- November 25, 2018

- Equipment

- KaplyaDegtya

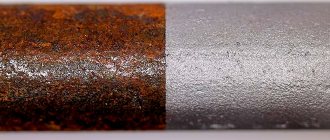

For some reason, it is believed that metal bluing cannot be carried out at home, that such an operation is performed only in factories. In fact, this opinion is wrong and at home, using simple improvised means, you can not only protect metal from rust, but also give it a beautiful black or blue color. So, let's look at ways to perform blueing work using a knife as an example.

Features of home technology

It is quite natural that using industrial methods of knife bluing at home is unprofitable from either an economic or technical point of view. In production, steel blueing is achieved by changing the structure of the upper layers of metal using chemicals. Using this method at home is not advisable; there are much simpler, but quite effective ways to blue a knife at home.

Bluening methods

There are three ways to blue steel:

- Cold - when the product undergoing bluing does not experience thermal effects.

- Hot - during the bluing process, the product is subjected to some kind of heat treatment.

- Treatment with an oxidizer is the most difficult method for home use, since it requires not only the use of chemicals, but also heating to high temperatures.

Now let's take a closer look at what techniques for bluing a knife can be used at home. Before using any of the methods, it is necessary to degrease the steel with alcohol and wipe dry with flannel.

Burnishing a knife at home

Before starting work, you need to prepare the product, for this you need:

- Clean the steel from contamination.

- Treat the tip with a degreaser. You can use gasoline or ether as it. We immerse the steel in a degreaser to completely remove the oil. If the blade is too massive, it can be cleaned in the bathroom with a solution of caustic soda.

- Now the metal object needs to be transferred to a can of paint, but you must not touch the surface of the steel with your hands.

Alkaline method

This is a simple way to process metal at home. Necessary things for work:

- stainless steel container;

- scales;

- liquid (water);

- body protection elements;

- substance NaNO2 (sodium nitrite);

- substance NAOH (sodium hydroxide).

Step-by-step work plan:

- For 1.5 hours, the metal product will boil in an alkali solution. It is important that the solution boils throughout the entire time. Add water if necessary.

- The second stage is coming. Now you need to completely clean the metal of any fat and oil. This is necessary so as not to spoil the appearance of the product. The knife edge can be treated with a solvent.

- The last stage is soap treatment. A clean blade should be washed with soap.

Blueing - protection against corrosion.

Oil bluing

Using this method, you can process a knife without spending a lot of money and resources. This is one of the easiest ways to blue metal. To work you will need 3 things:

- olive oil;

- fine-grained sandpaper;

- alcohol lamp.

Action plan:

- First, we will treat the blade with hard paper to get rid of unevenness on the surface of the steel. The fact is that these flaws can spoil the appearance of the knife, so the metal surface must be polished with sandpaper.

- Coat the steel with a thick layer of oil. We bring it to a lit alcohol lamp. We burn the steel until it acquires a uniform black color.

- After blackening, let the item cool. We get rid of any remaining oil using a cloth or napkin.

Blueing makes the steel harder.

Burnishing with egg white

This is one of the most interesting ways to treat a metal surface. To work you need:

- chicken egg white;

- fire (stove or other fire source);

- soda solution.

Step-by-step instructions:

- Let's prepare all the items to get started. The egg white needs to be beaten. The metal product must be washed in a soda solution and then coated with egg white. Now the blade needs to be dried - to do this, you need to put it in a cool place for a couple of days.

- When the blade is dry, it needs to be cleaned of the unnecessary protein layer. The high temperature that forms in the fire source will help us with this. In general, the product must be kept in the fire for the metal to acquire a crimson color.

- Now let’s cool the product. As you can see, the excess protein has fallen off, and the blade has a rich black color.

Hardening a steel knife.

Lemon acid

This bluing will protect the metal from corrosion and give it a beautiful black color. The method of bluing steel using citric acid has been used for a long time, but is only suitable for high-carbon metals. In addition, you should know that bluing a knife in citric acid is best done when the knife performs purely decorative functions, since this method of blackening metal is not durable and the entire coating will come off very quickly when sharpened.

In order to blacken a knife using citric acid, you will need:

- citric acid – 1 sachet;

- water heated to 90 - 95 degrees;

- machine oil;

- knife.

Pour hot water into a glass or stainless steel bowl and dissolve citric acid in it in proportions of 1/10, that is, 1 part citric acid to 10 parts water. Place the knife in the water and leave it for about 50 minutes. Move the knife periodically, as the bubbles formed on its surface will impede the access of air and interfere with the bluing process. After 50 minutes, the steel should turn black, which means that the bluing process has come to an end. All that remains is to rinse the knife in clean water, lubricate it with machine oil and wipe dry.

This method of bluing, although it protects the metal from rust, is rather of a decorative nature due to the fact that with the slightest impact, the coating comes off and the procedure for bluing the knife will need to be carried out again.

Metal blackening

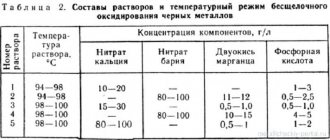

Depending on the acidity of the environment in which the workpiece is processed, the color of the resulting coating changes, from yellow to black. Therefore, bluing and blackening of metal are not the same thing. The required shade is selected by varying the intensity and duration of heat treatment and the percentage of solution components.

Metal blackening

If you take a mixture of 7 parts copper nitrate and 3 parts alcohol denatured alcohol, apply it to the product and heat it over a fire, then as it heats up the coating begins to change its color. When the desired shade is achieved, stop heating.

It is also possible to blacken steel by coating it with oil and calcining it in an open flame. The result is a durable film of deep black color. There are other compositions for blackening.

Coca Cola

Another way to blacken a knife at home is using Coca-Cola. By the way, this drink is very versatile and is most often used not for its intended purpose, but for all kinds of experiments, including with metals. So, to blue a knife in Coca-Cola you will need:

- glass or metal container made of stainless metal;

- Coca Cola;

- knife.

The bluing process is similar to the previous one, but does not require heating. To bluing using this method, you need to place the knife in the drink for a day or two, periodically turning it over and releasing the bubbles. After this time, you need to replace the drink with a new one and re-place the knife there. This procedure must be performed until the knife acquires a beautiful black color, usually within a week, changing the drink every two days. Make sure that the Coca-Cola completely covers the knife by 5 centimeters and do not forget to turn it over periodically, since bubbles accumulating on the surface of the knife will interfere with the blackening process.

After this, you need to rinse the knife well in clean water, possibly with some soap, and lubricate it with machine or gun oil. Without lubrication, rust appears on the metal very quickly; it becomes visible already during the drying process.

This method of bluing is best suited for narrow, flat surfaces; for example, bluing a bayonet in this way will allow you to achieve a more even coating than on any complex surface with many bulges and bends. In addition to Coca-Cola, you can also use Pepsi-Cola. Blackening occurs due to phosphoric acid, which is part of these drinks.

This method of bluing a knife is quite durable. According to reviews, even if small scratches appear during use, the coating does not come off. In addition, the product turns out absolutely smooth, as if it had not been subjected to any influence. The only disadvantage of such bluing is that it takes quite a long time and requires constant contact with the product (it is necessary to turn the knife up to 4-6 times a day), since otherwise the bubbles will result in piebald inclusions on the surface of the knife.

What does steel blueing do?

Some inexperienced craftsmen often do not know what metal bluing is. This method of processing is used quite rarely, believing that it is a rather complicated procedure. In fact, any manufacturer can achieve positive results with his own hands with minimal costs of materials and labor.

During chemical or thermal bluing, an oxide film with a thickness of 1...3 to 10...15 microns is formed on the surface of the steel. The thickness of the resulting layer largely depends on the technology used. When performing this operation, the main goals are achieved:

- the steel product's corrosion resistance increases;

- parts that have been processed are able to remain resistant to aggressive environmental influences.

If there is action of alkalis, acids and special heat treatment, then the surface is covered with oxide,

2Fe + O₂ = 2FeO.

Oxidation, when iron exhibits diatomic properties, forms black films. Depending on their thickness, the color of the product also changes. If there is a sufficiently thick film (up to 12...15 microns), then the surface is black. To damage such a coating, you need to apply quite a significant amount of force.

Acetic acid

Burnishing a knife in vinegar is practically no different from the two previous methods. The knife must also be placed in vinegar and periodically shaken and turned over to prevent bubbles from settling on the surface of the product.

In addition, if the knife handle is plastic or plastic, then it must be protected from the effects of vinegar, for example, by covering it with paraffin.

Blazing a knife can also be done in heated vinegar, then this method will be more similar not to blackening, but to etching of metal.

You can not completely immerse the knife in vinegar, but wrap the blade in a fleecy cloth well soaked in vinegar, but this method is more labor-intensive, since the cloth must be periodically wetted.

The coating turns out to be quite beautiful, not completely black, but rather dark gray. This kind of bluing of a knife is not particularly durable, so it is best used for decorative knives and other metal interior items.

It should also be said that not any metal can be blackened with vinegar, but only hydrocarbon metal. Therefore, during the first hours, carefully monitor how the steel behaves. If you notice that white inclusions appear on the surface, then this method of bluing, unfortunately, is not suitable for this metal; subsequently the inclusions will not disappear, but will only become more contrasting.

Rusty varnish

Burnishing a knife with rusty varnish has both its advantages and disadvantages. The main advantage of this method is that it is possible to burnish knives that have tin solder on them, since all previous methods are not suitable for these purposes - the tin will either dissolve or will not change its color. In addition, using rusty varnish, you can carry out spot bluing of a knife, that is, blue only certain areas of the blade or handle. The coating layer is quite thick, compared to previous methods, and the steel itself is matte after such bluing.

The disadvantages of blueing a knife in this way are that knives, especially industrial ones, are most often made from various alloys, and rusty varnish is very sensitive to impurities, that is, each metal in the alloy will be painted in its own color and red-brown and brown spots. If you notice such an effect when applying varnish, it is necessary to remove the varnish as quickly as possible, even before oiling the surface, otherwise these stains will not be removed later and the knife will be damaged.

Other significant disadvantages include the fact that this method of bluing a knife is sensitive to various nuances of the process: the quality of degreasing, drying temperature, and bluing time. In addition, the bluing process is quite lengthy and requires your direct presence, since the varnish must be applied several times and each time after drying, steam it, and then rinse under running water. All these procedures must be repeated until you are satisfied with the final result. After that, you need to place the knife in boiling oil for about 5 minutes, and then wait for it to cool completely and only then begin the grinding process with a soft flannel cloth.

Means for bluing metals

Relatively simple methods of bluing, available for doing it yourself, include surface application of oil, saltpeter and the purchased composition “Clover”

Sapphire for bluing

Oil coating

This is one of the most popular home methods. The technology is divided into the following operations:

- The part is sanded and degreased with a solvent.

- Cover with oil.

- In a muffle furnace it is heated to 350-400 °C. It is permissible to use an oven.

- The cooled part takes on a black or brown tint.

- To saturate the color, the procedure is repeated.

The oil is applied with a brush or by dipping the product into a container of oil. Different types of oil are used, such as

- weapons;

- olive;

- flaxseed

Use of saltpeter

Home craftsmen achieve excellent results using saltpeter solution. You can purchase a ready-made solution, or you can make it yourself:

- water-1000 ml;

- sodium nitrate - 0.5 kg;

- caustic soda - 0.5 kg.

After boiling for an hour, a smooth surface of a deep blue-black color is obtained that does not require further processing.

Means "Clover"

The gel-like product can be purchased in 50 ml jars and is used for alloys with a chromium content of no more than 3 percent

Means "Clover"

It is designed to restore localized corrosion. To obtain a bright shade, the product will have to be applied several times. The product should first be sanded and wiped with a degreaser.

Apply clover with a brush and leave for two minutes. The white-yellow coating that appears is washed off with water and the part is wiped with a rag.

Hot bluing method

In addition to the above, methods of bluing a knife using calcination are also used at home. Before burying a knife in this way, it must be coated with linseed oil, animal fat or wax. After which the knife must be well heated over fire. Some people do this in a regular kitchen frying pan, but keep in mind that the dishes will be damaged after this.

Before using this method, you can first immerse the knife in a solution of copper sulfate and ammonia: 100 grams of vitriol and 10 grams of ammonia are diluted in one liter of clean distilled or settled water. Dipping and heating the knife must be done several times until you get the desired color of the metal.

Metal processing methods

Metal blackening occurs in the following ways: alkaline, acid and thermal. Such work can be carried out on an ax, weapon and other metal products.

Alkaline bluing

The most popular method of blackening steel is chemical oxidation with an alkaline composition. The result obtained is quite high quality and durable when the technology is strictly adhered to. The method is based on the ability of the metal to oxidize. The work is carried out at 135-150 degrees, and you should be prepared for the characteristic smell.

Alkaline blackening is best done outside the apartment. This can be done in the yard or garage, in a room with good ventilation.

So, let's begin. The first step is to degrease and thoroughly clean the surface of the metal object. Remember that bluing at home is impossible without preparing a good alkaline composition.

You can do this as follows:

- Pour 100 ml of plain water into a porcelain bowl.

- Add 100 grams of technical soda and 30 grams of sodium nitrate.

- Stir thoroughly and heat the resulting composition to 135-150 degrees.

The solution is ready, now you need to immerse the product that you plan to burnish into it for half an hour. Then the metal is washed with distilled water, dried and lubricated evenly with machine oil.

As a result of alkaline bluing at home, a bright black color with a blue tint should appear. To obtain a thicker oxide film, the percentage of alkali in the solution should be increased.

In the video: do-it-yourself alkaline bluing.

Acid bluing

Before bluing, the product should be thoroughly cleaned with sandpaper. Then you can degrease it by dipping it in kerosene or sodium triphosphate for 10-20 minutes. After this, the part is dried, and at this time you can prepare a solution for blackening.

It is prepared as follows:

- Add 2 grams of tartaric and tannic acid to 1 liter of water.

- The ingredients are thoroughly mixed.

- The solution is heated to 140-150 degrees.

The part should be immersed in the heated mixture for 14-17 minutes, then rinsed with plain or boiling water (for better cleaning of the solution).

The last stage is to immerse the product in machine oil for 60 minutes. Then you need to wipe it, dry it and you can use it.

Thermal bluing

This option appeared first, so it is easier than others to implement, but no less effective. The method is based on heating metal products until oxygen reacts with the metal itself. The heating intensity varies depending on the desired result.

The table shows the resulting color at different temperature conditions.

| Temperature | Color |

| 220-229 | Pale yellow |

| 230-255 | From golden yellow to red yellow |

| 256-280 | Lilac, purple |

| 281-295 | Blue |

| 296-320 | Blue, dark blue |

To implement heat treatment, you will need machine oil (500 ml), a machine oil tray, pliers, a gas hair dryer and dry wipes. Heat treatment should be done on a brick or other non-combustible surface.

Progress:

- The hairdryer must be turned on at maximum temperature and the product held over it.

- The heated part is completely immersed in oil, while holding it with pliers.

- Take out and blot the product with a napkin.

- Repeat the entire procedure 3 more times from the very beginning.

This method will not give the metal a black color. Blackening by this method is necessary to prevent rust; decorative bluing is rarely done using this method.

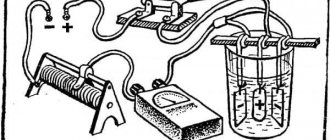

Chemical bluing

Burnishing a knife in this way can only be carried out under conditions of good exhaust and ventilation, as otherwise it can be hazardous to health!

- Place a knife in a mixture of saltpeter and caustic soda (30 grams of saltpeter and 100 grams of soda) heated to 140 - 160 degrees and keep it there for at least half an hour. With this method of bluing, a beautiful deep black color is obtained, giving off a blue tint.

- Dilute potassium or sodium hydroxide in a high concentration in an alkaline solution and place a knife in this solution. This method will give a bluish film on the surface of the knife.

Types of steel bluing

The bluing itself is divided into several types. Basically, this classification is based solely on the processing method.

Chemical and thermal effects are applied to the metal surface.

The first type is based on the fact that the workpiece is alternately coated with several chemical mixtures for processing.

- All of them in symbiosis create such an environment that when all these chemical compounds interact with oxygen, nitrogen and other environmental gases, the formation of that very oxide film occurs.

- The disadvantages of this method of steel bluing include possible harm to health.

- If you make a mistake and apply chemical components in the wrong dosage, a toxic compound can form.

- It will release harmful vapors into the atmosphere that negatively affect human health.

- In addition to visual differences, after chemical treatment the structure and some physical characteristics of the metal in question change.

After chemical treatment, it is time for thermal treatment. Here everything is much simpler, the workpiece is placed in a special compartment and the temperature is raised to the required levels. Next, the workpiece is allowed to cool for some time and used for further production needs.