Benefits of using a spray gun

- Significant reduction in painting time. The spray gun increases work productivity and reduces time spent by almost half.

- Applying a uniform and thin layer of paint reduces material consumption and ensures quick drying of the ceiling and walls.

- No streaks or drips - the dispersion is distributed on the surface in an even layer and, unlike brushes and rollers, does not leave any marks.

- Ease of operation and simplicity of the mechanism, thanks to which you can easily carry out high-quality finishing of premises with your own hands.

Spray gun design

Manufacturers of spray guns strive to ensure maximum ease of painting, so they supply a set of replacement nozzles. Nozzles or nozzles have different diameters from 0.5 to 3 mm, which significantly expands the possibilities of using the tool. The nozzle can be selected depending on the required spray intensity; the smaller the nozzle diameter, the lower the air pressure, so for working with viscous paints it is recommended to use larger diameter nozzles.

Important! A spray gun for water-based paint copes better than other devices with painting ceilings of complex configurations, with relief elements or stucco.

Applying water-based paint with a spray gun

Water-based paint has many advantages, but is it possible to save it when painting various surfaces?

Much depends on the conditions of the room in which repairs are required, since temperature and humidity play an important role when processing various surfaces. A diluted water-based paint can be used to paint brick, plaster, wood, concrete or metal.

Eco-friendly and easy to use, water-based paint is a viscous and relatively sticky liquid. The quality of coloring and the shelf life of the water-based coating depend on the method used to apply this composition.

Various types of sprayers are suitable for painting surfaces with water-based paints. To understand which spray gun is better, you need to study their technical characteristics.

The sprayer is a convenient device that you can make yourself. Spray guns for use in household and industrial environments are sold in specialized stores. Professionals recommend purchasing spray bottles to accurately and evenly apply paint to the surface.

Painting the ceiling with water-based paint using a spray gun allows you to significantly save the material used for painting, the consumption of which is significantly reduced. Water from the surface evaporates quickly after applying the water-based emulsion.

After this, a coating of polymer film remains, which can be resistant to mechanical damage if the paint is applied correctly with your own hands using a spray device.

The use of a spray gun for water-based paint both for repairs and for domestic needs is due to the long service life of the coating, which is about 15 years.

Before painting with a water-based composition that has significant viscosity, it is necessary to study the technology of applying paint to the surface of a wall or ceiling.

How to choose a spray gun

The modern market offers a huge range of spray guns, so everyone can choose the best option for painting walls and ceilings with their own hands. With such variety, it is very important to choose the right professional spray gun for painting; for this you should know a few rules.

First of all, it is recommended to pay attention to the material from which the device body is made. The best solution would be a device with an aluminum body and anti-corrosion nickel coating. Housings made of plastic have less weight, which certainly makes painting the ceiling walls more convenient, but unlike the previous option, the plastic housing is short-lived. The holes in the spray bottle cap can be made of aluminum, brass or stainless steel.

Spray guns differ in the location of the paint tank and the material used to make it. In modern models, the tank can be located at the top or bottom, which does not have a significant impact on the quality of painting. As for the material, metal tanks are easier to wash, while transparent plastic ones allow you to control the consumption of water-based paint.

Important! For greater convenience, the sprayer body with the tank located at the bottom must be held horizontally. This is problematic when painting ceilings, so in this case it is better to choose a model with a lower tank.

The spray gun for water-based paint is available in three varieties, which differ in their operating principle:

- manual;

- electric;

- pneumatic.

It is important to know the diameter of the nozzle (nozzle) of the spray gun

As you may have realized, spray technology is not the only thing to consider.

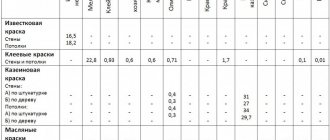

This pneumatic tool has such a parameter as the diameter of the nozzle (nozzle). It must match the density of the material to be applied. Everything is simple here - use the table:

| Nozzle diameter | Application material |

| 1,7-2,0 | Putty, thick materials |

| 1,5-1,7 | Acrylic primer coatings |

| 1,4-1,5 | Acrylic paints/varnishes |

| 1,2-1,3 | Base coats, metallic paints |

Spray guns can be either with monolithic tips or with replaceable nozzles.

For household needs, nozzles with 1.5 mm nozzles are the most popular - they are suitable for almost all types of paint coatings and provide good speed and quality of painting.

Characteristics of hand-held spray guns

The hand-held spray gun has a simplified design, which includes a tank with a built-in pump that creates pressure, and a tube with a hose for spraying paint on the surface of the ceiling and walls. The manual device is the most budget-friendly, but it is quite difficult to work with it, since its resource is limited by the amount of compressed air, and after every 5 minutes it is necessary to replenish it with a hand pump. Also, a significant disadvantage of this device is the large dispersion of the surface being painted, to reduce which it is recommended to use high-quality water-based paints and control their viscosity during the painting process.

Despite some difficulties in use, with this spray gun you can paint a surface area of up to 250 sq.m. within an hour.

Operating principle of traditional spray guns

The operating principle of traditional guns is based on the fact that air is supplied to the spray head of the gun under high pressure.

The paint and varnish material is drawn out of the spray gun nozzle mainly under the influence of rarefaction arising in the air flow escaping from the spray head. The air speed in the nozzle approaches the speed of sound.

The strong impact of air on the paint and varnish material breaks it into many tiny droplets, which are then transferred with the air flow to the surface to be painted.

When you press the trigger lever of the spray gun, the air valve first opens, allowing the supply of compressed air to the head, and only after that the locking needle of the gun moves. This prevents paint from forming on the head.

| Rice. 2. Design of a traditional spray gun |

Color coding

Attention! All Graco recommendations below are based on the American market using American materials that are known to be of high quality and stability. It is not possible to directly apply the recommendations to materials produced in the CIS countries due to the noticeably unfavorable quality of these materials.

Green and blue nozzles: ██████████████████████████████ ███████ ████████ ███████████████

| Finishing decorative paints | 008 — 010 |

| Lucky | 010 — 014 |

| Stain, polish, mordant | 012 — 014 |

| Oil paints, enamels | 012 — 015 |

| Latex paints | 015 — 019 |

| Acrylic paints | 015 — 019 |

| Silicate paints | 015 — 019 |

| Emulsions | 017 — 021 |

| Silicone paints | 021 — 025 |

| Multicolor (mosaic paints) | 023 — 025 |

| Block fillers | 023 — 025 |

| For large-scale projects | 025 — 031 |

Brown nozzles: ██████████████████████████████

| Block fillers | 027 — 031 |

| Fire retardant materials | 029 — 035 |

| Polymer putties | 029 — 041 |

| Elastomers | 027 — 033 |

| Mastics | 041 — 047 |

| Epoxy materials | 043 — 061 |

| Bitumen with fibers | 047 — 053 |

| Bitumen | 031 — 071 |

| Mineral paints | 027 — 033 |

Features of electric sprayers

An electric spray gun, compared to a manual device, greatly simplifies painting walls and ceilings with your own hands, especially for those who have decided to do such work for the first time. In addition, this device is indispensable for finishing the ceiling - it is characterized by high performance and ease of use.

The device operates on 220 V AC power and does not require auxiliary equipment for its operation, as is the case with a pneumatic sprayer. Painting can be done in two ways: airless spraying and low pressure spraying, the first option being the most common. The manufacturers of the device have adjusted the diameter of the nozzle so that the work is as efficient as possible, so you don’t have to worry about the quality of the jet.

In its design, an electric spray gun resembles a hair dryer, where a spray module is located at one end, and a paint container is attached to the other. The main disadvantage of an electric sprayer is the need to dilute acrylic paints in water, as a result of which the viscosity of the composition decreases, and several layers of material have to be applied to the surface.

Spray selection criteria

The spray gun works on this principle. Compressed air enters the device, passes through the nozzle and turns the paint into many particles that make up the dispersion torch.

Hand-held devices are used for painting small bedrooms and kitchens. They are designed for long-term use. For large rooms, it is recommended to choose a construction tool equipped with a compressor.

The device body is made of aluminum alloy, which increases resistance to mechanical damage. Before starting work, check the tightness of the tank, lubricate the cylinder and sleeve with oil.

When choosing an electric spray gun, you should focus on products from Bosch, Elmos, Wagner, Paint Zoom, Black and Decker. When spraying water-based emulsion, the decisive factors for high-quality coating are the size of the nozzle and the optimal air pressure of the electric tool.

Manufacturers of spray guns powered by mains power adjust the nozzle diameter to ensure efficient operation of the devices. The cost of such devices depends on the operating pressure range. Branded products cost from 6 thousand rubles.

Specifics of using a pneumatic spray gun

A pneumatic sprayer is the most effective option not only for water-based paint, but for all paint materials. A professional spray gun allows you to process about 400 sq.m. within an hour, but at the same time its cost is significantly higher than its electric and manual counterparts.

The pneumatic apparatus operates using a compressor, which provides a continuous supply of high-pressure compressed air, mixing it with paint and further spraying it onto the surface of the walls and ceiling. Convenience and ease of use make this device an ideal option for both professional finishers and beginners who decide to do the repairs themselves. Before starting work, it is necessary to prepare the material for painting; for this, water-based paint is diluted with water and the resulting composition is stirred well.

Advice! If you do not plan to paint walls and ceilings in a large room, and the work is one-time in nature, then it makes no sense to purchase an expensive pneumatic sprayer; in this case, you can use a conventional manual device.

And some more tips:

- For convenience and more delicate work, choose spray guns equipped with adjustments - air flow, paint flow, and torch shape. For example, adjusting the spray pattern on your paint sprayer will help achieve wider coverage.

- Working with a paint sprayer requires careful cleaning of the air leaving the compressor from oil, which will inevitably be in it. If your compressor is not oil-free, you need to take care of cleaning the air from oil - install a filter at the outlet

Having replenished your knowledge base, you can safely go for a spray gun. To consolidate, better understand and remember, we recommend that you watch a specially prepared video that will help you determine which spray gun is better:

How to use a spray gun

In the process of using a spray gun, there are some nuances that affect the quality of work and require special attention:

- When painting the ceiling with your own hands, you cannot keep the device in one area for a long time, otherwise drops will appear in this place, which will disturb the aesthetics of the coating.

- The stream of paint should be clearly perpendicular to the base, since the slope will increase the consumption of paint, which does not fall on the walls, but is splashed in the air and settles on objects located in the room.

- Painting must be done in a circular motion, constantly checking how evenly the paint is applied.

- Do not apply a subsequent layer to a wet surface. The drying time of the paint is at least 5-7 hours, and in the case of water-based compositions - up to 12 hours.

- Before painting, it is necessary to thoroughly clean the base, remove small particles of dirt, dust and oil stains. If you follow the technology, using a spray gun will ensure high-quality DIY repair work and will help significantly save paint.

Table 1. Selection of airless nozzles

| Applying topcoats or primers | Standard coatings | Industrial coatings | ||||||||||||||||||||

| Nozzle in inches | 0.007 | 0.009 | 0.011 | 0.013 | 0.015 | 0.017 | 0.019 | 0.021 | 0.023 | 0.025 | 0.027 | 0.029 | 0.031 | 0.033 | 0.035 | 0.037 | 0.039 | 0.041 | 0.043 | 0.045 | 0.047 | 0.051 |

| l/min | 0.2 | 0.3 | 0.5 | 0.7 | 0.9 | 1.2 | 1.5 | 1.8 | 2.2 | 2.5 | 3 | 3.4 | 3.9 | 4.4 | 5 | 5.6 | 6.2 | 6.8 | 7.5 | 8.2 | 9 | 10.67 |

Another important parameter influencing the choice of nozzle size is the viscosity of the material applied by the airless spray apparatus. In general, the choice of nozzle is as follows:

| Nozzle size | Viscosity of the material, type of composition |

| 0,007”-0,011” | Primer, varnishes, water stain, coatings with low viscosity close to water |

| 0,011”-0,013” | Low viscosity pigmented paint materials, latex paints |

| 0,015”-0,019” | Acrylic and oil paints, PF type paints, two-component EP type |

| 0,019”-0,023” | Facade paints, anti-corrosion epoxy highly filled materials, zinc-filled compounds such as Zinol, Zinotan, fire retardant materials, chalk and whitewash |

| 0,023”-0,035” | Thick fire retardant compounds such as Vup2, waterproofing materials such as TechnoNIKOL, putty |

| 0,031-0,051” | viscous, paste-like compositions, ultra-viscous or viscous fire retardant materials, bitumen or polymer waterproofing, putties for airless spraying |

What affects nozzle wear?

The main thing is abrasive particles in the paint material; the more such particles, the faster the nozzle wears out. The abrasiveness is especially high in homemade compositions used for painting with lime or whitewash. To reduce wear of the nozzles, a filtration system of the painting apparatus is used. Also, an important factor influencing the wear of nozzles is the operating pressure at which materials are atomized - the higher the pressure, the faster the wear occurs.

Guided by the rules presented above, it is possible to independently select a nozzle for airless spraying.

HVLP spray gun - low pressure

HVLP - from the English words High Volume Low Pressure, translated as “High flow at low pressure.” They appeared as a result of tightening environmental laws in the United States and the European Union. Hvlp spray guns allow you to work at low pressure, which increases paint transfer to the part by up to 65% and produces almost no “fog” than conventional high-pressure guns. Paint consumption is also significantly reduced.

The disadvantages of hvlp are high air consumption; a high-performance compressor, hoses and quick couplers of the required diameter must be used. Air consumption is about 350 liters per minute. Also, when beginners use hvlp paint sprayers, the likelihood of smudges and sagging increases due to operation at low pressure.

HVLP is one of the most popular systems used in the production of spray guns..

Also worth noting is RP

(Redused Pressure) reduced pressure. Can only be used by Sata. Designed for applying varnish or acrylic.

Paint spray systems

To better understand the difference in the types of spray gun, consider the simplified principle of operation when spraying. Compressed air comes from the compressor under pressure. Next, in the spray gun, the air is combined with the paint coming from the barrel. Combining in the air cap, the paint is split by air and a torch is formed at the outlet of the nozzle.

The type of spray gun determines the pressure with which the paint material is sprayed. Below are the most used spray systems by which spray guns differ.

- HP (High Pressure) - high pressure.

- HVLP (High Volume Low Pressure) - low pressure, high volume.

- LVLP (Low Volume Low Pressure) - low pressure system, low volume.

HP system spray guns

The system is long outdated. Spray guns of this type have been used in auto body repair shops for a long time. For stable operation of the device, a pressure of 4 atmospheres is required. At the moment of spraying, the pressure in the nozzle should not exceed 3 atmospheres. Such a device requires a small volume of compressed air to operate; the compressor is not very productive.

The HP system spray guns form a wide spray, and the paint and varnish material is applied evenly. The main disadvantage is the low coefficient of transfer of paints and varnishes to the surface. That is, when spraying, a mist is formed, as a result of which some of the materials do not reach the surface. Thus, only 45-50% of the sprayed material covers the surface, the remaining 50-55% does not settle on the surface.

Advantages: high speed of painting surfaces; low-power compressor, wide torch which forms a uniform application of the material.

Disadvantages: low transfer coefficient of sprayed materials to the surface; Also, increased pressure can contribute to the raising of dust during spraying, which can settle on the surface being painted.

Read also: How to read single line electrical diagrams

HVLP spray guns

HVLP spray guns are characterized by low pressure and high volume, they are very common nowadays and are used when painting cars. The power of the spray gun depends on the compressor itself. Guns use a huge volume of air during operation, while spraying takes place at a fairly low pressure. Due to the low pressure during spraying, a large percentage of the material falls directly on the surface to be painted (about 80%).

Electric spray guns of the HVLP system have proven themselves well when coating with paints with Mother of Pearl or Metallic effects. Like all paint guns, spray guns of this type have their advantages and disadvantages.

Advantages: these include a good percentage of material transfer. Low level of fog formation during painting. Low pressure when spraying, will not raise a large amount of dust. High performance is also inherent in mini-pistols.

The disadvantages will include a high-performance compressor, which will need to be maintained in order to produce large volumes of air during operation. The need to use a large diameter hose to connect the compressor to the spray gun. When painting, paint and varnish materials must be applied at a short distance from the surface. The process requires a high degree of professionalism from the painter in order to carry out painting without smudges.

LVLP system spray gun

LVLP - low volume, low pressure. A variation of the automotive spray gun was developed in order to avoid the disadvantages inherent in the HP and HVLP spray guns.

Different manufacturers may have different abbreviations for LVLP system guns. For example, SATA has the same technology called RP (Reduced Pressure), DeVILBISS has GTI PRO, Walcom has GEO and HTE (High Transfer Eficiency). The purpose of using such devices will be to combine low air flow with a high material transfer coefficient.

Such sprayers operate at an inlet pressure of 1.5−2 atmospheres. Spraying is possible at pressures from 0.75 to 1.25 atmospheres. LVLP systems have low air consumption when compared to HVLP. Thanks to this, it is possible to lower the requirements for the production of compressors, which makes them more budget-friendly. The percentage of material transfer will be about 75%. Painting machines of this type have proven themselves to be excellent when applying absolutely any paint and varnish materials.

Advantages: does not require a large volume of air during operation. During painting you will need about 280 liters per meter. Quite a high percentage of material transfer to the painted surface. Due to the low pressure that occurs during spraying, there will be no dust in the room where painting is taking place. Low spray mist and high performance. The gun can be adjusted and configured for almost any material: putty, acrylic, varnish, etc.

Specialists and car painters using spray guns of the LVLP system did not find any significant shortcomings compared to other systems.

Spray guns with a lower tank. There are guns that use a large container for the material; they are inconvenient when painting horizontal surfaces.

How to decide which spray gun to choose for painting a car? If your goal is to paint all the time, for example, in your own car repair shop. It is better, having the appropriate budget, to purchase a Premium class spray gun, that is, take a good, proven pistol. You can choose one of the brands of the high expensive segment, since you will have to do daily work and it is important that the spray gun serves you as long as possible.

The HVLP spray gun has a nozzle size of 1.5 mm and is quite successfully used when applying various types of paint and varnish products. If you need to use a primer gun, then it is better to take the Italian Record 220 with a 2.3 mm nozzle. This nozzle will be enough even for using liquid putty.

As an option, you can buy a cheap, good quality gun with a nozzle size that will be suitable for varnish, paint and primer. With its help, you can take the first steps in mastering the science of painting.

Only later, when you thoroughly understand all the intricacies of the work. Choose for yourself the spray gun that will be most convenient for you and close in technical parameters, and leave the old one and use it as a primer. It is important that the compressor fits the spray gun. Try to properly adjust the operation of the spray gun so that the material does not spread and is applied evenly.

Read the instructions carefully, watch video tutorials, consult with experts, and then the process of painting a car will bring you pleasure and, possibly, income.

It is more convenient to spray paint large and complex surfaces. The spray gun will help you quickly and efficiently paint the ceiling and walls, fences and radiators, car bumpers and old chests of drawers. The main thing is that the tool is of high quality, otherwise it will ruin the whole job. How to choose a pneumatic spray gun?

When purchasing equipment, you need to take into account many factors - the materials that will be sprayed, the desired quality of painting, and the qualifications of the technician. If you have a compressor, then the spray gun should be selected according to its power. Otherwise, you first need to select a paint sprayer, and then a compressor for it.

Tank capacity and location

As a rule, pneumatic paint sprayers are equipped with filling tanks of 0.8–1 liters. These are containers that are attached directly to the “gun”. Thus, the artist constantly holds the entire volume of paint in his hand. If you need to paint very large surfaces, use specialized tanks with a volume of up to 100 liters. They are connected to the spray gun with a hose.

Types of fastening the tank to the spray gun

Filler tanks are located below or above the “gun”. Their position does not depend on the type of spray gun (HP, HVLP or LVLP). You need to choose a model with a container arrangement that will be convenient for the master. But we can highlight several objective pros and cons of each solution:

- The lower tank does not block the technician’s view during painting. And during a break, the spray gun can be placed on the table (the bottom of the container is flat). But the paint from the lower tank is supplied to the sprayer only under compressed air pressure. Therefore, there is always some unused material left at the bottom of the tank. Also, the lower tanks often have a slightly larger volume than the upper ones.

- The advantage of the top tank is that no paint remains in it - all of it flows into the spray gun under the influence of gravity. As a result, such units can spray thicker paintwork materials. It is also believed that the upper tank balances the weight of the device and the material well. This makes the sprayer more comfortable to hold and your hand does not get tired so quickly.

In addition to the listed characteristics, you should also pay attention to whether the selected spray gun model has the ability to regulate the paint supply, direction and configuration of the torch. You definitely need to hold the device you like in your hand - it should be comfortable to use.

When choosing a sprayer, you need to hold the device in your hand and understand how convenient it is

Spray gun Jonnesway: reviews of the spray gun Jonnesway JA HVLP 6109

Content:

Traditional tools for painting work are brushes and rollers. The quality of the coating and the speed of painting when used are not very high and are determined by the skills of the performer. Over time, measures have been created to simplify and speed up painting. One of them can be considered paint sprayers. In the field of body repair, painting is carried out exclusively using these tools. This article discusses the general features of these tools, their design and classification, describes some models of one of the Taiwanese manufacturers - the Jonnesway JA HVLP 6109 spray gun and others, provides their characteristics and user reviews as an assessment.

Painting guns are understood as devices designed for applying liquids of various viscosities to working surfaces, which can be represented, for example, by paints and varnishes, disinfectants, and impregnations. They are most often used for applying paints and varnishes, as the name suggests.

Paint guns have a design similar to spray guns, but somewhat more complex. The operation of these devices consists of supplying a substance under pressure and spraying it.

Most of them have a pistol-shaped body. The main parts of the spray guns are represented by a tank for the material, a body, a trigger, and a spray head.

The main parameters of paint sprayers include:

- air flow (for pneumatic) or power (for electric) - determines productivity, duration of continuous operation and energy consumption;

- productivity - the volume of sprayed substance per unit of time;

- nozzle diameter – determines the possibility of spraying various substances depending on the viscosity;

- paint tank volume - determines the frequency of refilling and ease of use (tools with a large tank rarely need to be refilled, but they are large in size and weight).

Paint sprayers are suitable for the following work:

- applying paint to surfaces made of various materials;

- treating metal surfaces with anti-corrosion agents;

- applying primer to metal surfaces;

- treating wooden objects with varnish or stain;

- applying lime to the surfaces of ceilings and walls, that is, whitewashing;

- spraying disinfectants;

- treating plants with insect repellents;

- carrying out preparatory work, which consists of removing old coatings in the form of paint or wallpaper from the walls by applying a solvent or aqueous composition to them, respectively.

There are several principles for classifying the devices in question.

The first one is based on the energy source. Depending on this parameter, paint guns are divided into pneumatic and electric. Tools belonging to the first type are driven by compressed air energy. As a power source, they are equipped with an air network, a compressor or a hand pump. This injection equipment is selected depending on air flow and operating pressure.

Based on operating pressure, pneumatic paint guns are divided into high and low pressure devices. Models belonging to the first type are economical, but high-pressure spray guns are more versatile, as they are capable of spraying more viscous liquids than low-pressure tools. Such paint sprayers are used in the automotive industry, other areas of production and construction. They are classified as professional equipment.

In electric paint sprayers, the operating pressure is created by a built-in motor or plunger pump. In other words, instead of a compressor, such devices require a 220 V network. Compared to pneumatic ones, electric paint guns are more convenient to use due to their compactness, but are inferior to them in the quality of the coating created. Therefore, the devices in question are used mainly for domestic purposes.

Also, when classifying painting consoles, technical characteristics are taken into account. The main parameter on the basis of which pneumatic tools are divided is the characteristics of the spraying of the substance.

In spray guns, the mixture can be sprayed using airless, air, combined methods, or in an electrostatic field.

Spray guns operating on the basis of the second spray method are widely used. The air spraying process includes two stages: breaking up the substance and forming the shape of the torch. The main advantage of the method is the optimal ratio of speed and quality of work performed.

The most significant drawback of devices operating on the basis of this principle is the high consumption of the sprayed substance. This is explained by the fact that only a certain part of the torch of small liquid droplets formed in the spray head by compressed air is deposited on the surface being treated. A significant part of the substance is dissipated in the form of aerosol fog and settles outside it. In addition, this determines the low environmental friendliness of the painting process carried out using spray guns of this type, since most paints and varnishes contain a large amount of toxic solvents.

Another important characteristic that is taken into account when classifying air spray guns based on the principle of air spraying is the amount of compressed air pressure in the spray head. According to this parameter, these instruments are divided into three types: CONV, HVLP, LVLP. For the third type of paint sprayers, no single name has been developed. The given abbreviation is relevant for Jonnesway painting consoles. For standardization and clarity, the manufacturers of the equipment in question introduced color coding for spray guns. In accordance with it, conventional type instruments are designated white or silver, HVLP – green, LVLP – blue. Markings are applied to the adjusting screws and the air cap cover.

CONV, or conventional spray guns, were the first of this type of device and were very widespread almost until the end of the last century. The pressure values at the inlet and outlet of these devices are approximately equal and amount to 3 - 4 bar, as a result of which such systems are called direct.

The advantages of conventional devices are considered to be the homogeneous composition of the torch, which determines the high quality of the coating, and the relatively low air consumption of approximately 300 l/min, which allows the use of low-power compressor equipment.

The disadvantages of the tools under consideration include the low transfer coefficient of the sprayed material to the treated surface (30-45%), due to the principle of pneumatic spraying. As the device emits liquid, a significant amount of it is dispersed in the form of mist without reaching the surface being treated.

Some users increase the pressure as a measure to increase the transfer coefficient of the substance to the material. However, due to the significant acceleration of the fluid flow, this only leads to the fact that the drops, hitting the working surface, bounce off it. As a result, not only productivity decreases, but also the consumption of the sprayed substance increases.

HVLP (High Volume, Low Pressure) spray guns were developed in the early 80s due to stricter environmental regulations and laws. The devices in question are characterized by an inlet pressure of 2 bar. At the outlet, thanks to the design features, it drops to 0.7 bar.

This measure allows you to significantly increase the transfer coefficient of the sprayed substance onto the surface being treated, in comparison with conventional paint sprayers (up to 70%), as well as the quality of the coating. In addition, thanks to this, such tools can significantly reduce the consumption of the sprayed substance.

However, HVLP spray guns require some skills from the user, since the high degree of transfer of the sprayed substance to the surface being treated causes the possibility of smudges. In addition, the devices under consideration place increased demands on the characteristics of compressor equipment. It must have high performance in order to consistently supply a large volume of air to the tool.

LVLP (Low Volume, Low Pressure) spray guns can be considered as the next stage in the development of these devices after HVLP. They eliminated the main disadvantage of HVLP tools, which is high air flow. In addition, they slightly depend on the instability of pressure in the pneumatic lines. All this has significantly reduced the requirements for compressor equipment. In addition, LVLP devices, with a low air flow rate, provide a high coefficient of transfer of the sprayed substance to the treated surface of 70% and high quality coating. This is due to the fact that with the operating pressure of such devices being 1.6-2.3 bar in the spray head it is up to 1.2 bar.

When classifying electric paint guns, the placement of the motor is taken into account. According to this parameter, the devices under consideration are divided into models with a built-in and remote motor. In the first case, the device is presented in the form of a gun-shaped housing that combines a motor and a sprayer. In models of the second type of spray gun, the engine and sprayer are located in separate housings connected by a flexible hose. Tools with a remote motor have more power than spray guns with a built-in motor, but are less convenient to use due to their large size and weight.

Jonnesway is a Taiwanese company engaged in the production of hand tools, pneumatic tools, diagnostic and measuring equipment, as well as furniture for industrial premises. It was created in 1982.

The manufacturer in question is especially known in the field of automotive repair, both professional and amateur, thanks to its wide product range, which includes several lines of professional equipment:

- hand tools: screwdrivers, wrench sets, pullers, ratchets, etc.;

- pneumatic tools and equipment for them;

- measuring and diagnostic equipment: stroboscopes, testers, compressors, pressure gauges;

- other tools: spray guns, sandblasters.

Among the assortment of this manufacturer are pneumatic models of paint guns. The Jonnesway official website contains 8 tools in the “spray guns” section. It is most advisable to consider one device from this manufacturer, representing each operating system of pneumatic spray guns (CONV, HVLP, LVLP).

JA-507S

The simplest Jonnesway model is the JA-507S. It belongs to the conventional type devices and is classified as professional equipment. The tool in question is designed for spraying paints and varnishes. The body of the JA-507S, as well as the paint reservoir, are made of aluminum, and the seals are made of solvent-resistant acetate polymer. The tank is located on the bottom side of the housing. The needle and its seat are made of stainless steel, which makes this device capable of spraying water-soluble materials. The JA-507S is additionally offered with a wide range of interchangeable nozzles, which allows it to be used for working with substances of various viscosities.

Main parameters:

- air flow - 421 l/min;

- nozzle diameter - 1.6 mm;

- paint tank capacity - 1 l;

- dimensions - 175x295 mm;

- weight - 0.8 kg.

JA-HVLP-6109

The Jonnesway JA-HVLP model 6109 spray gun can be considered a mid-level device. This is a professional spray gun that is highly environmentally friendly. Its body consists of a forged aluminum alloy, a fixing ring made of aluminum alloy with electrochemical coating, a needle and its seat made of stainless steel, a spray head made of chrome-plated brass, and seals made of acetate polymer. Circular drilling in the air cap and cutting nozzles in its wings allow for optimal crushing of the sprayed material and the shape of the spray torch. Additionally, various nozzles are available.

As standard, the tool is equipped with an air regulator with a pressure gauge. The nozzle of the HVPL system is suitable for spraying all types of paints, which determines a wide range of applications for the spray gun in question, including woodworking and other industries. This spray gun model is also suitable for painting car bodies.

Due to the relatively small volume of air consumed, the tool provides low consumption of the sprayed substance.

Main parameters:

- air consumption – 297 l/min;

- working pressure – 6 bar;

- nozzle diameter – 1.4 mm;

- paint tank capacity – 0.6 l;

- dimensions – 170x325 mm;

- weight – 0.7 kg.

Reviews indicate the high quality of application of the substance to the work surface with this paint sprayer.

JA-LVLP-25G

The manufacturer positions the Jonnesway JA-LVLP-25G model as the most advanced spray gun. This tool, like the spray guns discussed above, is classified as professional equipment. Its body is made of forged aluminum alloy, the needle and its seat are made of stainless steel, the spray head is made of chrome-plated brass, the seals are made of acetate polymer, and the fixing ring is made of aluminum alloy with electrochemical coating. These materials are traditional for Jonnesway spray guns.

JA-LVLP-25G is designed for spraying various paints and varnishes. This tool is most common in the field of body repair and furniture production. To operate, it must be connected to a compressor or air line with a pressure of at least 6 bar and a capacity of 400 l/min. In terms of technical characteristics, the paint sprayer in question is considered an intermediate option between devices based on the HVLP system and RP system models.

The main advantages of this device are low air consumption and low consumption of the sprayed substance with a high transfer coefficient to the surface being treated. In addition, the JA-LVLP-25G has a convenient design and light weight, making it convenient and easy to operate and can be held with one hand during operation.

The spray gun is suitable for most types of paints and varnishes. It is considered optimal for applying multi-layer coatings, since the tool forms a thin covering layer on the surface being treated and eliminates the possibility of smudges.

Main parameters:

- air flow – 283 l/min;

- working pressure – 2 bar;

- nozzle diameter – 1.4 mm;

- paint tank capacity – 0.6 l;

- dimensions – 170x325 mm;

- weight – 0.53 kg.

autokuz.ru

How many spray guns should you have?

Many car painters purchase several guns at once for different materials and purposes. There are spray bottles recommended for base, primer or varnish. The ideal option would be when you can afford three pistols. In this case, you will not have problems with paint particles getting into the varnish that was sprayed before.

Of course, it is not necessary to purchase three spray guns. Many car painters who have one paint gun with a 1.6 nozzle apply all materials from varnish to primer. This requires more effort and time to thoroughly clean the tool after spraying different materials.

When choosing a spray gun, be sure to pay attention to the parameters suitable for your compressor. Or, after purchasing a spray gun, select a compressor for the gun. The main parameter of the compressor is the supply of a certain volume of material at constant pressure while using the tool. There is a basic rule for a good compressor operation: it should produce 2 times more cubic units per minute than the spray gun requires at a given pressure. If the compressor performance is insufficient, good atomization will not be obtained, then the compressor will produce an insufficient amount of air.

Hoses and fittings are also important when choosing a spray gun. If you use a ¼ inch hose, normal air flow will not be possible. Find a good 3/8 diameter hose with built-in fittings with good flow. These preparations will significantly improve the air flow in the hose.

Which spray gun should you choose?

Each type of sprayer has its pros and cons:

- HP allows you to paint evenly and quickly, but due to the formation of a large amount of paint dust in the air, it does not provide ideal painting quality. When applying glossy materials, you will have to polish the surface after drying. To work with such a spray gun you will need good personal protective equipment.

Advice! HP is the best option for a novice craftsman and for spraying inexpensive materials. This is a simple and inexpensive spray gun for home use.

Purpose and principle of operation of spray guns

Spray guns are used primarily for uniform painting of surfaces.

But the matter is not limited to just painting. The tool is suitable for spraying liquids, powders and suspensions, similar to a spray gun.

A number of jobs can be performed in everyday life using paint sprayers:

Read also: How to peel off fingers from superglue

- The application of decorative and protective coatings is, in fact, the core use of the tool. Therefore, working with large volumes of paint, varnish, impregnations, stains and even glue is rarely possible without a spray gun.

- Spraying plants in garden plots. Tree crowns, flowers and shrubs are treated with specialized compounds. In addition, spray guns are used to treat ticks as the most effective way to get rid of these dangerous arachnids in the country.

Spring whitewashing of tree trunks is another effective option for using this tool.

- Priming surfaces is especially important when processing large areas.

- Disinfection of premises with detergents. When fighting fungus, use a special antiseptic.

In fact, the spray gun is capable of working with any liquid solutions, the size of individual fractions of which easily passes through the nozzle opening, and the viscosity corresponds to the recommendations of the gun.

The principle of operation of spray guns is to mix paint supplied under pressure with air, as a result of which it is broken into fine dust.

This allows you to apply the working composition to the surface evenly.