The deterioration of water supply lines affected the quality of water supplied to apartments and private houses. Its use for cooking and drinking is impossible without the use of filters. The best degree of purification is ensured by installing reverse osmosis - the most advanced filtration system to date. To install it yourself, you will not need any special skills or special tools.

How a reverse osmosis filter works and how it works

Initially, installations of this type were used for desalination of sea water. But as soon as technology made it possible to produce such devices in a smaller and more expensive design, they firmly occupied their niche in the household filter market.

The principle of operation of the device is based on the phenomenon of reverse osmosis - pressing water through a membrane with microscopic holes, the size of which matches the size of H2O molecules. All larger particles are retained, so the output is practically demineralized water. Impurities that do not pass through the membrane filter are discharged into the sewer system in the form of a concentrated salt composition.

Distilled water is harmless to the body, but it is also devoid of beneficial salts that are vital for it. Therefore, after final purification, it is recommended to subject the water to additional mineralization, increasing its usefulness and improving its taste.

INTERESTING FACTS!

- The purest water, free of impurities, does not freeze at 0 °C, but goes into a state called supercooling. It does not turn into ice until -38 °C and remains liquid. Scientists have found that for ice crystals to appear, a point of formation is needed, a foreign body in the water - an air bubble, a speck. If you shake a bottle of super-chilled water, bubbles will form and it will instantly freeze.

- Water is an excellent conductor of electricity. But not distilled, because electricity is carried by molecules of impurities and ions of substances dissolved in it.

- Everyone is familiar with the three physical states of water – liquid, solid and gaseous. Scientists distinguish five phases of liquid water and as many as 14 phases of ice.

- At -120 °C, frozen pure water becomes viscous and viscous, and at -135 °C it will become glassy - solid, but without a crystalline structure.

For long-term operation of the membrane, water is first passed through filters that remove mechanical suspensions and other impurities from it. Thus, the water purification system using reverse osmosis consists of 4–5 stages, to which additional elements can be connected if desired.

Installation of additional accessories

The operation of even such serious equipment as a reverse osmosis filter can be made more efficient by installing additional elements.

Such as for example:

- Pressure regulator. The equipment is designed to protect water supply elements from pressure drops, exceeding permissible values at the entrance to the filtration system and to compensate for water hammer.

- Leak protection system. It is installed in front of the filter and shuts off the water in case of leaks or water getting on it. Minimizes risks and limits the amount of damage caused, but does not completely eliminate the possibility of leaks.

- Nitrate prefilter . Used for effective removal of nitrates, the installation location is agreed upon with specialists.

- Ice maker. It is connected through a tee into the gap in the connecting tube leading to the drinking tap.

Before installing the filter, measure the pressure in the line with a pressure gauge. For values greater than 6.6 atm, a gearbox is installed; for values less than 2.2 atm, a pump is installed, which will create greater pressure.

For devices that are most often used to improve the functionality of reverse osmosis, a more detailed description is provided below.

Item #1 - Pressure Booster Pump

The membrane filter, which is the basis of the reverse osmosis system, can only fully function at a certain water pressure in a private house or apartment.

If the maximum pressure does not exceed 2.8 atm, then for normal operation of the filter it is necessary to additionally install a pump.

If you have to purchase additional equipment, it is better to do it from one manufacturer and be guided by the connection diagrams developed by him.

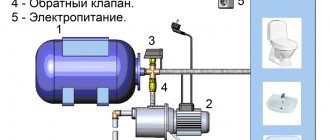

An example of one of the possible schemes. The pump can be placed in the gap of the supply tube before the first prefilter, as well as after the second or third

The pump is installed only in conjunction with a pressure regulation sensor, which is responsible for turning it on when the pressure drops and turning it off when it rises to the maximum.

The sensor is mounted in front of the storage tank, in the rupture of the tube. If the quality of tap water is poor, a main coarse filter is installed in front of the pump.

Fix the pressure booster pump on a horizontal or vertical surface using a special bracket and screws

If there is a danger of increasing water pressure in the system to 3-4 atm, then to prevent leaks, you need to install a special pressure reduction valve in front of the pump.

Element #2 - ultraviolet lamp

Sometimes favorable conditions arise in a reverse osmosis filter for the rapid development of microorganisms due to an increase in water temperature or the system being idle for a long time.

This leads to the fouling of prefilters with microorganisms, a decrease in pressure and a deterioration in equipment performance. And then ultraviolet filters are used to disinfect water.

The device consists of the following parts: a stainless case with a UV lamp located inside and a power supply that converts the mains voltage into the values necessary for the lamp to operate and protects it from power surges.

Water passing inside the housing is illuminated by ultraviolet rays and disinfected.

The UV lamp can be installed after the filter or in front of it. When installing a lamp in front of a filtration unit, it is often used in conjunction with a prefilter

The installation location of the ultraviolet lamp may depend on the goals that need to be achieved:

- at the inlet to the filter - to eliminate strong biological contaminants in tap water;

- between the tap and the container - to protect against microorganisms from entering the tank from the drinking tap.

For ease of installation, the lamp has two clips that help secure it to the filtration unit or any other surface.

Element #3 - water mineralizer

The water that passes through the membrane filter is 90-99% purified and gets rid of any impurities, including mineral elements that are useful and necessary for the body. This water tastes sour.

Mineralizers replenish the lack of essential minerals and adjust the PH level. Mineralizer cartridges of different brands may differ in their composition and resource and enrich the water with calcium, zinc, magnesium, and other elements.

The mineralizer is installed after the membrane filter and is connected mainly to a double tap. Thus, the user has the opportunity to choose between simple purified and mineralized water

In some models of reverse osmosis filters, the mineralizer also plays the role of a filter and is installed as the last stage of purification.

Water purification stages

Water preparation is carried out in a pre-treatment unit. These are three different types of filters:

- Coarse cleaning – retains particles of sand, rust and other mechanical suspensions.

- Carbon - removes chlorine compounds, phenol and other dissolved substances.

- Fine cleaning – captures particles up to one micron in size.

The prepared water seeps through the membrane into the storage tank. The concentrated brine, containing all the impurities, goes through the pipes into the sewer system.

Before use, another final stage of cleaning is provided: a carbon post-filter or mineralizer.

Principle of operation

It must divide the total flow into two parts: in one, passed further to the end-use points, there will be no pollution at all, in the other, discharged, almost all undesirable impurities will remain. A finely porous membrane with holes 0.0001 microns in size is responsible for this - only those particles that are equal to or smaller than H2O molecules pass through such cells, but others will settle on the walls and bottom of the tank, after which they will be collected and sent to the sewer.

To prevent chlorine residues, rust flakes and other relatively large fractions from clogging such a thin barrier, water is passed through pre-filters. They are more “coarse” - with a mesh of 5 and 1 microns - and a cartridge with carbon filler is placed between them. This combination allows you to effectively retain solutions of chemical reagents, heavy metal salts and other harmful components.

The two separated parts of the stream are permeate and concentrate. Up to 60-65% of the second one consists of impurities (hence the name), and it must be disposed of, that is, drained. But the degree of purification of the first reaches 98%, however, along with undesirable substances, useful ones that have a positive effect on organoleptics are also removed.

To correct this problem, the liquid suitable for further use is passed through a mineralizer - a special bioceramic filter with tourmaline loading. It has restorative properties, that is, it releases the substances it contains, which make the composition of H2O again close to natural. Even the simplest filler made from coconut shells and activated carbon already removes the unpleasant aftertaste, not to mention more advanced options.

Subtleties of choosing an osmotic filter and additional elements

Before going to the store, several measurements are taken. They will help you make the right choice.

- The pressure in the pipes is measured. To force liquid through the membrane and normal operation of the reverse osmosis system, at least 2.8 bar is required. If it is less, you cannot do without a booster pump - a pressure booster pump with a transformer.

USEFUL INFORMATION: How to choose a UPS for a circulation pump?

- The approximate water consumption in the family is calculated. Based on this indicator, the required performance of the cleaning system is determined. First of all, it depends on the membrane used. For domestic use, a 50G (8 l/hour) or 75G (12 l/hour) membrane is sufficient. Gallon (G) per day is a unit of measurement for membrane performance adopted by global manufacturers. 1 G=3.785 liters.

- Based on the throughput of the membrane, a water flow limiter is purchased. This is a calibrated tube through which the liquid is discharged into the sewer. For a 50G membrane, a flow limiter with a value of 300 is suitable, for 75G - 450, for 100G - 550. With low pressure in the water supply, you can use a limiter with a lower value.

- It is also recommended to measure the space under the sink to be sure that the selected model will fit there.

- To properly seal the connections, purchase FUM tape.

Tips for use

If, after starting the system, the drinking water has a milky tint and contains small air bubbles, do not worry. This is the influence of air dissolved in water, it is not dangerous. This effect will disappear after a few days or weeks.

If the pre-filters become dirty too quickly, as well as the presence of mucus on the cartridges, this may be a symptom of low pressure in the water supply network. The problem is usually solved with a pump.

Sometimes washing the carbon filter can cause the third filter to become dirty immediately after installation. To prevent this from happening, it is better to install the third filter after the carbon cartridge has been washed. But you should not try to rinse the carbon filter under running water, as this can ruin it.

Do not neglect washing the carbon cartridge, as this can lead to rapid clogging of the membrane. The same effect can be produced by too high pressure in the water supply system, too infrequent replacement of pre-filters or the use of low-quality cartridges, or clogging of the sewer system.

If scale forms in the kettle when boiling water, you should check the connection order. There may be a hose connected to the drinking tap through which the concentrates are supplied, and the purified water goes down the drain.

If the purified water has acquired an unusual smell and taste, it is necessary to check the pre-filters as soon as possible. Perhaps their resource has been exhausted and needs replacement. This phenomenon may also indicate the presence of bacterial contamination.

The membrane cartridge of the reverse osmosis system is housed in a plastic housing. It must be replaced every 3-5 years depending on the salt content in the purified water

Pre-clean cartridges should be replaced every six months or more frequently. A new membrane usually needs to be installed every three to five years. The condition of the purified water should be checked annually. If the salt content exceeds 20 mg/l, the membrane must be replaced.

DIY installation and connection of reverse osmosis

The preparatory work is simple:

- We block the access of water to the apartment.

- Relieve the pressure in the pipes by opening one of the taps for 1 minute.

The installation procedure is specified in the instructions included in the delivery kit. In most cases, the device is placed under the sink: this arrangement provides easy access for preventative maintenance and hides it from sunlight.

The connection diagram can be seen in the following image.

Fact 1. The arrangement of the modules affects the production of filtrate of the required degree of purification

The operating principle of the desalting system can be represented by the diagram shown in Figure 1. The feed pump (4) and valve (7) independently regulate the operating supply pressure and filtrate output Y (the ratio of the permeate volume to the volume of incoming water). Since desalting requires a very high filtrate yield (within the limits of sedimentation and sedimentation) and at the same time a sufficiently high fluid velocity in each module (and this entails poor separation in each module), this task can only be achieved with a system that includes simultaneously parallel connection of modules and either recirculation or the addition of a second and even third successive levels of processing of the incoming stream (the concentrate of the first level is supplied to the second).

Fig. 1 Simplified diagram of the operation of an osmotic installation element

Drinking tap installation

A separate tap for clean drinking water is installed on the sink or on the countertop nearby.

- Drill a hole at the mounting location. We choose it so as to avoid kinks or twisting of the eyeliner.

Some craftsmen cover the surface of the countertop around the future hole with adhesive tape: this helps avoid chipping. They drill in two steps: first with a 6 mm drill, and then widened to 12. The torn edges are trimmed with a needle file.

- Having equipped the faucet with a decorative cover and a rubber washer, insert it into the hole. From below we put on a smaller rubber washer, a plastic ring and the rest of the elements indicated in the diagram, and tighten the threaded connections.

You should carefully remove chips and other contaminants from under the rubber gasket that ensures tightness.

In the future, all that remains is to connect the drinking faucet to the outlet tube from the reverse osmosis filter.

Osmosis connection diagram. Purification stages

The principle of operation of the reverse osmosis method is embodied in three stages:

- Preliminary water purification. Occurs in large vertical flasks. In the figure below they are indicated by numbers 3, 4, 5.

- Passage through the membrane. The reverse osmosis membrane body (horizontal flask) is designated number 7.

- Post-cleaning stage. The flask is marked with number 12.

The reverse osmosis connection diagram is in the figure below.

Water that has passed the pre-purification stage enters a semi-permeable membrane, where it is divided into two streams: one passes through the membrane and is cleaned, the second washes it from the outside and, with all contaminants rejected by the membrane, is drained into the drain. The reverse osmosis water purification system does not work quickly, so the liquid that has passed through the membrane accumulates in a special tank (No. 11 in the figure), from where it is sent for post-treatment. At this stage of water filtration, additional purification from odors and/or mineralization occurs.

It is an excellent representative; it removes up to 99.9% of all impurities contained in water and prevents the formation of scale in heating devices.

Advantages:

- Space is saved significantly: the drinking tank is also installed inside the housing.

- The filter is easy to keep clean when installed under the kitchen sink: no dirt gets on the structural elements of the system, there are no protruding elements or protruding connecting pipes.

- The dismountable housing provides convenient access to parts and replacement elements.

- The world-wide standard of “inline” cartridges allows the use of analogues of Atoll filter elements in a wide range, for example, manufactured by Omnipure (USA) or Pentek (USA).

- Inline-size cartridges are enclosed in a plastic case and have quick-release connections, so the procedure for replacing them is hygienic (no contact with contaminated surfaces) and simple (no special tools required).

Connection to water supply

The connection to the water supply is made through a coupling (adapter, tee), into which the water supply tap from the kit is inserted. Typically, a tee is mounted at the junction of the water supply with a flexible line going to the mixer.

Procedure:

- Disconnect the cold water mixer supply from the water supply.

- We connect the liner to the adapter, checking the presence of the rubber gasket.

- Screw the water supply valve into the adapter coupling.

- Unscrew the nut from the water supply fitting and put it on the plastic tube from the filter kit (see photo).

- We pull the tube itself onto the fitting and tighten the nut by hand without using a wrench, with a little force.

- The water supply tap can be equipped with a quick-release collet connection; in this case, you just need to insert the tube until it stops.

- Close the water supply tap and check the joints for leaks.

The tightness of the connections is ensured by the use of FUM tape.

If necessary, a booster pump is placed between the pre-filters and the osmotic membrane. This will extend the life of the pump: it will not wear out due to sand and rust. The pump control relay should be located between the membrane and the storage tank.

Three-way valves are used to install measuring instruments, such as a pressure gauge.

A four-way bypass valve is located in this same area. It will shut off the water when the storage tank is filled.

USEFUL INFORMATION: How to assemble a water supply system from metal-plastic pipes with your own hands

Installation is simplified if all devices are placed in a single housing by the manufacturer. These models are the easiest to install yourself.

Replacing filtration elements

To replace the cartridge fillers with your own hands, close the water supply shut-off valves and the device. Then open the purified water tap and drain the remaining liquid.

Next, disconnect the plastic tubes and remove the equipment from the cabinet. You can remember the location of the tubes by marking them or using a camera (if the tubes are colored).

Unscrew the housing caps and remove the exhausted cartridges and filtration membrane. Plastic flasks and lids are washed with dishwashing detergent.

When installing new filter elements, carefully follow the installation procedure and check for the presence of a rubber gasket on the cover.

Rubber sealing rings are wiped dry before installation. The system is assembled and washed in the same way as when installing a new device.

Replacement filter elements are carried out with the following frequency:

- reverse osmosis membrane - every 24-30 months;

- carbon post filter - once every 12 months;

- prefilters - once every 6 months.

The frequency of replacement largely depends on the quality of the water. New replacement elements are replaced with the same ones, checking their markings.

Using cartridges that have reached the end of their lifespan can be even more harmful to health than untreated water.

Connection to sewerage

To drain dirty water into the sewer, a hole with a diameter of 7–8 mm is made in the drainage pipe of the sink. Then the order will be like this:

- We glue a gasket onto the part of the clamp with the hole.

- We fix the clamp so that its fitting coincides with the drilled hole in the drain pipe.

- Use a wrench to tighten the nuts on the clamp.

- We insert an outlet tube lubricated with silicone, which is usually black, into the clamp fitting. All these parts are included in the delivery kit. The tube should be directed downward and not rest against the wall of the siphon. This way, the water discharged into the sewer will make less noise.

Important! Do not place the drain hole at the lower bend point of the siphon. It is advisable to do it above the water seal. The area on which the clamp will be attached must be flat, without bending: this is the only way to achieve a tight joint.

Tools

0 votes

+

Vote for!

—

Vote against!

Modern tap water is an environment that contains not only dissolved minerals and harmful inorganic impurities, but also pathogens that cause outbreaks of infectious diseases. To prevent poisoning and the spread of infectious diseases that are transmitted by water, filter units are used in everyday life and in industrial settings, which, despite the hopes placed on them, do not always cope with the task as efficiently as possible. In this regard, there was a need to invent specialized filter units that could be used to effectively remove harmful impurities from water, which scientists dealt with very successfully by developing a design for a water purification system with reverse osmosis. Due to the fact that water purification by reverse osmosis is the most promising and reliable method of preparing drinking water, in this article we will consider the main operational characteristics of such systems and the detailed methodology for their installation.

Content

- Osmosis and reverse osmosis: a brief description of the concepts

- Water purification by reverse osmosis: the principle of operation of membrane systems

- The structure of the filtration membrane and its functions

- Main components of reverse osmosis units

- Reverse osmosis water purification process

- Benefits of reverse osmosis filters

- Do-it-yourself reverse osmosis systems: recommendations from experts

- How to install a reverse osmosis system? Basic provisions

- How to extend the service life of the system? Replacing cartridges

Osmosis and reverse osmosis: a brief description of the concepts

Osmosis is a phenomenon that underlies the metabolism of all living organisms and implies the entry of nutrients into the cell and the removal of metabolites from it. The implementation of these processes is carried out through a semi-permeable membrane, which allows molecules of some substances to pass through and prevents the passage of others. If on different sides of a semi-permeable membrane, which is capable of passing only water molecules, there are salt solutions with different concentrations, it is natural to expect an equalization of concentrations, which will lead to the movement of water molecules from a less concentrated solution towards a solution with a higher concentration. The driving force in this case is osmotic pressure.

Reverse osmosis is a concept that occurs when a solution with a higher concentration is exposed to external pressure, the value of which exceeds the osmotic pressure. In this case, water molecules move in the opposite direction, that is, from a more concentrated solution towards a solution with a lower concentration. Thus, excess pressure, the magnitude of which exceeds the osmotic value, “forces” water molecules to diffuse through the membrane in the opposite direction, opposite to forward osmosis.

Water purification by reverse osmosis: the principle of operation of membrane systems

The water purification method, which is based on the reverse osmosis process, has been used since the early 60s of the last century as the main method for desalinating sea water. Today, using such installations, hundreds of thousands of tons of bottled drinking water are produced per day, the effectiveness of which is not questioned. Briefly, reverse osmosis filters can be characterized as follows: they are devices based on innovative water purification technology. If you don’t go into details and discard all technological nuances, water filtration in them is carried out thanks to the presence of a special membrane designed to remove impurities that are in a dissolved state in water. Using reverse osmosis water purification technology, you can purify water from particles whose sizes do not exceed 0.001-0.0001 microns. This range includes most of the impurities that can be found in water: hardness salts, dyes, small molecules, sodium ions, sulfates and nitrates. If, before the direct use of reverse osmosis installations, additional purification steps are used, such as micro-, ultra- and nanofiltration, as well as mechanical purification, the cleaning efficiency using reverse osmosis installations will increase significantly.

Reverse osmosis photo

The operation of reverse osmosis systems is based on baromembrane technologies, according to which the driving force of the process is the pressure difference created on both sides of the semi-permeable membrane. It is made from porous materials such as polyamide or cellulose acetate films, as well as hollow fibers. From the point of view of design features, there are two types of filter elements:

- Hollow fiber;

- Rolled.

Important! In water treatment systems, the most common are roll-type reverse osmosis elements, consisting of two semi-permeable membranes and a layer of flexible tape-type elements that are wound around a central perforated drainage tube. The source water to be purified enters the roll module and, due to its structural features, it is divided into two streams:

- Permeate is purified and demineralized water that has passed through a membrane;

- Concentrate is water characterized by a high content of impurities that have not passed through the membrane pores.

The structure of the filtration membrane and its functions

The filtration membrane is a composite polymer characterized by uneven density and consisting of two layers that are inextricably connected to each other. The outer layer thickness is 0.00001 inches. It serves as a barrier and rests on a less dense layer that is 0.005 inches thick. The reverse osmosis membrane is a filter element that meets all requirements; therefore, theoretically, in the water passed through the membrane, regardless of the initial concentration of minerals in the water, there should be no impurities at all. In fact, the water passed through the filter contains a small amount of mineral impurities in a concentration of 6-7 mg/l, which also meets the sanitary requirements for drinking water.

The main function of a filter membrane, as the name implies, is filtration, which is carried out through the pores of the material. The water that passes through the filter membrane contains low molecular weight compounds and ions that are smaller in size than water molecules. Other impurities present in water, such as viruses, individual molecules, as well as dissolved salts and metal ions, are retained.

During the operation of a reverse osmosis installation, the surface and pores of the semi-permeable membrane gradually become contaminated, which negatively affects the performance of the installation. To restore the device to its original performance characteristics, it is necessary to flush the device, also called a regeneration cycle. The most common method of cleaning the membrane surface is by backwashing with a stream of water or blowing with compressed air.

Important! To increase the time interval between cleaning the device, experts recommend adding chemical reagents to the wastewater flow to prevent the formation of sediment. The most commonly used reagents are sulfuric acid and/or inhibitor, which are added to the water after it has passed through the pre-treatment unit.

Main components of reverse osmosis units

The composition of reverse osmosis water purification plants is quite variable and depends on the composition of the water being purified and the conditions under which the process is carried out. However, there is a standard basic package that includes the following functional elements:

- Pre-filter , designed for preliminary water preparation, during which solid particles up to 5 microns in size are removed;

- Filter block , designed for installation of membrane modules that are directly involved in water filtration;

- Pumping equipment , in other words, a reverse osmosis pump that creates the necessary pressure difference to ensure reverse flow of liquid;

- Installation piping;

- Regulating and control instruments providing control and automatic control of the reverse osmosis installation;

- Flushing unit , designed to provide flushing of the membrane surface at the right time in order to increase the productivity of the installation.

Additional cartridges that perform secondary functions and are installed in the system to improve the quality characteristics of water:

- Mineralizer , thanks to the use of which the water being purified is saturated with minerals and salts necessary to maintain normal salt balance in the body. In addition, water that has passed through reverse osmosis water purification filters has a higher pH level;

- Ionizer designed to ionize water and remove negative ions. Water that has passed through filters with ionizers is characterized by easier absorption in the human body, promotes the most optimal regulation of pH levels, as well as the removal of toxins from the body;

- Bioceramic cartridge that restores the natural structure of water. Drinking water that has passed through a reverse osmosis unit with a bioceramic cartridge helps cleanse the body, remove toxins and slow down the oxidation of free radicals;

- Softening cartridge , by installing which you will receive water purified from calcium ions, which are responsible for water hardness.

Important! If you use a reverse osmosis unit with an additional cartridge, you must ensure that it has a double tap installed, designed for water that has undergone additional purification and water that has passed only through a reverse osmosis filter.

Reverse osmosis water purification process

The classic scheme for water purification using a reverse osmosis unit is five-stage, and includes a sequence of stages, the observance of which is recognized as the main guarantee of effective water purification. The operating principle of modern reverse osmosis units is based on the passage of water, which has undergone preliminary mechanical purification, through a semi-permeable membrane characterized by the presence of microscopic pores that trap contaminants, which are subsequently washed away by the flow of water into the sewer system. Preliminary mechanical purification is the first and necessary stage of water purification, since the largest particles, entering the pores of the filtration membrane, can clog them, which will reduce the operational characteristics of the reverse osmosis unit, or completely disable it.

The pre-treatment stage involves passing water through a filter that includes a system of cartridges, and consists of several stages, which will be listed below:

- Coarse filter , which retains large mechanical particles (sand and rust);

- Coal block , designed to purify water from petroleum products, phenols, chlorine and heavy metals;

- A fine filter is a stage during which the final purification of water occurs, implying the removal of particles smaller than 1 micron.

- In the fourth stage of purification, the water directly passes through the reverse osmosis membrane . At this stage, water is filtered through the pores of the membrane, the size of which helps to remove bacteria and other “small-caliber” impurities from the water;

- After water has been filtered through the pores of the reverse osmosis membrane, it accumulates in a sealed container made of metal or plastic, separated by a rubber membrane. On one side of the membrane, air is pumped into the container, and on the other side, water enters.

- After opening the tap, water is pushed out of the tank, after which it passes through the fifth stage of purification - carbon filter . After undergoing five-stage purification, the water becomes completely ready for use and has a pleasant taste and smell.

Important! The only drawback of reverse osmosis units is the duration of cleaning due to their low productivity.

Benefits of reverse osmosis filters

- The highest level of water purification compared to other filtration units;

- No need to use additional reagents during the operation of reverse osmosis units;

- Reverse osmosis units are characterized by a compact layout of the equipment included in their kit;

- On sale you can find many models of reverse osmosis filters, characterized by different performance and a wide range of operational characteristics, which allows them to be used for both domestic and commercial purposes;

- Ease of use and undemanding operation;

- Automated operation of the installation is another advantage of reverse osmosis filters;

- The design features of such installations are also at the highest level. Their distinctive feature is a modular system, thanks to which you have the opportunity to increase the productivity of an installation with standard equipment by integrating additional filter cartridges;

- The piping and fittings of reverse osmosis units are made from corrosion-resistant materials, which also has a positive effect on their performance characteristics.

Do-it-yourself reverse osmosis systems: recommendations from experts

- Before proceeding to the purchase of all the components for installing a reverse osmosis installation, it is necessary to determine the water pressure in the pipe. If it does not exceed 2.5 bar, you need to purchase a pump that increases the pressure.

- In addition, it is important to calculate the amount of water you will need per day. It must be remembered that the performance of the membrane, which can treat 50 to 100 gallons of water per day, determines the performance of the entire system.

- For the optimal selection of all filters and additional built-in cartridges, it is recommended to carry out a preliminary analysis of the water, namely its mineral composition. A standard reverse osmosis installation includes three pre-filters, however, in the case of high water quality and its optimal organoleptic characteristics, their number can be reduced to two.

- In addition to the above elements, it is necessary to purchase a water flow limiter, which is a tube with a calibrated hole and a plastic insert, which is designed to release the flow of water into the sewer system.

To select the correct flow restrictor, it is necessary to take into account the membrane performance:

- A membrane that can treat 50 gallons of water would require a 300 flow restrictor;

- For a membrane that treats 75 gallons of water, the flow restrictor is 450;

- For a membrane that treats 100 gallons of water, the flow limiter is 550.

- To increase system performance, it is recommended to install a reducer in front of the pre-filter.

- When installing reverse osmosis filters, all components of the system must be connected using plastic tubes in the correct sequence, and to seal the connections, use FUM tape and tow with sealant.

In the process of assembling reverse osmosis units, you will need the following materials:

Membrane and housing for it;

Filter system: mechanical filters, carbon filter, as well as additional filters;

- Storage tank;

- Reverse osmosis pump;

- Flow limiter;

- Pressure gauge for measuring water pressure;

- Cold water meter;

- Gearbox;

- Tap;

- Board for attaching filters;

- Two meters of small diameter pipe;

- Drainage clamp for the hose to the sewer;

- FUM tape and tow.

How to install a reverse osmosis system? Basic provisions

- Due to the fact that there are several ways to install reverse osmosis filters, first of all, from all the existing options, you need to choose the most suitable one for use at home. The most common option is to install and connect reverse osmosis under the sink.

- The system can be installed both vertically and horizontally. If, when placing the storage tank, you were faced with a lack of space under the sink, it can be placed in a kitchen cabinet or in a position on its side, which will not affect the functioning of the installation.

- In addition, the final water outlet must be connected to a separate faucet, which must be installed in close proximity to the sink or connected to some device, such as a coffee maker.

Important! Filters with a built-in membrane and additional cartridges must be positioned in such a way that during operation they are easily accessible for replacing cartridges.

- To ensure that water is discharged into the reverse osmosis system, a tee must be inserted into the cold water pipe.

Important! If it becomes necessary to install a booster pump, it must be placed in such a way that it is located in front of the reverse osmosis semi-permeable membrane, but after the pre-filters. Such a placement of the membrane extends the service life of the pump, since it does not become clogged with plumbing dirt.

- Due to this, the pump is powered from the electrical network; in order to avoid leaks and further short circuits, all joints must be carefully sealed.

- In addition, care must be taken to install a four-inlet bypass valve designed to shut off the water supply if the storage tank overflows. One inlet of the valve is supplied with water that has passed through a mechanical filter, and from the other, water is supplied to the reverse osmosis membrane.

- The remaining connectors are connected into the gap between the storage tank and the membrane. In case of installation of a system in which there is no storage tank, both connectors are directed to the sewer system.

- To install a drinking water tap on a sink, you need to prepare pipe clamps and fastening nuts. If there is no corresponding hole for the tap, it must be cut using a drill and a diamond-coated drill bit.

Important! When installing the filter, it is necessary to install a clamp on the waste pipe, which should be located above the hydraulic seal.

- After you have completed the installation, flush the system by draining some filtered water. To perform this manipulation, you need to close the valve to the tank and keep the tap open for some time. Having fulfilled this condition, close the tap and open the tank. After it is filled, all water must be flushed down the drain. If you implement all of the above recommendations, you can be sure of the proper quality of filtered water.

How to extend the service life of the system? Replacing cartridges

- In the process of water purification at home, it is important to maintain the proper condition of reverse osmosis units by promptly replacing consumables.

- Taking into account the amount of purified water, the amount of which can be tracked by meter readings, mechanical and carbon filters must be replaced at least once every 3-6 months;

- The service life of a reverse osmosis membrane is also variable and, depending on the quantity, temperature and quality of water, ranges from 1 to 5 years.

The need to replace the membrane can be judged by the following signals:

- Reduced pressure in the system;

- Deterioration in the quality characteristics of filtered water;

- The appearance of sediment in the membrane.

Important! If the cleaning system has not been used for a week, the membrane must be disinfected.

Installation of filter elements and storage tank

The filtration system modules need to be compactly and conveniently arranged under the sink. We select the wall on which the filter unit will hang and screw the screws into it. Then we proceed according to this scheme:

- We install the cartridges into the filter flasks, strictly following the order prescribed in the instructions.

- We insert the membrane into the housing.

- Lubricate the tubes for connecting the filter parts with silicone and connect them in the correct order.

Tube connection diagram:

- The water supply pipe is the inlet of the first filter.

- The storage tank is the inlet of the 5th stage filter.

- The output of the 5th stage is a drinking tap.

- The outlet of the membrane filter (4th stage) is a drainage hole (clamp).

How the tubes are connected:

- We cut the tube to size at a right angle (there should be a small margin, the tube will be recessed 1–1.5 cm on each side).

- We press our fingers on the collet - a plastic ring that protrudes from the flask - and carefully remove the plug. If it does not come out, you need to press a little harder so that the pressure is even.

- Press the collet again and insert the tube so that it goes in all the way.

- We put the locking clip-half ring on the collet.

- We check the quality of the connection by pulling the handset towards you.

To connect the storage tank, screw the tap from the kit onto the thread of the branch pipe, sealed with FUM tape, and insert the required tube into it.

Many manufacturers do not include a mineralizer as an additional stage. As a rule, the mineralizer combines the functions of a carbon post-filter and a mineralizing one.

How to install?

Methods for installing a water filter under a sink vary depending on what type of device is used. Let's consider each option in more detail.

Flow option

Such equipment crashes into the water supply.

The system is fixed under the sink, and a special tap is installed on it, through which purified water will be supplied.

It is convenient if the filter is retractable.

It is imperative to determine at the initial stage the location of the water tap and how many hoses it will require.

Installation procedure:

- First, a tap is installed to supply purified water.

- A branch is made that will ensure the supply of liquid to the filter. To do this, first turn off the tap and drain the remaining water.

- Next, disconnect the metal-braided tap connected to the water supply pipe. A tee is installed at the break site, after which the thread is strengthened. A shut-off valve is installed here.

- The filter is assembled if it is disassembled. All plugs are removed from the system, hoses and cartridges are connected.

- Using a hose, the filter inlet is connected to the tee. The output is connected to a tap for purified water.

Watch the video, which describes the procedure for installing a flow filter:

With reverse osmosis

The installation process is similar to the previous option. You need to start work by turning off the water.

Installation procedure:

- It is recommended to begin installation work by connecting a tap for purified water. For this task, the package contains everything you need: clamps, nuts.

- To install a thin faucet, you will need an additional hole. It is done with a tool such as a drill, paired with a diamond-coated drill. Hole diameter – 13 mm.

- On an enamel or porcelain surface, the top layer is cleaned down to the metal base.

- Using a 7 mm drill, a hole is made in the metal base. Work should be done carefully. Then the same procedure is repeated, only a 13 mm drill is installed. Now the tap is installed with the nut tightened.

- The filter is equipped with a connection to the water supply. It includes a tap with an outlet to the tube and a special tee. The instructions indicate in what order they are connected.

- The insert is installed. Each connection is pre-wrapped with fum tape.

- The supply line is disconnected from the tap through which cold water flows.

- We attach and secure the insert. You need to screw it in carefully without damaging the tubes.

- When installing the filter, a clamp must be installed on the waste pipe, preferably above the siphon.

- We install the storage tank, after which we wrap its threads with Teflon tape. Next, a plastic tap is attached to it.

Useful video that describes the process of installing a reverse osmosis filter:

This completes the installation. Now let's figure out how to check the functionality of the systems.

Assembly and installation of systems of popular brands: video

The principle of installing reverse osmosis systems is the same, but the products of different companies have their differences. Filters from the following manufacturers are widely known on the Russian market:

- "Atoll" is the very first reverse osmosis system in Russia. Has extensive experience in developing, supporting and improving reverse osmosis technology in Russia for 25 years. A wide range of models will not leave even the most demanding buyer without choice. It is supplied both as a set of filter cartridges and as a compact ready-made unit. This module is easy to connect yourself. There are budget and advanced modifications.

Let's look at the installation process using the example of the Atoll A-575 Box STD reverse osmosis system (Sailboat)

USEFUL INFORMATION: Polypropylene pipe: technical characteristics

- "Geyser" - osmotic purification systems of the "Prestige" series. They come with a storage tank that allows you to collect water for drinking at any time. Models with the letter “P” in their names are equipped with a pump that increases the pressure in the system and are more expensive. The letter “M” indicates the presence of a mineralization module.

- "Aquaphor". One of the leaders in the production of filter systems. Each model comes with a 5-liter expansion tank. Osmotic membranes from Aquaphor work well even at low pressure in the water supply without installing an additional pump: just 1.5 atmospheres is enough. Another distinctive feature is the economical use of liquid: no more than 20% of the total volume of water is consumed to remove impurities from the membrane.

- "Barrier". The best model according to reviews is Osmo 100. Has 5 stages of cleaning, 8-liter storage tank. It is cheaper than analogs from other companies, but is not inferior to them in quality. The disadvantage is the lack of a mineralizer.

- "Aquapro". Well-proven filter systems with a good price/quality ratio. A popular model is AQUAPRO AP 600 with a large 12 liter storage tank and 5-stage filtration.

Pump advantages

- Increases filter productivity.

- Effectively purifies water with high salt content.

- The operation of the pump consumes a very small amount of electricity. The pump is equipped with a pressure sensor and a dry-running protection mode. It automatically turns off when purified water completely fills the tank.

- The pump operates very quietly, almost silently.

A reverse osmosis water filtration system with a pump is the optimal way to purify water for homes where the pressure in the water supply is low. By following our recommendations for installing and operating the filter, you will receive clean and tasty water for many years.

Start-up and flushing

Before starting operation, it is necessary to flush and check the system. This is done like this:

- Wash the filter elements by running water with the valve of the storage tank closed. About 10 liters of water are drained. Simultaneously with flushing, air is forced out of the system.

- Stop the flow of liquid into the filter. Check for leaks. If necessary, correct errors during connection.

- Fill the system with the valve of the storage tank open. This will take several hours. Afterwards all the liquid is drained.

- For drinking and cooking, use water only after refilling the container.

Why is permeate post-processing necessary?

The stages of post-processing or final correction of permeate deserve special attention. As part of household reverse osmosis systems, these stages are implemented using various post-filters installed on the purified water supply line from the storage tank to the tap. There are various options for post-filters that manufacturers equip with household reverse osmosis systems, but in practice they all perform three different functions:

- correction of water taste;

- ensuring microbiological purity of drinking water;

- remineralization and pH adjustment.

Let us consider in detail each of the problems solved by various options for post-processing of permeate in household reverse osmosis systems.

Almost all household osmosis systems use post-treatment of the permeate with activated carbon obtained from coconut shells. For this purpose, the reverse osmosis system is equipped with the so-called post-carbon - an encapsulated filter filled with high-quality coconut activated carbon. When water passes through this filter, important organoleptic indicators of water quality - taste and smell - are corrected. Postcarbon makes it possible to improve the taste of water for those consumers who find permeate tasteless, and also eliminates possible extraneous odors associated with storing water in a storage tank.

The question of the need to ensure microbiological purity of water after a storage tank in household reverse osmosis arose relatively recently. To solve this problem, routine maintenance of the system is usually carried out, including washing the tank with disinfecting reagents. The problem of the presence of microorganisms in water can also be solved using certain methods of post-treatment of water.

One such method is water disinfection using ultraviolet radiation. This physical method, which has been used for many years, is not only highly effective, but also has no negative impact on the chemical composition of purified water. Until recently, the wide spread of UV was significantly hampered by the high cost and energy consumption of the method, but today a large assortment of lamps of different power, including LED (UV-LED) disinfectants, allows its use in a variety of fields. For household water treatment, UV lamps are almost an ideal option. Compact and ergonomic, they are easily installed in purification systems, ensuring uninterrupted operation and effective water disinfection.

Another physical method of water disinfection that can be used in local water treatment is ultrafiltration. The essence of water disinfection using ultrafiltration is that when water passes through a semi-permeable membrane with a pore size of 0.001 to 0.1 microns, various impurities are retained: colloids, organic substances, algae and most microorganisms. More recently, this method has mainly been used to remove colloidal impurities and suspended matter on an industrial scale. Now, interest in its use for the removal of microorganisms in domestic water treatment has increased significantly.

Today, various companies produce compact, easy-to-use ultrafiltration cartridges, which are not inferior to UV lamps in terms of disinfection efficiency. Cartridges of this type are recommended for use after the storage tank of household reverse osmosis systems to further purify water from possible microbiological contamination.

The salt content of household osmosis permeate does not exceed 15–20 mg/l. In recent years, the global medical community has recognized that demineralized water does not harm human health. However, the taste of such water is significantly different from the usual one. It is to ensure the possibility of choosing the composition of purified water that there is such an option for household reverse osmosis systems as a mineralizing post-filter, or mineralizer. In general, a mineralizer is a filter filled with crumbs of various natural minerals. Reverse osmosis permeate, characterized by a pH of 5.8-6 and low salt content, upon contact with such crumbs, slowly dissolves it and is saturated with calcium, magnesium, sodium and potassium salts to a level of 50–100 mg/l. Also, in this case, the acidity of the permeate is corrected - the pH value increases to 6.5–7.

Is it possible to do without a mineralizer?

You can do without a mineralizer if you need distilled water and not drinking water.

If you plan to regularly use water from the filter for food, we strongly recommend installing a mineralizer.

Water without a mineralizer has no taste, no beneficial microelements , and if you drink such liquid for a long time, you may encounter health problems.

Components of a standard kit

Before installing the device, find out the pressure in the water supply. If the value is less than the parameter of the selected filter, you will need to include a charge pump; if it is more, then a reduction gearbox. When you need to constantly have a certain supply of clean drinking water, add a reserve tank to the kit. A typical kit includes:

- platform made of enameled steel with holes for wall mounting;

- glass with cartridge for mechanical cleaning;

- flask with cartridge for charcoal cleaning;

- briquetted coal in a flask for post-purification;

- housing installed on the site and the membrane itself is 50 gallons = 154 liters per

- faucet for flushing;

- carbon post filter;

- nickel-plated tap with installation kit (connector, ball tap and for storage tank);

- 3 meters of tube.

day (standard);

When making a purchase, the customer receives a reverse osmosis installation, which you can assemble yourself using detailed instructions, keys, a drainage clamp and connecting tubes included in the kit. Stores selling filters and accessories for water treatment will accommodate the buyer halfway if it is necessary to change the configuration.

Kits from manufacturers already include a storage tank, the volume of which can also be replaced with a larger or smaller one from 4-12 liters, membranes are also replaced (available for 36, 75, 100 GPD, 1 gallon is equal to 3.875 liters). Polypropylene flasks and lids are equipped with sealing rings that protect against leaks.

Structurer

What is a reverse osmosis filter structurer? This is the part that is responsible for water purification, specifically tourmaline ionizers and bioceramic cartridges. Outwardly, it looks like a cylinder, the body of which is made of plastic. Inside there is a glass tube containing a filter agent. Activated carbon, tourmaline, clay, etc. are used as fillers. Tourmaline is a type of quartz sand that has high absorbent properties. If it is heated, electrostatic discharges appear on the surface, creating an electromagnetic field. This helps to further disinfect water due to the ionization effect

As a result, the water becomes healthy, very soft and pleasant to the taste, so if you decide to use reverse osmosis, pay attention to these cartridges

The more degrees of purification there are in the system, the more expensive it is.