Garage door locks, their types and specifics of operation.

DIY garage lock. Currently, on the product market you can easily find all kinds of locks and other devices that prevent strangers from entering private property, including a garage. But despite the wide variety of types and models presented, locks for garage doors will occupy a leading position in the list of simple security systems for a long time. Garage locks are designed to keep your garage safe. Thanks to them, you can quickly open and close the gate without using any keys, which tend to get lost.

Possible designs

Among all the designs of garage locks, the following can be distinguished:

- Vertical. Suitable for swing doors. A kind of hook-holder that is fixed at the base of the gate. A bolt like this is very difficult to break.

- Horizontal. The most popular retainer. Installed at the top, center or bottom of swing gates.

- Additional locking fasteners. Mounted on a gate frame or canvas.

In turn, for greater clarity, we can divide all structures into certain types:

The rotating mechanism is a vertical tubular post, which is strengthened by four support axes and a lever in the center. The design is easy to fold.

The bolt lock is quite strong and durable. There is a thread cut on it, through which a key with such notches passes. The bolt bar is held in place by a spring.

The sliding lock consists of two bars with rings. When moving one over the other and aligning the rings, a lock is inserted from the inside to secure it.

Varieties

Differentiating gate locks is reminiscent of an extensive medical classification, in which there is no clear way to select preferences and criteria due to their huge number. Even people who are engaged in the retail sale of locking mechanisms and clamps find it difficult to distinguish between existing types.

The simplest thing is to divide it into horizontal, vertical and additional types. The main difference is focused on the direction of the locking tongue or more primitive devices for outbuildings, gates, and interior doors. These are places where the likelihood of a stranger entering is minimized due to the existence of basic, more reliable ones.

Deadbolt with lugs

A specialist who has a warehouse with hardware and lock products at his disposal can easily divide his assortment into the following categories:

- Specific hangar security mechanisms designed to lock massive metal doors and gates of enormous dimensions, the weight of which cannot be supported by any standard device.

- Container locks are massive and durable locks, often purchased in order to provide maximum reliability and protect a built-in garage or estate from burglary. They are more often used for sliding gates than for swing gates.

- Simple bolts, latches, latches and hooks, the main function of which is not so much locking as fixing or restraining.

- The most complex devices, such as electric drives or electronic automation with alarms. They are rarely successful for amateur enthusiasts. Those who can afford such luxury buy locks from Cisa, which even have access control on the keypad, or automation from Nice.

Deadbolt diagram

Sometimes there is a gradation in appearance, weight and functionality for a certain material. For example, a model of a lock for a gate made of corrugated sheets with a spring so that the gate or door closes spontaneously. Vertical constipation can be divided according to location - in the middle, below or above. There are also horizontal ones, differentiated by the same distinctive feature.

Drawing of horizontal lock

Construction type

Each owner of a plot of land, garage, container or warehouse should carefully study the types of locking structures. In this case, it is necessary to take into account not only reliability, but also the ability to confidently resist hacking or brute physical force. You can also purchase gates complete with a locking mechanism.

Automated systems

Automated garage locking systems would also be a good solution. Such mechanisms fall into two categories:

- Electromagnetic. The principle of protection is based on the operation of an electromagnet: under the influence of voltage, it fixes the sash immovable. A key card or code is used as unlocking.

- Electromechanical. The mechanical basis is the crossbar system that sets the door in motion. You can unlock this lock using a key, code or application.

To prevent the buttons from jamming, we recommend periodically changing the password code. The proposed move will help prolong the use of the automated lock.

Modern types of constipation

Progress does not stand still, and now it is not uncommon to see electric drives or electric locks on gates. For the automation of swing gates, both solenoid-type drives and a device consisting of electric motors and cables are used. The latter type is often assembled independently, unless, of course, it concerns sliding gates, which work precisely on this principle.

Electromagnetic locks are quite often found in special stores and organizations dealing with access control systems. The principle of their operation is that when voltage is applied to it, an electromagnet is triggered, which attracts a wicket or gate leaf to itself. Moreover, the attraction occurs with quite a lot of force, and without special equipment it is almost impossible to open such gates.

Mounted electromagnetic gate lock

Electromechanical locks are practically no different from conventional locks, except that the bolt in them is set in motion using electricity, and such a lock can be opened not only with a mechanical key. Both types of locks are activated using a magnetic key, radio key fob, magnetic card, RF tag , hidden button, code panel and similar systems.

For some particularly avid security enthusiasts, companies may now offer a fingerprint detector that will open the gate when a fingerprint is read. For gates, these systems are usually additionally equipped with audio or video intercoms, which allow you to talk to a visitor from home and open the gate for him. Recently, these devices operate on an electric current of no more than 12 volts, which makes them safe for use and eliminates electric shock.

Electromagnetic lock option for welded gates

Of the most economical options, there are mechanical combination locks. They open when you press certain groups of numbers at the same time.

There is a very wide selection of locks and latches for gates and gates on the market. Various designs of deadbolts and their types will allow almost every owner to choose deadbolts to suit their taste and needs. The choice of device depends on the goal to be achieved and, of course, financial capabilities. Some simple types of constipation can be made independently at home.

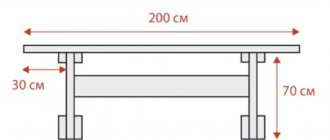

Diagram with dimensions for making a homemade gate bolt

Of course, sometimes it is enough to buy a standard mechanism, but often site owners assemble them themselves.

What you can do yourself

Any protective system made independently has its advantages: it allows you to manufacture a structure that is no longer produced, and also save time and money. We offer detailed instructions for making garage locks with your own hands, so that you can choose the most suitable option.

The easiest way to create locks is the time-tested pinwheel. Finding it on sale is extremely problematic. In short, it is a strip fixed with a through bolt; when locked, it rotates around a horizontal axis and fits into the grooves.

The turntable closes only from the inside and ensures a tight fit of the swing gate leaves.

The materials you will need are a metal strip or beam (optimal thickness - 50 mm, length - two-thirds of the width of the gate).

- We fix the beam in the center of the gate, to the edge of one of the leaves, secure it with a through bolt (10- or 12-mm) and place washers on it.

- We install several hinges for locking at the top and bottom, which will allow the doors to be opened with a rotational movement.

It would not be superfluous to treat the materials for the lock with an anti-corrosion compound to preserve the mechanism in bad weather and precipitation.

Horizontal crossbar

In other words - a latch. This type is often used for entrance gates. Unfortunately, it will not create a tight fit of the sashes, however, it still remains a reliable and durable system.

Creating a locking device:

- We bend a piece of reinforcement (diameter - 20 mm) into the shape of the letter L or weld a handle.

- We install pieces of pipe, rings or hinges on the sashes.

- We attach a tube (diameter a little more than 20 mm) to the opposite flap to tightly fix the segment.

Threaded locking mechanism

To make locks on this type of garage door, you will need a metal strip. The length of the material must exceed the length of the sashes. On one side, we install the bar on a separate eyelet on the wall.

At the end of the other side you need to create a hole in the rail for the bolt. We make a thread in the wall or gate hole. A metal casing is attached on top of it to further protect the mechanism.

Security vertical bolt

We install the structure on the frame; a lever is attached closer to the edge of the sash. The main material is a profile pipe or a metal corner. To make the bolt, you need to weld several pieces of pipe to the frame and make holes in it to secure the sash.

A lock is also needed to secure the lock itself. This will be facilitated by a protrusion for the locking lever.

When creating a hole, take into account all the parameters of the gate - length, height and weight.

Electromechanical lock

To independently create a combined electromechanical design, use the lever mechanism we have already mentioned. The plates with figured cutouts are removed from the lock, replaced with a guide and attached to the crossbars. For them, a hole is made in the end of the second gate leaf (less fixed).

The corners are welded at the fastening site, and then a lock is installed. The power source is a battery or power supply. This type of locks is quite expensive. Do not forget also that without electricity in the garage it will not function.

Vehicle safety comes first. We have collected information about the designs, types and operation of additional garage lock mechanisms; We have collected material on how to create locks to protect garages with your own hands. Everything to make the garage a fortress for the iron horse.

We hope we have made a contribution to protecting your car from intruders. We welcome comments and sharing our information.

Barrier for garage doors

The barrier does not ensure a tight fit of the gates, but it is impossible to open the gate from the outside. The strip is made from a wooden block or channel.

- We drill a hole for a rotary bolt (M10 or M12) at a distance of 8 cm from the end of the bar. Bolt length - take into account the thickness of the sash, the thickness of the locking strip itself and two washers, leaving a thread for tightening the nut;

- drill a hole for the bolt in the gate leaf, attaching a strip of lock;

- it is important that the bolt on which the barrier rotates has a wide, strong head, since it bears the entire load and emphasis;

- We weld three gripper grooves onto two sashes. One groove on the sash, where the barrier strip was secured, is closer to the end, the second - opposite, on the other sash, also closer to the end of the sash, the third - at the farthest end of the second sash, so that the end of the barrier strip fits into it.

Additionally, in the last groove you can make eyes for attaching a padlock. In the video, the process is clear and easy to perform; all you need is welding and a few strips of metal. https://www.youtube.com/watch?v=ir22ua7vpa8

Main types of latches

Garage gate latches vary in design. Some of them can be done independently without significant difficulties. Others are best purchased in a store or ordered from a specialized company.

Horizontal latch

Horizontal latches are most widespread. Suitable for locking gate leaves and gates. The design of the devices is simple: a rod, a fixing ear and a holder.

Image No. 1: diagram of a simple horizontal latch

Latches are installed on the outer and inner sides of the sashes. For maximum protection, you can attach a lock to the mechanism; for this purpose, special ears are welded onto the lock.

Vertical latch

Photo No. 2: vertical gate lock

This design has also become widespread. The latch for swing gates securely fixes the doors. The locking function is performed by a metal rod curved in the shape of an G. In the closed position, it goes into recesses on the floor or ceiling.

Image No. 2: this is what the vertical lock looks like on the general diagram of swing gates

The convenience of a vertical latch is that it is not visible from the outside of the structure. This feature makes it more difficult for an attacker to enter your territory.

Self-closing latch

Photo No. 3: self-closing latch on the gate

To make a latch that will latch itself, you need to attach a fixed metal strip to the sash. If the gate is closed, the lever clings to the plate and prevents the gate from opening. The latch is attached to one bolt. The second one is screwed in nearby to limit the mobility of the lever. To unlock the door, you simply press the lever that releases the bar. To close the lock, slam the door.

Overhead sliding lock

Photo No. 4: overhead sliding lock

A convenient type of latch for gates and gates, which is an improved modification of the horizontal latch. The rod of such a valve is flat. The design is easily attached to any flat base and ensures reliable locking of the doors.

Secret castle

Photo No. 5: secret lock on the gate

If a secret lock is installed on the door, the key hole will not be visible from the outside. At the same time, there is a valve on the reverse side. To open it, you need to unscrew the hexagonal head of the bolt. When turned, the rail secured by it sets the valve in motion, and the doors open or close.

Deadbolt lock with rack system

Photo No. 6: bolt lock with rack and pinion system

It is better to buy such locking structures ready-made. The lock consists of a key with recesses and a base. Its main advantage is its extended service life and high strength indicators. There is also a drawback: the key can be easily faked if desired, so in addition to the deadbolt lock, you need to install a mortise lock.

Image No. 3: deadbolt lock diagram

Spring-based espagnolette

Photo No. 7: latch with a spring base

An espagnolette for sliding gates, which has a spring base, will be a good addition to a combination or mortise lock. The spring simplifies the process of opening/closing the doors. Most often, such structures are installed from the inside.

Image No. 4: diagram of a latch with a spring base

Reliable locking options for garage doors

The most convenient designs are those with springs. They firmly hold gates and doors. Such locking designs can be installed anywhere - on the gate frame or on the door leaf itself.

Garage door locks - main types of design:

- horizontal locking mechanisms, which can be installed in the center of swing gates, or at the top and bottom;

- vertical constipation;

- additional locking mechanisms, which are usually installed for convenience rather than for safety. They simply prevent the doors from swinging open from a gust of wind or draft.

Options for convenient and reliable locking mechanisms for garage doors:

- mortise lock;

- sliding lock of the invoice for swing gates;

- rotary lock;

- screw and crossbar mechanism;

- garage door lock with fixation. The lock can be fixed using a groove, rotary or spring method.

The choice depends only on personal preferences and financial capabilities. It is quite possible to make analogues of some expensive mechanisms at four times cheaper with your own hands.

A little about mortise locks

The lever lock mechanism, which ensures secrecy, is not recommended for a garage, especially in the northern regions. Often the plates of this “Tetris” jam, and opening the lock becomes very problematic.

A simple and reliable security mechanism that is suitable for any lock in the garage - a rack and pinion lock. We cut a saw on the edge of the bolt and on the key itself (you need corner grooves and protrusions). When the drill-like key is inserted and pressed, the gate opens easily. Such a simple and reliable mechanism can be installed even on a large massive lock.

This design can withstand any frost. The only negative is that the key is too big. But you can’t limit yourself to just a gate lock; you need reliable side and central locks for swing garage doors.

How to make a gate latch with your own hands

Making a gate latch with your own hands is quite simple if you have basic welding skills and the right tools. Since individual types of designs are manufactured differently, as an example we will focus on a simple version of the locking system - a latch with a spring.

Required material

To work you will need:

- metal plates of the required size;

- steel rod;

- metal eye;

- spring;

- metal cable.

Necessary tool

Prepare the tools you will need to make the latch:

- vice;

- roulette;

- pencil;

- hacksaw for metal;

- hammer;

- screwdrivers and wrenches;

- screwdriver;

- electric drill;

- welding machine.

Stages of work

- Marking. Determine the location where you plan to place the valve. Make notes on the gate or wicket using a tape measure and pencil.

- Drawing. Draw a diagram of future constipation. The design of the garage door latch is shown schematically below.

Image No. 5: DIY latch diagram

- Making the frame. Weld the rod holders to the metal plate. Attach the handle to the rod and insert it together with the spring into the finished frame.

- Product installation. The latch is mounted on metal doors using a welding machine or a screw connection is used. If the gate is wooden, a simple fastening with self-tapping screws will do. Opposite the rod, make a hole for fixing the valve.

- Manufacturing of torsion mechanism. You are almost finished - you have made and installed the gate latch yourself. However, for now it can only be opened from the inside. To upgrade the lock, build a torsion bar mechanism. Take a metal cable and drill a hole for it in the bottom of the sash. Secure the cable to the bolt eye and pull the free end to the outside through the hole. Now, by pulling the cable, you can open the latch from the outside.

Sliding locks

It’s easier to buy it in a store and just weld it to the swing garage door leaves. But, if this is not possible, then you can make such a valve yourself:

- you need a metal strip - length 40 cm and width - 5 cm;

- this strip should move along the guide grooves;

- guides on both sides of the leaves can be welded to the leaf on a metal plate on the gate leaf;

- We attach the bolt itself to the other sash with metal screws or welding;

- We attach brackets to the strip, from the edge and to the edge of the guide so that they can be additionally secured with a padlock.

Be sure to check the correct alignment of the grooves and strips several times so that they do not jam when closing. Then you can lubricate the locks with machine oil.

Important tips for making your own constipation

Note! To ensure that the constipation lasts as long as possible, protect it from external influences. For these purposes, a protective pocket made of metal or other material is suitable - such a device will prevent moisture from entering the mechanism.

If you are planning to buy a sliding gate with a wicket, you can make your own latch to lock the system. An important condition for proper installation is taking accurate measurements and creating a competent drawing. This job can be easily handled by a handyman who has the necessary tools in his arsenal.

If the description of the process seemed complicated to you or you are not confident in your capabilities, we recommend purchasing a ready-made lock and ordering its installation from the Masterovit company. In this case, you can rest assured that the mechanism is installed correctly and your property is not in danger.

Modern types of constipation

Progress does not stand still, and now it is not uncommon to see electric drives or electric locks on gates. For the automation of swing gates, both solenoid-type drives and a device consisting of electric motors and cables are used. The latter type is often assembled independently, unless, of course, it concerns sliding gates, which work precisely on this principle.

To close the gate, two types of locks are mainly used - electromechanical and electromagnetic.

Electromagnetic locks are quite often found in special stores and organizations dealing with access control systems. The principle of their operation is that when voltage is applied to it, an electromagnet is triggered, which attracts a wicket or gate leaf to itself. Moreover, the attraction occurs with quite a lot of force, and without special equipment it is almost impossible to open such gates.

Mounted electromagnetic gate lock

Electromechanical locks

For some particularly avid security enthusiasts, companies may now offer a fingerprint detector that will open the gate when a fingerprint is read. For gates, these systems are usually additionally equipped with audio or video intercoms, which allow you to talk to a visitor from home and open the gate for him. Recently, these devices operate on an electric current of no more than 12 volts, which makes them safe for use and eliminates electric shock.

Electromagnetic lock option for welded gates

mechanical combination locks

It is recommended to change the combination of numbers as often as possible for greater security. In addition, over time, the numbers begin to wear off, and it is not difficult to determine which ones need to be pressed to open the lock.

There is a very wide selection of locks and latches for gates and gates on the market. Various designs of deadbolts and their types will allow almost every owner to choose deadbolts to suit their taste and needs. The choice of device depends on the goal to be achieved and, of course, financial capabilities. Some simple types of constipation can be made independently at home.

Garage Door Deadbolts

To protect the garage from burglary, several locks are usually installed on the garage door. The problem is that the basic standard designs of locks are already known to thieves and therefore can be opened quickly. But there is a way out - you can make a reliable deadbolt for garage doors with your own hands.

The good thing about homemade locks is that you can make them of a design unknown to attackers, with which they will not know what to do. High security locks are even more secure. Swing gates allow you to install almost any locks and bolts on them. It is difficult to install locks on other types of gates (sectional, up-and-over) by yourself, so it is better to use the services of specialists to solve this problem.

Choosing the best locking system option

Garage doors, for the most part, have a standard design: two leaves attached to the frame via hinges. Accordingly, the choice of a locking system is mainly determined by the preference of the owner.

For external gates

For external gates, a latch (horizontal bolt) and a flask locking system are optimally suited. The design of the latter is quite simple, so installation of the structure is not difficult, and the mechanism will last for many years.

For swing gates

For swing garage doors, it is recommended to use a vertical deadbolt. This is due to the fact that open doors can be fixed by lowering the metal pipe. The latter will keep the garage door from gusts of gentle wind.

Types of deadbolts

To securely fix the sashes, latches are used that press one or both sashes, as well as internal bolts that open from the outside in a special way.

Flask latches have a lever and work on the same principle as the latches on flasks and cans, hence the name. Such locks pull the gate to the frame and press it tightly.

Container locks are also suitable. They are based on a cam mechanism that rotates the rod to close or open them with just a little effort. Ready-made locks of this type may have an additional security mechanism.

Screw fasteners - turnbuckles - do a good job of attracting the gate to the frame, but opening and closing them takes a lot of time.

Latch type bolt

The latch for swing gates is most often made of a metal rod with a diameter of 1 centimeter. Using welding, the handle is attached to it in a T-shape or simply bent. It is additionally important to prepare a hollow tube (it is advisable to choose dense steel). The inner diameter of the tube should allow the rod to pass freely inside without backlash or delays.

Algorithm for performing the work.

- Divide the tube prepared in advance into 3 parts - one long up to 10 centimeters and two short (about 5 centimeters each).

- The long part is attached to one leaf. For the second - a short part. Attached by welding.

- Insert the rod into the tube, and secure another short part within the edge. Check that the doors open and close without obstructions.

- In addition, eyelets for a padlock can be installed.

Revolving lock

This is simple and effective for garage doors, however, it is difficult to find them on sale. However, it is easy to make a pinwheel yourself. It is located from the inside of the garage, there are no parts from the outside, so it is impossible to open it from this side. It acts as a lock for the doors; it is closed from the inside and exits through a gate, which is locked from the outside.

The pinwheel is an iron strip or a profile rectangular pipe. A through bolt acts as an axis.

- Holes for the bolt are drilled in the middle of the pipe and in one of the flaps

- If there is an additional lock on the bolt, make ears for it.

- Temporarily screw the bolt and mark the places where the brackets into which it will fit will be located. They should be in the shape of the letter L, one facing down, the other up.

- Unscrew the bolt and attach the brackets.

- An eyelet for a lock is made on one of the brackets.

- All parts protruding from the outside are cut down and welded.

Varieties and characteristics

Garage valves can be mechanical or electric. The first type of constipation is divided into the following types:

- flask;

- rotating rack;

- constipated;

- horizontal;

- screw;

- protective.

The optimal solution, in terms of installation time and ease of use, is a vertical latch, which can be used to secure closed and open gates.

The listed types of mechanisms differ in their design features and scope of application.

Flask locking systems

The flask lock consists of two elements: a lever with a hook, which is fixed to a loop mounted on the second leaf or frame of the garage door. This reliable mechanism withstands long-term use and is not sensitive to blockages. In order to break the structure, considerable effort will be required.

Rotary rack

The rotary rack (eccentric) garage lock is a structure consisting of:

- a tubular stand mounted vertically on a gate or wicket;

- a lever that is mounted in the central part of the rack;

- hooks located in the upper and lower parts of the rack.

The latter cling to small cylinders installed on the garage door frame. In terms of strength, this mechanism is no different from a flask, but requires the use of alloy steel in the manufacture of hooks and stands.

Locking pin

The locking pin has the following design: a cylinder is welded in the center of one of the doors, onto which a rotating metal (less often wooden) bar is fixed. Further, closer to the ends of the latter, 2 rod clamps (stops), which are usually made from angles, are mounted on the garage door.

This locking mechanism was popular among garage owners 20 years ago. It was believed that the pinwheel could not be opened.

Horizontal crossbar

Horizontal garage door locks are easy to use. These valves have the following design:

- 2 pieces of small diameter pipe are welded onto one of the flaps;

- 1 scrap is welded onto the second leaf;

- A pipe of smaller diameter, bent on one side in the shape of an “G”, is inserted into these scraps.

Deadbolt with a secret

You can make a garage door secret with your own hands, for example, this way:

On the inside of the sash, sections of a rectangular pipe with a cross-section of 15 cm are welded, which act as guides. A rectangular rod 4.5*4.5 cm moves along them. One of the guides is welded at the end so that the bolt does not fall out. The length of the bolt is 120-180 cm.

The bolt on the outside has 4 bolts, of which only one has a useful function - it keeps the bolt locked. The rest are just for distraction.

A fake keyhole, behind which there is a part of the castle, also acts as a disguise. If you insert a key or master key into it, a complete illusion of opening the lock will be created; in reality, nothing happens. In this case, a special screwdriver or spark plug wrench is used to open the bolt. There are cuts in the rod, when the key hits them, it moves the bolt.

On top there is an internal safe lock with long bolts.

Opening the gate with this tricky lock goes like this:

- slightly unscrew the required bolt holding the bolt,

- insert a special key (screwdriver) into the lock, open the bolt with several turns,

- open the safe lock,

- open the second flap, which is held from the inside by vertical bolts.

The lock must be lubricated regularly, all 4 bolts must be unscrewed one by one so that it is not clear which one is used more often.

How to make a simple pinwheel deadbolt

Do-it-yourself “spinner” deadbolt for garage doors:

- a metal strip (5 mm) or a wooden beam can serve as a locking mechanism for double-leaf gates. The length of the strip or beam is 2/3 of the width of the gate;

- Such a turntable rotates on a bolt (12-15 mm) which is installed in a fixed gate leaf, approximately at a level of 60 - 70 cm from the ground, so that it is convenient to open and close the gate;

- on one and the other side of the valves, at a height of 60 - 70 cm, we weld two groove profiles into which the valve strip should freely fit when closed;

- distance - approximately in the center of each swing gate leaf - the strip in the closed position should protrude slightly beyond the edges of the retaining profile;

- In order for the bolt to easily turn on both sides, we put two washers on it.

Important. From the outside, the head of such a bolt must be ground off and painted over so that it is not visible

Barrier type bolt

The design principle is similar to a turntable bolt, only the locking metal strip is fixed not into separately welded narrow grooves, but into a channel that is welded across the entire width of the second gate leaf.

Additionally, you can weld eyes on the end of the channel and the locking strip so that you can secure the bolt with a padlock.

Sliding bolt for gates with fixation

If you can simply make a turntable or a barrier with your own hands, if you have a welding machine, then it is better to buy a good, reliable gate valve for a garage door in a store. Depending on the material of the valves, you can choose the design and size of the valve.

The disadvantage of such a lock is that there is no strong fixation; in strong winds, the gate leaves made of corrugated sheets become twisted. Therefore, it is better to install three latches securing the doors at a distance of 50 cm from above and below and one in the center of the gate on the stiffening rib.

Vertical bolts

A vertical bolt is simply a fitting (12 or 14) bent on one side in the shape of the letter G, approximately 70 cm long. The principle of locking the doors with a vertical lock:

- Pieces of pipe must be welded to the gate leaves on both sides; the diameter of the reinforcement rod must fit into this pipe;

- We cement two more pieces of pipe into the garage floor on one side and the other - this is fixation for the shut-off valves;

- in the closed state, the fittings are fixed in the pipe, the gate cannot be opened.

To make it convenient to open the gate, weld fixing grooves on both sides into which you will insert the curved handle of the fittings of such a vertical bolt.

Espagnols

The design principle is the same as for a vertical bolt, only the fittings and the pipe along which it moves are fixed on the gate leaves in a horizontal position, approximately in the center.

For security, you can weld padlock lugs onto the hasp.

All of the above locks do not secure the gate leaves tightly. You need to install several simple valves or start making a more complex but reliable lock that tightly presses the doors.

Sea container type locking mechanism

A convenient design of a lock for swinging garage doors, which every garage owner will appreciate - no need to bend over and reach when opening and closing the garage door. It’s easy to make constipation yourself:

- on the pressing flap we weld ring clamps with a leg for a smooth pipe with a diameter of 15 - 16 mm in three places. The first is at a distance of 20 cm from the top of the gate frame, the second is in the center of the leaf and the third is 20 cm from the floor;

- We attach two hooks on both sides of the pipe;

- We weld two clamps for hooks to the frame at the top and bottom;

- When turning the pipe, the hooks securely fix the pressing flap.

In the middle of the rotating locking tube with hooks, you need to weld a 30 cm piece of pipe - this will be a handle for conveniently turning the bolt. The principle of such a lock can also be seen in trucks - it fastens securely and hermetically.

Bolts and latches for plastic decorative fences and gates

Gates, wickets and fences made of modern materials, such as plastic chain-link mesh (PVC) are beautiful, inexpensive and convenient. But what type of lock can be installed on such gates and gates? If you choose a plastic picket fence for building a fence and the same gate, then the best option is a magnetic lock.

Metal products are not suitable for such modern designs and do not look very nice. Magnetic locks are reliable, durable and practical devices.

Attaching such a lock to a gate leaf or a gate is not difficult with your own hands. All parts are attached with self-tapping screws. As you can see in the photo, such a locking device is the best solution.

Latch lock

The lock structure is shown in the figure. The main feature is your own individual key with which you can open it.

- For the base of the lock, a metal sheet approximately 3 mm thick is used. A round plate with a diameter of 10 cm is cut out of it.

- For the overlays, the same sheet is used, they are made rectangular 120*22 mm. Using a vice, they are bent as shown in the figure.

- A guide tube with a diameter of approximately 10 mm is made, one end is cut at an angle of 60 degrees, as in Fig. 4.

- A valve is made.

- The overlays are welded to the edges of the base.

- To fix it to the gate leaf, holes are made in the corners of the plate.

- The guide tube is inserted into the hole in the plate, the bevel should be directed towards the plates. The tube is welded perpendicular to the base.

- A valve is placed in the linings.

- Screw 2 screws with a diameter of 4 mm (M4) into the valve. They act as limiters for the valve.

- Next they make the key.

- One of the ends is bent at a right angle. On the other side, make a cut at an angle of 60 degrees. Cut out the beard and collect the key.

- Several additional holes are drilled in the valve.

The most successful options for locking garage doors

Of all the different designs of constipation, the least reliable are latches and latches. The design of such a mechanism is simple to the point of primitiveness. Essentially, it is a metal rod in a steel cage. When the rod is moved using the side lever, the edge of the locking element fits into the slot on the adjacent leaf and blocks the movement of the gate.

You can install it on the gate with your own hands in five minutes, but its resistance to burglary is extremely low, primarily due to the weak housing of the clip.

If you need a truly powerful garage clamp, you should use one of the following designs:

- Flask lock for garage doors;

- Rotating rack mechanism;

- Constipation - pinwheel;

- Bolts on welded frame.

Espagnols and vertical locks

The easiest way to make different types of latches. To do this, you need a piece of pipe in which cuts are made for the open and closed position of the bolt.

Homemade bolts can be vertical or horizontal; they are suitable for swing and sliding gates. Their disadvantage is that they are not able to tightly tighten the sash to the frame, so they need to be improved or additional locks installed. If the latch is vertical, then it fits into a hole in the floor or ceiling of the garage. To make the lock more durable, a piece of pipe of a suitable diameter is inserted into the hole in the floor. To prevent the lock from falling out, stoppers are made on it, as in the photo. The bolt itself should be quite long, the holes in the floor should be about 0.5 m deep.

The vertical bolt can be made in such a way that it is lifted by a hidden cable. The cable is raised by a gear that is rotated by a screwdriver or key inserted into a hidden hole next to the keyhole. As a safety net, an emergency cable is made, which is located in a different place and which can be pulled manually if the mechanism breaks.

You can make various types of locks and deadbolts for your garage yourself, some of them are simple to make, some require the ability to operate a welding machine. An important advantage of homemade locks is their non-standard design, which will better protect the garage.

Safety lock for swing gates

The technology for making a lock for swing gates is easy to understand when working with a structure made of corrugated sheets. This material is most often found on fences of summer cottages, barn doors, and garages. Locks are attached to frames made of corrugated pipe or frames made of metal corners. The owner decides for himself which method of fixation to choose.

A profile pipe is a reliable, but unattractive option. The iron corner is a prettier part, but rather weak in terms of strength and rigidity.

Locks for swing gates, assembled with your own hands from corrugated sheets, are traditionally sliding overhead mechanisms that engage with the frame. The process of installing them begins with calculating the number of parts and determining the location. Double-leaf gates require two locks - just one for each leaf.

The master's auxiliary tools are a vice, screwdrivers, pliers, a set of keys, and a tape measure. Electrical equipment that will be useful is a drill, grinder, and welding machine.

The main work is done like this:

- Mark on the frame the location of the bolt, the length of the rod and the place where it is inserted into the soil.

- Two identical rods are cut from metal rods and shorter pins are welded in the upper part, making it easier to lift and lower the device. The length of the rod must be calculated so that it can hold the entrance panels closed. The pin must be immersed in the ground to a depth sufficient to protect the object.

- The recesses are broken through with a garden drill, maintaining diametrical correspondence with the rods.

- 2 iron rings are welded to the frame of the valves, in the holes of which a lock will be placed.

- A hook-hook for the lock handle is welded a little higher (it will be needed to secure the mechanism after opening the gate).

As you can see, arranging locks for gates with sheets of corrugated sheets is quite within the capabilities of a novice master. Self-manufacturing of devices saves budget and increases design reliability. Remember that even the most expensive lock can easily be cut by an experienced attacker. So why take the risk when you can put a reliable lock on the gate and brag to others that it was made with your own hands.

Basic models of constipation

In the modern world, there is a huge variety of products and gate bolts are no exception. Their main differences lie not only in appearance, but also in the method of fastening, type of design and ease of use. Masters distinguish 3 main types of such mechanisms, each of which can be made with your own hands:

- Horizontal, which are divided into upper, central and lower. Horizontal locks are best installed on garage doors.

- Vertical, which also have 3 subsections - upper, central and lower.

- Additional. Such elements are most often placed on the gates of private houses or the doors of outbuildings.

Deadbolts

Folding gates

Another popular and simple option for garage doors is folding or folding ones, which do not take up as much space when opened.

Do-it-yourself sectional garage doors are made like swing doors, but each leaf will be divided in half. This will help fold each side in half when opening and save the space required for plowing.

There are other advantages of folding garage doors:

- Original external design of the gate sections.

- Convenient way to open and close.

- When opening a place, such gates practically do not engage.

- If one of the sashes or sections is damaged, it can very easily be removed for repair or replacement separately from the entire structure.

- The cost of gates is slightly higher than in the case of swing gates, but still quite affordable.

The disadvantages primarily include problems with constant rapid wear of mechanisms. In addition, the safety of this version of the gate is not very high compared to the same swing gates.

Latches and latches for sliding gates

You can also use other locking devices for gates, such as garages.

Emphasis

Deadbolt lock

To understand how to make a bolt for a sliding gate, you should carefully read the recommendations. This design is quite effective; it cannot be opened from the outside. To make it, you will need sliding parts from a GAZelle car.

But some craftsmen also assemble it from scrap materials. First, two corners are attached to the sliding gate. They should have round holes, and the clamps should be placed at the same level. Under them in the ground you need to make a small depression of round diameter.

Option from professional pipe

A tube with a bend in the shape of the letter “L” is passed through the holes of 2 corners. It is inserted into a hole in the ground. This model is often mounted on sliding garage doors.

Vertical constipation

With their help, you can protect the area from entry by unauthorized persons. First, the pipe is installed on the wall or frame of the gate itself. Reinforcement is being made for the lever. A small diameter tube is attached to it. It will keep the structure from opening. This mechanism is also suitable for gates made of corrugated sheets.

Advantages of self-production and place of use

Making your own locks allows you to use old spare parts and materials, save money and make a reliable design. If you have a large gate installed, but there is no locking mechanism, then you will not be able to protect the yard area, house and buildings.

If you install the lock yourself, the attacker will not know how to open it due to the non-standard design, which will protect against theft. Of course, if the thief is a professional, he will open the lock with a hairpin or a crowbar.

But still, a strong barrier will cause him inconvenience. For garden plots, homemade bolts are used.

To protect a more valuable place - the garage, locking bolts are used in combination with padlocks. And for private homes, the most complex options are suitable: barriers, padlocks and electronic locks.

Categories of devices can be used to protect the territory:

- Regular latches, latches, etc. They cannot protect against burglary, but they will prevent opening and secure the closed position.

- Container category - they are large and durable. Suitable for sliding and swinging sashes.

- Mechanisms produced for hangars. They lock heavy doors that other devices cannot handle.

- Systems equipped with electric drive and alarm. They are suitable for private homes.

Owners select the category of constipation depending on the required functions. Often the private sector does not require signaling; container mechanisms are sufficient.

Rotary rack locks

An eccentric or rotary lock, made in the form of a vertical tubular post mounted on the gate leaf in four support clips, is considered no less reliable. In the central part, a lever is attached to the rack, with the help of which the rack pipe can be rotated around a vertical axis. For convenience, the lever is bolted, which makes it possible to fold it by lowering it down.

Which is better: heated floors or radiators?

Warm floorBatteries

A massive hook is welded onto the upper and lower ends of the pipe. Thick and short cylinders are installed on the threshold and on the top beam of the garage door frame. When the tubular post is rotated, the hook rotates around a vertical axis and engages with the cylinder at the top and bottom of the gate.

The strength of the mechanism is not inferior to the flask design, but a more complex version to make with your own hands requires the use of alloy steels and high-quality welding.

Other options for simple fasteners

You can make a very simple but easy-to-use gate clamp from two metal plates with a common axis of rotation. In order to fix the gate in the desired position, you just need to press the bar with your foot, after which it will immediately lower and prevent the doors from closing. The disadvantage of such an emphasis is that it requires clearing the installation site of snow in winter.

Another fairly simple option for a gate stop requires two fairly strong nails and a piece of steel wire a little less than 1 cm thick. In order for the supporting strength to be maximum, you need to make sure that the angle between the main element of the stop and the ground surface is 50 degrees.

In order for such a latch to begin to perform its main function, it is enough to lightly hit it with your foot after the gate is opened and brought to the selected fixation point. Then, with the help of a slight movement of the foot, you can remove the latch from the working state and calmly close the gate. One of the main advantages of such a device is that it does not require maintenance either in winter or summer.