In recent years, it has become increasingly popular to independently resolve repair issues, including laying self-leveling floors. If you also decide to perform this operation yourself, then you cannot do without a number of specialized tools. One of them is a needle roller for self-leveling flooring, which allows you to obtain an even distribution of the mixture and a uniform floor covering.

When pouring floors, it is absolutely necessary to roll the grout. Otherwise, when it hardens, voids filled with air will form in it, which will quite clearly spoil the appearance of the floor and its performance characteristics. The fact is that when it hardens with bubbles inside, the floor will receive an undesirable porous structure, which will increase its fragility.

Rolling allows you to get rid of even the smallest bubbles, allowing you to avoid problems in the future, including when installing quite heavy furniture on the floor. A self-leveling floor properly treated with a roller will not sag or break, which means it can last for a very long time.

Specialists who constantly work on decorating or renovating apartments or houses have similar items in their arsenal of different sizes and for different needs. But when independently deciding the issue of installing a self-leveling floor, you need to take care of purchasing such things. In this material we will look at what rules should be followed when choosing rollers.

Principle of operation

The needle roller comes in different sizes and for different purposes. The width of this tool can be either 20 or 60 centimeters. It is most convenient to work with a roller, which has a fairly large working surface, but there are situations when you need to go with a roller in a narrow or hard-to-reach place, and then small tools come to the rescue, penetrating where a massive tool will not go. If you don’t want to buy a whole “family,” you should pay attention to medium-sized rollers.

Related article: Gardens in miniature: how to make a mini-garden with your own hands and what they are like

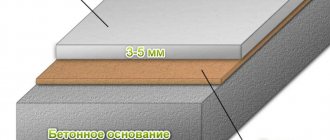

Another important detail that you need to pay attention to when purchasing a roller is the length of the spikes. Their size ranges from 8 to 35 millimeters. This parameter must be selected based on the idea of how thick the coating you are going to make. The main thing is to mix the layers thoroughly so as not to give any chance for air to ruin your desire to get a strong, durable coating.

Criterias of choice

Guidelines that predetermine a high-quality product that is best suited for a certain type of work and type of mixture will help you make the right choice of tools.

Manufacturer . The result of finishing work directly depends on the quality of the tool. Rollers of the following brands deserve trust: STAYER, Sibrteh, TUNDRA, KUBALA, NN STRONG, Zubr, MATRIX, Bauma.

How to replace a needle roller . If necessary, you can replace the needle roller with a squeegee. This is a special construction tool that resembles a wide spatula with notches along the working part. It is available with a simple or telescopic handle. The design is durable, able to withstand sufficient pressure when passing through the mixture.

There is another alternative to the roller – sandals. They are made from wooden blanks that follow the shape of the shoe sole. On the outside there are teeth in the form of nails. After filling the floor with the solution, you need to put sandals on your feet and walk carefully over the entire area.

Material . When selecting a roller, you should pay attention to the material from which it is made. This directly affects its service life. Metal (steel) rollers are considered stronger and more durable. Plastic products quickly break down.

Width, mm . Roller manufacturers offer tools with a working part width of 150-600 mm. Oversized products are suitable for working in large rooms. Narrow models make it convenient to pass through niches and hard-to-reach places. When processing drywall, you can use rollers of any width. If you plan to remove wallpaper, preference is given to medium width (about 400 mm).

lie down on the floor their work hot soups six hundred students engineers

Needles . The length of the needles is selected taking into account the thickness of the floor being poured. It should be a little larger than the fill. The range of rollers is represented by products with spike lengths of 8-34 mm. When using short teeth, it will be impossible to efficiently remove air bubbles from the mixture. In addition, the risk of solution displacement increases due to close contact of the base of the instrument with the floor.

Pen . The rollers are offered with regular and telescopic handles. The second option is preferable, as it allows you to adjust the length of the handle, which relieves stress from your hands when doing a large amount of work.

When purchasing a tool with a niche for a handle, you will have to deal with modifications. The handle not only needs to be fixed, but also the correct length must be chosen so that your back and arms do not get tired while pushing out air bubbles.

Form . The tool is available with different variations in the shape of the spikes: sharp cone-shaped, spherical and teardrop-shaped. According to experienced craftsmen, teardrop-shaped teeth are less effective. Sharp needles are best used for viscous mixtures, including epoxy resin-based compounds. When working with liquid mortar, it is recommended to use spherical spikes.

When working with a needle roller, the solution splashes heavily. For more comfortable use of the tool, it is recommended to give preference to models with a protective cover. It can be easily removed from the structure and can be easily cleaned from the building mixture. Clothes and walls will remain clean when passing such a roller.

Needle rollers with a wide working part and long needles are equipped with a protective cover.

Where are they used?

A self-leveling floor roller is useful when pouring any type of floor. This applies to:

- gypsum-based mixtures;

- cement mixtures;

- polymer self-leveling floors.

In the latter case, the thickness of the floors is relatively small, it is only 1.5 centimeters, so you will need to use rollers with small spikes. When pouring floors of another type, their thickness can already be up to 3 centimeters; accordingly, it will be necessary to choose a roller with longer spikes.

If you plan to process a floor whose thickness is less than five centimeters, then it is better to opt for a roller that has sharp rather than rounded needles for better quality work.

Most rollers are made of plastic, so before purchasing, you should check with a consultant to see how resistant the needle roller is to solvents and other chemicals used in finishing.

Video on preparing self-leveling floor solution

What is needed for a self-leveling floor? It seems that the process of installing a polymer coating is quite simple, but it requires precise execution of all stages of work, the implementation of which is simply impossible without the necessary tools and auxiliary materials. If you can make slippers for self-leveling floors yourself, then you will have to purchase other special equipment in the store.

If you want to get a reliable and high-quality coating, purchase the necessary equipment responsibly, then you can safely walk on the self-leveling floor for at least 20 years.

What does it look like

There are two types of needle rollers - these are tools for working with drywall and the roller we are interested in is for processing self-leveling floors. The cylindrical base of the device is finished with spikes and is attached to a special handle.

The most common material, as already noted, for making a roller is plastic. It is quite light and practical, so you can use the roller for a long time without getting tired or slowing down the pace of work. However, there are also options that are made of metal. Such products are heavier, they are more often used where it is necessary to process a large area.

Related article: How to get rid of the smell of cat urine: videos, tips, recipes

For ease of use, manufacturers often equip the needle roller with a special telescopic handle, which allows you to effortlessly process a fairly large area. This handle is also made of plastic or wood, which allows for greater lightness and maneuverability of the product, ensuring normal operation.

https://www.youtube.com/watch?v=dON94h47BJs

What is it needed for?

A needle roller is necessary for removing air bubbles from the self-leveling floor, stripping off old wallpaper and bending sheets of drywall. In the first option, it serves as a layer leveler, and the needles pierce air bubbles in the solution.

A self-leveling self-leveling floor spreads and levels well, but without the use of a needle roller, bubbles will remain in it, which will evaporate through the pores over time, and voids will remain, due to which the floor will become brittle, begin to crack and swell.

How to use a roller

Working with this type of roller means that you need to go over it with such a tool every time you pour the mixture. That is why it is better not to take risks and immediately choose not the most budgetary, but the highest quality and most suitable option for the situation.

The roller helps distribute the mixture evenly over the surface, but in most cases a special leveling bar will also come in handy.

For better performance of self-leveling floors, other rules must be followed:

- Before pouring the floor, thoroughly clean the base;

- use only high-quality materials and tools;

- allow the floor to dry under the conditions specified in the instructions;

- use only high-quality materials for processing and painting;

- Remember that such a floor is, first of all, necessary in rooms where it is necessary to strictly adhere to sanitary standards.

General terms of delivery and pickup

Pickup is carried out at the address

Moscow, 41 km MKAD, shopping center “Melnitsa”, row Zh 5/6.

– when paying on the spot, payment for products occurs before the machine is unloaded (deposit);

– in case of partial or complete refusal of high-quality and paid for products at the time of delivery, the funds are returned to the buyer in proportion to the reduction in the cost of the order;

– when ordering goods according to an individual size or with cutting to an individual size (linoleum, gypsum board, plywood, cable, rolled metal, etc.), 100% prepayment of the order is made, refusal of quality goods sold by the meter, as well as goods manufactured Custom size is not possible;

– delivery is carried out daily from 9-00 to 18-00;

– the cost of delivery does not include unloading, lifting, as well as cutting and sawing of materials;

– unloading time is limited depending on the weight of the cargo;

– delivery is carried out to a place where the car can travel without violating traffic rules and risking damage to the vehicle;

– pick-up is carried out only after prior agreement with the manager of the online store;

– large-sized material (insulation, barrels, etc.) is calculated based on the cubic capacity of the cargo;

– additional requirements for the car, for example, a small height for entering a parking lot or an open body for vertical unloading, are paid additionally: + 25% of the cost of the standard tariff.

| Cargo weight | up to 100 kg | up to 500 kg | up to 1 t. | up to 1.5 t. | up to 2 t. | up to 2.5 t. | up to 3 t. | up to 4 t. | up to 5 t. | up to 7.5 tons with crane-manipulator | up to 10 tons with crane-manipulator |

| Load length | up to 6 m | up to 6 m | up to 6 m | up to 6 m | up to 6 m | up to 6 m | up to 6 m | up to 6 m | up to 6 m | up to 10 m | up to 10 m |

| Moscow within the Moscow Ring Road | 800₽ | 1100₽ | 1500₽ | 1900₽ | 2300₽ | 2700₽ | 3100₽ | 3800₽ | 4800₽ | 6500₽ | 9000₽ |

| Cost of 1 km outside the Moscow Ring Road | 40₽ | 40₽ | 40₽ | 40₽ | 40₽ | 40₽ | 40₽ | 40₽ | 40₽ | 70₽ | 70₽ |

| Standard time for unloading | up to 15 min | up to 15 min | up to 30 min | up to 30 min | up to 45 min | up to 45 min | up to 45 min | up to 1 hour | up to 1 hour | up to 1 hour | up to 1 hour |

| Transport downtime during unloading in 1 hour | 200 | 300 | 300 | 400 | 400 | 400 | 500 | 500 | 500 | 1000 | 1000 |

| Delivery costs may vary due to non-standard conditions, wishes and unloading locations. |

Cost of loading and unloading and lifting to the floor

| Weight | Unloading (with elevator) | Access without elevator (1st floor) |

| up to 300 kg | 2 rub/kg | 2 rub/kg/floor |

| up to 1000 kg | 1.2 rub/kg | 1.2 rub/kg/floor |

| up to 3000 kg | 1.1 rub/kg | 1.1 rub/kg/floor |

| up to 5000 kg | 1 rub/kg | 1 rub/kg/floor |

| from 5000 kg | individually | |

| Bulk product | individually | |

| Drywall/Plywood/Sheet materials | 50 rub/sheet/floor | |

| Profile/Slats/Beams | 30 rub/piece/floor | |

| Insulation | 30 rub/pack/floor | |

| The cost of unloading may vary under non-standard conditions, wishes and unloading locations. |

Multiline phone

Delivery to Russian regions:

– delivery to Russian regions is carried out through the transport company SDEK 2 times a week;

– shipment of goods to the transport company occurs only after 100% payment of the order;

– transport company services are fully paid by the buyer upon receipt;

– for cargo over 10 kg, delivery to SDEK shopping center is 500 rubles.

– return of goods of proper quality through TC is carried out at the expense of the Buyer.

Opening hours:

Monday-Saturday: from 8:00 to 19:00

Where can I buy the tool?

Such a tool can be found in different places if necessary. If you want to touch and check the product before purchasing, you can go to a specialized store. This method is good for inexperienced finishers, who will likely benefit from expert advice.

Good options at lower prices can be found in any construction market. True, these rollers will not always be of high quality. However, the price will allow you to purchase several options at once.

For those who have already decided on the manufacturer and material, you can even choose a suitable roller in the online store. In this case, you don’t even have to go anywhere; you can make purchases while lying on the couch.

Related article: How to make a balcony with your own hands (photos and videos)

Surface preparation

To ensure that the created even surface layer does not crack around the perimeter of the room, it is necessary to stick a damper tape, preferably made of foamed polypropylene. Next, using a level (regular or laser), you need to find the lowest and highest points of the floor base. From the highest point, you need to mark the height to which you plan to raise the surface - at least 5 mm, and mark on the walls a control line to which the layer of filling the leveling mixture will reach.

Preparing the foundation does not require any special construction skills from you. First, check for holes and cracks. They should be sealed, and all fragile elements should be removed along with debris and dust. If you have an old vacuum cleaner, it is very advisable to vacuum the surface with it. Then the clean surface must be primed. The primer will take approximately 4 hours to dry. After this time, you can begin preparing the working solution.