No material, including steel, can last forever. It must be protected from moisture, sunlight and low temperatures. Oxidation of a metal creates a thin protective film on its surface that prevents oxygen from the air and water from destroying the material. At the same time, the technical characteristics of steels, aluminum and its alloys change.

From a chemical point of view, oxidation is the oxidation reaction of a metal and the formation on the surface of a thin layer of crystals bound by oxygen and other substances. The technology for applying a protective coating has several types of varying complexity. The simplest one was used several centuries ago and is available to anyone who wants to cover a part with a protective film at home. Complex technology requires special equipment and is carried out only in production conditions.

Chemical oxidation

This process involves the processing of metals with solutions, mixtures, melts of chemical elements (oxides such as chromium oxides). This oxidation allows for the so-called passivation of the metal surface. It involves the creation of an inactive (passive) formation in a metal layer close to the surface. A thin surface layer is created that protects the main part of the structure.

Technologically, this process is implemented by lowering the prepared metal part into an alkali or acid solution of a given percentage.

They keep it there for a certain time, which allows the oxidation-reduction reaction to fully occur. Then the part is thoroughly washed, subjected to natural drying, and final processing.

Chemical oxidation of steel

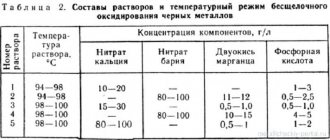

To create an acid bath, three types of chemically active acids are used: hydrochloric, nitric, and orthophosphoric. The acceleration of the chemical reaction is stimulated by adding manganese, potassium, and chromium compounds to the acid solution. The oxidation reaction occurs at a solution temperature in the range from 30 °C to 100 °C.

The use of solutions based on alkaline compounds allows the use of additives of sodium nitrate and manganese dioxide compounds. In this case, the solution temperature must be increased to 180 °C, and with additives up to 300 °C.

After the procedure, the part is washed and dried. Sometimes potassium bichromate is used to consolidate the chemical reaction process. To increase the shelf life of the formed film, chemical oxidation with oiling is carried out. Sometimes this process is called chemical oxidation. The final coating with oil results in a reliable anti-corrosion coating with a striking, highly decorative black color.

Carburization (cementation)

This is the saturation of the surface of steel objects with carbon. This operation improves the hardness, wear resistance, and endurance of the material surface. The underlying layers remain viscous.

This chemical-thermal technology is suitable for items made of low carbon steel (0.25%) subject to contact wear and variable loads.

Mechanical processing is required first. Non-cemented areas are covered with a layer of copper or coatings.

The temperature regime is determined by the carbon content in the steel. The lower it is, the higher the temperature. For carbon adsorption and diffusion, in any case, it should be 900 - 950 ° C and higher.

Steel Cementation

Thus, by saturating the surface of steel parts with carbon, a concentration of this element in the upper layer of 0.8 - 1% is achieved. Larger values lead to increased brittleness.

Cementation is carried out in a medium called carburizer. Based on its phase, the technology is divided into gas, vacuum, pastes, solids, and ionic.

The first method uses coal semi-coke, charcoal, and peat coke. To speed things up, activators are used and the temperature is increased. Upon completion, the material is normalized. Due to the duration and low productivity, this chemical-thermal technology is used in small-scale production.

The second technology involves the use of suspensions, coatings or slips.

The gas environment is most often used in carburization due to speed, simplicity, the possibility of automation, mechanization and the achievement of a specific carbon concentration. In this case, methane, benzene or kerosene are used.

A more advanced method is vacuum cementation. This is a two-step process under reduced pressure. It differs from other methods in speed, uniformity and light layer surface, absence of internal oxidation, better production conditions, and equipment mobility.

The ion method involves cathode sputtering.

Cementation is an intermediate chemical-thermal operation. Next, hardening and tempering are carried out, which determine the properties of the material, such as wear resistance, endurance during contact and bending, and hardness. The main disadvantage is the duration.

Anodic oxidation

This type is called electrochemical oxidation of steel. Sometimes it is called anodic oxidation of steel. The term anodizing is also used. It is based on the chemical process of electrolysis. It can be carried out in both solid and liquid electrolytes. The prepared workpiece is placed in a container with an oxide solution.

The electrolysis reaction is possible by creating a potential difference between two elements.

The surface of the oxidized product is characterized by a positive potential. Chemically active elements with a negative potential are isolated from the solution. The interaction of oppositely polar elements is called the electrolysis reaction (in our case, anodization).

Anodic oxidation

The anodization reaction can be performed at home. It is required to strictly comply with safety regulations. The reaction involves harmful reactive fluids and unsafe voltage.

The use of anodic oxidation makes it possible to create protective films of various thicknesses. The creation of thick films is possible through the use of a sulfuric acid solution.

Thin films are obtained in solutions of boric or phosphoric acid. Using anodization, you can give the surface layer of metal beautiful decorative shades. For this purpose, the process is carried out in organic acids. Oxalic acid, maleic acid, sulfosalicylic acid are used as such solutions.

Micro-arc oxidation is a special anodizing process. It makes it possible to obtain coatings with high physical and mechanical characteristics. These include: protective, insulating, decorative, heat-resistant and anti-corrosion properties. In this case, oxidation is carried out under the influence of alternating or pulsed current in special baths filled with electrolyte. Such electrolytes are weakly alkaline compounds.

Anodic oxidation at home

Anodizing allows you to obtain a surface layer with the following properties:

- reliable anti-corrosion coating;

- good electrical insulators;

- thin but durable surface layer;

- original color scheme.

Anodizing stainless steel requires a special approach. This is due to the fact that such steel is considered a neutral (inert) alloy. Therefore, in production, when anodizing a large number of parts, a two-step procedure is used.

At the first stage, stainless steel is anodized together with another metal that is more suitable for this process. It may be nickel, copper, other metal or alloy.

At the second stage, the stainless steel itself is oxidized directly. To simplify the oxidation process, special additives, so-called passivating pastes, are being developed today. These compounds speed up the reaction process of stainless steel.

Where are processed products used?

Sometimes a treatment method using alkaline and oxidizing agents is sufficient. Forged fences and fences that are not painted with colored paint, but treated chemically, thermally or electrochemically, look aesthetically attractive.

This method of finishing metal products is used to:

- Protect the surface from corrosion when the product is used for construction purposes. Even when there is no direct negative impact on a metal object, protection of this kind is simply necessary.

- Protect surfaces from aggressive environmental influences, for example, fences, window bars, poles and metal parts of building decor.

- Form a layer that forms an electrical insulating shield. This is applicable in technology and buildings that should protect people from the effects of electric current.

- Change aesthetic or decorative properties if there is no desire to paint parts, changing their unique relief.

Such products and parts are used in everyday life, construction, and jewelry. Resistance can be increased by using an auxiliary coating – paint and varnish.

Often bluing is sufficient. The detail acquires dark shades with a characteristic tint. Additional finishing methods allow you to vary the color scheme.

In any case, oxidation of metal products and parts is simply necessary in order to preserve their positive characteristics. The procedure is carried out at home and in factories, in compliance with specific operating technologies. Auxiliary substances are also necessary: an oxidizing agent and an alkali. The correct temperature conditions and sufficient holding time will lead to high-quality blued metal of any alloy.

Master classes on oxidation at home (2 videos)

Oxidized metal (20 photos)

Thermal oxidation

According to the term, oxidation occurs at relatively high temperatures. The value of this indicator depends on the steel grade. For example, the process of thermal oxidation of ordinary steel occurs in special furnaces. A temperature close to 350 °C is created inside. A class of alloy steels undergo thermal oxidation at higher temperatures. It is necessary to heat the workpiece to 700 °C. Treatment continues for one hour. This process is called steel bluing.

Blueing

Steel pistol after bluing

Nitriding

This term refers to the saturation of the material with nitrogen. This process is carried out in ammonia at 480 - 650°C.

With alloying agents, this element forms nitrides, characterized by dispersion, temperature stability and hardness.

This chemical-thermal treatment technology increases hardness, resistance to corrosion and wear.

Preliminary mechanical and thermal treatment is required to achieve final dimensions. Non-nitrided fragments are coated with tin or liquid glass.

Typically a temperature range from 500 to 520°C is used. This gives a 0.5 mm layer in 24 - 90 hours. Thickness is determined by duration, material composition, temperature.

Nitriding

Nitriding leads to an increase in the number of processed parts due to an increase in the volume of the top layer. The amount of growth is directly determined by its thickness and temperature conditions.

In the liquid method, cyanide-containing, less often cyanite-free and neutral salts are used. Ionic chemical-thermal operation is characterized by increased speed.

Nitriding is divided according to its target properties: it achieves either improved corrosion resistance or increased wear resistance and hardness.

This is interesting: Passivation of metal: purpose, technology, methods

Plasma oxidation

This oxidation is carried out in an environment with a high concentration of oxygen using low-temperature plasma. Plasma is created due to discharges that occur when high- or ultra-high-frequency currents are applied.

Plasma oxidation is used to form oxidized films on fairly small surfaces.

It is mainly used in electronics and microelectronics. With its help, layers are formed on the surface of semiconductor compounds, the so-called pn junctions. Such films are used in transistors, diodes (including tunnel diodes), and integrated circuits. In addition, it is used to increase the photosensitive effect in photocathodes.

Plasma oxidation

A type of plasma oxidation is oxidation using high-temperature plasma. Sometimes it is replaced by an arc discharge with an increase in temperature to 430 ° C and higher. The use of this technology can significantly improve the quality of the resulting coatings.

Classification

Chemical-thermal treatment of steel is divided based on the phase state of the saturation medium into liquid, solid, and gas.

In the first case, diffusion occurs on fragments of contact between the surface of an object and the environment. Due to its low efficiency, this method is not widely used. The solid phase is usually used to create liquid or gaseous media.

A chemical-thermal operation in a liquid involves placing an object in a molten salt or metal.

In the gas method, the saturation element is formed by the reactions of dissociation, disproportionation, exchange, and reduction. Most often in industry, heating of solids is used to create gaseous and active gaseous media. It is most convenient to carry out work in a purely gaseous environment due to rapid heating, easy adjustment of the composition, no need for reheating, and the possibility of automation and mechanization.

As you can see, classification based on the phase of the medium does not always reflect the essence of the process, so a classification was created based on the phase of the saturation source. In accordance with it, chemical-thermal treatment of steel is divided into saturation from solid, steam, liquid, and gas media.

In addition, chemical-thermal technology is divided according to the type of change in the composition of steel into saturation with non-metals, metals, and removal of elements.

According to the temperature regime, it is classified into high and low temperature. In the second case, heating is carried out to the austenitic state, and in the first case, it is heated higher and ends with tempering.

Finally, chemical-thermal treatment of parts includes the following methods, distinguished on the basis of execution technology: carburization, nitriding, metallization, nitrocarburization.

Diffusion metallization

This is the surface saturation of steel with metals.

Can be carried out in liquid, solid, gas media. The solid method involves the use of ferroalloy powders. The liquid medium is a molten metal (aluminum, zinc, etc.). The gas method involves the use of metal chloride compounds.

Metallization

Metallization produces a thin layer. This is explained by the low intensity of diffusion of metals in comparison with nitrogen and carbon, since instead of interstitial solutions they form substitution solutions.

This chemical-thermal operation is performed at 900 - 1200°C. This is an expensive and lengthy process.

The main positive quality is the heat resistance of the products. In view of this, metallization is used to produce items for operating temperatures of 1000 - 1200 ° C from carbon steels.

Based on the saturating elements, metallization is divided into aluminizing (with aluminum), chromium plating, boriding, and sicylation (silicon).

The first chemical-thermal technology makes the material resistant to corrosion scale, but aluminum remains on the surface. Aluminizing is possible in powder mixtures or in a melt at a lower temperature. The second method is faster, cheaper and simpler.

Chrome plating also increases resistance to corrosion and scale, as well as to acids, etc. For high and medium carbon steels, it also improves wear resistance and hardness. This chemical-thermal operation is mainly carried out in powder mixtures, sometimes in a vacuum.

The main purpose of boriding is to improve resistance to abrasive wear. Electrolysis technology using molten boron-containing salts is widespread. There is also an electrolysis-free method that involves the use of chloride salts with ferroboron or boron carbide.

Sicylation increases resistance to corrosion in salt water and acids, wear and scale of some metals.

Laser oxidation

This technology is quite complex and requires special equipment. To carry out oxidation use:

- pulsed laser radiation;

- continuous radiation.

In both cases, infrared laser systems are used. Due to laser heating of the top layer of material, it is possible to obtain a fairly resistant protective film. However, this method is only applicable to a small surface area.

Laser oxidation

Heating the workpiece

Heating the workpiece is a critical operation. The quality of the product and labor productivity depend on the correctness of its implementation. You need to know that during the heating process the metal changes its structure, properties and characteristics of the surface layer and as a result of the interaction of the metal with atmospheric air, scale is formed on the surface; the thickness of the scale layer depends on the temperature and duration of heating, the chemical composition of the metal. Steels oxidize most intensively when heated above 900°C; when heated to 1000°C, oxidation increases 2 times, and at 1200°C - 5 times.

Chrome-nickel steels are called heat-resistant because they practically do not oxidize.

Alloy steels form a dense, but not thick layer of scale, which protects the metal from further oxidation and does not crack during forging.

When heated, carbon steels lose carbon from a surface layer of 2-4 mm. This threatens the metal with a decrease in the strength and hardness of the steel and hardening deteriorates. Decarburization is especially harmful for small-sized forgings followed by hardening.

Carbon steel blanks with a cross-section of up to 100 mm can be quickly heated and therefore they are placed cold, without preheating, in a furnace where the temperature is 1300°C. To avoid cracks, high-alloy and high-carbon steels must be heated slowly.

When overheated, the metal acquires a coarse-grained structure and its ductility decreases. Therefore, it is necessary to refer to the iron-carbon diagram, which defines the temperatures for the start and end of forging. However, overheating of the workpiece can, if necessary, be corrected by heat treatment, but this requires additional time and energy. Heating the metal to an even higher temperature leads to burnout, which disrupts the bonds between grains and such metal is completely destroyed during forging.

General principles

The essence of this technology is to transform the outer layer of the material by saturation. Chemical-thermal processing of metals and alloys is carried out by keeping the materials being processed in environments of a specific composition of different phase states during heating. That is, it is a combination of plastic deformation and temperature effects.

This leads to a change in the parameters of the steel, which is the purpose of chemical-thermal treatment. Thus, the purpose of this technology is to improve hardness, wear resistance, and corrosion resistance. Compared to other technologies, chemical-thermal treatment differs favorably in that with a significant increase in strength, ductility does not decrease so much. Its main parameters are temperature and holding time.

The process under consideration includes three stages:

- dissociation;

- adsorption;

- diffusion.

The intensity of diffusion increases if interstitial solutions are formed and decreases if substitution solutions are formed instead.

The amount of a saturating element is determined by the influx of its atoms and the rate of diffusion.

The size of the diffusion layer is affected by temperature and exposure time. These parameters are directly related. That is, with an increase in the concentration of the saturating element, the thickness of the layer increases, and an increase in the intensity of the thermal effect leads to an acceleration of diffusion, therefore, over the same period of time it will spread to a greater depth.

The solubility of the saturating element in the material of the workpiece is of great importance for the diffusion process. In this case, boundary layers play a role. This is explained by the fact that, due to the presence of many crystalline defects at the grain boundaries, diffusion occurs more intensely. This is especially evident in the case of low solubility of the saturating element in the material. With good solubility this is less noticeable. In addition, diffusion accelerates during phase transformations.

Cyanidation, nitrocarburization

This is a technology for saturating steel with nitrogen and carbon. In this way, steels with a carbon amount of 0.3 - 0.4% are processed.

The ratio between carbon and nitrogen is determined by temperature. As it grows, the share of carbon increases. If oversaturated with both elements, the layer becomes brittle.

The layer size is affected by exposure time and temperature.

Cyanidation is carried out in liquid and gaseous media. The first method is also called nitrocarburization. In addition, according to the temperature regime, both types are divided into high and low temperature.

In the liquid method, salts with sodium cyanide are used. The main disadvantage is their toxicity. The high-temperature version differs from carburization in speed, greater wear resistance and hardness, and less deformation of the material. Nitrocarburization is cheaper and safer.

Nitrocarburization of steel

The final mechanical treatment is first carried out, and the fragments that are not subject to cyanidation are covered with a layer of copper 18 - 25 microns thick.

Protection of brass surfaces

Oxidation of products made of brass and bronze indicates that the parameters of oxide films and the color of surfaces largely depend on the components of these alloys. For example, with equal amounts of zinc and tin in bronze metal, an oxide film is difficult to form, but when lead is added, the quality of the oxide film increases sharply. When treating brass with ammonium sulfide, alloys with high levels of zinc are more difficult to oxidize than brass containing no more than 10% zinc.

The recipe, which has been used for a long time, based on the so-called liver of sulfur, has now been modified: now, after dissolving the crystals, ammonium sulfide is added to it. Based on the amount of solution, you can get a different color of the oxide film: from light brown to dark brown or even black. Moreover, the film is of excellent quality and uniform color.

Also, a 10% thiocarbonate solution can be used for processing alloys. However, the solution is only used for brasses and bronzes with low zinc content.

Another way to protect the surface of bronze and give it an attractive appearance is to treat it with sodium thioantimonate. The result is an evenly coated film with a reddish tint.

Oxidation is a process that requires deep knowledge of chemical and physical processes and, as a rule, expensive equipment. However, the simplest technology for applying a protective film is available to everyone; just follow the simple instructions described in this article.

What is the oxidation method?

Most metallic substances enter into an active phase with various chemicals. In some cases, it occurs with the release of a third-party substance, which can become protection for the main product. In the method under consideration, an oxide film appears after applying a special solution to the surface.

The liquid, under the influence of the redox reaction, leads to the creation of a top layer that increases corrosion resistance and also decorates the plane. It should be noted that there are several varieties of the process; they are selected depending on what effect needs to be achieved, as well as what material is being processed. Let's take a closer look at the views.

With your own hands

The methods presented above are used only in production, but if you are ready for independent experiments, then you need to create a small home laboratory.

For the experiment, take a small steel piece that will fit into a three-liter jar without any problems.

Stages of work

Do each of them consistently and thoroughly. Prepare all the necessary tools in advance.

Rough stripping

Use a steel brush or coarse sandpaper. You need to remove all rust down to the base, as well as other contaminants. It is better if you then go over it with fine-grained sandpaper to ensure a uniform surface.

Polishing

Special pastes with fine abrasives or discs on hand-held grinders are perfect.

Plaque removal

In other words, rid the element of grease, oil traces, and polishing paste residues.

Treatment

To do this, introduce a solution of sulfuric acid with a 5% content of the substance and place the workpiece there for 1 minute.

Washing

First, rinse the part in regular running water, and then boil it in a soapy water mixture. Now make a 5% solution of caustic soda in a container, place the workpiece there and heat to 150 degrees, hold for 2 hours. Then just let it cool and evaluate the result. You've got an oxidized coating - this is a wonderful effect achieved at home. To clarify the information you are interested in and purchase Russian-made metal bandsaw machines, contact the managers by phone 8 (908) 135-59-82;;. They will answer all your questions.

Scope of application of bluing technology:

High-quality oxidation ensures a long life for the protected metal. The list of iron parts processed in this way is extensive. The most popular bluing is when creating the following products:

- Industrial hardware: bolts, angles, staples, gratings, drums for winches, etc.

- Locksmith tool

- Electric motor parts and casings

- Figurines and small decorative compositions

Oxide protection does not tolerate extreme operating conditions. Therefore, bluing is excluded when creating parts in contact with a highly aggressive environment. Our company offers chemical oxidation services using our equipment (baths).

Application area of the coating

Most often, various products are subjected to chemical oxidation:

- cutting and metalworking tools (cutting tools for machine tools - face and end mills, tools with carbide inserts, drills, twist drills, hole saws, dies, taps, reamers, etc.)

- equipment components (spindle chucks, faceplates, gears, high-strength sprockets in chain drives, bushings, tool holders, collets, hand tools, parts of instrumentation and optical instruments, rods, etc.)

- other parts and products for various purposes (pumping, decorative, technological, automotive, etc.).

Manufacturers of bearings, including bearings for the automotive industry, process housings, outer rings, races, and covers. Chemical oxidation does not lead to changes in dimensions, but when running-in begins, the presence of the coating provides the rubbing surfaces with excellent extreme pressure properties.

Protecting silver surfaces

Silver oxidation is a method of processing silver products, during which the surface is chemically treated with silver sulfide. Layer thickness is approximately 1 micron. The procedure is carried out in solutions of sulfur compounds. The most common solution is liver sulfur.

As a result of processing, silver gets an aged appearance. Its color ranges from light gray to black or brown. In this case, the thickness of the applied layer affects the intensity of the color. You can adjust the color while polishing the metal - the bulges become light, and the depressions remain darker. Contrast allows you to emphasize the relief of the product. Oxidized silver is sometimes confused with blackened silver, although the surface treatment method in these cases is different.