Expanded clay is expanded baked clay. Inside there is a porous formation, outside there is a sintered shell.

Expanded clay was successfully used before the advent of modern insulation materials as a high-quality and inexpensive heat insulator. In some cases it is still used in this capacity. When working on floor screed, the material is used for leveling and as a mortar filler. It consists of fired, foamed clay granules of different fractions and shapes.

Advantages:

- Thermal insulation qualities. Within 0.07 – 0.16 W/(m*K). For comparison: foam plastic 0.031 - 0.04, mineral wool 0.045 - 0.07, reinforced concrete 2.0 - 2.04;

- Mechanical load. Compressive strength from 0.6 to 5.5 MPa. For comparison: foam plastic 0.03 - 0.4 MPa, concrete 5 - 60 MPa and higher;

- Moisture resistance. Water absorption 8 – 20%. Staying in water for a long time does not destroy the material;

- The material is fireproof. Non-flammable, does not emit any toxic substances when exposed to high temperatures;

- Biologically inert. Does not rot and is not a breeding ground for microorganisms;

- Rodents do not grow in expanded expanded clay. The mobility of the backfill does not allow making moves and making nests;

- Noise absorption. Achieved only when added to a cement screed, and not when dry backfilled;

- Over a long period of time, the properties of high-quality material do not deteriorate. In many old buildings (more than 50 years old), during demolition, expanded clay is discovered, with which nothing happened;

- The properties are not affected by temperature changes in any climatic zones;

- Low cost and availability;

- The work does not require any special tools or skills. A floor screed with expanded clay is essentially no different from a standard floor screed.

Flaws:

- For insulation, a large screed thickness is required. A layer with expanded clay less than 10 cm thick is ineffective;

- Dry floor screed with expanded clay is dangerous if water gets into the expanded clay layer. The material itself will not be damaged, but moisture under the concrete will remain, which can lead to increased dampness inside the room and the formation of mold.

Pros and cons of expanded clay

The use of expanded clay in a semi-dry screed provides the following main positive qualities:

- This floor is not afraid of severe frosts, as well as high temperatures. No amount of heat will damage the base of the subfloor. Semi-dry screed with expanded clay can be done even in rooms that are not heated throughout the year.

- With the use of expanded clay, any unevenness is eliminated, no matter how high they are. It is possible to install a floor screed to a height of 150 mm. In this case, some mixtures may be powerless.

- Using expanded clay concrete, you can be sure that rotting will not occur; it resists elevated temperatures, as well as the formation of corrosion. The service life is very long.

- The basis of expanded clay is baked clay. Its weight is much less than ordinary concrete. The pressure and load on the floor is reduced to a minimum. Can even be used on a wooden base.

Advantages of expanded clay

Among the shortcomings, the instability of this material to moisture is especially alarming. For this reason, there are some limitations to its use in certain circumstances.

Expanded clay should be stored under a special canopy or even indoors. The fact is that this material absorbs moisture very well, but at the same time releases it slowly. In this case, after repairs, high humidity will remain in the room for a long time.

Floor waterproofing

Waterproofing the floor is a mandatory step in installing wet screeds, including screeds on an expanded clay cushion. Essentially, by waterproofing you separate the apartment from its neighbors and avoid troubles with leaks.

Option 1. Liquid waterproofing

For this option you will need liquid waterproofing mastic. For apartments this is the most practical option. It is necessary to coat the joints of walls and floors and the joints of floor slabs with liquid waterproofing mastic or liquid waterproofing. This is done so that the water released when filling the floor does not flow to the neighbors. Particular attention should be paid to holes, cracks in the floor and openings for heating or water pipes. They must first be sealed with alabaster and also thoroughly coated with a waterproofing agent.

Option 2. Rolled floor waterproofing

A more reliable and more labor-intensive option. Can serve as an alternative to liquid waterproofing or improve liquid waterproofing as you wish.

It is worth noting that roll waterproofing is not cost-effective in apartment buildings with concrete floors. In such houses, 200 micron cellophane can be used as waterproofing.

I note that waterproofing the floor not only protects your neighbors from leaks, but also protects the screed from moisture from the lower floors. If your apartment is on the ground floor and there is a basement or a wet room below you, then roll waterproofing will be necessary. The material for roll waterproofing can be waterproofing, as in the photo.

Types of backfill

The density of expanded clay varies. The range of products is presented on the construction market. All that remains is to choose a more suitable option for installing a semi-dry screed indoors. The density can vary from 250 to 600 kg per cubic meter, which meets certain circumstances of use. Depending on this, the types are distinguished:

- Crushed stone. The size of each granule is 10-14 mm. Its main application is the preparation of concrete.

- Expanded clay sand for dry screed. It is necessary when it is necessary to create a thin screed. The size of the expanded clay does not exceed 5 mm.

- Gravel. Allows you to get a very light, but at the same time quite durable floor. There are three categories of expanded clay granule sizes: 20-40 mm, 10-20 mm, 5-10 mm.

Types of expanded clay for screed

When choosing a specific backfill, you should take into account what technology for constructing the subfloor will be used, as well as the room itself where the installation work is being carried out.

Conditions of use

Semi-dry floor screed with expanded clay can only be performed under certain conditions. The most basic is the installation of a thick screed, the thickness of which ranges from 6-10 cm. First, a layer of expanded clay is poured to level the surface, and only then a cement-sand screed is poured.

Expanded clay is also used so as not to create a load on the floor, especially if it is an old building. The cost of such material is not high and it will significantly reduce all costs by removing a sufficient amount of cement in the solution.

Expanded clay exhibits a huge number of qualities, and the most basic of them are an excellent layer of heat and sound insulation. Due to this, it is quite popular among buyers, beginners in the construction business and professionals.

How to level a wooden house?

To level the floor in a wooden house, two methods are used:

- Backfill between joists. The base is wooden logs. If they are on a foundation, then panels or subfloor boards must be attached to them. They can be tacked to the joists from below or secured to bars that are attached to the joists from the side. The use of lightweight expanded clay materials is an advantage - the load on the subfloor is small.

- Anchoring on the ground. The method is suitable for utility rooms or garages. But the expanded clay pillow is not laid out directly on the ground. First, the top layer of soil is removed, then a layer of gravel and sand is poured alternately. Everything is thoroughly compacted and covered with a protective film. Then the insulating expanded clay layer is poured onto a sand cushion, leveled, and lightly compacted.

Further actions with the leveled floor are carried out at the discretion of the specialist. You can start laying the floor right away or fill the entire expanded clay layer with concrete so that a wet screed is formed. The same layer can be used as rough insulation. This is done by laying another insulating layer, on top of which the finished floor will be laid.

Layers of screed

Before you start work, you should find out what layers a semi-dry screed for heated floors includes. First of all, this is a protective layer of waterproofing, which must be combined with a damper tape. You should not be afraid to make a larger layer in height, since in the future it will all be cut off after the installation work is completed. After this, expanded clay is poured to the required height, along which the beacons are placed. Options for beacons can be different. Everything will depend on imagination and possibilities.

Layers of screed with expanded clay

When all of the above has been completed, a semi-dry screed is poured, acting as a subfloor. If necessary, a reinforcing mesh is added to it, which can be replaced with fiberglass, which has recently become popular due to its large number of positive qualities.

Possibilities for wall insulation

Naturally. Nowadays, the world of building materials is updated almost daily—the exterior insulation of a house made of expanded clay blocks is a good example of this. Technologies for insulating expanded clay concrete blocks of walls from the outside differ in different countries - for example, in Spain everything will be done far differently than in the Russian Federation.

Modern insulation of a house made of expanded clay concrete blocks is distinguished by increased reliability and durability in operation.

Additional advantages include resistance to frost temperatures and water resistance. It is thanks to these characteristics that developers, even in apartment buildings, purchase such blocks in large quantities.

Necessary materials

The tool itself is prepared for screeding the floor in the room. It is very important to purchase all the necessary materials for work. You can even pre-calculate what and how much will be needed.

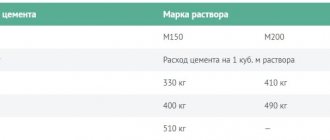

If the room measures 5*3 meters, that is, 15 m2, then the optimal screed layer will be 50 mm. From this it turns out that we will need a total of 0.75 m3 of screed (area multiplied by thickness). In this case, the proportions of sand and cement are usually 1 to 4 (sand 0.6 m3, and cement 0.15 m3).

Sand will be needed for backfilling under the expanded clay. If we take an approximate height of 20 mm, then it will be 0.3 m.3. Roughly speaking, such a room will require almost one ton of sand. Depending on the density of expanded clay, its quantity is calculated. With average performance and a thickness of 100 mm, it will take 1.5 m3. This option is suitable for performing “wet” screed. But the device of a semi-dry screed is not much different, where it is necessary to purchase the appropriate mixture with additives.

As for beacons, their number will, first of all, depend on the rule used and its length. With its length of one and a half meters, the above premises will require about five beacons over the entire area. The length of such beacons is selected over the entire width of the room - three meters.

The choice of expanded clay itself is focused on granules, or rather their fraction. To calculate everything correctly and independently, just open the calculation calculator, which can be found on the Internet. In this case, it would be a good idea to turn to familiar builders for help. They will tell you the exact amount of material that should be purchased. It is worth noting that the materials for underfloor heating screed do not differ in quantity.

Preparatory activities

The same preparation is performed for both conventional screeding and semi-dry screeding. That is, it makes no difference whether the floor screed is dry or semi-dry, which will be necessary for laying the floor covering. It is very important here to level the foundations where the work will be carried out. All existing cracks and pits are eliminated, if possible, using cement mortar. Bulges may be knocked off. We must not forget about the waterproofing layer, which can be ordinary polyethylene film. The better the material is chosen, the better qualities it will be able to demonstrate during operation.

After this, sand is poured in, acting as a cushion under the expanded clay. Usually its layer is 20-30 mm. The pillow must also be leveled using the rule. As for compacting sand, it will be sufficient to simply walk along the entire plane. In this case, the weight of a person is enough.

The choice of expanded clay is made depending on the fraction (fine, medium and large fraction). It is poured throughout the room, starting from the far corner. After filling the required layer, it should be leveled. Beacons are installed along the top of the expanded clay, serving as the basis for the subfloor level.

Profiles are used as beacons, which are mounted on the base using cement-sand mortar. Subsequently, the screed is poured, slightly overlapping the beacons, and they simply “hide” in the base of the subfloor.

Performing a semi-dry screed

When the expanded clay is poured, you can choose two options for further actions:

- Pouring cement laitance. The solution is installed directly on the expanded clay. The granules absorb moisture very easily. If this happens after pouring a semi-dry screed, then drying may occur unevenly, which will lead to shrinkage over the area. Some people pre-wet the granules in water, and only then backfill. But even this option does not provide a 100% guarantee.

- Separation of expanded clay from a semi-dry screed with a layer of waterproofing. Moisture from the solution will not get into the bedding, even if you simply lay down plastic film. The main thing is that it is intact over the entire surface and is not torn during the installation of the semi-dry screed.

Not everyone knows how to make cement laitance. For this purpose, twice as much water is used as with the standard screed design. Depending on the result obtained, you should see whether it is necessary to add additional water or cement. In this form, after pouring the expanded clay, it is necessary to let the layer sit and dry for at least a day. Only after this can the semi-dry concrete floor screed be poured.

If the beacons are removable, then they are pulled out only after a few days. The resulting grooves are sealed with mortar, carefully compacted and sanded until a uniform layer is obtained.

Expanded clay with mortar

There is also an option for making a semi-dry screed, when the solution itself is mixed with expanded clay granules. This process takes much less time than in the previous case.

Expanded clay is poured into a container that is prepared in advance, which is filled with water in the required quantity. Mixing is carried out using a mixer. The prepared dry mixture is poured into this, which must be thoroughly mixed until a homogeneous mass is obtained. You should be very careful with the amount of water. After all, semi-dry screed requires a small amount. Too much will lead to the manifestation of negative qualities.

There should be no lumps when stirring, and the granules themselves should become wet and acquire a gray tint. The mixture becomes slightly thick, with a consistency reminiscent of sour cream.

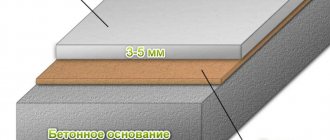

The finished solution is poured onto the prepared base to a thickness of 20-25 mm. But the thickness will depend on the evenness of the floor, as well as on the final result, which is necessary for laying the floor covering. The reduction in time occurs because there is no need to wait a day for the first layer filled with cement laitance to dry and harden.

After the initial layer of the “pie”, the second and subsequent ones are performed until the “rough” floor is formed. During the work, we do not wait for the previous layers to dry. The finishing layer is not only carefully compacted, but also leveled.

Practical advice

To increase the strength of the expanded clay screed, it is recommended to moisten it with water twice a day. This must be done carefully, do not fill it with water, and do not let the dry expanded clay get wet. Watering significantly improves the physical performance of the screed; the chemical reactions of the cement mortar proceed in a favorable manner. It takes two to three days to water the screed; the exact time depends on the weather. At high temperatures, the number of soakings increases; the top layer of the screed should not be allowed to dry completely.

Wetting the screed with ordinary water is necessary to ensure that the floor is level.

If the operating conditions of the building require an increased height of the expanded clay insulating layer, then it can be laid in bags. Plastic bags increase the stability of the position of the granules, expanded clay does not crumble under the feet of the master, and there is no need to use special additional devices and devices. To completely level the surface of the filling, a layer of small fractions 2–3 cm thick is added on top. This technology allows reducing time by 30%.

Expanded clay in bags

If possible, do not use expanded clay floor insulation technologies using cement laitance. The strength of the base will increase, but the heat saving effect will significantly decrease. There are many other construction techniques to increase the load-bearing capacity without reducing the thermal protection of the floor.

Expanded clay is shed with cement laitance

Expanded clay insulation is very profitable to do in outbuildings or garages. Especially if the construction site is uneven, and it is impossible to carry out excavation preparatory work for various reasons. Expanded clay will independently level differences in the base height up to ten centimeters; an increase in the amount of material does not have a noticeable effect on the change in the initial estimated cost of the object.

A noticeable effect of floor insulation with expanded clay can be achieved with an insulation layer thickness of at least 15 centimeters. This must be kept in mind when choosing the type of base for the screed. Not all premises allow the creation of floor coverings due to such a significant reduction in the height of buildings.

The more airtight the top waterproofing, the higher the thermal insulation performance. It increases due to the absence of air convection; waterproofing serves as a reliable obstacle to the movement of warm and cold air masses. The optimal method for the upper waterproofing of a floor screed is ordinary polyethylene film.