Self-leveling floors are a group of special materials that are applied to the surface by pouring. They are used to level the base and also to protect it. Self-leveling floors have unique strength characteristics and excellent appearance. When pouring such floors, many different factors are taken into account. The thickness of the self-leveling floor is one of them. To create such floors, there are several types of compositions. They differ from each other also in thickness.

Sex classification

Based on the thickness of the coating, self-leveling floors can be divided into:

- Thin-layer mixtures - here the layer thickness is less than 1 mm;

- Mixtures with a middle layer - up to 5 mm;

- Highly filled coatings – the layer is up to 8 mm.

Mixtures for application in a thin layer are used mainly in industrial premises. In this case, the load on the coating should be below average. Such finishing floor coverings are chosen for their efficiency and practicality. In addition, thin-layer bulk mixtures look great and are used to solve design problems. Despite all the advantages and high efficiency, such coatings do not have adequate wear resistance to abrasion. The coating wears off very quickly.

The average thickness of the self-leveling floor implies higher characteristics. Such mixtures can be poured in conditions where mechanical loads are expected to be above an average level, but below a high level. Advantages include cost-effectiveness, high resistance to mechanical damage, and excellent maintainability. These coatings are highly durable. The surface can be matte or have a glossy sheen - this is an excellent choice for apartments or residential private houses.

High fill coatings are designed for the most severe operating conditions. These mixtures, after hardening and polymerization, can withstand even very high shock and mechanical loads. Increased wear resistance makes such floors ideal for use in industrial workshops and production facilities. The floor is very resistant to abrasive loads.

Main characteristics of self-leveling compounds

According to Russian building codes and regulations, the cross-section of the screed must meet the parameters of 20-150 mm. Mobile or highly mobile dry compositions differ:

- viscosity. Contains gypsum and cement;

- filler The composition contains perlite and quartz sand;

- additional additives. Components with modifying and plasticizing characteristics, additives contribute to more convenient laying of the material, improve the spreadability of the solution, speed up the drying time, and reduce the shrinkage rate.

Self-leveling floors also include decorative finishing polymer mixtures. The compositions represent a series of household 3D and industrial protective coatings, which in composition and properties are similar to varnish for wooden and stone surfaces.

Photo: 3D self-leveling floor

Contains film-forming components based on high-strength resinous substances:

- acrylic;

- polyurethane;

- epoxy.

Apply with a roller or spatula onto a previously prepared mineral base. After hardening, the result is a varnish coating that is extremely resistant to abrasive, impact and other physical negative loads.

Layer thickness for high loads

Often, self-leveling floors are used in warehouses, underground parking lots, garages, and industrial enterprises. These floors are relevant wherever vibration or mechanical loads are placed on the floor. Also, in such conditions, temperature changes are not uncommon. There are many different mixtures for constructing self-leveling floors. For industrial premises, coatings based on methyl methacrylic resin are used.

The coating that appears as a result is highly resistant to moisture and ultraviolet radiation. After application, this floor will dry in 2 hours. In this case, there will be no seams on the floor. These compositions allow you to create decorative colored surfaces. The coating is highly repairable. The load that the floor can withstand is at least 15 tons. This self-leveling floor is not afraid of low temperatures, and the layer thickness is from 4 to 6 mm.

Device Features

When installing self-leveling floors, the master or the owner of the premises must comply with the requirements of current regulations, as well as the technological map. When applying the composition, the following nuances are taken into account:

- The self-leveling floor should be applied exclusively on top of a solid surface with a minimum porosity coefficient.

Preparation for self-leveling floor

- Before installing the material, it is necessary to remove dust from the screed and clean it of all solid particles and other debris.

Dust removal of screed

- To improve the adhesive properties of the material, before installing it, a layer of penetrating primer should be applied over the subfloor.

Penetrating primer for screed

- The self-leveling floor is an inextricable material, which requires careful preparation for installation. Before installing it, it is necessary to glue a damper polymer tape around the perimeter of the room to avoid destruction of the material due to linear expansion.

Rolling out self-leveling floor

- When installing a coating over an area of more than 50 - 60 m2, expansion joints made of angle steel or polymer materials are required.

Expansion joints

- When mixing a dry mixture, you should strictly adhere to the instructions on the packaging, observe the required proportions of water in relation to the dry material, and also ensure that solid particles are completely dissolved in the liquid. When lumps form, the finished coating loses its uniformity and strength properties.

Mixing the naive floor

- The self-leveling floor should be applied evenly; after installation, the coating is smoothed using special hard rollers.

Roller for self-leveling floor

If you follow the above technological map and use a high-quality composition, the self-leveling floor will serve for many years without complaints. After installation of the material, the finishing coating can be laid only after the surface has completely dried and reached the design strength dictated by the manufacturer.

Self-coating in the apartment

The installation of a self-leveling floor should be entrusted to professionals, since an experienced specialist will always be able to prepare a high-quality composition that will not be destroyed, regardless of operating conditions.

Coating installation by professionals

Acrylic-cement bulk mixtures

Having already become a classic, the mixture is suitable for those areas where the loads are extremely high. The coating is relevant for wet industries, various warehouses, and garages. As for thickness, to obtain high wear resistance characteristics, the layer is made from 10 to 20 mm. The material has excellent resistance to various types of chemicals, and is also durable, but subject to a minimum thickness.

Finishing lineups

These solutions are not used to level significant defects; they serve to create a decorative coating or increase the strength of the previous leveling layer. It is also not recommended to pour such compositions under laminate or parquet, since then their visual properties will be useless. The layer size ranges from 0.1 to 1 cm.

The beauty and strength of the floor depends on the quality of thin-layer finishing mixtures

Self-leveling floor in the apartment

Sometimes, when pouring self-leveling coatings in residential premises, you may encounter crooked foundations and low budgets. But the volume of material and financial expenditure completely depend on how thick the coating will be. If you know what thickness the self-leveling floor should be in different cases, you can make the perfect coating at minimal cost.

Low temperature conditions

As we said, the mixtures are for use in low temperatures and are made from methyl methacrylic resin. The composition also contains various additives that improve the characteristics of the mixture. In order to ensure maximum resistance to temperature changes, it is necessary to maintain a layer thickness of 5-7 mm.

Such coatings are usually made in refrigeration chambers, in rooms adjacent to them. And let’s gradually move on to how thick the self-leveling floor should be in residential buildings.

Minimum thickness or thin technology

In the technology of creating self-leveling floors, every millimeter is important. For example, coatings based on polymer mixtures are highly durable. In an apartment or house, a layer of 1 mm will be enough to forget about repairs for a very, very long time. But in order for the floor to turn out exactly like this, it must be done by real professionals. A small layer means low costs for materials, but in the screed you can often find various sinks, potholes, and depressions. This will entail increased consumption of solution and funds. In this case, the finishing layer must be kept minimal.

Starting mixtures

Such materials are used when the floor is very curved and covering it with high-quality mixtures will be too expensive. Cement-based compounds are suitable for leveling. The maximum thickness without reinforcement is 5 cm. If you plan to install reinforcing mesh, it can be increased to 8–10 cm.

Experts recommend not making one thick layer, as it will take too long to dry; it is better to lay the cake in 2-3 parts.

Starting mixtures provide a reliable foundation for high-quality coating

Saving mixture for self-leveling floor

There is no point in making a thick floor if a topcoat is used, and this is often the option that is used.

The base is prepared using basic and medium compositions. Such mixtures are not expensive - they contain gypsum, cement, sand, and various plasticizers. There are no polymer substances, so the thickness of this layer can be maximum. These mixtures are used primarily to level out serious unevenness. So, using such a base mixture, you can create layers up to 8 cm. And the minimum thickness of the self-leveling floor is 1 cm.

Filling algorithm taking into account recommended thicknesses

A more detailed analysis of the rules for choosing layer thicknesses can be done using the example of creating a decorative polymer floor with a pattern on a special film under the following basic conditions: an uneven cement-sand base with a height difference of 5...20 mm and average requirements for the performance characteristics of the floor. The layout of the layers is shown in the illustration.

In this case, the total thickness of the self-leveling floor layer (meaning both the leveling mixture and the finishing polymer composition on top of the decorative image) will be 25 + 5 = 30 mm. First, the base is prepared and primed (the process is discussed in detail in the article “Self-leveling floor: instructions for pouring it yourself”), then preliminary leveling is arranged using a suitable mineral (cement or cement-gypsum) mixture. Material consumption can be calculated using an online calculator. After the first layer has completely cured, you can pour the second layer of self-leveling floor (transparent polymer), after laying down a film with a decorative pattern.

The step-by-step process of pouring a “three-dimensional” self-leveling floor is discussed in more detail in the video.

Optimal layer thickness for self-leveling compounds

Polymer floors are quite expensive. At the same time, the thickness of the coating can be very small. Thus, polyurethane-based compositions make it possible to make layers up to 2.5 mm thick, which is optimal. If it is necessary to give the floor a gloss or paint the surface in different colors, apply only 0.3 mm of the composition. The maximum for this coating is 5 mm. You can do more, but it’s more expensive and doesn’t make much sense.

As for epoxy-based compounds, the optimal value here is also 2.5 mm. This thickness allows you to obtain sufficient strength characteristics without the floor being fragile.

Methyl methacrylate or quick-hardening mixtures can also be used with small thicknesses. But it's not worth saving here. For a high-quality coating, the layer must be at least 8 mm.

What does thickness depend on?

The thickness depends on the force of the mechanical load

. There are three main parameters that directly affect this coating parameter. These include:

- Degree of mechanical load. Particular attention should be paid to the mechanical stress coefficient: vibration level, surface wear resistance, as well as possible impact;

- Possibility of laying the thinnest layer possible, which will correspond to the type of binding material;

- The level required to level the rough foundation.

A self-leveling floor whose layer thickness is less than required will not last long, but you shouldn’t overdo it either, otherwise you will waste money on unnecessary materials.

Types of coatings

An example of a self-leveling coating

To understand what the minimum thickness of a self-leveling floor should be, you should find out the types of mixtures for this parameter:

Self-leveling floor consumption per m2: calculator and calculation

- Thin-layer. In this case, the layer will not exceed 5 mm. The coating protects the base from the negative influence of the environment. The consumption of the solution will depend on the quality of the screed and the type of dry mixture used;

- Self-leveling. The maximum layer of self-leveling floor will be 20 mm. This floor not only has antistatic characteristics, but also copes well with mechanical loads;

- Highly filled coatings. The minimum layer of self-leveling floor is 2 cm. These compositions are made from special fillers: quartz sand, expanded clay, magnesite, etc. They are often used if it is necessary to achieve a coating thickness exceeding the maximum value.

Types of compositions

An example of a polymer decorative coating

The thickness of the surface largely depends on the type of material used. You should pay special attention to this before purchasing a dry mixture.

Types of coatings:

- Methyl methacrylic. As a rule, thin-layer self-leveling flooring is applied to concrete and steel bases. One layer does not exceed 0.6 cm, despite this, the surface can withstand a load of 15 tons;

- Polymer. Self-leveling floor 4 cm is the optimal size for this coating. However, its minimum value will be only 2.5 mm. If the surface is additionally painted, this parameter may decrease to 0.3 mm;

- Acrylic-cement. This mixture is classic, it is resistant to chemical reagents and mechanical damage. Thickness ranges from 10 to 20 mm;

- Mixtures for low-temperature rooms. This solution is made on the basis of MMA (methyl methacrylic) resins. It consists of special frost-resistant components, while the thickness of the floor does not exceed 0.7 cm;

- Self-leveling cement-polymer composition. Specially designed for carrying out repair work on wooden, magnesite and ceramic bases. A fairly thick self-leveling floor (up to 5 cm), which has good adhesion to the base.

Important! The thickness of the layer for rooms where significant load is provided must be at least 10 mm. This parameter depends on the location of application of the coating and the possible degree of dynamic load.

Patterns

On industrial coatings, coatings are of great thickness.

Without taking into account the primer and base, the maximum layer of self-leveling flooring in an apartment does not exceed 7-8 mm. Usually, this indicator is enough for the surface to be durable and wear-resistant. In this case, the size of the finishing layer can be no more than 0.2 cm if the base has been well prepared.

Please note: The minimum thickness of any type of self-leveling coating starts from 1.5 mm. But for a standard living room it should be at least 2.5 - 4 mm. The situation is completely different with production facilities. Sometimes there are coatings with a layer of 10 cm. The self-leveling floor is applied in two layers to ensure a sufficient degree of strength. Such surfaces can easily withstand multi-ton loads without even a hint of deformation.

How to increase the strength indicator?

Quartz sand increases the wear resistance of the coating.

Unfortunately, the layer is not always strong enough for a particular type of room. In such a situation, specialists artificially increase the parameter by resorting to the use of such materials:

Reinforcement of self-leveling floor

- expanded clay;

- quartz sand;

- reinforcing mesh;

- self-leveling screed;

- magnesite.

With the help of these building materials it is possible not only to increase the size of the layer, but also to improve the technical characteristics of the coating. Mineral fillers are evenly distributed over the surface immediately before applying the finishing solution. Thus, the layer becomes larger.

Self-leveling screeds are also designed to increase this parameter. Depending on the type of self-leveling mixture, it can vary from 2 to 50 mm.

Advised by professionals

In order to obtain the highest quality surface at an affordable price, experts use some techniques.

So, if the base base is not too crooked to purchase medium or basic bulk compositions, but not so smooth as to get away with just a finishing coating, the situation can be corrected. You just need to sand the surface using a sanding machine. This will smooth out unevenness and save on materials.

In order not to purchase primer compounds, you can make them yourself from a small amount of dry compounds for self-leveling floors. The mixture is diluted and then applied to the base with a roller. When the product has dried, you can pour the finishing floor.

Where is which - we distribute the compositions throughout the apartment

You can also save on the correct placement of accents - where what composition should be used. For example, in the kitchen, only a polyurethane floor can be the final coating, because there most often heavy things fall to the ground, water, grease, and detergents spill there. It is best to use a polyurethane surface in office premises, in a word, where there is more traffic. In addition, polyurethane is very elastic, which means it does not care about constant changes in temperature conditions in the case of installing heated floors.

Epoxy compounds are best suited for rooms with high humidity - they are not affected by moisture. Moreover, in the bathroom the floor is unlikely to be threatened by anything heavier than a bottle of shampoo or a bar of soap. You should not lay them on top of a heated floor - epoxy resins do not react well to temperatures above +50 ° C, and may crack after some time under the influence of heat.

Methyl methacrylate self-leveling floors consist of acrylate resins and hardeners, which accelerate the already short drying time of the solution. By the way, you should work with such a composition with open windows and in a respirator - for the first few hours during and after pouring, there will be an unpleasant, pungent odor in the rooms, a kind of payment for speed. They are strong and durable enough to serve you in the living room and hallway, and they feel comfortable with constant changes in temperature, having the widest operating range: -70 ° C and +150 ° C.

Mineral mortars and polymer-cement mortars are suitable as the bottom layer of a self-leveling floor or a base for floor coverings such as laminate

But here, too, caution should be exercised. For example, a gypsum sand composition is not at all suitable for foundations in wet rooms (bathroom, toilet), but it would be appropriate in a living room or bedroom. https://www.youtube.com/embed/28rwom0XORk

Thick layer

When making thick layers, experts also recommend using special mixtures to level out differences rather than self-leveling floors. It should be noted that depending on the manufacturer, certain compositions have different qualities. Thus, one company produces products where the maximum thickness of the self-leveling floor is 80 mm, while another offers a layer of 100 mm. If possible, it is recommended to use concrete solutions to level out large differences. Leveling compounds are not suitable for finishing coats.

Experts do not advise making coatings as thick as possible - the floors will take a very long time to harden, and for a high-quality surface it is necessary to withstand a constant regime of humidity and temperature.

Scope of use

One of the fundamental indicators of the mixture is the level of resistance to low air temperatures. The place where the surface will be poured is also important - outdoors or indoors. The product is selected according to this. For installation in a building, compositions suitable for normal or intense humidity are offered.

For laundries, swimming pools, bathtubs and showers, mixtures that contain water-repellent components that prevent water from penetrating deep into the screed are preferred. The formation of moisture inside self-leveling floors leads to their premature destruction and wear.

The presence of heated floors is also necessary to take into account. Not all compositions are tolerant to temperature changes; screed with self-leveling properties is especially vulnerable. In such cases, mixtures are preferred whose packaging indicates that they are suitable for surfaces with a heated floor system installed.

Thin floor

Such mixtures are not used for leveling. They serve as a finishing coating. The minimum layer of finishing self-leveling floor is 1 mm, the maximum is up to 10 mm. When pouring the floor and working with finishing layers, be sure to take into account the fast drying speed.

In general, the quality of the floor does not depend on the thickness. For different compositions it is necessary to pour layers of different thicknesses. To obtain a high-quality surface at minimal cost, it is necessary to prepare the base. It is recommended to select the composition based on the conditions under which the floor will be used in the future.

Preparation of the solution

The correct ratio of dry mixture and water is as important as preparing the base. If you add less than the required amount of water, the mixture will not acquire the necessary mobility and fluidity and, accordingly, it will become difficult or even impossible to level it

If you add less than the required amount of water, the mixture will not acquire the necessary mobility and fluidity and, accordingly, it will become difficult or even impossible to level it.

If you add more water than the required amount, the solution will turn out to be very mobile, it will spread well, but after hardening its strength will be lower than it should be, so cracks may appear. In addition, due to excess water, the main components of the leveler will settle down, and the water will remain on top, and the solution will delaminate. Therefore, when pouring, you will have to control the level of the mixture using the upper water level. As a result, after pouring the self-leveling floor, the water will dry out, and the level of the floor itself will be below the calculated marks.

To avoid such problems, you must strictly adhere to the instructions for preparing the solution, which are written on the back of the leveler bag.

As a rule, the water consumption per bag is indicated there in the minimum and maximum quantities. For better spreading of the mixture, you should choose the maximum amount of water.

You should also pay attention that water is poured first, and then the dry mixture is poured into it. This minimizes its sticking to the walls of the container and prevents the formation of lumps.

When kneading, do not use too high mixer speeds. This leads to the enrichment of the solution with air bubbles, which subsequently form pores in the frozen finished floor.

After mixing according to the instructions, be sure to let the mixture stand for three to five minutes, during which all the necessary chemical reactions will take place and air bubbles will come out of the solution. After that, mix a little again and start pouring the floor.

How to reduce mixture consumption?

Any composition, even self-leveling, can be reduced. More precisely, reduce its consumption. There are several simple ways to help with this.

So, leveling mixture - you can reduce its consumption like this:

- Use an underlying layer of quartz quarry or washed river sand. Don't worry, the sand underlayment does not affect any characteristics of the floor.

- It is possible to lay polymer iso-film or polyurethane insulation.

- Primers and impregnations are also suitable for such a screed in order to reduce the consumption of the mixture.

Other prospectors are coming up with new ways to use fewer cubes of the mixture in the pour. But saving should not harm - the horizon should be smooth, the layer should be even, the shelf life of the mixture should not be yesterday.

Dependence of material consumption on its density

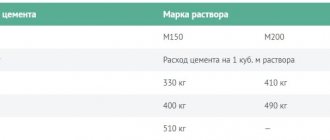

Table 1. Characteristics of self-leveling floor

This is a corrective parameter that is necessarily included in the calculations. The self-leveling mixture contains many components, additives, and fillers that manufacturers keep secret, so it is impossible to independently find out the density value; the indicator is indicated on the bags.

Average statistical data for calculating self-leveling floor:

- epoxy 1.4-1.65 kg per l;

- polyurethane 1.2-1.35 kg per liter.

The addition of heavy impurities increases the density of the composition and reduces the cost, because modifiers are cheaper than the main components. If there is a transparent finishing mixture on top, then the calculation is carried out separately, because the density is different.

How to save money

In some cases, it becomes necessary to fill the floor with similar materials, but it is necessary to increase the thickness of the layer. If your budget is limited, then you can use a little trick. At the mixing stage, various fillers are added to the solution: expanded clay, perlite, vermiculite, quartz sand or magnesite. These materials will not only save a little mixture, but will also reduce the pressure of the floor structure on the floor. In addition, they will increase the heat and sound insulation characteristics of the floor. The grain sizes should be no more than 1 cm to obtain a surface of the required quality.

Fillers not only provide significant savings, but also provide an anti-slip, high-strength coating

After selecting the material and determining the required layer, you need to calculate the total amount of mixture for the work. Typically, manufacturers indicate consumption per square meter based on a layer thickness of 1 mm or 1 cm. To calculate, multiply the consumption rate by the desired thickness and total area, and then add a 10% reserve for filling potholes and other small defects.