Rollers and brushes are a relic of the past. Today, both professionals and amateurs choose spray guns as a painting tool. And there are reasons for this:

- Excellent work quality

- Save time

- Reduced paint consumption

Spray guns are used everywhere - from construction sites and furniture workshops to car services. Each task requires a certain type of tool, and the main thing here is not to miscalculate. How to choose a pneumatic spray gun and not make a mistake? Let's look at this issue in detail.

To be fair, we note that in addition to pneumatic ones (“powered” by air from compressors), there are also electrical devices (powered by the network). However, it is pneumatic spray guns that are more popular.

Low pressure spray guns

At the moment, we have a wide selection of different types of paint sprayers. The presented varieties and modifications have their pros and cons, but the most common among the general spectrum are low-pressure spray guns. It is the HVLP and LVLP spray systems that have become a real treasure for thousands of professional and amateur painters around the world. Due to their efficiency and high quality of painting, these tools have gained well-deserved popularity, which continues to this day. What are advanced low pressure spray systems? Let's look at it in more detail.

High volume (HVLP)

One of the oldest spray systems, referred to in professional circles by the abbreviation HVLP (High volume, low pressure), which translates as “High volume, low pressure”. This model is a descendant of the primitive HP (High volume) aerosol system, which became the progenitor of all modern spray guns.

The ancestor of the device adequately coped with the task; it was very wasteful and transferred only up to 50% of the paintwork to the surface being treated, turning the remaining half into fog. The principle of how to convert a spray gun to low pressure was born back in the 80s of the 20th century and the reason for this was 2 specific factors: high paint consumption and environmental pollution.

HVLP spray guns have replaced classic HP spray guns in order to save materials and protect the atmosphere. Decoding the abbreviation “High volume, low pressure” means that at the entrance to the instrument, the air has a pressure of 3 atmospheres, and at the exit of the nozzle it decreases to 0.8 atmospheres (example). The transfer of material to the surface in the HVLP system reaches 75% and, by law, cannot be less than 65%.

Low Volume (LVLP)

The advanced LVLP (Low volume, low pressure) spray system combines the most effective technologies borrowed from its predecessors. This low-pressure paint sprayer is incredibly economical and, unlike its progenitor, more convenient to use.

The optimized design of LVLP systems requires a significantly smaller volume of air entering the device. If the inlet pressure is 2 atmospheres, then at the outlet this figure will be 1 atm, decreasing by 2 times. The size and quality of the painted spot is preserved, and in some models it even surpasses the previous spraying system. On average, material transfer to the surface of LVLP system spray guns is 75-90%.

Tank capacity and location

As a rule, pneumatic paint sprayers are equipped with filling tanks of 0.8–1 liters. These are containers that are attached directly to the “gun”. Thus, the artist constantly holds the entire volume of paint in his hand. If you need to paint very large surfaces, use specialized tanks with a volume of up to 100 liters. They are connected to the spray gun with a hose.

Types of fastening the tank to the spray gun

Filler tanks are located below or above the “gun”. Their position does not depend on the type of spray gun (HP, HVLP or LVLP). You need to choose a model with a container arrangement that will be convenient for the master. But we can highlight several objective pros and cons of each solution:

- The lower tank does not block the technician’s view during painting. And during a break, the spray gun can be placed on the table (the bottom of the container is flat). But the paint from the lower tank is supplied to the sprayer only under compressed air pressure. Therefore, there is always some unused material left at the bottom of the tank. Also, the lower tanks often have a slightly larger volume than the upper ones.

- The advantage of the top tank is that no paint remains in it - all of it flows into the spray gun under the influence of gravity. As a result, such units can spray thicker paintwork materials. It is also believed that the upper tank balances the weight of the device and the material well. This makes the sprayer more comfortable to hold and your hand does not get tired so quickly.

In addition to the listed characteristics, you should also pay attention to whether the selected spray gun model has the ability to regulate the paint supply, direction and configuration of the torch. You definitely need to hold the device you like in your hand - it should be comfortable to use.

When choosing a sprayer, you need to hold the device in your hand and understand how convenient it is

How to choose a low pressure spray gun

Everyone knows that numerous tool stores today are replete with a huge selection of goods for every taste, color and budget. Limiting the scope of attention only to low-pressure pneumatic spray guns, we can divide them into 2 groups: professional and amateur.

The name brand tools (DeVILBISS, SATA, Iwata, and Walcom) are extremely reliable, effective, and well worth the money. In the skillful hands of an experienced craftsman, such devices produce stunning results of the highest quality (almost factory quality). Budget, household low-pressure spray guns cost tens of times less, but in most cases, they cope with the task of applying a uniform layer quite adequately.

Transfer factor

The transfer coefficient is one of the most important parameters; it is the ratio of the mass of the dry residue of the coating material transferred to the product to the mass of the dry residue of the amount of coating material expended. For all spray guns, it is calculated under ideal conditions, which are not feasible when painting furniture. The actual efficiency of using equipment depends on the conditions of a particular production. According to our data, the maximum achievable transfer coefficient values when painting furniture facades are approximately 45% for pneumatic guns and 65% for airmix.

- product shapes

- equipment settings

- distance between nozzle and surface to be painted

- on the viscosity of paints and varnishes

Obviously, when painting small parts, the paint transfer coefficient will be lower than when finishing large surfaces. Also, paint loss will increase significantly if the gun is held too far from the surface or if the pressure is too high. As air pressure increases, fogging losses increase.

What is the difference between a spray gun and a paint gun?

A spray gun is for a professional painter what a scalpel is for a surgeon, the most important tool without which the desired result cannot be achieved. They work thanks to compressed air, which sprays small droplets of paint under pressure - this is to briefly describe the principle of operation, but on the market you will find a huge variety of devices that differ in both functionality and spraying features.

Externally, almost all paint sprayers are similar; a beginner is unlikely to distinguish a spray gun for water-based paint from an apparatus for paints and varnishes. The differences lie inside, in the structure of the air nozzles, in the design of the internal channels through which air passes. These features affect both the speed of task completion and ease of use. We touched on the topic of the device’s design, let’s look at it in more detail.

An electric spray gun (as it is called because it is powered by a compressor connected to the network) consists of a housing, a pump, a hose, a mixture flow regulator, a tank, a trigger and a switch button - such a description will make you think that this is an ordinary paint gun. . But what makes a spray gun a spray gun are those very nuances, for example, the air supply regulator, which serves to fine-tune the outlet pressure. Professional tools are equipped with a regulator for the shape of the “torch” – the output paint jet. The nozzle opening regulator controls the amount of paint supplied.

Main stages

Regardless of the type of wood, materials for painting and the wishes of the owner, there are steps required for all types of work:

- cleansing

- sanding (if necessary)

- primer

- applying paint

- varnishing

Based on the desired end result, other actions are added to this list - the use of templates, special compounds or devices.

The principle of operation of a paint sprayer - let's understand the abbreviations!

The spray gun operates from pneumatic energy, which is converted from electric energy by a compressor. Professionals select compressors for each instrument based on the required pressure and air flow. The lower the pressure for the spray gun, the more economical the tool will be, which is often what consumers prefer. For ease of selection, all devices are marked, knowing the decoding of which you will understand what kind of instrument you have in your hands. So, a tool with high feed efficiency is designated as High Transfer Efficiency or HTE, but if a device with low pressure and a small volume of air, then the marking will be Low Volume Low Pressure (LVLP).

Reduced pressure is labeled as RP - Reduced Pressure, and low pressure with a high volume of air - HVLP (High Volume Low Pressure). There are devices with medium pressure - MP (Middle Pressure), as well as LVMP (Low Volume Middle Pressure) - spray guns with low volume and medium pressure. And finally, the high-pressure spray gun is HP (High Pressure). There is no need to remember them all, just choose the best option and decide on a tool from this category , and knowing the abbreviation will allow you not to be deceived.

Preparing for coloring

On the walls and ceiling, you need to carry out preparatory work to level them:

- If there are seams or uneven spots on the ceiling, they are plastered and the previous whitewash is washed off.

- Primer is applied to the walls, and unnecessary holes are eliminated using putty. This applies to concrete or brick walls and ceilings. If the surfaces are made of wood, then they are pre-sanded.

- Car surfaces are also cleaned and primed. The car parts are cleaned of old paint, preparation is done, and only then the even areas of the car are painted with a spray gun.

After painting, you should carefully inspect the area under oblique lighting to see possible unevenness, drips, and sagging. If any are found, they should be immediately leveled by applying additional layers of paint. This must be done under installed side lighting in order to immediately see and evaluate the thickness of the new leveling layer.

Spray gun - benefits of low pressure

High pressure spray guns are proven tools. They can rightly be called veterans among all painting devices, although they have, in addition to advantages, significant disadvantages. A special feature of such devices is the high pressure of paints and varnishes at the outlet. If the recommended pressure at the inlet should be about 5 atmospheres, then at the outlet you will get approximately one and a half atmospheres. At the same time, the air consumption is small - in some models one hundred liters per minute is enough.

The advantages of HP (High Pressure) systems include a wide angle of paint spread over the surface, as well as a fairly high application speed. But the downsides are more complicated - most often, such systems are criticized for the low percentage of paint material reaching the target surface, since most of the paint simply flies away due to too high pressure. Scattered paint settles in an even layer on all nearby surfaces, so painting in enclosed spaces where there are other tools is not recommended.

In addition, high pressure promotes air turbulence, the flow of which attracts a lot of dust and debris.

All this sticks to the surface, and the only solution after painting is sanding and polishing. HVLP systems are a different matter. Initially, they were created under the auspices of environmental movements, which were concerned about the high level of environmental pollution caused by high-pressure spray guns. The design of low-pressure spray guns is based on a special structure of air channels, thanks to which more than half of the material gets onto the surface being treated and twice as much as when painting with high-pressure systems. The outlet pressure of low-pressure systems is about 0.7 atmospheres, while the inlet pressure is about 3. As a result, the developers killed two birds with one stone - they received an economical tool that is half as harmful to the environment as the previous one.

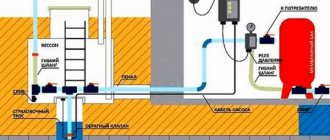

Choosing a compressor

Having a compressor in your garage is generally very useful. It is used not only for painting work, you can connect pneumatic jacks, a pneumatic impact wrench to it, with a compressor you can blow out clogged fuel lines, check connections for leaks, you can simply pump up wheels with it and use it for many purposes and not only as a car enthusiast. So you can use it every day and such a useful unit will definitely not gather dust in the corner.

So, the most popular compressors for painting are piston-type air compressors. They are divided into two types: oil and oil-free. Such compressors are extremely simple and reliable to operate and do not require professional maintenance.

Oil-free piston compressors are usually used for the simplest needs - pumping up tires, blowing out a jet, and finally, painting a garage door. Therefore, we will not consider them as a great assistant in car repair and painting. I will only note that in terms of cost, such oil-free compressors are the cheapest.

Now, let's take a closer look at what piston oil compressors are, what their characteristics are, as well as their differences. They have one thing in common: oil is poured into the electric motor crankcase. Also, compressors are available with direct drive and belt drive. Belt-driven compressors are also divided into two types: single-stage and two-stage. Two-stage ones make less noise during operation and are more productive. Belt-driven compressors are considered more reliable, which is determined by the features of its design.

What characteristics of compressors should you pay attention to when choosing.

- Power supply (220-230V, 380V, mixed - 220/380V)

- Power consumption (kW)

- Productivity (amount of air produced - liters per minute)

- Maximum discharge pressure into the receiver (atm)

- Receiver volume (liters)

Power supply - well, in principle, everything is clear here, if you have three-phase power in the garage, then the choice is obvious, if only 220 volts, then no questions arise either. I recommend monitoring the voltage in your garage using an AC voltmeter. Data should be taken for the morning, afternoon and evening. If the voltage is even and does not drop below 200 Volts, then everything is OK. If the readings jump from 230 to 160 Volts, then stable operation from the compressor cannot be obtained and in this case you should also take care of purchasing a voltage stabilizer.

Power consumption - when choosing, you should again rely on the quality of the electrical network where you will use the compressor. If the network is ancient, and Chubais never repaired it, the wires are thin and consist of twists, then the high power consumption can cause a fairly serious voltage drop and high current, resulting in overheating of the wires and the possibility of a fire. Therefore, when purchasing a high-power compressor, first make sure that the wires running from your garage to the distribution panel are not twisted and have a sufficient cross-section. If it is not possible to do this work yourself or you are not qualified enough, then seek help from a qualified electrician.

Performance is one of the most important indicators in the characteristics of a purchased compressor. It is measured by the amount of compressed air produced, liters per minute. If you are going to paint cars, then you should take into account that when working with various spray guns, air consumption is required, sometimes quite significant. And different spray gun systems have their own requirements for the amount of compressed air consumed. For example, spray guns of the HVLP system (low excess pressure - high air flow) consume from 170 to 550 l/min, depending on the design. Therefore, when purchasing a compressor, compare its capabilities with the air consumption requirements of the spray gun you are going to use. If these requirements are ignored, the compressor will constantly thresh without breathing, the outlet pressure will float, and the unit will overheat, which is not good. Well, the quality of painting will be appropriate. To protect against overheating, all compressors are equipped with a thermal relay that will turn off the unit if overloaded.

The maximum pressure pumped into the receiver is measured in atmospheres (atm), this indicator is approximately the same for all compressors of this type and amounts to 8-12 atm. The output pressure regulator sets the desired value, which can be monitored on the pressure gauge.

The volume of the receiver is measured in liters; for garage and painting work, I do not recommend taking less than 50 liters. Partially insufficient compressor performance can be compensated by increasing the volume of the receiver.

Price: from 600 hryvnia

Paint sprayers for professional use

The HVLP air spray gun is characterized by high volume and low pressure. Such pistols were created in the late 80s of the last century. Their purpose is to protect the environment.

The air channel of the device has a special structure, which is why paint is sprayed like this: at the outlet there is a low pressure, almost 0.7 atm, and at the inlet there is a high pressure, approximately 3 atm. Therefore, the material transfer is 70%. The rest is lost in the air.

In addition, the HVLP spray gun at the outlet has a low speed of paint or varnish.

This property is an advantage of this model, since there is a saving of material at the output.

In this case, a small foggy cloud is formed, but the composition must be sprayed at a close distance from the surface to be treated - no more than 15 cm. This is the main difference between the HVLP sprayer and the LVLP spray gun.

Before buying this pneumatic sprayer for car painting, it is necessary to familiarize the user with the advantages and disadvantages of the device.

Advantages of HVLP paint sprayer:

- High savings in paint and varnish. Almost 70% reaches the surface.

- High performance.

- Does not harm the environment, the formation of a small foggy cloud.

- Doesn't leave any trash.

Disadvantages of the spray gun:

- High air consumption (over 360 l/min). Because of this, powerful and efficient compressor equipment is needed.

- Large diameter air duct.

- Using an air filter. When the compressor operates, water and oil inclusions enter.

- Inconvenient when applied to hard to reach areas. The distance to the surface to be treated is no more than 15 cm.

- Required level of knowledge of a painter. If the application of the material is delayed, drips and layers may occur.

Application of hammer paint

Hammer paint is usually used to paint metal parts. It helps protect the surface from rust and hide unevenness. In addition, when applying hammer paint, a decorative pattern is obtained, which can give the product the appearance of a decorative element.

Hammer paint is easy to use and dries very quickly, which makes its use advantageous for uneven or old metal surfaces. It is often used to decorate car elements and metal furniture parts. When finishing work on wood surfaces with metal parts, hammer enamel is also used.

Although experts recommend using a roller to work with hammer paint, a spray gun can also be used. In this case, there will be no textured pattern, which is quite suitable for painting rusty car parts.

Selecting a spray gun

In order to buy a paint sprayer, you need to know for what purposes it will be intended and with what frequency it will be used. If the work is planned occasionally or by a novice car enthusiast who wants to paint the car body on his own, then a universal LVLP spray gun is suitable. If you need it for professional use, then experts recommend buying an HVLP spray gun.

When choosing a device, focus on the following parameters:

- Tank volume. In inexpensive models, the tank volume is 50 ml. In spray guns with capacious receivers up to 600 ml, the characteristics are much higher.

- Tank location. The container can be in 2 positions: top and bottom. At the top, the paint is supplied under the force of gravity. At the bottom, the suction force of the sprayer itself is created. A spray gun with a lower reservoir is much more convenient. While applying paint with a gun, you can vary it and also place it on the table.

- Engine power. When choosing models, they focus on power up to 1.3 kW.

- Pressure. Basically, it is up to 8 bar. If the pressure is higher, the compressor is switched off. For more powerful and expensive spray guns, the pressure reaches 10 bar.

- Performance. The main indicator that you need to pay attention to. To make the right choice, it is necessary to multiply the performance declared by the manufacturer by a factor of 0.65. Based on the results obtained, you can choose the right compressor.

Compared to HVLP technology, the LVLP spray gun is superior in many respects. It is more practical, versatile, and relatively inexpensive. Buying it is also not difficult due to its prevalence and widespread use.

Nozzle diameter

Nozzles for spray guns are produced in the form of replaceable nozzles. The nozzle diameter affects the size of the material particles ejected from the nozzle. The finer the nozzle opening, the finer the paint is sprayed. For thick, viscous compositions, larger diameter nozzles are needed. Nozzles should be selected for a specific material.

| Nozzle diameter, mm | Spray material |

| 1,7–2,0 | Liquid putty, thick, viscous paint |

| 1,5–1,7 | Acrylic primers |

| 1,4–1,5 | Varnishes, acrylic paints |

| 1,2–1,3 | Base coats (paints with a “metallic” effect, etc.) |

If the spray gun is not equipped with a replaceable nozzle, it is worth choosing the most universal diameter that is suitable for all planned work.

The diameter of the spray gun nozzle affects the type of material being sprayed.

On a note! The most popular nozzles are with an average diameter (1.3–1.7 mm). For example, a sprayer with a 1.5 mm nozzle is best for home repairs, and a 1.4 mm nozzle for painting a car.

If the spray gun is of high quality, it is usually equipped with a set of nozzles with a diameter of 1–3 mm. Often the kit also includes attachments that give different torch shapes.

Recommendations

Comments 8

And I bought Iwata Supernova. Cool thing. But miracles don't happen.

Kirill, hello. Good, judging by the reviews, but not a cheap thing. But the question is, is Iwata’s air consumption as stated? These are, in principle, economical spray guns, but no one writes anything in detail. They bought it and are happy, as they say, without details. I have been associated with Taiwanese STAR spray guns for three years, they are new on the market, no advertising stunts, they earn their money 110 percent. Iwata sounds louder, but always in practice, there are things that are not customary to talk about and clarify. Same thing for SAT. Write a few words about Iwata Supernova

The air consumption of an Iwata supernova is the same as that of a Sata. More precisely, I didn’t measure it, but Ivat’s paintwork dust is the same as the others. The fenka of the supernova with its split nozzle is its small drop. That is, the drops are small but not dry. The torch is very wide. It is pleasant to work with willow wool. But there is NO saving of air and paint.

I pump up my compressor (240 l/min) with real performance, a 100-liter tank, up to 8 atm, turn it off, adjust the operating pressure on the 2.0 spray gun and bleed air through it to 6 atm. I checked several different models, but not one model has a real consumption of 240 liters yet. For WALKOM SLIM HVLP, the flow rate turned out to be within 270 l/min, although it was stated 200. The air leaves in approximately 40 seconds. Many manufacturers make advertising moves. According to Super Nova. Rather, this is a model specifically for varnish. For the base, Iwata has more economical LPH models, at a pressure of 1.1-1.3 bar (if I’m not mistaken). If you need savings for a base for the future, then there are STAR models. The same real savings in material. About the split nozzle, yes, it’s Iwata’s trick. If the design is rearranged onto the red STAR body, you get the same wide torch. They tried to do this and at one time they called the spray gun “SUPER STAR”. There is a video on the Internet. Interesting about spray guns! My spray guns avtoremont-shop.ru/. For the base of a low pressure spray gun they are almost ideal. For varnish, you have to adapt and they will still only be for parts, not for covering the entire car with varnish. Their painting speed is lower. But there are also savings on varnish. I’m glad for your purchase of Iwata, you’ll have someone to ask you about. And take a peek!

Serge, I have two 2.2 kW compressors, several receivers totaling about half a cube. So air consumption is irrelevant. And even after welding, puttying, priming, sanding and pasting, you need a reliable and PREDICTABLE bullet. So as not to think about how to work. I picked it up and went to collect dust. That's why I strangled the toad and paid 25,500 for the supernova.

Yes it is clear. Needs trouble-free painting. But I still invite you to visit. I don't have a car yet. I do some repairs and sell spray guns!

I'll definitely stop by. It's a pity I rarely go out.

Great, I’ll give you the coordinates right away. Yes, this car repair, time, I know, is difficult to find!

It is more convenient to spray paint large and complex surfaces. The spray gun will help you quickly and efficiently paint the ceiling and walls, fences and radiators, car bumpers and old chests of drawers. The main thing is that the tool is of high quality, otherwise it will ruin the whole job. How to choose a pneumatic spray gun?

When purchasing equipment, you need to take into account many factors - the materials that will be sprayed, the desired quality of painting, and the qualifications of the technician. If you have a compressor, then the spray gun should be selected according to its power. Otherwise, you first need to select a paint sprayer, and then a compressor for it.