When finishing the roof of an outbuilding, it would be a good idea to inquire in advance about how to glue roofing felt to roofing felt - this is the material most often used to cover the roof of outbuildings.

It is clear that for a residential building, a thoughtful owner will select a more modern material that is more consistent with his ideas about the coziness of living, comfort, aesthetics and reliability (for example, metal tiles or soft roofing - which have now become very popular among a wide part of the population).

Moreover, the flammability and low fire resistance of roofing felt has long been a concern for almost all homeowners, especially those with real estate in the southern territories of the country, where the weather in summer cannot be called cool. But for a barn, warehouse or garage, especially not heated ones, roofing felt, as a finishing material, still remains quite attractive and suitable for mass use as a roof finish.

Many homeowners do not disdain it when doing roofing work, for example, at a summer cottage - in winter the house is empty anyway, so special thermal insulation and a noble appearance are not required from the roof. Working with roofing felt is only physically difficult - no special knowledge or professional skills are required from you. And another big plus that attracts people.

The material is one of the cheapest in terms of price, if we are talking about its traditional design, and not about the latest product options like roofing felt made from modified bitumen on a polyester base (this one costs an order of magnitude more).

How to glue roofing felt to roofing felt when installing a roof?

Roofers offer a variety of options, ranging from traditional to modern means. What to prefer is up to you to determine, based primarily on the calculated construction budget: both the type of roofing material purchased and the method of attaching it to the roof depend on the amount of funds.

Most of them are used when repairing old roofs or installing roofs on small buildings. Tempting with their extreme cheapness; discouraged by the need for preparation, which is associated with a very likely injury.

There are two types of bitumen mastics.

Cold:

Bitumen grade BN-90/10 is placed in an appropriate container and melted to a liquid state. The most important thing at this stage is to catch the right moment when the entire mass has melted and there are no solid fragments left in it, but the coking process has not yet begun - in this case, the bitumen is no longer suitable for gluing roofing felt. The formation of steam in the initial stages is normal; it is the water accumulated in the bitumen that comes out. Grayish smoke is also a standard sign. But when the hissing stops and the first bubble appears, the tank is removed from the heat.

The molten bitumen is cooled to approximately 85 Celsius (as soon as it stops boiling after removal from the heat, you can continue further).

A solvent is added to it, and the mass is kneaded until completely homogeneous. The solvent is usually diesel fuel, kerosene or gasoline. Take 7 kilograms of it for every 3 kilograms of bitumen.

Cold mastic is used for gluing in a warm, but not hot, state. It remains liquid even when cooled to 20 degrees. Therefore, it is safer to work with it, although the degree of adhesion of the layers of roofing material is considered lower.

- Preparing hot mastic will require at least three hours of time, a thicker-walled cooking vessel and a ladle, usually constructed from a tin can screwed to a long pole.

- Pieces of bitumen are loaded into the tank so that they fill a little more than half of its volume.

- When foam stops forming, filler additives are added to the molten composition: talc, asbestos, peat chips, chalk, limestone, etc. By weight, for every 8 kg of bitumen there are 1.5 kg of additives. Before adding, the fillers must be sifted so as not to accidentally add too large pieces.

- The mass is kneaded regularly; floating debris is caught with a scoop.

- At the end of cooking, waste oil is poured in at the rate of half a kilo per the above ratio of the remaining components.

Review of popular brands

There is a wide range of adhesives for roofing felt on the building materials market. Before purchasing, get acquainted with the characteristics, advantages and disadvantages of a particular variety. The most popular compositions include products from such brands.

"TechnoNIKOL"

One of the most popular mastics are Russian products. This type of glue does not require additional heating, so the process of laying roofing felt is greatly simplified. It can be glued to the following types of surfaces:

- metal;

- concrete;

- cement.

You can work with the substance at a temperature range from 5 to 35 degrees Celsius. The glue is applied to the bottom of the roofing felt with a notched trowel. The layer thickness is 1 cm. Available in 10 kg buckets. Work with the adhesive composition is carried out in well-ventilated areas. Make sure that the substance does not get on unprotected areas of the body or in the eyes. Do not use near open flame sources.

Abizol KL DM Tytan

The glue of this brand belongs to the cold varieties. When applied, a shell is created that is resistant to water, alkalis and weak acids. Abizol KL DM Tytan mastic is used for gluing roofing felt and waterproofing.

Before using this brand of roofing felt glue, prepare the surface. It must be clean and dry. Using a trowel or spatula, the composition is cold applied to the lower part of the material. The number of layers depends on the characteristics of the coating. For waterproofing, apply 2-3 layers; for installation of the material, one is enough. This glue cannot be used for interior work. Protect hands and eyes with special clothing when working with the composition.

AquaMast

This is also a cold option for roofing installation. A homogeneous multicomponent mass consists of bitumen, solvent, technological additives and filler. Thanks to this mastic, it is possible to glue roofing felt to ceramic, metal, wood, concrete and other types of surfaces.

Bituminous

The bitumen variety contains resins and certain chemical ingredients, thanks to which roofing material can be easily glued even to a slightly damp surface. The glue forms a protective film that is resistant to acids and alkalis.

To ensure that the quality of the work pleases the master, it is recommended to apply a layer of primer before applying the mastic. There is no need for this action only if the roofing material is glued to a similar surface.

Briefly about the main thing

Ruberoid waterproofing is considered a good budget solution for roofing and foundation work.

Previously, canvases were fastened with slats on nails, which is airtight and short-lived. It is more efficient to glue roofing felt.

Fixing the canvas can be done in 4 ways: fusing, gluing to hot, warm or ready-made mastic, using a canvas with an adhesive back layer.

In terms of reliability, the first place is occupied by the open flame method, followed by hot welding and cold welding.

Sheets of roofing felt can be glued together with mastic or by fusing. The edges, which overlap by 10-20 cm, are also fastened with bitumen double-sided tape.

Popular ready-made adhesives are TechnoNIKOL glue, Abizol KL DM Titan and AquaMast mastics.

Read later

Bitumen mastic AquaMast

This multi-component mixture is intended specifically for use by individuals and small organizations with little experience in construction work. Unlike the professional line of mastics:

- less technologically advanced;

- not intended for industrial volumes with high speed of work;

- not suitable for roofs with special operating conditions.

Suitable for most types of hard substrates, including wood. It is considered the best in its price category, thanks to:

- high resistance to temperature changes;

- low consumption of 0.8–1.8 kg per 1 sq. m;

- maintaining uniform texture and properties during freezing;

- wide range of temperature use: from –10 to +40 °C;

- short time for gaining final properties - 7 days.

Important! When using AquaMast mastic at temperatures below +5 degrees, keep the mixture in a warm room for at least 24 hours

Do-it-yourself mastic for roofing felt

Cold mastic is prepared from bitumen and solvent in a ratio of 3 kg to 7 kg, respectively. Pre-oil bitumen is heated until completely dissolved, after which it is allowed to cool to 85°. A solvent is added to it. Gasoline, diesel fuel, kerosene will do. The mixture is thoroughly mixed. This glue is ideal for minor roof repairs, as it has increased consumption compared to its hot counterpart.

By watching the video you will learn more information:

Hot mastic is prepared differently. Bitumen in the amount of 8 kg is placed in a container. The reservoir must be of sufficient volume so that it is only filled to 60%. Pieces of bitumen are gradually heated. Then add 1.5 kg of filler.

Talc, peat chips, alabaster, limestone, chalk and other materials are used as fillers. The fillers are pre-screened to prevent debris from entering the container. Next, add 0.5 kg of used oil and mix thoroughly. The temperature in the bucket is maintained at 200°C. The resulting mixture will reliably adhere to any rolled material, including soft roofing.

Mastics for cold and hot roofing felt stickers are not inferior to each other in terms of technical parameters. “Hot” adhesives require additional time to prepare for application. If the decking technology is followed, a roof with new waterproofing is guaranteed to last over 5 years without the need for repairs. With timely maintenance and ongoing repairs, the service life of such a roof is 25 years or more.

Ruberoid is a time-tested rolled waterproofing material. It is widely used in construction when performing roofing work and for waterproofing foundations.

The roofing material is glued to the base using preheated or cold bitumen mastic.

The second method is the most popular today because it is more economical and less labor-intensive. In addition, it is much more convenient to carry out work using cold glue.

Preparing the glue for use

The preparation of the composition before use is different for different types of glue. Cold glue for roofing felt is sold almost ready for use. It is heated to a low temperature, a solvent is added and mixed, after which it is ready.

Hot is prepared as follows: bitumen is placed in a thick-walled vessel and heated over low heat. After melting the main substance, add the necessary components and cook at low temperature according to the instructions.

Adhesive for rolled roofing material

This composition is a combined adhesive mass that includes several elements. In most cases, this is bitumen, a suitable solvent, some kind of filler, and also a variety of additives.

The key purpose of the product is not only gluing the material to a variety of surfaces, but also sealing joints

with him.

The trade recommends a large number of types of glue from popular and unknown manufacturers. Any brand has its own personal advantages, but the main practical task remains the same.

Qualities and properties

The special quality of the glue is to ensure an even connection without air voids here.

Figuratively speaking, all types of glue can be divided into compositions for cold and hot use.

Already from the name it becomes clear that cold mastic is used with very little heating and further mixing with a solvent.

Before use, the hot analogue is heated to an average temperature of approximately 200 degrees, which takes much more time.

Such mastics are used for foundation waterproofing, floors, walls and other parts of buildings and structures.

Which brands are much more famous?

These include adhesive for rolled roofing material “TechnoNIKOL”, Lepik na zimno, ASKOWIL and others.

Bitumen-based mastic

In its own composition, bitumen-based mastic contains a number of resins and some chemical elements that qualitatively improve the bonding of the material to a wide variety of surfaces. With its help, rolled roofing material

can be glued even to a wet surface without risking the quality of the connection itself. During operation, a layer resistant to aggressive compounds and water emerges, which is not afraid of alkalis or acids.

If you plan to work with old rolled roofing material, you need to thoroughly clean its surface, cut and glue all the inherent swellings, thus eliminating them.

Work process with bitumen-based mastic

- at the beginning of the event, the surface will be better primed. The same applies to concrete surfaces.

- The adhesive mass is applied equally throughout the entire area of the material.

- An overlap of at least 10 centimeters is required.

- No primer is required if you plan to glue rolled roofing material

to rolled roofing material.

Bitumen-rubber mastic

This product is used no less often than primitive bitumen mastic. It is made in the consistency of a paste, which has good adhesion to wood, plaster, and concrete surfaces. The saturated paste mixture does not flow when applied even to a vertical surface.

Mastic for rolled roofing material is considered not dangerous to the surrounding nature and to human health. It does not contain organic solvents in its composition, so it can be safely used on a balcony, terrace, garage, etc.

Work process with bitumen-rubber mastic

- Before using the product, the work surface must be thoroughly cleaned: grease stains, dirt and dust are removed from it.

- All inherent sharp edges must be rounded.

- First, the surface is covered with a special primer, which dries for two to three hours.

- Then, using a special metal spatula, mastic is applied to it twice.

- After applying the initial layer of 1 mm, it must dry for 24 hours, only then can the mastic be applied again.

You need to keep in mind that if events are held at low temperatures, the mastic takes a little longer to dry.

Advantages of using glue

The most reliable method of roofing felt waterproofing is deservedly considered to be the use of bitumen adhesive for rolled roofing material.

An important advantage of mastic over other methods of fixation is that when joining the joints of the material, air pockets do not appear.

Thanks to the mastic, a waterproofing continuous sheet emerges, which maintains its integrity during long-term operation.

As for the price of the product, there are significant differences between cool and hot mastic. For bitumen roofing felt adhesive, in other words, the cold category, it is much higher, which is clear: it does not require labor-intensive and lengthy preparation and is practically ready for use.

How to glue roofing felt?

To use any type of glue, it is necessary to prepare the surface: clean it from dust, dirt, crumbs, fill up holes and uneven surfaces. To get a good result, it is advisable to apply a primer. Let dry.

Bituminous roofing felt glue is applied to the prepared surface, roofing felt is laid on top, smoothing from the center to the edges so that there are no bubbles. If there are still bubbles, you need to puncture them, release the air and press the area tightly. After hardening, release.

Working with hot glue is more difficult. It must be used before it hardens.

To create a tight connection between the sheets of installation, you need to make a connection not end-to-end, but overlapping, placing one sheet on top of the other by about 10 cm. The seam should also be coated with glue. In this case, you can get a reliable sealed connection.

In all cases, when working with glue, regardless of manufacturers and types, it is necessary to follow the general rules:

do not carry out work near open fire;

carry out work using respiratory protection;

When using hot glue, work in protective clothing that protects against burns.

For a more reliable fit of the roofing material, you can use a manual roller. This will create a stronger seal and eliminate the possibility of air getting inside.

Video description

In this video, the master clearly shows the process of preparing bitumen primer in two ways:

Application of ready-made glue or mastic

In order to protect builders from burns and poisoning from smoke and fumes of organic solvents, ready-made adhesive compositions were developed.

Application of mastic for bitumen waterproofing Source pol-master.com

They are used in warm, dry weather without heating. Here the basic components are also bitumen resin and organic matter. Before applying the solution, the base must first be treated with the recommended primer. Manufacturers, as a rule, offer their line to obtain the highest quality results.

Here the practical part is simple. The surface is treated with primer. After 2.5-4 hours, the finished mastic or glue is applied in the recommended layer over the entire working area. A sheet of roofing material is laid and pressed manually to the base. The edges overlap by 10-20 cm, the joints are fastened with the same adhesive or double-sided tape.

Features of the roofing pie

The reliability of a soft roof is guaranteed only if the roofing pie is properly laid. You definitely need to plan and do the following on the roof:

- ventilation;

- vapor barrier layer;

- high-quality drainage of excess water;

- several layers of roofing felt.

Usually, for the reliability of a soft roof, roofing material is spread in 3 layers

Ruberoid is a material that requires installation in several layers. Unless it is a weld-on fabric (or something similar). This complex method of laying material has its own characteristics:

- the lower layers are thin, light and cheap lining roofing felt with fine-grained topping;

- top layer - with coarse-grained topping (mineral chips and others);

- if laying is planned over the entire roof plane, then the amount of bitumen mastic increases;

- In places where roofing felt is bonded, it is recommended to remove the topping to ensure a high-quality connection of the sheets.

Mechanical laying method

With this method, installation is carried out using roofing nails and slats. The effectiveness of this method is low, so it is rarely used. The rolls are rolled out over the entire surface overlapping and nailed to the sheathing with roofing nails. You can lay wooden slats along the joints and nail them.

The most convenient way to lay it is to use a material with a self-adhesive film on the bottom. Installing it requires a minimum of time. The film is removed, the roofing material is pressed to the surface.

Glue for roofing felt - prepare the mastic yourself

Bitumen mastic consists of bitumen and fillers. It can be cold or hot, the quality does not differ, but the price of the first variety is significantly higher. Let's look at how to prepare glue for both types of roofing felt.

"Cold" mastic

You will need bitumen (BN-90/10), a solvent (kerosene, diesel fuel, gasoline). The first component must be melted over an open fire, then cooled to 85 degrees Celsius and mixed with a solvent. The proportions are approximately as follows: 3 kg of bitumen per 7 kg of solvent. Particular care should be taken when warming up the BN-90/10; intense heating should not be allowed. You need to wait until the composition begins to gently boil over low heat; water comes out. After the boiling stops, the process is completed, you can begin further work. The entire mixture at 20 degrees Celsius retains a liquid state suitable for work, which is why it is called “cold”.

When heating bitumen, you can use its smoke and surface as indicators of the correct course of the process. Gray smoke and a slight hiss are okay, yellow smoke and bubbles are bad. After such a process, it is advisable not to use bitumen; coking has already partially taken place. Although if you notice this in time and manage to reduce the temperature, then the bitumen can be saved. It is especially undesirable to use the mixture after a fire, but this is already a completely advanced case; do not leave boiling bitumen unattended.

"Hot" mastic

This option takes a little longer to prepare, and it is advisable that you use a container with thick walls rather than a metal bucket. Some people purchase a special boiler, which is also equipped with a lid

This is important because no debris should be allowed to enter. Also prepare a metal can and a long piece of wood, build a kind of scoop from this, they will have to collect the “foam”

Fill the container with pieces of bitumen 60% and start heating over low heat, and when they melt and stop foaming, you can add filler (asbestos, chalk, peat chips, limestone, talc and others). All this requires good mixing. Do not forget to sift the additives before adding, so as not to accidentally add large debris, which will significantly reduce the quality of the mastic. Continue heating it all, using a ladle to remove all excess that floats to the top. After this, you can add the prepared oil and mix thoroughly. Now the mastic needs to be used before it cools down, which is why you should have everything ready, because we have already figured out how to attach the roofing felt.

Glue for roofing felt

The main purpose of the product is not only to glue the material to all kinds of surfaces, but also to seal the joints with it.

Trade offers many types of glue from different manufacturers. Each brand has its own advantages, but the main functional task remains the same.

Qualities and properties

The special quality of the adhesive composition is to ensure an even connection without air pockets in these places.

Conventionally, all types of glue can be divided into compositions for cold and hot use.

Already from the name it becomes clear that cold mastic is used with very little heating and subsequent mixing with a solvent.

The hot analogue is heated to an average temperature of approximately 200 degrees before use, which takes much more time.

Such mastics are used for waterproofing foundations, ceilings, walls and other parts of structures and buildings.

Which brands are the most famous?

These include glue for roofing felt "TechnoNIKOL", Lepik na zimno, ASKOWIL and others.

Bitumen mastic

In its composition, bitumen mastic contains a number of resins and some chemical elements that qualitatively improve the adhesion of the material to various surfaces. With its help, roofing felt can be glued even to a damp surface without risking the quality of the connection itself. In the process of work, a layer is obtained that is resistant to aggressive compounds and water, which is not afraid of alkalis or acids.

If you plan to work with old roofing felt, you need to thoroughly clean its surface, cut and glue any existing swellings, thereby eliminating them. Before the start of the event, it is advisable to prime the surface. The same applies to concrete surfaces. The adhesive mass is evenly applied over the entire area of the material. It is required to maintain an overlap of at least 10 centimeters. A primer is not required if you plan to glue roofing felt to roofing felt.

Bitumen-rubber mastic

This product is used no less often than simple bitumen mastic. It is made in the consistency of a paste, which has excellent adhesion to wood, drywall, and concrete surfaces. The thick paste-like mixture does not flow when applied even to a vertical surface.

Mastic for roofing felt is safe for the environment and human health. It does not contain organic solvents, so it can be safely used on a balcony, terrace, garage, etc.

Before using the product, the work surface must be thoroughly cleaned: grease stains, dust and dirt are removed from it. All existing sharp edges must be rounded. First, the surface is coated with a special primer, which dries within two to three hours. Next, mastic is applied to it twice with a special metal spatula. After applying the initial layer of 1 mm, it should dry within 24 hours, only after which you can apply the mastic again.

It should be taken into account that if events are carried out at sub-zero temperatures, the mastic takes a little longer to dry.

Benefits of using glue

The most reliable method of roofing felt waterproofing is rightfully considered to be the use of bitumen glue for roofing felt.

The main advantage of mastic over other fixation methods is that when joining the joints of the material, air pockets do not form.

Thanks to the mastic, a waterproofing monolithic sheet is obtained, which retains its integrity during long-term use.

As for the cost of the product, cold and hot mastic have significant differences. For bitumen roofing felt glue of the so-called cold category, it is much higher, which is understandable: it does not require labor-intensive and lengthy preparation and is in fact already ready for use.

Installation

Even an inexperienced craftsman can do the installation with his own hands; no special skills or tools are needed for this.

It is important to follow the manufacturer’s instructions and strictly follow the installation technology:

- First of all, inspect the condition of the roof. If the coating is severely damaged or blistered, it should be dismantled. If it is in satisfactory condition, you can lay it directly on the old base.

- The base of the roof must be thoroughly cleaned of debris and dirt. If it is made of concrete, then it is treated with bitumen mastic. The wood lathing is treated with an antiseptic composition.

- The roll of roofing material is cut into strips, the length of which is equal to the length of the slope, straightened and allowed to rest. Laying begins from the bottom of the slope, placing the material along the slope of the roof.

- The bottom film protecting the adhesive layer is carefully separated from the material, and then the roofing material is grafted onto the base of the roof. Using a rag or trowel, remove air bubbles from under the coating by patting and smoothing.

- The next strip is placed overlapping the first by 10-15 centimeters to protect the connecting seam from moisture penetration. The next layer is laid at intervals from the previous one so that the seams between them do not coincide.

Installation of material on a self-adhesive basis

The working process

Consideration of the question of how to properly lay roofing felt on a wooden roof should be divided into two main stages: preparatory and main, and it is in this order that we will consider them.

Preparing the base

As noted above, any gaps on the surface are not allowed, so before putting roofing felt on a wooden roof, it should be carefully prepared:

- First of all, it should be remembered that if the sheathing is made from edged boards, then it is necessary to choose materials with low humidity, otherwise they may subsequently begin to deform, which sometimes even leads to damage to the integrity of the roofing material. The elements are fastened in a checkerboard pattern using self-tapping screws, which should be at least one and a half times larger than the thickness of the board, and it is better to take fasteners with an even larger margin.

- If moisture-resistant plywood or oriented strand board is used, then the rough sheathing is first filled and only then the sheet material is attached. Again, the pieces should be staggered so that the seams do not coincide with each other.

OSB board is excellent for roofing, as this material resists changes in temperature and humidity well.

Main stage

Now let's look at how to properly lay roofing felt on a wooden roof:

First of all, you need to decide how many layers of material will be needed. Some people think that one layer is enough, but at least two are needed if the slope is from 30 to 45 degrees, if the angle is in the range of 15 to 30 degrees, then three layers are recommended, and for flatter roofs four may be required or even five layers.

The flexibility of the material makes it easy to install on roofs of complex configurations

Let's look at how to lay roofing felt on a wooden roof in the simplest way - by laying the sheets vertically: the work starts from the gable, located on the leeward side, the elements are laid one after another with an overlap of at least 10 cm, do not forget to immediately treat the joints with wood mastic. If the sheet is not enough for both slopes of the roof, then the elements are laid from the ridge with an overlap of 30 centimeters, the second layer is placed so that the joints do not coincide.

Sometimes the base layer around the perimeter of the valley is reinforced with a more durable material like glass insulation

Now let's look at how to lay roofing felt on a wooden roof using a combined method. Everything is simple here: the bottom layer is placed horizontally, and the second layer is placed vertically; if there are more layers, then they are also placed one after the other. Some experts claim that this option provides the best reliability and durability.

The top horizontal layer looks good on small roofs

We described above how to fix roofing felt on a wooden roof, now let’s look at the technology for carrying out the work:

- The slats or metal strips are cut into pieces of the required length, after which holes must be drilled in them half a millimeter less than the thickness of the screws in increments of 20 cm. Sometimes, to ensure strength, the fasteners can be placed closer to each other, it all depends on the characteristics of a particular roof. (See also the article Type of wood: features.)

- The slats are placed along the very edge of the roofing material or with an indentation of 1-2 centimeters; the elements must be screwed on carefully so as not to deform the slats.

- The last stage is the finishing of the gables and joints; the material is folded and secured with slats.

This is what a finished roof looks like with metal tape at the joints

Features of roofing felt for roofing

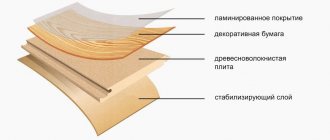

Roofing roofing felt is thick cardboard, which, to impart waterproofing properties, is impregnated with petroleum fusible bitumen, and then the inside is covered with a refractory bitumen composition and fine-grained topping (most often talc, asbestos, sand or mineral chips).

Ruberoid can be considered a universal material for any roof

There are types of roofing felt suitable for use in cold regions. During manufacturing, polymers are added to them, which reduces the threshold of material fragility and makes it resistant to temperatures up to 50 °C below zero.

Properties of roofing material

The choice of roofing material (GOST 1092393, interstate standard) with certain characteristics depends on the purpose and place of use. Roll material differs in density, type of topping and installation method:

- material density: 0.35–0.4 kg/m2;

- type of topping: coarse-grained, fine-grained, scaly, dusty;

- laying method: cold and welded.

Application area

The main purpose of roofing felt is to cover the roof. But this material is also used as a waterproofing layer on various construction sites.

Roofing felt is still the most popular roofing material

This type of roofing material is called lining material.

Advantages and disadvantages

Advantages of roofing felt:

- low cost;

- light weight;

- ease of installation.

But the disadvantages of this material are also significant:

- low strength - therefore the material is laid in 2-3 layers, which increases financial costs. Strength can also be increased using bitumen mastic;

- flammability - you need to carefully consider the design of the roof to reduce the risk of fire.

Therefore, roofing felt is most often used for the purpose of waterproofing or covering non-residential structures (garages, industrial buildings, etc.)

Material characteristics

Despite the fact that roofing felt is considered a rather difficult material to work with, its technical characteristics and low price have made it popular in the construction industry. To properly seal the joints, choose high-quality glue adapted to the characteristics of such a material.

As a rule, the composition of the substance includes the main component bitumen, as well as a filler, a composition for dissolving and other auxiliary additives. There are two types of glue offered on the building materials market - for cold and hot installation methods. They are used for any structural elements of buildings where roofing felt will be laid.

Some useful recommendations for arranging a roof covered with roofing felt

If you plan to lay roofing felt on the roof yourself, you should adhere to the technology of this process, not forgetting about your own safety rules.

- Before proceeding with installation work, it is necessary to ensure the quality of the roofing material sheets, since it should not have cracks, tears, folds or other damage. In addition to the surface of the canvas, you should inspect its cut. If light or white stripes or spots are found on it, this indicates that during the production process the base was unevenly impregnated with the bitumen mixture. Such material cannot be used for roofing or waterproofing, since it does not meet the declared characteristics, which means it will become a very unreliable coating.

- Before installation work, at least 24 hours in advance, rolls of roofing felt must be unwound and left in this position for straightening. To speed up this process, the canvas can be moistened with water. You should not straighten the euroroofing felt in advance, as it has high elasticity and unwinds easily when it is laid on the roof slope.

High-quality euroroofing felt does not require preliminary rolling - it fits perfectly onto the base right during the laying process

- The number of layers of roofing felt depends on the slope angle of the slopes. If it is less than 15 degrees, you need to purchase at least three layers of material. In the case where the roof slopes are steeper, it will be enough to lay two layers of sheets. Sometimes even five or six layers of roofing material are laid on flat roofs. Additional pieces of material are installed around chimney and ventilation pipes, as well as at the junction of the roof and the wall.

- Cutting roofing felt across the roll is done with a shoemaker's knife along a marked perpendicular line. A longitudinal cut (if a long strip of the same width is required) can be made by sawing off the whole roll, and a hand hacksaw is used for this purpose. To simplify the process of cutting ordinary roofing felt, it is often moistened with water.

- Laying this roofing material should be done in calm weather and, preferably, at an optimal air temperature of +20-25 degrees.

- Before starting installation work, the roof surface must be cleared of small debris. In addition, it is necessary to inspect the slopes to detect protruding areas and depressions. If such places are found, then the protrusions from the surface must be removed, and the recesses must be leveled with one of the polymer mixtures.

- Any surface on which roofing felt will be laid must be primed, and the wood (boards or plywood) must be treated with a complex composition that can protect it from rapid fire and biological damage from mold and insects.

- All joints of the sheets with each other, as well as with other roof elements, must be coated with waterproofing bitumen mastic.

Option for installing a roof aerator with expanded clay filling

- To ventilate the under-roof space, it is recommended to install a roof aerator on roofs covered with soft tiles or roofing felt.

- Ruberoid with a dust-like coating can subsequently be painted and roofing paints based on acrylic or polyurethane are used for this purpose.

A simple device for a convenient ladder for working with rolled roofing materials on steep roof slopes

If roofing felt will be laid on a rafter system with slopes installed at a large angle, then to facilitate work at height and ensure the necessary level of safety, it is recommended to make a special ladder that can be fixed to the ridge and, if necessary, moved to one side or the other

When performing roofing work, it is recommended to use a safety rope, and you need to move on the roof with extreme caution, without losing sight of the edge of the slope. Installation of all roofing materials must be done with gloves - there is a high risk of injury to the palms from the edges of the material

Laying roofing felt on a pitched roof

There are three ways to lay roofing felt on a pitched roof. Let's look at each of them!

Method one: vertically

When working with a gable roof, the first thing you need to take care of is strengthening the rafter system near the ridge. To do this, you need to nail additional sheathing under the ridge.

Rolls of roofing felt are laid horizontally on the lower slope. They are rolled out slowly towards the ridge. If the strip turns out to be long enough, you can still throw it over the ridge and continue on the other slope. In this case, an overlap is necessarily formed in the canvases.

So, let's move on to working with stingrays:

- Step 1: First, carefully inspect the wood deck, repair it if necessary, and treat it with a fire retardant.

- Step 2. To make it easier to roll out the roofing material, secure it to the pipe. Then it can be unwound like a spool - a brilliant idea. And with the help of hooks you can move it while rolling the roll. The first fixation will be on the canvas, which was thrown over the ridge, on the underside of the slope.

- Step 3. Cut the roofing felt into pieces so that it is 20 cm longer than the roof.

- Step 4. Cut several strips and lay the first piece along the cornice. It is important that the strip has an allowance along the edge at the bottom.

- Step 5: Now nail the strips in place with 13mm roofing nails. The bottom edge of the roofing material must be nailed to the eaves board, and the side edges to the side surfaces of the roof. Apply bitumen or adhesive liberally along the top edge. On a fairly large roof, it is better to lay each subsequent strip of roofing felt and nail it from the top edge. At the same time, it is important not to forget to overlap at least 75 mm on the lower strips of roofing felt, and the overlapped area must be coated with special roofing adhesive for roofing felt.

- Step 6. Lay the second strip of roofing felt overlapping the first so as to completely cover the nail heads. Use the last strip of roofing felt to make a ridge cap. Cut it to length and width so that it covers the timber sheathing of the roof edge by at least 75mm. This overlay must be firmly fixed at the edges with nails.

- Step 7. Wrap the roofing material around the corners of the roof and nail it. Take care of waterproofing the corners using roofing felt glue.

During all this, it is important to ensure that the bottom edge of the roofing material is wide and fairly even. This piece should be folded down and lowered under the eaves of the roof. It is there that the necessary drainage of rainwater will be ensured. Here are step-by-step illustrations:

You can check the quality of installation of such a roof like this: if within two hours the canvas does not slip, does not swell with bubbles or peel off, then everything was done correctly.

Method number two: across the slope

Here the strips are laid vertically. But they also start from the bottom, leaving 30 cm from the edge in order to then line it with planks. The ridge is overlapped so that each bend falls on the center of the canvas:

How can I replace roofing felt?

The most popular analogues of roofing felt are:

- rubemast - identical in composition to roofing felt, but has a reinforced layer of refractory bitumen. Bonds to the surface of the base more reliably and firmly. During installation, melting is performed using organic solvents;

- glass roofing material - fiberglass is used as the base material. This material is more plastic than roofing felt;

- roofing felt is construction cardboard impregnated with tar or coal products. Coarse mineral chips or sand are used as topping;

- glassine is construction cardboard impregnated with petroleum bitumen. It has unique water-repellent and wind-repellent properties. Used as lining material in roofing and wall structures.

Content

So, let's first look at what the roofing material itself is:

Due to constant improvements to the classic roofing material, it has many varieties. For example:

- Rubemast has a much thicker layer of bitumen under the cardboard base.

- Stekloizol is made from fiberglass or fiberglass. This material is valuable because it retains its elasticity at temperatures from -45 to +100 degrees Celsius.

- Glassine retains its cardboard base, but soft petroleum bitumen is used as impregnation. It is more universal in use and lasts up to 12 years.

- Gidroizol is generally asbestos paper impregnated with petroleum bitumen.

These varieties have some differences in installation, which we will definitely mention. Indeed, in practice they are often confused with classic roofing felt, or deliberately generalized for convenience.

Maintenance of the finished roof

No special care is required for finished roofing material roofing. You only need to check the surface for damage and tightness of the seams once a year (after the snow has completely melted). If a leak is detected, repair it immediately.

Ruberoid can be used to cover flat and pitched roofs

It is also recommended to carefully clear the roof of snow during the winter, but this can only be done with a wide wooden shovel so as not to damage the outer layer of the material.

Roofing felt service life

The service life of a simple roofing material is quite short: about 5 years. If fiberglass material is used, the service life increases to 10–15 years. The following factors influence the service life:

- quality of roll material;

- quality of fastening elements;

- thorough surface preparation;

- compliance with installation technology;

- competent design of the entire roof structure - base, ventilation, vapor barrier, drainage;

- the presence of unnecessary mechanical loads - do not walk on a roof made of roofing felt;

- carrying out timely inspections and repairs.