Forced ventilation systems are present in almost every apartment or private house. They consist of an air intake device and an exhaust duct, which can be made of various materials.

The plastic hood box has become widespread - an affordable and durable element that can be installed independently.

In order for the assembled system to work effectively, it is necessary to correctly calculate the cross-section of the channels, design and select the components of the air duct. Equally important is to carry out proper installation.

We propose to deal with all these questions in order. We have supplemented the step-by-step instructions for installing a plastic exhaust ventilation duct with visual photographs.

Plastic hood box: advantages and important installation points

Any kitchen is complete only when it is equipped with all the necessary appliances and systems.

A kitchen hood removes odors, drops of fat and oil from the air in the room. But the air duct is responsible for their further removal into the ventilation shaft. It would seem that this is an insignificant and unworthy detail, but in reality it is not so. It’s not for nothing that there are different types of such systems, for example, a plastic hood box is just as popular as, for example, a corrugated model or a metal one. And even somewhat superior to them in this matter. Today in the article we will find out how it compares favorably with its “relatives” and show what is included in its kit. We will also find out two important points that should be taken into account when installing it.

Video recipe: How to install a hood

| Author | Share | Rate |

| Victor Samolin |

Interesting on the topic: Operating principle and production of ventilation deflectors

Do-it-yourself tsag deflectors

Which exhaust technology to choose for your home

Comments on this article

Free Games Download An additional window in the ventilation duct does not increase its cross-sectional area. In the best case, the hood will throw three-quarters of the kitchen fumes into the ventilation, and a quarter will go back into the apartment. And in case of strong wind or draft from the lower floors, everything can come back. Or get to neighbors who, as you know, are not always tolerant and benevolent. 03.11.2015 at 20:43

Plastic ventilation duct: design details

For installation among various angles, turns and other features of the kitchen, manufacturers have provided, in addition to the main air duct (pipe), many additional parts that allow maneuvering when installing the duct.

An important part of them is the rotation (they are also called an elbow), they are made at 45 degrees, less commonly at 90. Moreover, they can be angular or rounded, thanks to them you can change the direction of the structure in the right place.

Adapters. they allow you to connect round and square profiles. It often happens that you need to connect a square air duct to a round outlet funnel on the hood, in which case an adapter is used. It also allows you to connect air ducts of different diameters and cross-sectional sizes of square and rectangular models.

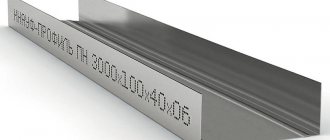

The dimensions of the plastic box for the hood (rectangular) are as follows: the smallest are 50 mm by 100 mm. The largest are 200 mm by 400 mm.

Connectors. When the length of one air duct to the ventilation shaft is not enough, an additional one(s) is used to put them together; this is what connectors are used for. They come, like adapters for connecting pipes, of different diameters and different profiles..

Tee. Used less often at home, since it is usually used to connect two or more hoods to the main air duct.

Non-return valve - allows you to prevent air from being drawn into the apartment from the ventilation shaft. It allows air to flow in only one direction. When the hood is turned off and the reverse draft is activated, it tightly blocks the exit to the shaft.

The ventilation duct is plastic, rectangular, square or round - they all also need a grille connector. It is attached over the hole into the shaft, onto which the rest of the box structure is subsequently fixed.

In addition, you will need fastening elements, their number depends on how many connections there will be in the entire output system.

Features of caring for hoods with a carbon filter without venting

In order for charcoal kitchen hoods to work effectively and efficiently, they must be maintained regularly.

When dirty, the grease filter must be removed and washed with special detergents. The carbon cassette should be replaced periodically. The frequency of manipulation is related to the intensity of use of the device and the features of the model. To replace the filter, you need to pull out the grease mesh from the device, then remove the cassette. After this, the element is replaced with a new one, which is mounted on the seat and then fixed. Next, the grease filter is installed in place.

In order for the hood to work effectively, you need to change the filters on time.

The cost of a carbon filter varies in the range of 250-3000 rubles. You can use a universal option that is adjusted to the size of the worn element. When some filters become dirty, it is enough to wash them under running water and dry them, and then put them back in place. Only Elica offers this refurbishable accessory. Depending on the model, you can simply replace the cassette filling or make a cleaner yourself.

To make a homemade filter for an exhaust hood without an outlet, you will need a sheet of padding polyester and activated carbon in tablets or granules. A filter is cut from the blank on the base of the pattern of the old product, which consists of two pieces. Coal filler is placed between the sheets of padding polyester. The finished filter is inserted into the cassette.

Some hood models are equipped with carbon filters covered with a protective fabric layer. It can be removed and washed and then reused. In such cassettes it is easy to replace the carbon filler, which is poured between the fabric layers.

The hood body can be wiped with a damp cloth and detergent.

Ventilation in the kitchen

The presence of a ventilation duct in the kitchen irritates many people, since it takes up a significant part of the usable space, as some believe. Its dismantling can free up an additional 0.5 sq. m of area, but you can’t do that.

Independent removal of such an element of the ventilation system as a ceiling duct can lead to the following:

- the ventilation shaft is formed according to the principle of a pyramid, when the ducts below serve as support for the upper ones, so dismantling any duct weakens the structure as a whole, since the upper elements of the system are deprived of support;

- Removing a ventilation duct in a separate apartment leads to the fact that for rooms located lower in the building's floor plan, access to the air exchange system is blocked.

In connection with the above reasons, the Housing Inspectorate always reacts sensitively to violations related to general building communications. Therefore, the minimum that you face in the event of dismantling a kitchen element such as a ventilation duct is a requirement for its restoration.

Different ceiling levels and a sleeve as an element of style

Arranging a ceiling in the form of several levels is another way to aesthetically design a hood hose.

The second-level design will help not only hide the sleeve, but also securely secure it in the area between the ventilation and the hood.

The main thing is to place the sleeve so that it does not deform. This method of masking is ideal in cases where:

- the owners have started renovations and plan to radically redo the ceiling;

- an apartment in a new building is being prepared;

- A very old building is being reconstructed;

- the ceiling height is very high, and there is a desire to reduce it by making a two-level structure;

- The usable area of the room is large enough or when decorating the interior of a studio apartment.

Features of the practical use of boxes

One of the most interesting solutions can be called a rotating elbow with a variable angle. Often, air flows in a ventilation system do not always have to be turned at right angles. Sometimes two plastic boxes need to be joined at an angle of 30o or 60o. It is almost impossible to make a docking station without “changes”.

You can buy boxes in three different sizes on the market - 35 cm, 50 cm and 100 cm. Each section of a plastic box is a finished product, at one end of which there is a landing belt, at the other - an extension. By inserting the belt of one section into the extension of the second, you can easily assemble an air duct for a ventilation system of any complexity.

The main thing here is not to get confused; when assembling a ventilation system, the receiving unit is first assembled, this could be the exit from the hood or the entrance window in the shower stall. There must be a seating collar on the receiving unit fitting. We put the first section of the box as an extension onto the girdle of the receiving unit. It turns out that all subsequent plastic sections will be placed in the direction of the flow. The joining with any shaped elements is carried out in a similar way.

Some manufacturers even put arrows on the surface of the box to make it easier to navigate during assembly. Why is this being done? Most ventilation systems are assembled without the use of rubber seals or gaskets at the joints. If the box is installed correctly, the air flow will suck air from the room through the leaks. The air pressure in the flow is always lower than outside the box.

If you assemble the ventilation system incorrectly, then due to dynamic pressure, polluted air will leak through the cracks at the joints of the ducts.

Often, craftsmen resort to an interesting way to check the correct assembly of the ventilation system. Instead of inspecting each plastic box, looking for marks and arrows, a stream of smoke is directed into the hood and an electric fan is turned on. If the ventilation system is assembled incorrectly, then wisps of smoke will be visible at the joints of the plastic boxes.

For long-distance ventilation systems, as a rule, plastic boxes with rubber gaskets at the joints are used. The most problematic places through which air siphons are located at the outlet of the rotary elbows. Leaks can be easily detected by dirty spots on the plastic surface around the joint line.

Preparation for installation

Before starting the main work, you need to free up the space where the work will be carried out, remove unnecessary fasteners and old coating from the wall and ceiling surfaces. Then you should prime the walls and ceiling. Next, markings are made for the frame. You need to start from where the pipe will be located. As a rule, it rises vertically upward and runs horizontally under the ceiling.

The marking order is as follows:

- The required distance is measured from the lowest point of the ceiling and marked on the wall. A horizontal line indicating the lower boundary of the box is drawn using a level.

- A distance is set aside from the top of the wall, a mark is made and a horizontal line is drawn across the entire ceiling.

- From the two extreme points on the wall and ceiling, two more lines are drawn, perpendicular to each other. It is better to use a plumb line and level for this. On the other edge they do the same. As a result, the outlines of the future box should form.

Advantages and disadvantages of plastic boxes

It is clear that, in addition to plastic systems, there are metal air ducts, but the popularity of metal ducts is significantly inferior to plastic. There are quite a lot of reasons why plastic boxes are chosen for ventilation installations, here are just a few of them:

- Great appearance. A light-colored plastic pipe, or one painted to match the decorative finish of the walls, looks much more attractive than a galvanized or painted metal box;

- The light weight of the plastic box allows you to fix the ventilation system in almost any suitable place. For example, in pockets of suspended ceilings, on walls and in niches of kitchen furniture;

- The price of a plastic PVC duct is significantly lower than that of a similar metal air duct. For example, the most popular box, with a cross-section of 220x90 mm, costs $4.5 per meter, metal will cost $6-7;

- Good corrosion resistance of a plastic pipe compared to a metal box.

The last point, as practice shows, is one of the decisive values for ventilation systems in a bathroom or kitchen. The air flow of these rooms contains a large amount of chemically active substances and water vapor. As a result, the metal rusts, and pinpoint traces of corrosion appear on the joints and side surfaces. Ventilation ducts have to be painted or replaced with plastic air ducts.

Often, sellers of components and parts for arranging ventilation systems claim that plastic boxes create less resistance to air movement than metal ones. In reality, at air flow speeds of 3-5 m/s, the difference is almost unnoticeable, and the amount of dust and grease settling inside the boxes is approximately the same, regardless of the material.

For your information! The only, most important and most important disadvantage of plastic boxes is their high flammability.

PVC can withstand maximum long-term heating up to 120°C; at 200°C the plastic box begins to flow and lose shape; at 560°C the process of thermal decomposition begins with the release of very toxic gases. If we add to this a constant flow of air due to natural or forced ventilation, then very quickly smoke and decomposition products will fill all the rooms.

Therefore, metal boxes must be used in places where heaters and electric motors are installed. Otherwise, a flaming motor on a kitchen hood can lead to serious consequences.

Plasterboard models

This is a decorative, budget option. You can make it yourself. It will easily disguise an air duct made of corrugated material, which is clearly visible in the photo of the hood duct.

- Ventilation in the bathhouse - the best schemes and recommendations for their installation. Features of bath ventilation systems (90 photos)

- Exhaust pipe: the best models, characteristics, tips for selection and use (100 photos)

- Why windows sweat: main reasons, possible consequences and methods of elimination (80 photos)

The characteristics of the material limit the applicability of the model - it is used only as a decorative element. The benefits will be as follows:

- ability to adapt to a variety of interiors;

- variety of finishing solutions;

- budget.

Materials for choosing boxes for the kitchen, advantages and disadvantages

Decorative boxes that hide the elements of the ventilation system not only perform a decorative function, but also reduce the noise of the hood electric motor

It is important what material the box is made of

It must be resistant to moisture, temperature changes, and not subject to chemical and mechanical stress during cooking.

A box made of any material must be regularly cleaned of dust, grease and dirt. The materials from which boxes are made have their pros and cons.

Therefore, when purchasing or making your own, you need to take this into account. The structures are made from the following materials: plastic, metal, wood and plasterboard.

Plastic construction

Plastic is polyvinyl chloride. Plastic boxes have a round and rectangular shape. The rectangular box is more organic and looks good with the kitchen cabinets.

Quick and easy to assemble. The material has great sound insulation, is durable and has a long service life, and is not subject to corrosion. Easy to cut and adjust to fit. It is very light in weight.

The disadvantages of plastic include the fact that the white color becomes yellow, matte, or gray over time. Forms dents under the weight of objects or from mechanical impact.

After some time, its surface becomes porous, where dust and dirt penetrate, which is difficult to remove. When assembling connections of plastic elements, you must follow the sequence.

To ensure tightness, so that dirty air does not fall on the surface of the box and penetrate into the room, silicone should be applied to the joints. There are many different connecting parts available for sale.

With their help, channels are connected in any direction and at any angle. The fasteners of the structure must be placed often along the entire length at a distance of at least a meter, and also strengthened at the junction of parts with each other.

Metal construction

A metal box or hood is a more reliable design. Stainless steel is the ideal starting material. Ordinary metal is coated with powder-based paint.

Stainless steel is easy to clean, does not absorb dirt, is strong and durable. Features a stylish modern design. There are no visible scratches on it. The material is not subject to corrosion.

The disadvantages include the high price and the presence of a monotonous range of colors. Complexity of assembly, the need to maintain accurate measurements. The design is heavy and requires reliable fastening.

A box made of this material does not protect against noise, and fingerprints remain on the surface, which are difficult to erase. It does not always fit into the interior of the furniture and looks bulky.

When assembling a metal frame, welding is used and cut with a grinder. If the metal sheet is thin, replace welding with metal glue. The sheets are overlapped.

Plasterboard structures

A cheap, lightweight material - drywall is easy to assemble in any configuration and shape. It is necessary to install metal profiles for installation.

Allows you to assemble a box to hide the air duct in a short time

When working with drywall, care must be taken as the material is quite fragile.

The material is convenient and easy to process, so the box can be made and assembled by yourself, without unnecessary expenses or the involvement of a craftsman. The finished box can be processed, puttied and finished with tiles, wallpaper, mosaics and other decorative materials.

With proper use and pre-treatment against impacts, it will last a long time.

Decorative wood box

A wooden box looks harmonious with a kitchen set made of the same material. Possessing the same properties, it will be part of the kitchen, complementing the design of a certain style, and also fulfilling a functional purpose.

Wood is an environmentally friendly, reliable, good material that requires little maintenance. The disadvantage is the heaviness of the finished structure.

90 degree bends for rectangular ducts

To rotate a rectangular ventilation duct at a right angle, a 90-degree bend is used. At ITAL it is produced from durable, wear-resistant polymer plastic - PP (polypropylene) or HDPE (low-density polyethylene).

These materials are chemically neutral and are designed to last for several decades without repair. Maintenance of working ventilation made of polymers does not require large expenses.

The minimum dimensions are 10x10 cm, the maximum is 1.5x1.5 m or more. The proportions can be any. Products are manufactured with two types of connections at the customer’s choice: for complete tightness with flanges, or with socket fastenings to simplify installation.

If you need to design a complex air duct system for an industrial enterprise or non-industrial building, contact our specialists. We carry out all turnkey work - production of ventilation sections, delivery to the site, installation, warranty and post-warranty service.

You can buy or order a plastic rotating section of the air duct 90 degrees in any size.

Bends 45 degrees rectangular ducts

The production of plastic bends at 45° at our enterprise is carried out in any size and proportions. The minimum dimensions are 100x100 mm, the maximum is not limited. The shape and size of the outlet is matched to an existing air duct or developed as part of a single project - in the case of a complex order of chemical-resistant ventilation in its entirety.

The connection of this shaped part with the remaining elements of the ventilation system (most often straight sections) occurs using flanges or a socket. For a 100% sealed air duct, a flange type of connection is used. The socket mounting method is characterized by ease of installation. Considering the light weight of the plastic parts, this is easy to do even alone without special tools.

You can order a 45-degree bend from chemical-resistant polymer plastic, such as low-density polyethylene (HDPE) or polypropylene (PP). The choice of material should take into account the characteristics of use - temperature conditions, air mass composition and other parameters.

We recommend ordering an accurate calculation from our engineers. This guarantees you the lowest cost and high quality products.

Main characteristics of ventilation ducts

The main indicator by which a ventilation duct is selected is throughput.

Ventilation ducts are also characterized by:

- section shape;

- material;

- section diameter.

The dimensions of ventilation ducts are calculated using special tables that take into account the speed of air movement through the pipe and its throughput.

Form

rectangular boxes and a deflector with a round cross-section

The cross-sectional shape of the box can be:

- round;

- square or rectangular.

Round boxes have several advantages:

- The smooth inner walls of boxes with a round cross-section do not create obstacles to the passage of air flow;

- They are easy to clean as there is no place for dirt to linger;

- They create a little noise;

- Lower power fans can be used.

The main disadvantage of round air ducts is that they are difficult to hide in the interior.

With equal throughput, the cross-sectional area of a round box is 12% less than a rectangular one.

The largest and most powerful ventilation systems are equipped with rectangular steel ducts.

Disadvantages of boxes with a rectangular cross-section:

- Internal corners create air resistance;

- To cover pressure losses, it is necessary to install more powerful and energy-consuming equipment;

- More aerodynamic rumble.

Despite the disadvantages, the rectangular section is also popular in cottage construction. A flat ventilation duct is easier to hide behind a suspended ceiling.

Material

plastic ventilation ducts

Ventilation ducts are made from:

- steel (stainless or black galvanized);

- plastic.

You can build a ventilation duct in a garage or shed with your own hands from other available materials, such as boards or drywall. But the structure must be airtight!

Plastic boxes for ventilation do not deform over time and do not change color.

Other advantages of plastic ventilation ducts:

- easy to install;

- inexpensive;

- resistant to corrosion;

- if necessary, they can be further processed (for example, rolled);

- It is easy to select ready-made shaped parts.

Ventilation ducts are made from ABS plastic in various sizes, with round and rectangular cross-sections.

Section dimensions:

- plastic: 11x5.5 cm, 12x6 cm, 20.4x6 cm;

- round diameter: 10 cm, 12.5 cm, 15 cm.

Steel ventilation ducts are made from stainless steel sheet or black galvanized steel. Galvanized ventilation ducts are installed in residential and industrial buildings. Galvanized ventilation ducts are produced in standard sizes, and also made to order in especially large diameters. Shaped parts are also made to order.

Pros:

- do not rust;

- easy to install;

- easy to use;

- meet sanitary standards, since microorganisms do not take root on galvanized and stainless surfaces;

- any equipment can be installed directly on the network.

Recommendations from the pros!

Accessories for a bath Do-it-yourself gazebo Concrete fence Do-it-yourself potbelly stove Do-it-yourself veranda Screw foundation Do-it-yourself country toilet Decorative brick Stone fence Pouring a foundation How to make a fence Wicket from corrugated sheets Do-it-yourself fireplace Brick fence Do-it-yourself flower beds Forged gates Do-it-yourself porch Pool for a bathhouse Chicken coop do it yourself DIY staircase Metal gates Installation of lining Installation of polycarbonate Pump for a summer house Arrangement of a garage Fences for flower beds Do-it-yourself blind area Steam room in a bathhouse Railings for stairs Do-it-yourself cellar Painting walls Press with your own hands Grilles on windows Rolling gates Do-it-yourself barn Alarm system for a summer residence Benches for a summer residence Fence posts Floor screed Solid fuel boilers DIY greenhouse Fence installation House insulation Attic insulation Foundation insulation

Plastic boxes

Plastic boxes are made of polyvinyl chloride - a special material that has many positive qualities. These structures are environmentally friendly, resistant to various chemical liquids, are highly durable, are not afraid of temperature changes and are lightweight.

Unlike structures made of wood and MDF, these products are round, rectangular or square pipes that have a fairly neat and presentable appearance and fit into the interior of any room.

Another advantage of plastic ventilation structures is that they are easily hidden under suspended ceilings. Due to their reliability and durability, such structures will not cause forced dismantling of the ceiling due to unexpected damage to the ventilation duct. In addition, these structures can be easily covered with sheets of plasterboard, decorated with wallpaper or simply painted.

Quite often, plastic boxes are simply placed above kitchen cabinets. In this case, they look much better compared to corrugated pipes, which over time become covered with a layer of grease and dirt and are very difficult to clean. Plastic boxes are easy to care for, they have a neat and attractive appearance and do not spoil the interior of the kitchen. The disadvantages of these products are the high cost and complexity of installation.

Types of exhaust systems

The devices differ in operating principle, mounting method and shape.

According to the principle of operation, hoods are divided into:

- Active, with a built-in motor or fan.

- Passive, working only due to good traction.

There are two ways to attach a hood in the kitchen:

Open – when the entire structure is visible. This option looks aesthetically pleasing thanks to the designers’ developments. But the price of such a hood is higher.

Built-in - when all elements except the facade are hidden from view.

There are 4 forms of hoods:

- Island - attached only to the ceiling. Often used in kitchens with island-type work areas.

- Wall-mounted – attached to the wall.

- Built-in – great for small spaces. There are no air ducts here; the product is attached to a wall or duct.

- Corner is essentially a wall-mounted kitchen hood. Designed for cases where the stove is located in a corner.

Preparatory work

There are several stages of work on making a box in the kitchen from plasterboard. In order for the result to be good, you need to strictly adhere to the plan, which will be described below. What should be done:

- prepare surfaces for installation;

- make a schematic drawing of the box;

- apply markings to the ceiling;

- calculate the material;

- purchase everything you need;

- prepare the tool.

Now let's look at each stage in detail:

- The ceiling and walls where the box will be mounted are cleaned of old finishing material.

- The surface is primed.

Option for the design and decoration of a plasterboard box in the kitchen - All irregularities where the guides pass must be plastered, cracks and chips in the floor slab must be repaired, if there are large gaps in the corners, they are foamed.

Surface preparation should be done very carefully. Do not forget that the kitchen is a wet room, and the old coating may peel off over time.

Nuances of masking communications

Open gas pipes and valves do not look very nice. This can be corrected by placing them in a decorative casing. There are many options for these elements in hardware stores.

The second option is to make a box from plasterboard. It is made according to the dimensions of pipes and other elements of the communication system. The outer walls of the boxes are designed to match the color of the furniture or kitchen walls.

When choosing the option of how to close heating equipment, you should remember that the gas boiler and communications must remain freely accessible if they need to be repaired or checked for operating condition.

Conclusion

A range hood is a very necessary device in any kitchen. In conditions of constant cooking - frying, steaming, boiling - the air becomes a haven for a huge number of dirty particles that cannot be seen by the eye. They are subsequently inhaled by family members and can lead to unpleasant consequences.

A hood is a useful device, but to harmoniously combine its appearance with the overall kitchen set, you will need to purchase a ventilation box. It can be easily ordered - such boxes for hoods are provided by the Leroy Merlin company, and they are of very high quality. But if you wish, you can do it yourself.