To perpetuate the memory of the deceased, relatives erect a monument at the burial site. In order for it to last longer, it is necessary to choose durable fastening materials. Granite and marble do not lose their decorative properties for decades. But it’s not enough to spend money on a gravestone - you also need to install the memorial complex with high quality, using high-quality materials to hold all the elements together.

It is important to choose an adhesive for granite monuments that will last as long as the stone.

Advantages of granite adhesive

Craftsmen fasten the elements using reinforcement and glue. But it is not always possible to install metal rods without damaging the stone. But even when using reinforcement, it is better to additionally apply an adhesive composition.

Some craftsmen install using cement. But, as a rule, even a properly mixed solution begins to crack and collapse after a few years, unable to withstand temperature changes and external influences. The adhesive for monuments includes components that make the mass plastic and resistant to the vagaries of the weather. Such compositions can withstand from 35 to 50 winter periods and are resistant to moisture and sun.

Species diversity

Manufacturers offer many options for gluing a monument to the base. In order not to get lost in the variety, you need to know that they differ in composition.

Two-component epoxy compounds

This type of glue is based on epoxy resin. When purchasing, you need to take both components, which are mixed in equal proportions. Kneading is done before work. The composition can withstand high temperature changes, has good adhesion to the surface, and can withstand frost down to -50 °C and below. Water absorption is almost zero. Available in white and translucent versions, but can be tinted with colors. Used for grouting, gluing, and laying mosaics. This is one of the most suitable types of glue for white marble and granite monuments.

Epoxy adhesive

Polyester type

Polyester compounds are used when installing artificial stone slabs. Manufacturers produce colors so that you can choose a color for any type of stone. Available in liquid, solid and semi-liquid form. Mix in the recommended proportion with the hardener.

Polyester adhesive for gluing granite

Polyester glue is a polyester-based mastic. Composition with high adhesion, used at positive temperatures. You need to work quickly with this glue - it hardens within a short period of time. It lends itself well to sanding and grouting. By selecting the desired consistency, you can work on planes with any slope. For setting, hardeners are needed, which are added immediately before work. You can choose a transparent or colored option to hide the seams as much as possible.

Polyester glue

Impregnants

This variety is most often used for grouting joints and eliminating minor defects. The substance perfectly fills all microcracks and forms a film that protects against the penetration of moisture and sunlight. It is characterized by high frost resistance.

Cement

Cement-based solutions are the most popular. Special additives are added to cement, which, after drying, form a reliable adhesion of surfaces that is resistant to the vagaries of the weather. Before work, you need to dilute the composition with water according to the instructions.

What to pay attention to

The composition must have excellent adhesion and not change the original properties after hardening. It is not recommended to use universal mixtures, because in terms of frost and moisture resistance they are not able to satisfy the requirements for mixtures that should be used in conjunction with natural stone. This is especially true for cold climates, where operating conditions are the most difficult.

When choosing a glue brand, experts recommend paying special attention to the manufacturer. Those located in northern countries take into account the frost resistance factor and produce adapted adhesives

Domestic companies today have mastered the technology for producing high-quality mixtures. In all respects they are not inferior to imported analogues. However, the cost of Russian-made products is not much lower than foreign ones. The cost is sometimes unreasonably high.

Rules for choosing adhesive for granite

Before purchasing, it is better to consult with a specialist than to glue the monument to a granite base or repair a chip. You need to purchase goods in construction or funeral stores. What you need to pay attention to:

- The adhesive must be designed for outdoor use. Information about this is on the packaging. These compounds are resistant to weather changes.

- It is important to consider the temperature at which gluing will be carried out. Most formulations are designed for positive temperatures.

- The glue must be suitable for working with natural stone. This material is heavier than its artificial counterparts.

Requirements

For exterior work, frost-resistant adhesive for granite is selected. However, this is not the only important characteristic. Severe requirements are placed on stone adhesives.

Granite adhesive must meet the following characteristics:

- Strength. The glue that holds granite together should not be susceptible to the negative influence of environmental factors. It is resistant to aggressive substances, ultraviolet radiation, and alkali.

- Long service life. Granite itself is a durable material, so the glue must match without changing its properties and appearance over time. If the glue begins to crack, peel, or change color, this will only indicate a waste of time.

- Setting speed. The glue must harden quickly so that the product can be used literally within a couple of hours after work.

- Versatility. The adhesive must be suitable for exterior and interior use so that the product can withstand extreme temperatures equally well.

Review of popular brands of glue for tombstones

The assortment is large and you can choose how to fasten granite together on a monument in accordance with your budget and needs.

Glue "Liquid nails"

Liquid nails

“Liquid nails” are a quick and sure way of gluing surfaces. It is suitable for both horizontal and vertical locations, including heavy pedestals. Fixation is done very quickly, so when working with it you need precision and dexterity. After setting, it will not be possible to adjust the position of the glued object. Already ready to use.

Stone Service Neva

This line includes several options for stone adhesives on different bases. It has proven itself well in our weather conditions. Adhesive compositions are produced for granite monuments and for various needs. In addition, the assortment includes pigments to ensure that the adhesive joint is invisible on the stone.

Ceresit CM 117

Tile adhesive Ceresit CM 117 is also suitable for natural stone. Frost-resistant, moisture-resistant. Reliably glues in vertical and horizontal directions. Before gluing the monument, dilute it with water in the recommended proportion.

Preparation of the solution

To obtain all the properties declared by the manufacturer, it is necessary to prepare the solution according to the rules. Be sure to carefully observe the proportions of dilution of the dry mixture with water. You need to prepare the solution in the amount that can be used within the expiration date of the diluted product indicated on the package. This usually takes three hours.

The required amount of water is poured into a clean container, stirred with a mixer or a drill with a special attachment, and turn on low speed. Add the mixture little by little to the resulting whirlpool.

Adding the mixture to water, not vice versa, otherwise lumps will appear in the solution, which will make application difficult. When the mass has become homogeneous, proceed to using the composition.

The mixture is added to water, not vice versa, otherwise lumps will appear in the solution.

How to do gluing

To install a granite monument, it is best to hire a master who specializes in this. The monument consists of a stand, a stele and a flower bed. For work you will need tools and materials: glue, spatula, dishes for preparing the mixture, solvent, rag.

If the product is hollow, before gluing the granite monument to the granite base, the inside is filled with concrete, screwing in reinforcement for reliability. It is important that the base is level, check this with a level. The slightest distortion will subsequently lead to deformation of the entire structure.

Operating procedure:

- Preparation. The bonded surfaces are cleaned of dust and dirt. It is advisable to wash with a degreasing dishwashing detergent. Wipe to completely remove moisture.

- Coat both parts with solvent.

- Prepare glue according to instructions. The mass should be homogeneous, without lumps.

- Using a spatula, apply an even thin layer to the granite and align both parts of the monument. Place in the correct position.

- Remove any remaining glue with a rag. You can go around the edge with sealant.

- Wait until completely dry. Sand if necessary.

Installation of the monument

Gluing tiles to the wall

Before gluing granite to the wall, you need to properly prepare it. They start with cleaning work, removing all types of dirt, dust and any stains that can reduce adhesion. If large flaws are found on the surface, they are repaired with a layer of plaster. Then they move on to preparing the dry mixture; when the solution is ready, they move on to the main stage of work.

To reliably glue natural stone to the surface, first apply an adhesive agent to the wall surface with a tool, and only then to the tile material. The slabs are transferred to the wall, pressed against the base, and the material is maintained in this position for some time; the heavy weight requires waiting for the glue to fix. This is how you need to proceed with all the slabs, while checking the evenness of the rows with a level. If all work is carried out according to the rules, then a marble wall, staircase or other object will serve for decades and delight the owners with its beautiful appearance.

To reliably glue natural stone to the surface, first apply an adhesive agent to the wall surface with a tool, and only then to the tile material.

Adhesive for marble and granite can create a reliable layer that will firmly hold the slabs for many years. But at the same time, you should choose the product with special attention, otherwise you will have to carry out frequent repair work, which will deteriorate the appearance of the structure. There are many high-quality compounds on the construction market, but when purchasing, they ask for a certificate of conformity and quality so as not to fall for a fake, which will ruin all the work with its poor strength and low quality. The gluing process itself is simple, you can do it yourself.

How to glue a photograph to a granite tombstone: rules for choosing special equipment

You can paste the photo on the monument yourself. The composition for this is selected depending on the material on which the image is applied.

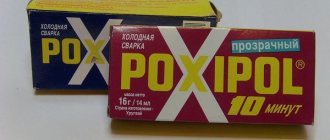

The adhesive layer in this case is very thin; it is important that it fills cracks well, does not allow water to pass through, and withstands temperature changes. Two-component epoxy glue Poxipol or liquid nails are suitable.

The process of gluing a photo to a monument

Sequence of work:

- Degrease both surfaces.

- Attach the photo to the plate and trace it with a marker or pencil to accurately mark the place of gluing.

- It is advisable to rub the back surface of the ceramic tile with the image with sandpaper to improve adhesion.

- Apply glue to the back of the photo and attach it to the stele. Press down.

- To prevent the image from slipping when setting, secure it with wire or twine. Bison glue is used to seal the seams.

- Wipe off excess glue.

A granite monument is a lasting memory of the deceased. It is durable and beautiful. Reliable adhesive for installing a monument will help keep the memorial in its original form.

Gluing a ceramic plaque with a photo to a granite monument

The first thing to do with the monument is to outline where the plaque will be located. To do this, simply apply it to the surface of the monument and draw an outline with a pencil.

Inside this outline it is necessary to make many small notches. We take a chisel or core and hammer the notches. Just don’t make strong impacts, these shouldn’t be holes, you just need to make the surface rough enough and get rid of the polish.

There is no need to drill anything, as the monument (not all of it, of course) can simply crack!

Now about the plate with the photo, depending on which surface (material) you choose, choose this method of degreasing. In my case it was ceramics, and that's what I did.

Using a file, I made marks on the ceramic on the back side of the plate, making a cage, and treated the surface with coarse sandpaper.

When this procedure is completed with the plaque and monument, take Feri or similar detergent and plain water and thoroughly wash the mounting surfaces of both the monument and plaque.

Be sure to wait until it dries completely!

Next, we do the following - we first buy gasket sealant for the car engine, I bought German Wuerth (see photo below), it was recommended to me in the store, it can withstand decent temperatures.

Now all that remains is to figure out how to press this sign to the monument for a while, preferably for a day. I did the following:

You have to wait at least 24 hours, but it took us a week because the cemetery is far away.

There may be better quality sealants, but I used this one (note the numbers 300 - it can withstand a larger temperature range):