Modern interior is a new approach to design, using only aesthetic design solutions. Relatively recently, a material such as PVC (polyvinyl chloride), a type of plastic, has become one of the leaders. Despite the dominance of white, many brands have long been producing options with increased decorativeness, color and texture. There is a demand for products with imitation of natural wood, stone, and brick. PVC has excellent technical characteristics. Resistance to negative influences has made polyvinyl chloride one of the most versatile materials. Panels are used to decorate technical and living spaces, walls and ceilings, interiors and facades. PVC cladding has virtually no weaknesses. Even from a renovation planning standpoint, plastic products outperformed other options. The key parameter of PVC panels is size. They determine the installation location.

Types of PVC panels according to purpose

This finishing material is widely used for finishing walls and ceilings. The former have characteristics of greater strength, the latter are lighter. When choosing, you should pay special attention to the purpose of the model you like.

Attention! PVC wall and ceiling panels are not interchangeable.

Dimensions of PVC panels - wall models have a length of 2.5 ÷ 6 m, a width of 25 ÷ 30 cm and a thickness of 6 ÷ 10 mm. Considering that the ceiling is not subject to mechanical stress during operation, ceiling products are made thinner. The sizes of PVC panels for the ceiling are 6 ÷ 10 m, 25 ÷ 30 cm and 4 ÷ 5 mm. Manufacturers offer products with matte, glossy and painted surfaces.

Using PVC panels as a finishing material, you can do without preliminary preparation of the base. Installation can be carried out without the use of special equipment, which significantly expands the possible scope of use.

Wall panels are highly durable

Lining

PVC lining has the following size standards: length - 3-6 m, width - 100 mm and thickness - 10 mm. Products of standard size are used primarily for exterior finishing. To use them indoors, just cut them to length. Textures and patterns are applied to seamless lining. The material is seamless and generally has high aesthetic qualities. At the same time, for decoration, seams sometimes “turn” into a plus. Panels of seamless systems have standardized dimensions. Widths are 100, 250 and 380 mm. The indicators correspond to lengths of 2.7, 3 and 6 m. Thickness, as a rule, always remains at 10 mm. For ceiling cladding, wide lamellas are chosen, and for walls, on the contrary, narrow ones are chosen. Regardless of the size, the installation of the lining is carried out in the same way and in the same way for different situations. It is recommended to form a metal base, especially when it comes to seamless structures.

Dimensions of PVC panels - standard dimensions

Standard dimensions of the material are determined by the type of panels. There are slats on sale with a thickness of 5-10 mm, the former are more fragile and require care during installation.

Advice! Forms of standard sizes are suitable for finishing small rooms, and for cladding the ceiling of a large plane, you should choose elongated slats - they are easier to install.

Dimensions of PVC ceiling panels accepted by manufacturers:

- lining – narrow and long dies 10 cm wide, up to 3 m long;

- reinforced lining up to 3 m long, but 12.5 cm wide;

- sheet panels with a width of 80-203 cm and a length of 1.5-4.05 m are manufactured;

- elongated dies 25 cm wide and 6 m long.

On a note! Before purchasing material, you need to take into account the width of the room and the layout. For example, with a room width of 3 m, lamellas 6 m long can be rolled out with virtually no residue by cutting the shapes in half.

Leafy

Sheet panels are distinguished by a “knocked down” configuration. The sheets cover a lot of space at one time, making work much easier. Sheet products are suitable for implementing interesting design ideas. The length of the panels is in the range of 95-245 cm, and the width is 50-122 cm. The thickness is usually small - from 3 to 6 mm. The sheets are made thin to keep the mass of products within acceptable limits. However, some manufacturers make thick versions. Sheet elements are not only of the correct shape; on sale there is also a brick version with edges designed for folding parts into a puzzle. In addition to the brick pattern, imitations of wood, tiles, mosaics and slate are made. The most common parameters are dimensions 980×480, 980×498 and 955×480 mm. The optimal thickness for such sheets is 4 mm.

Advantages and disadvantages of the material

Main advantages:

- plastic panels are insensitive to moisture, therefore suitable for kitchens and bathrooms;

- they do not deteriorate due to leakage, the plates can be removed, dried and put back in place;

- the material is lightweight, making it easy to install even without help; installation indoors takes only a few hours;

- they are inexpensive;

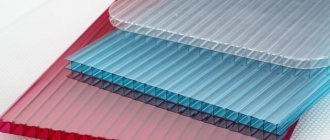

- a layer of air between the stiffeners increases sound absorption and also helps retain heat;

- you can hide wires or additional insulation above the ceiling;

- lighting is easily integrated into PVC panels;

- plastic tolerates temperature changes well from -80 ° C to + 80 ° C, therefore it is suitable for balconies and loggias;

- the material is durable, manufacturers provide a guarantee of about 10 years;

- if necessary, it is easy to replace individual panels;

- It is enough to take care of it, just wipe it with a sponge or a soapy rag, but products with abrasive particles, strong alkalis or acids are not suitable;

- They are available in a variety of designs, have many colors, textures and patterns, so they are selected for almost any interior.

But the material also has its drawbacks:

- seams are visible on the panels, so it will not be possible to create a uniform ceiling; this drawback is also noticeable in seamless options, although their cracks are less noticeable;

- the height of the room is reduced, as with all hanging structures;

- poor-quality finishes burn and release toxic substances when heated, as well as immediately after installation;

- It will not be possible to mount a multi-level ceiling, since there are no suitable elements and accessories.

Manufacturers

Currently, hundreds of large and small companies produce building materials. Which manufacturers of PVC panels for the bathroom are best to focus on when purchasing this type of product? Experts advise choosing products from well-known brands. Leading companies value their reputation, so they offer certified panels for sale. They are safe for health. Among domestic manufacturers, the following have proven themselves well:

- "Plast-Decor";

- AnV-Plast LLC;

- "Ural-Plast";

- LLC "Planet Plastic";

- "Decoplast";

- "Sadko"

- "Kronaplast";

- "Komplast";

- "Alta-Profile";

- Green Line LLC;

- Pareti LLC.

They offer quality material at a relatively low price. Among the leading foreign firms, the following should be highlighted:

- Forte (Italy). The company's product range is quite wide. Among the products produced are Le Murino plastic panels covered with stone chips.

- Deceuninck (France).

- Venta (Belgium). It also has production workshops in Russia. This allows us to produce products of European quality at affordable prices.

- Chinese products, as a rule, are not of high quality. However, this does not apply to Shanghai Zhuan. It produces certified panels at reasonable prices.

- Grossfilex (France). It also has its own factories in Russia for the production of plastic panels.

- Blancoplast (Germany).

- Vox (Poland).

- Wavin (Netherlands).

- Rolplast (Belgium).

Dimensions of PVC panels - standard parameters

PVC panels are two sheets of polyvinyl chloride connected by stiffening ribs. One of the faces is the front one, designed using a specialized technique, that is, it has decor. PVC panels not only perform a decorative function when decorating a room, but also create additional insulation in the house. TO

In addition, plastic products protect the surface of the ceiling from exposure to aggressive environments, and also hide some of the ceiling’s imperfections (irregularities, leaks).

Manufacturers produce PVC panels not only for ceiling surfaces, but also for vertical surfaces (walls). Basically, when choosing a finishing product made of polyvinyl chloride, you should pay attention to the standard sizes of the slats. But manufacturers make decorative panels not only according to the standard, so you can order panels of any size.

The length of the slats can be different: 270 cm, 3 m, 395 cm and 1.2 meters. Thanks to this variety, it is possible to install it on the required surface with a large area. Panels with a length of 595 cm are in greatest demand, because they can be used as a finishing material for small and large rooms.

The width of the building material can vary from 10 to 50 cm. Basically, panels with a product width of 10 and 12.5 cm have a visible joint. The most popular slats are 25 cm wide; when installed, virtually no visible joints are formed. Panels with a width of 300 and 375 mm are used as finishing material for any surface, but they must be at least 10 mm thick.

The thickness of the products depends entirely on their purpose. The ceiling slats have a thickness of 5 to 8 mm. For such products, strength does not matter. Wall building materials have the greatest thickness (10 mm), unlike previous options, because they must withstand mechanical damage and exposure to ultraviolet radiation.

For joining and fastening panels, manufacturers produce PVC profiles that correspond to the parameters of the planks. The length of such profiles varies from 270 to 600 cm.

With thermal transfer or thermal printing

The manufacturing principle is to form a pattern or image on a polymer film and then apply temperature to transfer the pattern to a plastic panel. Actions are performed on special equipment. The process is called thermal transfer. The products have gained popularity due to their increased resistance to high temperatures and the thermal effects of steam, heat and direct sunlight. Assembling the system will not cause difficulties even for beginners. The dimensions of the material are given to standard values: 250 mm for width, 8-10 mm for thickness, 2.7, 3 or 6 m for length. Thermal printing makes it possible to apply highly complex designs on PVC panels in almost any color and shade. The technology works thanks to high temperatures and accurate calculations. The thickness is traditionally 8 mm, and the full parameters are, respectively, 300 × 25 × 0.8 or 270 × 25 × 0.8 cm.

Types of plastic panels

Depending on the parameters, PVC planks are available in different varieties.

Plastic tile panels

The tile material is similar in appearance to ceramic tiles. The standard dimensions of this product are 30x30 cm, 98x98 cm, 100x100 cm, their thickness can vary from 1 to 5 mm. Tile panels can be used in combination with simple tile options that imitate natural stone.

Plastic wall panels

Wall slats are used to decorate wall surfaces. Thanks to a wide range of products, it becomes possible to create an original image in the interior of the room. The width of the products is from 15 to 50cm, the size is 2.6m, 2.7m, 3m, thickness is from 6 to 10mm.

Plastic sheet panels

They are large in size. When working with this type of panel, a significant area is covered - it will be unusual and interesting to design.

Standard sizes: width – 50-122 cm, length – 0.9-2.44 m, thickness – 1-6 mm.

Plastic lining panels

It has a smooth glossy finish and is available in a variety of colors. The connection is made using a male/female locking system, which makes installation easy. Vertical laying of boards visually makes the ceiling higher, and horizontal laying makes the wall wider.

Standard sizes: width – 10-30 cm, length – 0.9-3 m, thickness – 4-8 mm.

Plastic panels with 3D effect

This type of product is used not only in the design of residential buildings and apartments, but also in office buildings and shops. The original drawing allows you to create a unique design in the room. Lamels with this effect imitate natural wood, natural stone, ceramic tiles. Standard parameters: width – 25 cm, 37 cm, 50 cm, dimensions – 2.7 m, 3 m, thickness – from 8 to 10 mm.

With thermal transfer

The production technology of this type of product is carried out in such a way that an image or pattern is displayed on a polymer film, after which this image is transferred to a plastic building material under the influence of high temperatures using specialized equipment. Thermal transfer panels are considered the most popular among homeowners, since they are highly resistant to high temperatures, and installation will not cause any particular difficulties even for a novice builder. The width of the panels is 25 centimeters, the size is 2.7, 3 and 6 meters, the thickness is from 8 to 10 mm.

Laminated products

The method of manufacturing laminated panels is that a film with a pattern and bandage is glued to the front side. This manufacturing method gives the finishing material additional performance characteristics; It is quite difficult to spoil such a model or image. Laminated panels are treated with an antiseptic that prevents small dust particles from settling on the surface of the product. The quality of panels of this type is confirmed by the appropriate quality certificate. Width – 25 centimeters, dimensions – 2.7 and 3 m, thickness – from 8 to 12 mm.

With 3D effect

Products with 3D graphics decorate apartments, private houses, public places, office and shopping centers. Three-dimensional drawings can expand space, and are better than glass, mirrors and light shades. In addition to the print itself, the coating can simultaneously imitate stone, tile or wood. Clients have a wide choice of effects, and there should be no problems with the correct design of the room. Buyers are offered options with widths of 250, 370 and 500 mm. The length of the lamellas is 2.7 or 3 m, and the thickness is 8-10 mm. The possibilities of 3D design are not limited to drawings. The coating of products may contain large bulges - instead of a play of shadows and depth of color. Such plastic strips are also called 3D panels. Volumetric plastic coverings are much easier to install than options made from other materials. And their additional advantages are:

- design diversity;

- ease of care;

- favorable price-quality ratio.

How to calculate the required quantity?

Before you begin calculating the required amount of building material, you need to find out the perimeter of the working surface on which PVC panels will be mounted in the future. Afterwards, along the general perimeter, it is necessary to calculate the area of the existing openings, then the resulting difference must be divided by the perimeter of the finishing product.

Let's consider an example where the external walls of a one-story house with an area of 6x8 meters and a height of 2.5 meters will be faced with PVC slats. This room has 4 window openings and 1 door. In this case, PVC panels with parameters of 2.5 mx30 cm will be used.

Total wall surface perimeter: (6 + 6 + 8 +

x2.5 = 70 m2.

We calculate the difference between the total area of the building and the openings of the rooms: 70-10.62 = 59.38 m2.

Area of 1 PVC product: 2.5x0.3 = 0.75 m2.

We calculate the required number of panels for work: 59.38 / 0.75 = 79.17 pcs.

The resulting number must be rounded up. As a result, 80 pieces of PVC panels are required for cladding a one-story house.

When purchasing decorative plastic panels, it is necessary to take into account not only the room parameters, but also the installation method. In this case, you should take into account the price category of the parts, since long panels differ significantly from short slats, but, in turn, this does not affect the quality of the products. Also, when finishing the walls, decide on the thickness of the finishing building material, because the thicker the panels, the better the sound and heat insulation in the room.

Calculation of the required material

Wall and ceiling panels have standardized parameters. For the first option, the following indicators are provided: length - 2.5-6 m, width - 250-300 mm, thickness - 6-12 mm. Narrow elements are easier to assemble. Ceiling strips have the following parameters: length - up to 10 m, width - 125-380 mm, thickness - 3-5 mm. The ceiling version may be smaller than the wall version, because the load on the ceiling is always less. Calculating the amount of material begins with measuring the perimeter of the base for the sheathing. The perimeter of windows and doors is subtracted from the result, and the resulting indicator is divided by the perimeter of one panel. Calculations are translated into determining area. The opposite sides of the room are summed up and multiplied by the height. The area of windows and doors is calculated only in one plane, multiplying the height by the width. The difference between the results obtained is divided by the area of one panel.

Calculating the material will not be difficult, but planning the original configuration will require special calculations.

Recommendations for working with plastic

Before installing the finishing product, it is necessary to keep the panels in the room where such installation is required. The product must be acclimatized. This is necessary so that the building material gets used to the ambient temperature.

In addition to finishing materials, you will need additional elements:

- inner corner;

- initial profile;

- finishing profile;

- plinth.

Installation begins from the corner of the room towards the window or door. First, the inner corner is installed. The slats must be cut to size and the slabs must be cut to suit the installation method.

The plastic product is inserted into the corner profile and mounted on the sheathing. You can use a mechanical stapler for this, but clamps are considered the best option. They are installed at the bottom of the groove and fastening is carried out through the hole in the clamp. This fastening method does not deform the plastic product, and also ensures 100% fastening of the building material. Fasteners are selected at the rate of 2 dowels per 1 meter of profile and 2 self-tapping screws with large plugs per 1 meter of PVC plank size.

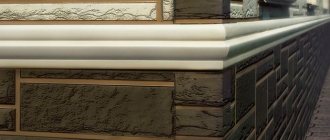

Subsequent elements are assembled using the “male in groove” method. In this case, the panels should be joined as tightly as possible. At the end of the cladding, a joint is formed between the wall surface and the floor, which must be covered with a plinth. To seal the joints on the ceiling, a more decorative ceiling plinth is used, which should be in harmony with the overall decoration of the ceiling.

The number of skirting boards is calculated based on the total area of the ceiling. Standard plinth 3 meters long. The total perimeter of the ceiling surface must be divided by the size of the baseboard, after which the resulting value is rounded to a multiple of 3.

Processing with plastic products can be carried out at temperatures from -5 to +50 degrees, so wall decoration in bathrooms and saunas is not carried out. At the locations of switches and sockets, it is necessary to first install special boxes and lay an electrical cable. When installing the strips, you need to drill holes for switches and sockets.

There are 2 methods of gluing plastic products:

- on the crate;

- onto the adhesive solution.

Installation of facing panels or sheet metal can only be done on the frame. This is due to the large size of the products. The frame in this case can be made of wooden or metal slats. The height of the frame depends on the number of irregularities on the working surface.

Plastic building materials in the form of tiles are mainly attached with glue. In this case, it is necessary to carry out preparatory work. The surface must be cleaned of various contaminants, leveled and treated with special means. The tile panels are glued as tightly as possible so that no gaps form under the products.

Sheet

These panels are significantly different from those described above. Most often they are made from foamed PVC. The thickness of the sheets varies from 1 to 30 mm.

The width and length of this type of panel varies significantly. These parameters can range from 327 to 2000 mm. When producing sheet panels, special substances are added to the composition, making the material impact-resistant and very light. Due to this, it has wide application.

Which PVC panels for the bathroom are better? What to take, clapboard or sheet? Perhaps it would be better to purchase a panel? The answers to these questions depend on the purpose of using the material. For finishing ceilings, lining is often used, since it is lighter. Sheets are definitely not suitable for this purpose, as they are more difficult to install.

Technology and installation methods

The strips are fastened using the tongue-and-groove principle with a contact depth, which allows for quick installation and dismantling of the coating. There are two main installation methods: on a frame (cassette) and without it. In the first case, a metal base with rectangular holes is assembled. In the second, such lathing is not needed; only approximately smooth walls and an adhesive or concrete base are enough. The disadvantage of this option is the difficulty of replacing individual elements. The ceiling is finished in only one frame, and this is due to the ability to hide communications and place built-in lighting fixtures, for example, spotlights, in some places. The material is glued to the walls to create the most durable surface. Plastic structures last longer if they do not sag due to pressure on the edges. If the frame method is used, it is better to glue the plastic to the pre-assembled drywall.

Decorative options

Decorative PVC wall panels are becoming perhaps the most popular among finishing materials in the interior. Cladding with PVC panels is a labor-intensive and dust-free finishing method. The installation of PVC panels is carried out similarly to the process of assembling a children's construction set, so even a non-professional can handle it.

The quality and aesthetic features of decorative panels allow you to implement original design ideas in conditions of budgetary and guaranteed quality repairs. The presence of 120 colors and textures, various shapes and textures will help you accomplish these tasks.

When buying plastic panels, make sure that they are smooth and do not have waves, dents, or changes. It is desirable that they are from the same batch and do not differ in color or shade

The quality of the installation will only be achieved if smooth slabs are used: without distortions, shifts and with invisible joints.

Please pay attention to the availability of sanitary and hygienic safety certificates, product compliance with technical specifications and GOST. You can see the installation of PVC panels below

You can see the installation of PVC panels below.

Application areas of panels and beautiful examples

You should not use plastic over the entire wall area if moisture exchange in the room is of great importance. For example, a mini-greenhouse with a dozen flowerpots will be ruined by continuous finishing with PVC panels. But in places with rapid pollution and high humidity, a material such as plastic is indispensable. These include window slopes and separate rooms: bathroom, kitchen, hallway, balconies and loggias. The panels are in perfect harmony with plastic windows and doors. However, the perfect combination can easily become redundant if you decorate the interior without thinking. But well-chosen panels will decorate the decor in almost any style direction. Buyers have a wide choice of textures and patterns. With minimal design skills, it won't be difficult to decorate a room in a quality, nautical or historic space.

Bedroom

Silence and comfortable temperature are important for the bedroom. PVC panels will not only improve the design, but also provide high-quality heat and sound insulation. From the headboard side, the bed can be decorated with original plastic panels. White color options are suitable for youth interiors, for example, for decorating a niche. Wood-colored coating is used to decorate bedrooms in country log houses. Under panel panels are used as expensive cladding. Plates are also combined with wallpaper in a contrasting color or tone. The material is suitable even if the bedroom is decorated in the spirit of minimalism in neutral colors or in a restrained version of the classic style. A confectionery-colored and nautical-themed room with a predominance of blues and light blues is also a suitable environment for cladding with PVC lining.

Bathroom

In this part of the body the panels will definitely not be superfluous. The color of grout on tiled floors often deteriorates and PVC finishing is a beneficial alternative. PVC plastic is not only “not afraid” of moisture, but also does not deteriorate due to temperature changes. If a problem arises with the water supply or communications under the panels, the operation will be quickly resolved, and the coating will be restored just as quickly. Light colors are more beneficial for the bathroom. PVC sheets make the color even more saturated and improve the visual expansion of the space. Straight lines between the panels add expressiveness to the interior. In the bathroom, options with a wavy pattern or texture will be relevant. Traditional wood products along with similar sanitary ware are a completely acceptable solution for bathrooms. The panels usually pair well with glass, metals and ceramics.

Optimal colors for the bathroom:

- blue and white;

- blue;

- green with white;

- green with pink;

- brown with white.

Kitchen

Like the bathroom, the kitchen “requires” finishing with moisture-resistant materials. The PVC coating does not interfere with wet cleaning in any way. In combination with decorative properties, panels become the best option and are gradually replacing tiles from their dominant position. The trend is also supported by the low cost and ease of installation of PVC shells. At the same time, in terms of decorative properties, it is approximately not inferior to a tiled floor. Even an untrained person can assemble the panels. This is an additional saving. It is appropriate to use all types of coatings inside: glossy, matte and satin. Drawings and prints will not make the situation worse. The apron is finished with skinal, a type of PVC panel. The space near the stove is decorated with LSU sheets. For kitchens, heat-resistant options are chosen and these properties are the first to be asked about.

Living room

It is not customary to completely decorate a guest room with one material. PVC sheathing can be combined with different types of coatings. Modern style in the living room is achieved through spectacular transitions. For example, one of the walls is covered with a board, and the rest are “set” in a color contrasting with it. In the living room, it is important to use panels “like” leather, brick, stone and wood. A 3D version of a ceiling panel is an opportunity to significantly “increase” the height of the room. The same design techniques are used on partitions, arches, columns and other elements of the premises. The panels perfectly emphasize horizontal niches, which are increasingly found in living rooms. Tile-shaped slabs are used to create specific designs, with joints at different angles, at different levels and with built-in lighting. In this case, the choice often falls on panels with a natural or artificial wood pattern.

Methods of drawing

There are several of them:

- Offset printing. This is the most budget option. The pattern is rolled onto the surface using a special roller. The top of the product is coated with glossy or matte varnish. Using the offset printing method, they create an imitation of tree bark, stone, marble, and so on.

- Thermal transfer. In this case, a film with a pattern is pressed onto the surface of the panels and ironed with a silicone roller heated to 180 degrees Celsius. Under the influence of heat, the image is printed on the panel, after which the film is removed. Such surfaces do not need to be coated with varnish, since the color pigments of the design are securely attached to the product. They do not wash off or wash off.

- Lamination. With this method, the panels are covered with a very durable film. It gives the product a decorative appearance and protects it from mechanical deformation. Laminated panels are more expensive than others. However, they are also more reliable.

Which PVC panels for the bathroom are better? Undoubtedly, laminated ones are most suitable for wall decoration. Their main advantage is increased strength. However, there are other criteria that need to be taken into account when purchasing this material.

How to choose and buy high-quality PVC panels

Having decided to purchase PVC panels, you should first decide on a suitable model. Considering the large range of products offered by manufacturers, in the selection process it is worth focusing on the main purpose of the room. Based on the chosen stylistic design of the room, it will be easier to make a choice in favor of one model or another.

During the purchasing process, you should make sure that all products have a perfectly flat surface. Only in this case will the formed coating have a presentable appearance. All slats must be from the same batch so that they do not differ in color. It is best to make a purchase in a specialized store.

If you have not yet decided on a suitable model, we suggest you look at photos of PVC panels in the interior to make your choice easier

1 of 6

Panel quality characteristics

High-quality material must meet a number of characteristics, many of which can be determined visually:

- the strength of the material can be judged by the number of stiffeners, which in no case should be deformed;

- the color should be uniform and the pattern clear;

- when connecting two copies of a product, they must be connected without gaps, which is very important;

- there should be no waves on the surface of the panels;

- Panel measurements must exactly correspond to the data indicated on the label. If this is not observed, then this indicates that the manufacturer has saved on raw materials;

- It is better to make a purchase in a trusted, branded store, where you can protect yourself from purchasing a low-quality fake.

Dimensions of PVC panels and release form

The thickness can be 5 mm or 8 ÷ 10 mm. For these standard sizes, manufacturers offer moldings in standard configurations and sizes. The sizes of plastic panels depend on the form of their release. Manufacturers make cladding 3 m long. For the widest panels, the length can be 2.6; 2.7 or 3 meters. Some manufacturers offer material up to 6 m long. This length is sufficient for finishing indoor walls without horizontal seams. The width depends on the release form:

- Liner. Width 10 cm. Manufacturers offer planks with a standard wide lock, which is sometimes called European, and with a narrower one (polka dots). In double-profile structures, the width increases to 12.5 cm, but this material has found limited use. Upholstery colors may vary. However, the most popular products are white;

- Panels. Width can be 15 ÷ 50 cm;

- Sheet. Width 80 ÷ 203 cm with length 150 ÷ 405 cm. Sheet thickness can reach 30 mm.

Manufacturers offer products of various shapes and sizes.

Wall

Options for the wall with any form factor have a thickness from 6-8 to 12 mm. Seamless modifications have a length of 2.6, 2.7 or 3 m and a width of 15-50 cm. The length of standard panels is represented in a wide range - from one and a half to three meters. The longest options are purchased for offices. 6- and even 10-meter slats are made to order. Standardization applies to wall panels. In addition to unusual options, there are nine standard sizes on sale. For a width of 100 mm, there are length options of 2.7 and 3 m. The indicator of 175 mm corresponds to a 3-meter length. The 238 mm version comes with a length of 2.6 m. Panels with a width of 250 mm are 2.7 or 3 meters long. Products of 375 mm have the same compliance. Three-meter panels also come in increased width: 400 or 500 mm. Standard dimensions are also a width of 1035 mm with a length of 0.5 m, and 1220 mm with a length of 2.44 m.

Dimensions of PVC ceiling panels

When choosing a plastic profile for the ceiling, you should not only pay attention to the appearance of the desired material, but also correlate its dimensions with the configuration and size of the room. It is worth giving preference to the standard size, which minimizes waste. So, if the ceiling in the bathroom is 1.5 m wide, then PVC ceiling panels with a length of 1.5 ÷ 3 m are often chosen. Using slats whose length is a multiple of the length of the room can reduce the number of butt seams.

Ceiling finishing is often done with products 2.5 ÷ 4 meters long and 10 ÷ 50 cm wide. Overlays and profiles of standard width are quite popular. The choice of standard sizes depends not only on the size of the room, but also on the shape and location of the lighting fixtures.

The size of PVC panels may vary.

Laminated products

The material is made by gluing a film with decoration and images onto the front side of the panels. Manipulation gives PVC planks improved performance properties. It will not be easy to spoil the design, and the plastic itself will receive some protection from mechanical stress. Laminated products are treated with an antistatic agent to prevent dust microparticles from accumulating on the surface of the images. The decorative film is covered with a transparent polymer film. The quality of the panels is confirmed by the appropriate certificate. In terms of dimensions, the thickness of the products is usually in the range of 8-12 mm, the length is either 2.7 or 3 m, and the width is 250 mm. Plastic panels are painted with special compounds. They hide natural imperfections in the form of minimal unevenness and smooth them out. The surface of laminated products can be either glossy or matte.

Common sizes of PVC panels for walls

For convenience, we will combine data on wall finishing material into one table.

| Visualization | Length, cm | Width, cm | Thickness, mm |

| Rack | 90 ÷ 300 | 13,5 ÷ 30 | 6 ÷ 8 |

| Regular wall | 260, 270, 300 | 15 ÷ 50 | 8 ÷ 12 |

| Tiled | 30, 98 | 30, 98 | 2 ÷ 4 |

| Sheet | 98 ÷ 244 | 50 ÷ 122 | 3 ÷ 6 |

Advantages and disadvantages

Plastic panels are popular and in demand finishing materials. The relevance of such cladding is explained by many advantages.

- Plastic panels are wear-resistant materials. They are not afraid of moisture and dampness. Thanks to this quality, the finish can be safely used when decorating a bathroom or kitchen.

- High-quality plastic panels retain their original appearance for many years.

- This finish will not require complex and regular maintenance. Plastic does not accumulate dust and dirt. If stains appear on its surface, then you will not have to purchase special and expensive compounds to remove them - most stains from plastic panels can be removed with a regular damp cloth.

- Plastic panels are inexpensive. This is why many consumers choose this finishing option. It will cost several times less than decorating walls with tiles or wood.

- Wall panels made of plastic boast good sound insulation qualities.

- Installation of such finishing materials is simple and quick. It can be produced without the involvement of specialists, which allows significant savings.

- Using PVC panels you can create zoning of the available space.

- Such finishing materials are light in weight, so working with them is easy and convenient.

- Plastic is a material that is very easy to process. Thanks to this quality, these coatings are presented in a fairly rich assortment. To decorate a room, you can choose canvases with absolutely any images and colors.

- Plastic is a safe material. Even at high temperatures, it does not emit hazardous and harmful substances. However, when purchasing panels, you should ask the seller for a quality certificate and make sure that the plastic contains no toxic compounds, since such components may still be contained in low-quality material.

- Finishing materials can be installed not only in city apartments, but also in private houses. In addition, they are well suited for installation in cramped conditions.

- Using this material, you can hide many floor defects: cracks, drops, potholes, depressions and other flaws.

- Behind plastic panels you can hide various communications, for example, electrical wiring.

Despite the large list of positive qualities, plastic wall panels also have their weaknesses.

- The material is highly flammable. In the event of a fire, this product burns very intensely and spreads choking smoke into the room.

- In a room with plastic finishing, a characteristic chemical smell can linger for a long time. But here it is worth noting that many owners did not notice this shortcoming.

- Plastic panels do not tolerate temperature changes well. Under such conditions they may become deformed.

- Plastic itself is not the most reliable and durable material. Panels made from such raw materials may break from an accidental impact or under severe loads.

- These products are not “breathable” finishing materials. They prevent the movement of air through the walls, and this is simply necessary for high-quality ventilation. For this reason, experts do not recommend installing such coatings in children's rooms.

- The voids that are present in plastic panels can become a home for insects. This problem is especially relevant for the southern regions of the country.

- Before installing the facing material, it is necessary to carefully prepare the floors. Many masters consider this fact to be a disadvantage, since it takes a lot of time.

Types of plastic wall panels

Based on the type of connection between panels, they are divided into three categories:

- seamless slats;

- panel with embossing;

- beveled plastic strips.

Seamless slats

Plug connection allows installation of a continuous cover

The discrete panel joints are equipped with male and female locking locks.

The panel, with its lateral protruding edge, fits into the groove of the next lamella; for this purpose, it is formed almost in the form of a continuous facing plane.

It is not recommended to mount panels directly on walls. There is no need to waste time and materials to get a perfectly smooth fence surface and then cover it with a coating.

Relief panels

The panel has a thin edge on the side that fits completely into the groove of the next strip to a width of 5 mm.

Vertical grooves on the finishing plane visually form the appearance of a fence made of wooden boards (cladding).

Plastic panels with bevel

Panels of this type can be quite wide. The side surface of the lamella ends with a decorative strip (bevel). The connection method is similar to that of embossed panels.

Frame installation

Make markings on the wall. Two wooden slats should be positioned horizontally at the top and bottom. Vertical slats should be at a distance of up to 40 cm from each other so that the plastic does not bend;

Drill holes and insert dowels into them. Secure all slats;

The starter and corner panels need to be installed first. They are screwed with self-tapping screws to a wooden frame;

Secure the panels by inserting them into the appropriate plastic fasteners.

Recommendations for working with plastic when finishing

If the wall is flat, the material can be attached directly to it. It makes sense to make a frame when you need to cover up the old finish (wallpaper, paint, tiles) or level a wall without plaster.

In addition, the rotation improves sound insulation, helps retain heat and leaves room for ventilation behind the plastic.

making a wooden base is cheap and easy. Modern antibacterial compounds contribute to the long service life of wooden structures. The bars are installed parallel to the direction of the PVC panels, every 50-60 cm.

The frame is also made of U-shaped plastic profile, its advantage is that it is insensitive to moisture, lightweight, does not deform from extreme temperatures and is not electrically conductive.

The profile must be secured in increments of no more than 30 cm, with self-tapping screws or dowels every 0.5-1 m. To join U-shaped parts, cuts are made at 90˚, 45˚, 30˚. To secure the plastic, you will need clamps (clamps).

To work with panels you will need moldings:

- internal and external corners;

- joints;

- the edges; baseboard;

- finishing elements;

- F profiles

Dimensions of PVC panels for living rooms

When treated with an antiseptic, it is permissible to make a frame in the living room from a wooden beam.

The premises are decorated with wood, stone, and white brick. Use decorative, laminated or mirrored plastic.

One of the walls can be decorated with other forms of PVC material. Rectangular or square structures measuring 0.3-0.98 m are used, and the seams are separated.

Dimensions of PVC panels for bathrooms and toilets

For a bathroom, it is better to make a frame from a galvanized or plastic profile. A material without a relief is best suited - due to high humidity, fungus or mold can form, and a rough surface is difficult to clean.

Bathroom panels go well with ceramic tiles, textured plaster or paint. The main thing is to choose the right shades. It will work out well if you alternate the width and contrast of the elements.

Prints and patterns of different colors will help you create an original design. PVC panels for the bathroom go well with a slatted ceiling, into which mirror inserts can be made.

Dimensions of PVC panels for the kitchen

An inexpensive alternative to ceramics for kitchen decoration can be inexpensive panels (panels at a low price).

You can choose combinations of brick and natural masonry, mosaic, pattern or ornament.

There are tile modular options from which the designs are made; models can be combined to completely decorate the kitchen or its individual areas.

A few additional tips:

When purchasing plastic material, you should pay attention to the absence of surface defects and dented joints. There should be no translucency on the stiffeners. When lightly pressing the product, tears and cracks should not form. Choose panel widths to reduce waste

For small apartments it is not advisable to use a panel with a width of 500-600 mm. The quality of the material can be checked by folding it. It should not have any cracks or cracks. In most cases, the more expensive the material, the better it performs. Leave (from mold and mildew) ventilation holes.

If you want to make lighting or built-in lights on the ceiling from PVC panels, it doesn’t hurt to make markings and prepare holes in advance.

Tiled

This option is used not only in technical rooms such as the bathroom and kitchen. Tile panels of large sizes and non-standard shapes are purchased for the living room. Bathroom decoration most often consists of simple square products. In large bathrooms, the parameters reach 1x1 m - on the walls and ceiling. Modular options with many tenon joints are placed on the floor. It is better to clad small bathrooms with 10x10 cm panels with inclusions in the form of textural elements. Compositions in the form of mosaics are attached to the surface due to the connection between the elements and glue. Meter samples are often placed in kitchens, corridors, and terraces. The undeniable advantage of plastic lies in its external diversity. It is much easier to give this material an unusual shape than ceramics. As a result, any combination of ornaments, textures and colors become available.