to glue PVC tiles to the floor , it is important to familiarize yourself with the main existing types of this flooring. This knowledge will help not only to choose the optimal material for finishing the floor, but also to understand whether PVC tiles will be laid with glue or using interlocking joints.

PVC boards are usually divided according to the installation method or structural features.

Based on their structure, the following types of PVC tiles are distinguished:

- multilayer tiles;

- single layer tile.

The first type of flexible tile has a rather complex multilayer structure, where the main layer is the top laminating layer. Depending on the purpose and cost of such flexible tiles, the thickness of the laminating layer can vary between 0.2-0.5 millimeters. The thicker the laminating layer, the higher the abrasion resistance of the flexible tile. Therefore, in rooms with high traffic, it is recommended to lay PVC floor tiles with a maximum lamination layer thickness.

It should be noted that multilayer PVC panels can externally imitate wood, natural stone, grass or marble chips .

As for single-layer flexible PVC tiles, they have a uniform structure. This finishing material is made from polyvinyl chloride. In such a single-layer tile, the pattern runs through the entire thickness of the material. Therefore, this material is characterized by maximum abrasion resistance and retains its original appearance even many years after installation.

There are also divisions into individual types of PVC tiles based on how they are laid on the floor:

- using glue. To lay such a coating, as one might understand from the name, a special adhesive composition is used;

- using special locking connections. In this case, a special tile is used that has special locks, reminiscent of those used in laminate. This type of PVC tile does not require the use of special adhesives. However, to use this type of PVC tile you will need to level the floor. Products can be laid on an existing wooden floor or plywood. In this case, it is possible laying this pvc tile on plywood and wooden floors;

- laying tiles with a self-adhesive backing. These tiles have a special adhesive layer on the back side, which is used to fix the material to the floor surface. In this case, installation is carried out by removing the protective film from the adhesive base of the PVC panel and then fixing the tiles on the floor surface.

Also on topic: Laying clinker tiles: step-by-step instructions

It is important to remember that regardless of the method used for laying PVC tiles on the floor, you will have to do some preliminary floor preparation. It is highly recommended not to neglect this stage, since the reliability and quality of laying PVC tiles with locking or any other type of connection on the floor will largely depend on the preparation of the floor.

Glue selection criteria

- Before purchasing glue, you need to know in which room the installation will take place.

- An excellent option for home use would be Homakoll 222. This adhesive is water-based and is used for absorbent substrates.

- In more complex cases, two-component polyurethane adhesive homakoll Tile 2K PU is used. It is suitable for damp areas and all types of substrates.

- Professional installers prefer to use homakoll 164 Prof.

- If it is assumed that individual sections of the tile can be replaced in the future, you should opt for clamps. They are also suitable for creating mosaic compositions. And if a mistake occurs in installation, it can always be corrected.

Tools for laying PVC tiles

A beginner must know not only how to lay PVC floor tiles , but also what tools to use to do this. Without the necessary tools, laying such tiles will be extremely problematic.

Laying flexible PVC tiles on the floor is carried out using the following tools:

- construction knife for cutting finishing material. For this tool, the most important parameter is ease of use, as well as the sharpness of the blade. Therefore, give preference to cutters with a metal rubberized handle and a durable blade made of high-quality metal;

- a construction pencil or permanent marker, with the help of which not only the room is marked, but also the places for cutting PVC tiles;

- tape measures for measuring sizes;

- a notched trowel used to apply adhesive to the floor;

- a rubber roller used to roll laid tiles to eliminate residual air.

Also useful in this work will be a construction hair dryer, which can be used to heat PVC panels if need to be cut. Once all the material, glue and all the necessary tools have been purchased, you can begin preparing the floor.

Expert advice

- When calculating the required amount of material, add 10%. If there are not enough tiles, you may not find the desired batch. If it remains after installation, do not be discouraged; it can be used to repair damaged areas in the future.

- Before starting installation, measure all walls and corners of the room; there are often differences and this must be taken into account when installing.

- Always take preliminary measurements before applying adhesive or removing protective film.

- Use a metal ruler to cut the tiles. Make the cut from the front side only.

- If the tile is glued, then you should not move it. If you still need to do this, then warm up the lamella with help. Construction hair dryer.

Floor preparation process

Before you begin, it is important to understand what preparatory work will need to be done before this stage.

First of all, you will first need to dismantle the old flooring in the form of parquet, linoleum, laminate or tiles. Taking into account this fact, laying PVC tiles on linoleum or any other old floor covering is not allowed . Neglecting this recommendation significantly increases the risk of getting a low-quality floor made from PVC tiles.

It is not recommended to lay PVC tiles on old floors.

It is important to carry out all preparatory work with extreme caution in order to minimize the likelihood of damage to the concrete or wooden floor. All detected cracks, sagging and holes should be repaired using a special putty for floors.

If PVC tiles are laid on an uneven wooden floor, it will first need to be leveled using plywood sheets. In this case, all fasteners and joints between sheets of plywood must be pre -puttyed.

Also on the topic: Laying tiles on a slope: making a shower with a slope towards the drain

You can also easily insulate your floor using plywood.

At the next stage, the resulting subfloor is treated with a primer to improve adhesion. At the final stage of preparing the surface to be finished, it is cleaned of debris and dust, and also degreased.

You will also have to prepare the facing elements themselves for installation. bring them into the room where the floor finishing work will be carried out. The material to be laid will have to remain in the open package in the room for at least a day. In this case, the air temperature in the room should be 25 degrees.

If you have problems preparing the floor, you can simply watch a video about laying PVC tiles on the floor.

LAYOUT OF AXLES IN THE ROOM

It is recommended to lay tiles from the center of the room, dividing the room into axial lines and finding the center of the room. To do this, you need to draw a guide from the center of one wall of the room to the opposite wall, then do the same for the other wall. The intersection angle of the guides should be 90 degrees (see Figure 1). The central center line from which laying begins is determined according to the laying scheme and design solution.

| Figure 1 Center of the room | Figure 2 Laying tiles |

| Figure 3 Laying planks | Figure 4 Laying diagonally |

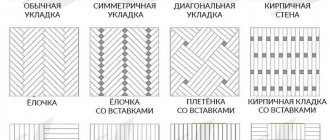

Methods for laying flexible PVC tiles

Before you start laying this material, it is important to find out what the main methods of installing it on the floor are. It is often customary to use the following types of layouts for finishing floors in living rooms and offices:

- traditional;

- diagonal;

- with offset;

- modular or herringbone layout.

In order to understand what each option for laying PVC tiles on the floor is, check out their photos, which can be found on the Internet on thematic sites and forums.

Permissible base moisture

After all the preparatory work has been completed, do-it-yourself installation of vinyl floor tiles is carried out only after checking the moisture content of the base. You can find out whether the coating is ready for construction work in the following way:

- Place a paper napkin on the concrete screed and cover it with polyethylene;

- Attach the edge of the plastic film to the floor using regular or masking tape;

- Place some weighty object on top of the napkin and leave it in that position for half a day;

- Installation of floor tiles can be carried out if the napkin remains dry. If it is wet, all installation work will have to be postponed for at least another couple of days.

Installation technology

PVC tiles are laid as follows:

- For gluing flexible tiles, it is recommended to use an acrylic-based adhesive . In this case, the tiles must be glued so that there are no air bubbles left under them;

- The glue is applied not only to the floor, but also to the back side of the tiles using a notched trowel. The adhesive composition is evenly distributed over the surface of the tile using a spatula, after which the flexible PVC panel is firmly fixed to the floor. Protruding adhesive residues from under the tiles are removed using a rag soaked in alcohol. To improve the quality of adhesion, the tile is additionally rolled with a rubber roller;

- work on laying PVC tiles must be carried out very quickly, as acrylic glue tends to dry quickly;

- after laying the tiles, its edges near the walls are covered with a plinth;

- When using tiles with an adhesive backing, the process of laying them will be completely similar to laying tiles with adhesive. The only difference is that in this case the use of glue will not be required.

If you have additional questions regarding how to lay PVC tiles on the floor, watch the YouTube video about the technology and methods of laying this flooring.

How to choose the right material

When choosing a material for installation, you should first of all consider where you plan to do the installation.

Material selection

Customer reviews should also be taken into account. There are many different companies on the market. One of the most popular is Tarkett. Tarkett vinyl tiles have received excellent reviews. It is very suitable for installation in domestic areas and is of excellent quality.

For commercial premises it is better to use material of class 32-42. Positive reviews are also left about the manufacturer Fine Floor. The flooring of this company is made from innovative materials and has excellent characteristics.

Reviews about a particular company will help you quickly make a purchasing decision.

Wall finishing with vinyl laminate

Vinyl flooring is highly valued for its versatility. It has become fashionable to decorate walls with this material. There are many advantages of using quartz-vinyl coatings on walls:

- Simple and quick installation

- Surface water resistance

- Easy to clean

Thanks to the above advantages, vinyl coverings are ideal as backsplashes in the kitchen.

Increasingly, walls in the bathroom and toilet are being covered with vinyl flooring. In the picture: Quartz-vinyl coating Quick-Step Ambient Glue Plus Carrara White Marble (picture clickable)