Sometimes it is necessary to paint many objects, and if we are talking about processing a large area, then using a roller or brush can significantly delay the repair period. In addition, it is not easy to get a beautiful, even result with them. The spray gun is able to distribute the dye over the surface not only quickly, but also evenly and smoothly. The layer turns out beautiful and thin. It is important to choose the right tool to get a quality result. The spray gun for painting a façade house will be discussed in detail below.

What is the difference between a spray gun and a paint gun?

The essence of the spray gun is to supply air, due to which the necessary pressure is applied to the solution. The way the process is carried out provides the basis for obtaining several varieties of the product. Types of spray guns are electric, mechanical and pneumatic.

Visually, a beginner will not be able to understand what the difference is between them; masters know that the difference between the types lies internally in the spraying part. So there is an airless spray gun for thick paint, varnishes. The pace of work and comfort depend on the internal design. So, speaking about the difference between a spray gun and a paint gun, it must be said that it lies in the details of the mechanism.

The essence of the spray gun is to supply air, due to which the necessary pressure is applied to the solution.

How many spray guns should you have?

You can purchase several paint guns for different purposes and materials. There are spray guns recommended specifically for varnish, for primer and for base.

If you can afford to have three spray guns, then this will be ideal. In this case, there will be no problems with particles from the paint that was sprayed before getting into the varnish. Of course, it is not necessary to purchase three different spray guns. There are painters who have one spray gun with a 1.6 nozzle, with which they apply all materials from primer to varnish. This requires more time and effort to thoroughly wash the spray gun after spraying different materials for further use.

The principle of operation of the spray gun

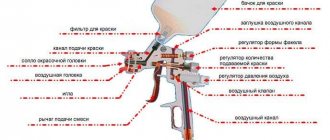

A spray gun is a means of applying liquid solutions to a variety of surfaces. Consists of a tank, pump, trigger, switch button, hose, solution flow regulator. The main purpose is to distribute paint over the surface. Some people wonder what the difference is between a paint gun and a paint sprayer, the answer is nothing. These are two names for the same type of equipment.

It can also be used for spraying other liquids: disinfectants, primer solutions, spraying preparations for plants. The main thing is to select solutions whose particles can pass through the nozzle, and the viscosity level suits its characteristics. Here it should be noted how a spray gun differs from a spray gun, for the possibility of using the device not only for paint and varnish products, but also for other liquids of suitable viscosity, and such equipment is called a spray gun. The principle of operation involves the combination of paint with air, which leads to the transition of the coloring matter into fine dust covering the wall.

A spray gun is a means of applying liquid solutions to a variety of surfaces.

The main elements of any HVLP system: spray gun, turbine and hose

These three integral parts of HVLP systems, working in concert, produce a thin and uniform coating film on the surface. Of course, the main elements are the atomizer and the turbine. A powerful turbine will not be able to smooth out the imperfections of the atomizer, and the best atomizer will not work well in conjunction with an anemic turbine. But a crumpled or damaged hose can reduce the effectiveness of the entire system to zero. Let's consider the properties of each element separately.

HVLP system Turbinaire 1537 GT | HVLP system Campbell Hausfeld HV 3500 |

Low pressure spray guns

There are a large number of types of pneumatic tools on sale, and beginners do not understand which option is best to choose. Among all the variety, many professionals highlight a low-pressure spray gun. This is due to obtaining high quality painting and economical consumption of the product. There are two types of HVLP and LVLP.

Among all the variety, many professionals highlight a low-pressure spray gun.

High volume (HVLP)

The name of this type of low pressure sprayer stands for high volume, low pressure. This is an improved version of the first devices with a similar principle. The first models were characterized by increased paint consumption, and they also polluted the surrounding space.

When using this equipment, the pressure at the inlet is increased, and at the outlet it is reduced significantly. The law directs manufacturers that material carryover should not be lower than 65%, usually this figure is 75%.

Due to a decrease in outlet pressure, the length of the paint torch is reduced. It is recommended to leave the length from the nozzle to the base being processed no more than 10-15 centimeters.

When using this equipment, the pressure at the inlet is increased, and at the outlet it is reduced significantly.

Low Volume (LVLP)

This type, the most modernized version of the first sprayer, the abbreviation from English translates as - low volume, low pressure. The economy of the dye is surprising, and it is also very convenient to work with.

For the spray system to operate, less air pressure is required, and its reduction at the outlet will be approximately halved. The quality of the resulting paint layer does not suffer from this, and its size is not reduced. The transfer of funds for such devices is 75-90%.

Thanks to improvements in the tool, LVLP construction can be worked at a distance of 20-25 centimeters from the object. And this makes the painting process even easier, and less skill is required from the master. A good option for beginners.

The economy of the dye is surprising, and it is also very convenient to work with.

Purpose of the tool

The decision to use such a tool in their own household was made by a fairly impressive number of craftsmen. After all, to do this, it is absolutely not necessary to spend money on expensive products from famous brands: you can build something you need in your household with your own hands, using an ordinary household vacuum cleaner.

When planning to carry out quick, high-quality and easy painting using a special paint sprayer, you should carefully study the quality of the component parts of the device. Considering the fact that processing with such a device is carried out, as a rule, over large areas, the reliability and durability of the device as a whole and its individual parts becomes the main requirement when choosing the right model.

You should purchase paint guns based on the work to be carried out. Qualified paint and finishing specialists can often use up to five devices simultaneously, due to the characteristics of the surfaces being treated, the materials being sprayed and the size of the objects. You should choose a suitable product only after studying all the requirements for a gun for painting work.

Pros and cons of low pressure

Modern spray guns for wood varnish or other types of paints and varnishes are distinguished by their low consumption of paint and varnish products, the safety of working in nature, and do not harm it. It is comfortable to work with them; a lot of practice is not required from the master. But the tools also have disadvantages.

First of all, it’s worth considering the advantages that professionals note in comparison with a high-pressure spray gun:

- Low requirements for compressor performance – minimum 150 l/min;

- Low consumption rates, 75-90% of paintwork materials are transferred to the surface;

- Improved performance;

- An excellent indicator of the quality of paint distribution and the creation of torch spots with small edges, without the formation of blur;

- Comfortable work even when working with large areas;

- Resistant to changes in air pressure supplied through the compressor.

Disadvantages noted:

- The torch turns out to be of small diameter, but does not spray much around the edges;

- Difficulty distributing viscous solutions;

- The whimsicality of setting up the device before painting.

Modern spray guns for wood varnish or other types of paints and varnishes are distinguished by their low consumption of paint and varnish products, the safety of working in nature, and do not harm it.

Paint spray systems

To understand the differences between the types of paint guns, let’s consider, in a simplified way, the principle of spraying. Compressed air from the compressor under pressure enters the spray gun, paint from the barrel flows through another channel, passing through the air cap, it splits the paint coming out of the nozzle and forming a torch. The pressure with which the spray gun sprays the paint material determines the type of spray gun. Below are the main spray systems by which spray guns differ.

- HP (High Pressure) – high pressure.

- HVLP (High Volume Low Pressure) - high volume, low pressure.

- LVLP (Low Volume Low Pressure) - low volume, low pressure.

- HTE (High Transfer Efficiency) – High transfer efficiency.

HP system spray guns

This is an outdated spray system. Paint guns of this type have been used for a long time to paint cars in body repair shops.

For their operation, an input pressure of 3–4 atmospheres is required. Actually, at the moment of spraying the pressure is approximately the same. These spray guns require a small volume of compressed air. They do not require a very powerful compressor to operate. HP system spray guns are capable of creating a wide spray pattern and uniformly applying the paint material. The main disadvantage of such spray guns is the low coefficient of transfer of sprayed materials to the surface. When sprayed, such spray guns produce a paint mist that does not fall on the surface to be painted. Thus, 30–45% of the sprayed paint forms a paint coating, and the remaining 55–70% settles outside the painted surface.

So, to summarize, we will describe the advantages and disadvantages of spray guns with the HP spray system.

Advantages:

- No high performance compressor required.

- A wide torch is formed, which facilitates uniform application of the paint and varnish material.

- High speed of application of paint and varnish material.

Flaws:

- Low coefficient of transfer of sprayed materials to the surface to be painted.

- The high pressure of spraying raises dust in the workshop, which then settles on the painted surface.

HVLP spray guns

HVLP (High Volume Low Preassure - high volume, low pressure). Spray guns of this type have become widespread and are now successfully used by painters when painting cars. These paint guns use a large volume of air to operate and spray at low pressure. HVLP spray guns with a sufficiently high input pressure (2.5 - 3 atmospheres) spray paint materials at low pressure (less than 1 atmosphere). Due to the low spray pressure, a large percentage of the sprayed paint material is transferred to the surface to be painted (about 75%).

Spray guns of this type have proven themselves well when applying paints with metallic and pearlescent effects.

Let's look at the advantages and disadvantages of HVLP paint guns.

Advantages:

- High percentage of transfer of paint and varnish material to the surface to be painted when sprayed.

- Low fogging when spraying.

- Low spray pressure does not raise much dust in the painting area.

- High performance.

Flaws:

- A powerful compressor is required to constantly supply a large volume of air to operate the spray gun.

- It is required to use a hose to connect the compressor to the spray gun with an increased diameter.

- It is required to apply paints and varnishes at a short distance from the surface. This requires a certain level of professionalism from the painter in order to paint without smudges.

Low pressure spray guns LVLP system

LVLP (Low Volume Low Pressure - low volume, low pressure). Spray guns of this spray system were invented to eliminate the disadvantages of HP and HVLP sprayers. Different manufacturers may have different abbreviations for paint guns with a similar spray system. For example, SATA has a similar technology called RP (Reduced Pressure), DeVILBISS has GTI PRO, Walcom has GEO and HTE (High Transfer Efficiency). The purpose of these spray guns is to combine low air consumption with a high transfer coefficient of paint and varnish material.

These sprayers operate at an input pressure of 1.6–2 atmospheres, and atomization is carried out at a pressure of 0.7–1.2 atmospheres. LVLP spray guns have reduced air consumption compared to HVLP spray guns. This allows the compressor performance requirements to be reduced. In this case, the percentage of transfer of paints and varnishes to the surface to be painted during spraying is about 70%.

LVLP paint guns have proven themselves well when applying all types of paints and varnishes.

So, let's list the advantages and disadvantages of sprayers with an LVLP spray system.

Advantages:

- It does not require too much air volume when operating the spray gun (about 200 l/m is required).

- High percentage of transfer of paint and varnish material to the surface to be painted.

- Due to the low spray pressure, it does not raise much dust in the painting area.

- Low fogging when spraying.

- High performance.

- No dependence on pressure drop.

Flaws:

- Low Spray Speed

- Creates a smaller spray pattern than HVLP spray guns

How to choose a low pressure spray gun

There are many sprayers for varnish and other paint products on the market, and they can vary greatly in price. If repairs are not done often, and you plan to purchase equipment for one-time use, then there is no point in choosing expensive options. Given the lack of experience, it will not be possible to distribute paint as beautifully as possible at first with any type of equipment - expensive or cheap.

If the task is to become a professional and constantly perform painting work, then you should choose a high-quality spray gun. When purchasing, both a novice and a master should pay attention to the following parameters:

- The ratio of compressor performance to air consumption level, the compressor should produce 20% more;

- The diameter of the nozzle, this takes into account the viscosity of the material; for varnishes it should be larger.

If repairs are not done often, and you plan to purchase equipment for one-time use, then there is no point in choosing expensive options.

Making your own sprayer

You can build a device for spraying on a car surface or any other surface with your own hands. In this case, you should make sure that the selected vacuum cleaner model is optimally suited for use as a compressor. The ideal option would be household vacuum cleaners with a reverse blowing mode, which allows you to connect the hose to the other side of the vacuum cleaner. Such features are typical for old Soviet vacuum cleaners: “Whirlwind”, “Rocket”. It is important that the vacuum cleaner has pressure at the required high level, and upon completion of the work or in the event of a malfunction, it can be repaired quite easily.

Old-fashioned models of vacuum cleaners come with their own attachments, changing which allows for effective spraying. Converted vacuum cleaners can do a great job of DIY car painting.

By following simple recommendations for transforming an old vacuum cleaner, you can not only make the necessary device with your own hands, but also perform a whole range of finishing or repair work:

- You need a blank made from a small piece of polystyrene foam, which is given the desired shape.

- The shape of the foam piece and the neck of the liquid container must match.

- Holes are drilled in the foam, one of which should be made on top of the workpiece, where the rod will be placed. It is permissible to use a plastic pen body as a rod.

- A horizontal hole is also made and drilled where the rod is installed.

- Bottle caps are used as a stop in the vertical hole.

A paint spraying tool made using a vacuum cleaner is not intended for large-scale work and prolonged manipulation. You can paint car parts or other small objects.

By acquiring such a tool at home, you can quite easily carry out paint manipulations, ordinary painting work, and cope with other tasks that go beyond the scope of repair procedures with your own hands.

The best pneumatic spray gun using spray technology

What equipment is best to choose for coloring will be described now. Above we talked about the features of LVLP and HVLP type spray guns. There is also their predecessor, which was also mentioned by HP.

The last option can be purchased if a beginner is working, it will be easier for him to handle, but in this case more coloring matter will be spent and the quality of the dispersion will be low. For this reason, polishing will be necessary. If the quality of the coating is not so important, then HP is the best option.

LVLP is popular among professionals due to its ability to significantly save colorant and work at close range. And the third type is an intermediate option among these two types.

LVLP is popular among professionals due to its ability to significantly save colorant and work at close range.

Expensive segment spray guns

Manufacturers of professional spray guns, which are leaders and occupy the market segment of expensive premium paint sprayers, are described below. These are not the only brands of expensive professional spray guns, but they are the most famous.

DeVilbiss

DeVilbiss is a British company that has been manufacturing spray guns for over 100 years. In many countries, professional painters use paint sprayers from this company. DeVilbiss spray guns are lightweight and ergonomically designed.

DeVilbiss has recently had its own representative office in Russia and you can easily purchase any model of spray gun and accessories.

SATA

The spray guns of this company are developed by German engineers. They are of high quality and have their own developments. The paint sprayers of this company are characterized by high wear resistance, which is important for continuous use in workshops.

IWATA

Anest Iwata is a Japanese company that has been around for over 80 years. Produces very high quality spray guns. Has its own innovative developments. The model range includes paint sprayers with a side-mounted tank that can be rotated. By changing the angle of the barrel, it is very convenient to paint hard-to-reach places, as well as horizontal surfaces, and you are not afraid that the paint material will spill out or stop spraying due to the unstable supply of paint from the barrel.

Having personal experience of using a spray gun from this company, I can say that the gun is easy to set up, applies any paint and varnish materials perfectly and copes well with painting with a “transition”.

It is important to know the diameter of the nozzle (nozzle) of the spray gun

In order for the sprayer to apply the solution, the diameter of its nozzle must be suitable for the selected paintwork material. There is equipment with interchangeable nozzles, which allows you to use them for different products.

For household needs, a 1.5 mm nozzle is usually chosen, which is suitable for many types of paints.

In order for the sprayer to apply the solution, the diameter of its nozzle must be suitable for the selected paintwork material.

Nozzle size selection

The nozzle (paint nozzle) has a certain size. The paint material flows through the nozzle, and the tip of the needle is inserted into it, regulating the flow of paint. The needle is moved back and forth by a trigger. When the trigger is fully released, the needle is pressed by a spring and hermetically closes the nozzle. For materials with different viscosities, nozzles of different diameters are used.

- 1.2 – Local painting.

- 1.3 – 1.6 – application of base and varnish. Also suitable for applying water-soluble paints.

- 1.4 – 1.7 – application of varnish and acrylic.

- 1.6–2.2 – priming

- 2.5–3.0 – application of liquid putty.

These are general rules that do not have to be followed strictly. Some painters choose one nozzle size and apply any materials perfectly.

Applying primer requires a larger nozzle, otherwise you will have to dilute it very thinly, which is not advisable. For acrylic primer, its filling capacity is important, and with a large amount of thinner it decreases.

Spray gun tank – Upper or Lower, Plastic or Metal

The master himself decides whether the tank will be upper or lower. Convenience is important here. When it's at the bottom, the view is not blocked, but when it's at the top, the paint is completely used up.

The material chosen is metal; if the paint contains solvents, the plastic will collapse under their influence. But the device is lighter than plastic.

Metal is chosen as the material for the tank; if the paint contains solvents, the plastic will collapse under their influence.

Spray guns from China

Many Chinese manufacturers make uncertified copies of spray guns from well-known manufacturers. Most often they turn out to be similar in appearance, but not in quality and characteristics. Some Chinese paint guns can be used to paint more or less normally, but they are characterized by instability in operation. As you can imagine, many Chinese manufacturers are reducing the cost of production technology for paint sprayers.

Among the budget spray guns made in China, we can note the products of the company VOYLET .

They produce paint sprayers of various models, intended for both industrial enterprises and car repair shops. They have acceptable product quality. VOYLET spray guns meet the requirements of modern standards for applying various paints and varnishes.

Auarita paint guns , which have positive reviews, given their inexpensive cost and Taiwanese STAR .

Saving Tips

To avoid wasting too much paint, it is necessary to dilute it in advance to the required level of viscosity. Here they follow the instructions from the manufacturer.

Before work, the air supply level, torch size, and paint supply are also adjusted. All these parameters depend on the brand of the spray gun, so the settings are tested in advance in an inconspicuous area.

To avoid wasting too much paint, it is necessary to dilute it in advance to the required level of viscosity.

A spray gun can significantly reduce paint consumption, as well as the time for repairs. When choosing equipment, it takes into account the experience of the master, for what purposes it will be used and the budget.

Turbine HVLP system

An HVLP turbine is essentially a type of turbine used in vacuum cleaners, but it blows air in the opposite direction. Several fans placed in series, called stages, pump a large volume of air at relatively low pressure. The more stages in the turbine, the greater the air flow (measured in liters per minute - l/min) and the better the degree of paint atomization. However, turbine performance (airflow and pressure) is affected by many other factors, such as engine speed or fan blade size, so turbines should not be compared based on the number of stages alone.

A suspension of dust particles in the air will certainly affect the quality of the finishing coating, which is why different HVLP systems use one or another air purification method. Some have one filter, others have two filters (one for cleaning the engine cooling flow, and the other for the air line). ApolloSpray uses high quality filters on every air duct.

Users of HVLP systems often complain that turbines are too noisy, and we cannot but agree with this remark. The sound they make is similar to the noise of a working vacuum cleaner, with which they are closely related. The Fuji Q3 is a pleasant exception: you can have a quiet conversation while standing next to a running turbine.

The best HVLP systems also cope with undiluted compounds

Finishing compounds can be thin, like water (for example, stains), or thick, like honey (for example, paints). The thickness of the liquid is called viscosity, and to obtain a quality result it should be taken into account first. The higher the viscosity, the more air is required to atomize the liquid. HVLP systems vary in their ability to spray viscous formulations without prior thinning.

Measuring the viscosity of the coloring composition

Some systems handle spraying undiluted finishing compounds that are simply poured into the tank, but most require first reducing the viscosity of the paint. To ensure that the compound has the optimal viscosity for spraying, dip the viscometer into it and note how long it takes for the liquid to flow into the hole at the bottom. If it takes longer than indicated in the instructions for the HVLP sprayer, you will need to add a solvent to the composition.

To measure the viscosity of the composition, most systems are equipped with a viscometer. Campbell Hausfeld models come with a viscosity bar, while the Accuspray does not come with any measuring equipment. Viscosity changes with temperature (the higher the temperature of the composition, the less solvent is required), so we carried out all tests in a room at an air and composition temperature of +21ºС. While all systems are capable of spraying stains and undiluted oil-based varnishes, only three models—Accuspray, Fuji and Turbinaire—can apply viscous compounds without adding solvents.

All models with nozzles and needles are supplied complete with the system. Most manufacturers offer optional kits consisting of a needle and nozzle that allow you to apply more viscous compounds without thinning. If you frequently work with paints that are too viscous for the standard kit, these add-on kits can come in handy.

These articles may also be of interest to you:

- Airbrushes and spray guns - spray painting

- Replacing the siphon and sink drain

- Installation of facade blocks

- How reliable is a glass ceiling or glass floor?