Building a boiler room for a private home can save heating costs if you think everything through in advance.

SP 402.1325800.2018 classifies such premises as an economic group and determines the requirements for construction and maintenance for them. Thus, a window in the boiler room of a private house is a mandatory safety condition.

The boiler will operate efficiently only if the power is correctly calculated, the installation location is selected, and the operating requirements are met.

The parameters of a boiler room, regardless of its location, are determined not by area, but by cubic capacity

SP 402.1325800.2018 regulates the procedure for organizing a boiler room in a private house. Failure to comply with these rules often leads to unfortunate events associated with the failure of gas equipment and even its explosion.

Each boiler installation is inspected by regulatory authorities throughout its service life.

Window size and other requirements for the boiler room

A window is required.

The number and size of the windows should be proportional to the area of the room - for every ten cubic meters of the room there should be 0.3 square meters. m. glazing. For example, the requirement for window area applies specifically to the glazed part of the window, and not to the entire window, including the wooden or metal-plastic frame.

It is also prohibited to install gas equipment in living rooms, as well as in rooms with a ceiling height of less than 2.2 meters. The area of the room can be arbitrary, but not less than 15 m. Cube. Walls, ceilings, and floors in the boiler room must not be finished with flammable materials.

The doors in the room with the boiler should be slightly raised above the floor so that a visible gap (at least twenty millimeters) is formed between the door leaf and the threshold. This rule must be observed to ensure the proper level of air circulation in the boiler room.

Conclusions and useful video on the topic

In the video attached below, a specialist talks about what form an easily resettable structure in a boiler room can take:

Glazing standards for an operating gas boiler house must be met. Since this increases, and significantly, safety in the house. After all, releasing excess pressure in time can save people’s lives and their property from destruction.

Below, under the article, you can ask questions, supplement our material with valuable information, or share your own experience of arranging windows in a boiler room. Tell us what difficulties you had to face when setting up a boiler room in a private house and how you managed to overcome them.

Window in a gas boiler room. SNiP requirements

Window size in a gas boiler room SNiP

According to the SNiPs in force today, as well as the Instructions for the placement of units for heating and hot water supply of the Ministry of Construction of Russia, when placing units with a power of up to 150 kW in a separate room located in a residential building, the room must meet a number of requirements. In particular, the window in a gas boiler room must be of a certain size.

The height from floor to ceiling in the boiler room must be at least 250 cm. If the gas boiler is supposed to be installed at some elevation, then the ceiling height is calculated from the top point of the elevation. The boiler room must have a door. Doors must also be installed at the entrances to adjacent rooms.

The volume of the gas boiler room must be at least 15 cubic meters. If a gas water heater for hot water supply is also installed in the boiler room, the volume of the boiler room according to SNiP standards does not increase.

Window area in a gas boiler room SNiP

The boiler room must have a window or several windows facing the street with a total glazing area of at least 0.5 square meters. If the volume of the gas boiler room is larger, then the window area according to the standards must be larger - for each additional cubic meter of volume, the window area in the gas boiler room must be increased by at least 0.03 square meters. A window is required in the boiler room for ventilation in case of leaks.

The boiler room must have an air flow from the street through an opening of at least 150 x 200 millimeters. Or under the door in the boiler room there should be a gap below the floor of at least 20 millimeters.

SNiP for a window in a gas boiler room

The room is separated from adjacent rooms by walls or partitions with a fire resistance limit of 0.75 hours, and the fire spread limit must be zero. Natural lighting is established based on the glazing area of the window in the gas boiler room.

When placing heat generators in the basement or basement, access directly to the street is required. A second exit to the utility room is allowed, but the door must be fireproof and the door width must be at least 800 millimeters.

In practice, these requirements are not always met. Inspectors may turn a blind eye to some deviations during acceptance. They only look rather harshly at the volume of the boiler room, the size of the window in the gas boiler room , the presence of doors and hoods. But gas boiler houses are always designed with reference to SNiP standards.

Design

What has already been said is quite enough to understand that drawing up a project for a gas boiler house is far from so simple. It will be scrupulously checked by government inspectors, and the slightest deviation from the norms will immediately mean rejection of the entire plan. Engineering surveys are carried out strictly taking into account the materials of geodetic and engineering exploration of a specific site.

A package of design materials is also prepared taking into account:

- parameters of sewer communications;

- urban planning plans;

- technical conditions for connecting to general purpose networks;

- permits issued by regulatory authorities;

- legal documents.

Even before the key work on the project, the so-called main technical solution is prepared. In addition to it, there should be sections such as:

- justification of the feasibility of investments;

- feasibility study;

- expert materials;

- documentation on designer's supervision.

The design sequence is as follows:

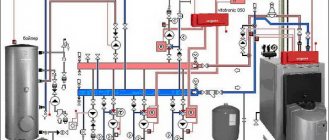

- development of a detailed installation diagram;

- preparation of specifications;

- drawing up an energy balance;

- assignments for related organizations to arrange networks;

- three-dimensional modeling and coordination of its results with the customer;

- generation of design materials taking into account the virtual model and its testing;

- coordination with controllers (if everything is done correctly, they will give consent);

- formation of a working design that will guide the builders;

- designer's supervision over the implementation of practical work.

According to SP 402.1325800.2018:

5.4 For space heating, heating gas boilers with a closed or open combustion chamber, including single-circuit and double-circuit, or heating devices designed to operate on gas fuel, boilers with a coaxial chimney, gas convectors and other gas-using equipment that have permits for use should be provided , issued in the manner established by the current legislation of the Russian Federation. For hot water supply, flow-through, capacitive gas heaters or double-circuit boilers should be used. Gas-using equipment must be factory-made and equipped with automatic regulation and safety. Gas boilers must comply with GOST R 51733, GOST R 54826, GOST R 54438, GOST R 54439, gas tank water heaters - GOST R 54821, gas convectors - GOST R 51377.

Installation of gas convectors should be carried out in accordance with Appendix E.

5.5 When installing a gas stove and instantaneous water heater or heating boiler with a closed combustion chamber in the kitchen, the volume of the kitchen should be taken in accordance with 5.1.

When installing a gas stove and a cylinder water heater, a gas stove and a heating boiler with an open combustion chamber (single-circuit or double-circuit) in the kitchen, the volume of the kitchen must be 6 m larger than the volume provided for in 5.1.

When installing gas equipment intended for heating and hot water supply in a separate room (heat generator room), the area of this room (heat generator room) must be determined from the conditions of ease of installation and maintenance of the equipment, but be at least 15 m3 with a height of at least 2.5 m (for heating boiler with an open combustion chamber).

5.6 Gas-using equipment powered by natural gas may be placed in the basement and basement floors of single-apartment and semi-detached residential buildings. It is not permitted to install technical devices and gas-using equipment in bathrooms and sanitary facilities.

Requirements for emergency exits from premises where gas-using equipment is installed must comply with current fire safety standards.

5.7 It is not allowed to provide for the installation of more than two heating boilers or two storage tank water heaters in one room.

5.8 Gas generators should be installed in accordance with the requirements of the manufacturers’ instructions: in a heated ventilated room, in an unheated ventilated room, and also outdoors under a canopy.

At existing facilities, gas generators should be installed after performing a hydraulic calculation of existing gas networks and checking the capacity of the metering station.

5.9 Ventilation of rooms intended for installation of gas-using equipment must be natural. The exhaust is provided at the rate of three air exchanges per hour, and the influx is based on the volume of the exhaust and an additional amount of air for gas combustion. The dimensions of exhaust and supply devices are determined by calculation.

Requirements for ventilation and smoke ducts must be provided in accordance with Appendix G SP 402.1325800.2018.

In kitchen-dining rooms, the hood is provided at the rate of one air exchange per hour and an additional air volume of 100 m3/h for operating a gas stove (SP 60.13330).

5.10 As easily removable enclosing structures, it is necessary to use glazing of window openings with a glass area at the rate of 0.03 m2 per 1 m3 of room volume or use window structures with double-glazed windows in accordance with GOST R 56288. Reinforced glass, other double-glazed windows, triplex, stalinite and polycarbonate for easily removable structures do not apply.

5.11 The door from the room where gas-using equipment is installed must open outward.

5.12 The distance from the building structures of the room to the heating gas-using equipment should be taken in accordance with the requirements of the manufacturer’s instructions. If there are no requirements in the instructions, gas-using equipment should be installed based on ease of installation, operation and repair. In this case, the following requirements must be met:

- wall-mounted gas-using equipment for heating and hot water supply must be installed on walls made of fireproof materials at a distance of at least 2 cm from the wall, including the side wall;

- walls made of fire-resistant and non-combustible materials must be insulated with fireproof materials or factory-made screens made of tempered laminated glass in accordance with GOST 30698, which do not support combustion and the spread of flame over an insulated surface, at a distance of at least 3 cm from the wall, including the side wall. The insulation should protrude beyond the dimensions of the equipment body by 10 cm and 70 cm from above;

- the installation height of wall-mounted equipment should be convenient for operation and repair;

- the horizontal clear distance from the protruding parts of the heating equipment to the household gas stove must be at least 10 cm;

- When installing equipment on a wooden floor, the latter must be insulated with fireproof materials with a fire resistance rating of at least 45 minutes. The floor insulation must protrude beyond the dimensions of the equipment body by at least 10 cm.

5.13 In existing single-apartment residential buildings, installation of gas stoves is allowed in rooms that meet the requirements of 5.1, but have a minimum height of up to 2.0 m inclusive, if these rooms have a volume of at least 1.25 times more than the standard specified in 5.1. Moreover, in houses that do not have a dedicated kitchen, the volume of the room in which the gas stove is installed must be twice as large as specified in 5.1.

In kitchens and rooms with sloping ceilings, having a height in the middle part of at least 2.0 m, the installation of gas-using equipment should be provided in that part of the kitchen where the height is at least 2.2 m.

Conversion to gas fuel of existing factory-made heating boilers intended for solid or liquid fuel is possible when the boilers are equipped with gas burners with automatic safety devices in accordance with GOST 17356.

5.14 Each facility where gas-using equipment is installed must be equipped with a gas metering unit in accordance with the current legislation of the Russian Federation. Installation of gas metering units should be carried out in accordance with Appendix B.

5.15 When the gas pressure in internal gas pipelines is above 0.0025 MPa, regulators-stabilizers in accordance with GOST R 54824 must be installed in front of the gas-using equipment, ensuring optimal gas combustion mode.

According to SP 42-101-2003 it is recommended:

pp. 6.17 ....In the room where gas-fired heating equipment is installed, it is allowed to use window openings as easily removable enclosing structures, the glazing of which must be carried out according to the condition: the area of individual glass must be at least 0.8 m2 with a glass thickness of 3 mm, 1.0 m2 - at 4 mm and 1.5 m2 - at 5 mm .

pp. 6.18 It is recommended that the following conditions be observed for rooms intended for the installation of gas-fired heating equipment:

- height of at least 2.5 m ( 2 m - with equipment power less than 60 kW);

— natural ventilation at the rate of: exhaust — in the volume of 3 air exchanges per hour, inflow — in the volume of exhaust and an additional amount of air for gas combustion. For equipment with a power of St. 60 kW the dimensions of exhaust and supply devices are determined by calculation;

- window openings with a glazing area at the rate of 0.03 m2 per 1 m3 of room volume and structures enclosing from adjacent rooms with a fire resistance limit of at least REI 45 - when installing equipment with a capacity of over 60 kW or placing the equipment in the basement of the building, regardless of its power;

- exit directly to the outside - for premises on the ground and basement floors of single-apartment and semi-detached residential buildings when installing equipment with a capacity of St. 150 kW in accordance with the requirements of MDS 41-2

pp. 6.19 In residential buildings, it is recommended to install household gas stoves in kitchens that meet the requirements of manufacturers’ instructions for installing gas stoves, including in kitchens with sloping ceilings, having a room height in the middle part of at least 2 m , while the installation of the stoves should be be provided in that part of the kitchen where the height is at least 2.2 m.

pp. 6.23 In the absence of requirements in the manufacturer’s passports or instructions, gas-using equipment is installed based on the conditions of ease of installation, operation and repair, and it is recommended to provide for the installation of:

gas stove:

- near a wall made of fireproof materials at a distance of at least 6 cm from the wall (including the side wall). It is allowed to install the slab against walls made of fire-resistant and combustible materials, insulated with non-combustible materials (roofing steel on an asbestos sheet with a thickness of at least 3 mm, plaster, etc.), at a distance of at least 7 cm from the walls. Wall insulation is provided from the floor and must extend beyond the dimensions of the slab by 10 cm on each side and at least 80 cm on top;

wall-mounted gas-using equipment for heating and hot water supply:

- on walls made of fireproof materials at a distance of at least 2 cm from the wall (including from the side wall);

- on walls made of fire-resistant and combustible materials, insulated with non-combustible materials ( roofing steel on an asbestos sheet with a thickness of at least 3 mm, plaster, etc. ), at a distance of at least 3 cm from the wall (including from the side wall).

The insulation should protrude beyond the dimensions of the equipment body by 10 cm and 70 cm from above. The horizontal clear distance from the protruding parts of this equipment to the household stove should be at least 10 cm.

When installing the above equipment on a wooden floor, the latter must be insulated with fireproof materials, providing a fire resistance limit of at least 0.75 hours. The floor insulation must protrude 10 cm beyond the dimensions of the equipment body.

6.24 The clear distance from protruding parts of gas-using equipment in passage areas must be at least 1.0 m.

According to MDS 41-2.2000 it is recommended:

clause 5.1 When placing a gas stove, instantaneous water heater for hot water supply and a heating unit for heating with a power of up to 60 kW in the kitchen, the kitchen room must meet the following requirements:

— room volume of at least 15 m3 plus 0.2 m3 per 1 kW of power of the thermal unit for heating;

pp. 5.2 When placing thermal units with a total power of up to 150 kW in a separate room located on any floor of a residential building, the room must meet the following requirements:

— the volume and area of the room are designed based on the conditions for convenient maintenance of thermal units and auxiliary equipment, but not less than 15 m3;

General requirements for the premises

Each room equipped with a gas boiler has its own requirements, some of which are general.

- A boiler room of any type must have water supplied to replenish the system and a sewerage system to drain the coolant.

- Mandatory ventilation and removal of the combustion product through the chimney. If the boiler is of low power up to 30 kW, then the exhaust can be removed through the wall.

- Natural lighting is a must. The glazing must have an area of at least 0.8 m2, and then it is normalized to 1 m3 - 0.03 m2 of glazing. The window must be hinged and open outward.

- The window should have a window or transom for ventilation in case of gas leaks.

According to the latest version of SNiP, a room for gas equipment for hot water supply and heating with a power of over 60 kW must be equipped with an air pollution control system, which, if triggered, stops the gas supply automatically.

And when determining the size of the boiler room, for the boiler and the heating boiler, their power is summed up.

Legislation on windows in boiler rooms

The issue of glazing of premises where gas boilers are located is regulated by SP 402.1325800.2018, which came into force on June 6, 2022.

But the norms of this document only state that there must be windows in the boiler room and regulate their type and area. And all other details are set out in GOST R 56288-2014, which is referenced by SP 402.1325800.2018.

The shape of the window in a room with a gas boiler can be any. The main thing is that it corresponds to the established area. And also, you need to remember to provide a window or any other method for ventilation

Therefore, the design of the boiler room must be carried out taking into account the standards set out in these two by-laws.

Standards and rules for calculating window area

Boiler room requirements

There are certain requirements for a window in a boiler room of a private house. The design must comply with all fire safety standards for residential premises. In accordance with SNiP standards adopted in 2022, the window opening must be calculated in the ratio of 0.03 square meters per cubic meter of room.

The air flow must pass through an opening from the street of at least 150*200 mm. To reduce the amount of heat loss, you need to insulate the lintel above the window, and also insulate the window slopes on the street side using penoplex.

SNiP standards state that a gas boiler can only be installed in a room with a window. It must be equipped with any ventilation device. The window in the furnace room should be considered not only as a source of lighting, but also as the most important element of ventilation.

The calculated area of 0.03 per square meter should not be the window itself, but the glass. It, in turn, represents an enclosing, easily resettable structure. If these conditions are not met, gas services will not allow the boiler room to start.

The term “easily releasable enclosing structure” refers to a building element that must be easily destroyed to relieve excess pressure. Due to this function of structures, reinforced glass is not suitable for them. They are characterized by strength, so the glass will not break under load. Excess pressure will not be released.

Cannot be used in boiler rooms:

- Stalinite;

- polycarbonate;

- triplex.

According to GOST standards, it is permissible that ordinary glass can be replaced by window elements:

- with a rotating design, which consists of an easily resettable flap - during a gas explosion it should open outward and rotate around the hinges under the influence of excess pressure;

- with a displaceable part, which consists of a frame with a double-glazed window - during a gas explosion, the structure collapses under the influence of pressure and falls out.

The pivoting sash on a window structure can be vertical or horizontal. The variety of options increases the functionality of the window.

An important condition for windows to a gas boiler room is the presence of safety locking elements, latches and breakable parts of the fastenings. Their task is to ensure that when excess pressure occurs, the sliding or rotating mechanism of the window is freely released.

What should windows be like?

SP 402.1325800.2018 states that a gas boiler can only be installed in a specially equipped room with a window.

Moreover, this element of the boiler room design must be equipped with:

- window;

- any other device suitable for providing ventilation of the boiler room.

That is, the indicated design features of the window indicate that it is considered not only as a source of natural light. And also as an important element of the boiler room ventilation system.

Boiler room glazing area

Clause 5.10 of the above-mentioned Code of Rules states that the glass area must be at least 0.03 m² for each cubic meter of volume of the room where the gas boiler will be installed.

This is the standard value for buildings classified as fire/explosion hazard group B.

The profile Code of Rules indicates the minimum window area in a room with a gas boiler. But, in fact, this figure indicates what the opening should be to ensure effective release of excess pressure

Moreover, you should pay attention to the fact that the above area should be occupied by the window as a whole, namely glass. Which, moreover, must be an easily removable enclosing structure, otherwise the boiler room will not be allowed to operate.

Why are easily resettable structures needed?

In the Russian Federation, the issue of gas explosions is acute. Thus, dozens of these incidents occur annually in the country. The most notorious was January 2008, during which 10 explosions occurred, killing dozens of Russians.

And the reason is aggravated by cheap but very durable modern windows that can withstand significant excess pressure for a short time. As a result, the pressure on the building structure increases significantly. And it often cannot withstand horizontal loads, since the same walls are not designed for this. As a result, the buildings simply stack up like houses of cards.

It should be remembered that a window in the boiler room should be provided at the stage of creating project documentation. Or Gorgaz will not give permission for construction

There are 2 ways to combat this negative phenomenon, which include:

- strengthening the structure of buildings;

- use of easily removable structures.

And, since the first option is expensive and not always available, the main way to protect against the negative consequences of explosions was the use of LSC.

Which have been present on the Russian market for a long time, but their high cost has not contributed to their popularity. The government decided to “facilitate” this by making the use of easily resettable structures mandatory in a number of cases.

Read about fire safety requirements for the installation of gas boiler houses in our other article.

Requirements for windows in a gas boiler room

The parameters of the room intended to house a boiler room or boiler room are determined by building codes and regulations:

- minimum volume - 15 m³;

- minimum area - 6 m²;

- height from finished floor to finished ceiling - 230 cm or more;

- finishing is done with non-combustible materials;

- the wall-mounted boiler is mounted 1 m from the floor or higher, the distance from it to the nearest wall should be more than 1 m.

If a column for heating water is additionally installed, then the size of the boiler room does not need to be increased.

Such a room must be equipped with windows with frames made of aluminum or metal-plastic with a total glazing area of 0.5 m². When increasing the volume of the boiler room, for each added 1 m³, 0.03 m² of glazed surface is added.

If the room is much larger, it needs to be divided by a partition made of non-combustible materials. These rules apply to equipment using gas boilers up to 150 kW; in a private house, the power of the boilers used is less. 1 kW of boiler power is enough to heat 10 m² of living space.

Boiler rooms for private houses of more than 1,500 m² are equipped in separate buildings, erected in compliance with fire safety and explosion safety standards.

If the boiler power does not exceed 60 kW, it can be placed in a kitchen area, but fire safety rules must be observed, including those related to ventilation and air circulation in the kitchen.

Not only size requirements apply to a boiler room window, but also structural requirements. You cannot use double-glazed windows - only single-pane glazing. This is because the gas boiler window is an easily removable structure designed to divert the shock wave in the event of a gas explosion to the outside to prevent damage to the home. The window should have a window so that it is possible to ventilate the boiler room in the event of a gas leak.

The window in the boiler room, in addition to the function of ventilation and removal of the blast wave, also serves to provide natural lighting to the room with gas equipment, so that the boiler room can be navigated in the event of an emergency situation with a power outage.

Parameters for choosing heating in a wooden house

All types of heat supply can be used in a wooden house. But first you need to analyze all the factors influencing your choice. Often, heating options for a wooden house directly depend on several of them.

Types of boilers for home heating

The primary task is to determine the optimal energy carrier. It can be solid fuel, gas, electricity or diesel fuel. It all depends on the cost and the possibility of constant supply.

You cannot install heating in a wooden house with your own hands without the following preliminary stages of analysis:

- Fuel selection;

- Heat generation equipment: boiler, convector (gas, electric), film heating;

- Development of a layout diagram for heating devices. Thermal distribution throughout the house will depend on this;

- Analysis of fixed costs for heat supply. The best option is gas heating in a wooden house. But this takes into account the complex preparatory stage of obtaining permits.

If there is a connection to the gas main, the choice is made on this type of fuel. If it is possible to purchase cheap (and high-quality) diesel fuel, make water heating for a wooden house with a boiler (or burner) of this type

The total area of the building and the degree of its insulation are also taken into account.

Boiler room glazing material

It is especially worth remembering that any window structure must be made of aluminum or plastic material . These materials are considered practical and sustainable, and they are also considered eco-friendly species. Each of them must meet the requirements, that is, it must be stable under any temperature influences.

It is the aluminum profile that can protect against any weather conditions. And if there is a strong wind outside, it will not allow you to create a draft and put out the fire in the boiler. Thanks to this, there will be no fire hazard.

In addition, it will be necessary to agree on the basic requirements, where the presence of single-chamber and double-chamber double-glazed windows can be taken into account. Thanks to this, you can keep the heat in the room and create comfort when you are in it.

Window as part of the ventilation system

A window is necessary in a boiler room not only to serve as an explosion valve, but also for emergency ventilation of the room when excessive steam or smoke is generated. However, you should not think that you can independently equip a ventilation system in the boiler room by installing the required number of windows.

There are a number of requirements for the ventilation device in the boiler room:

- The diameter of the ventilation duct should not be less than 110 mm.

- The horizontal ventilation pipe must be mounted with a slope towards the street.

- A hole in the boiler room door leaf can replace the gap between the door and the floor, which was mentioned at the beginning of the article. However, the best option would be to use both ventilation methods simultaneously.

- The inlet openings must be at least 8 square meters. cm/1 kW of heating equipment power.

The listed requirements for the arrangement of a boiler room are only a small part of the information drawn from many regulatory documents.

Famous manufacturers

Many companies are engaged in the production of window structures. The most famous are:

- KBE is a manufacturer that produces the best options for premises where gas equipment is installed.

- Novotex Termo - windows from this company are suitable for warehouses, hangars, workshops and boiler rooms.

- Rehau GENEO is a variant of aluminum glazing with single-chamber glass.

It is important to know which window should be in a gas boiler room, since failure to comply with the requirements will lead to large losses. The entire process of gasification of private houses is under the control of special services

Violation of the rules can lead not only to large fines, but also to an emergency situation.

Requirements for free-standing combustion chambers

Separate boiler houses are built for powerful heat generators, the operation of which requires an enhanced safety regime.

Requirements for furnaces built separately from a residential building:

The premises are equipped with concrete floors or covered with fireproof finishing. For equipment weighing over 200 kg, a reinforced base with a height of 15 cm is prepared.

Heated water enters the house through an insulated pipeline with low heat loss. A free-standing furnace does not take up the usable space of the house, is safe to use and does not disturb the architectural appearance of the building. Can be used for heating a group of buildings, for example, a house, a bathhouse and a greenhouse.

Requirements for doors

Two types of doors are used in furnace rooms:

- external without reinforcement for access to the street;

- internal fire protection for communication with residential premises.

External doors should be easy to break off their hinges in the event of an explosion. Then the energy will be directed outward and cause less destruction than with a rigidly and firmly fixed canvas. But in any case, you need to protect the premises from strangers who could enter and damage expensive equipment.

Interior doors are designed to contain flames in a fire for 15 minutes. Type 3 fabrics with a fire resistance limit of EI 15 comply with the standard. They retain their integrity and thermal insulation properties for a period of time sufficient for the evacuation of people from the house and the arrival of rescue services.

Important. The width of external doors is at least 80 cm. They must open to the street.

Boiler room ventilation

The requirements for a boiler room in a private house are very strict regarding ventilation. Combustion products formed when burning fuel are dangerous to humans. Inhalation of carbon monoxide leads to severe poisoning. High concentrations cause paralysis and even death.

Gas leaks in the network create a danger of explosion. Methane, propane and butane are heavier than air. They accumulate in the lower level of the room. That is why it is recommended to install gaps near the floor under the outer door or grated exhaust openings in the wall to remove hazardous substances. For every 10 kW of unit power, 0.01 m² of cross-sectional area of the supply channel is required.

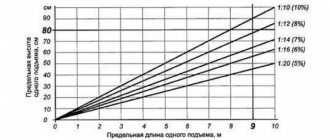

Natural ventilation, recommended by the standard, includes supply and exhaust ducts to replace the air in the room. Their area is calculated based on the triple volume of the room and selected using special tables, diagrams or using online calculators.

For every 10 kW of power, 0.01 m² of cross-sectional area of the supply channel is required.

Combustion products are discharged through a chimney or a coaxial pipe built into the wall. In the first case, the cross-section of the channel must correspond to the diameter of the boiler pipe. The optimal shape is a circle or oval.

The chimney walls protect against condensation. Warm air, moving through the pipe, cools, which leads to the precipitation of water vapor in the form of dew. In winter, the moisture freezes and the channel narrows. This contributes to the deterioration of the removal of combustion products.

Protection against condensation is carried out by lining the chimney or installing a stainless steel pipe inside. Angles and turns must be smooth, and the joints of channel elements must be sealed.

Important. To ensure good draft in the chimney, the top of the pipe is placed 500 mm above the roof ridge, provided that the distance from the parapet to the duct is no more than 1.5 m.

In other cases, the ventilation duct may be lower. Separate smoke removal systems are installed for the two units.

Features of choosing and installing doors

If the boiler is installed in an extension or one of the rooms of the house (including the basement), then the door to the boiler room from the house must be fireproof. That is, the structure must withstand at least 15 minutes of exposure to open fire - this will allow people to evacuate in the event of a fire. Fireproof doors must be made of metal and open towards the living space.

External doors in the boiler room of a private house (free-standing or in an extension) must be unreinforced (weakly reinforced). This will allow the blast wave to blow the door outside - the energy of the explosion will be directed to the street, and not to the internal walls of the house. In addition, gas will escape through the torn doors.

The door for the boiler room also serves as one of the ventilation elements - the leaf with a grille in the lower part ensures air flow into the room. The use of such a design may be a mandatory requirement of the boiler room installation project.

What to follow

When asked how to choose a heating boiler, they often answer that the main criterion is the availability of a particular fuel. In this context, we will highlight several types of boilers.

Gas boilers

Gas boilers are the most common types of heating equipment. This is due to the fact that fuel for such boilers is not very expensive and is available to a wide range of consumers. What types of gas heating boilers are there? They differ from each other depending on what type of burner is atmospheric or inflatable. In the first case, the exhaust gas goes through the chimney, and in the second, all combustion products escape through a special pipe using a fan. Of course, the second version will be a little more expensive, but it will not require smoke removal.

Wall-mounted gas boiler

As for the method of placing boilers, the choice of heating boiler involves the presence of floor and wall models. Which heating boiler is better in this case - there is no answer. After all, everything will depend on what goals you are pursuing. If, in addition to heating, you need to supply hot water, then you can install modern wall-mounted heating boilers. This way you won’t need to install a boiler to heat the water, and this will save money. Also, in the case of wall-mounted models, combustion products can be discharged directly onto the street. And the small size of such devices will allow them to fit perfectly into the interior.

The disadvantage of wall-mounted models is their dependence on electrical energy.

Electric boilers

Next, we will consider electric heating boilers. If there is no mains gas in your area, an electric boiler can save you. These types of heating boilers are small in size, so they can be used in small houses, as well as in cottages with an area of 100 sq.m. All combustion products will be harmless from an environmental point of view. And installation of such a boiler does not require special skills. It is worth noting that electric boilers are not very common. After all, fuel is expensive, and its prices are rising and rising. If you are asking which heating boilers are better in terms of economy, then this is not an option in this case. Very often, electric boilers serve as backup heating devices.

Solid fuel boilers

Now it’s time to consider what solid fuel heating boilers are available. Such boilers are considered the most ancient; such a system has been used for heating premises for a long time. And the reason for this is simple - fuel for such devices is available, its quality can be firewood, coke, peat, coal, etc. The only drawback is that such boilers are not able to operate in autonomous mode.

Gas generating solid fuel boiler

A modification of such boilers is gas generator devices. This boiler differs in that it is possible to control the combustion process, and the productivity is regulated within the range of 30-100 percent. When you are thinking about how to choose a heating boiler, you should know that the fuel that such boilers use is wood, and their humidity should not be less than 30%. Gas fired boilers depend on the supply of electrical energy. But they also have advantages over solid fuel ones. They have high efficiency, which is two times higher than solid fuel devices. And from the point of view of environmental pollution, they are environmentally friendly, since combustion products will not enter the chimney, but will serve to generate gas.

The rating of heating boilers shows that single-circuit gas generator boilers cannot be used for heating water. And if we consider automation, it is great. You can often find programmers on such devices - they regulate the temperature of the coolant and give signals if there is an emergency.

Gas generator boilers in a private home are an expensive pleasure. After all, the cost of a heating boiler is high.

Liquid fuel boilers

Now let's look at liquid fuel boilers. Such devices use diesel fuel as a working resource. To operate such boilers, you will need additional components - fuel containers and a room specifically for the boiler. If you are thinking about which boiler to choose for heating, then we note that liquid fuel boilers have a very expensive burner, which can sometimes cost as much as a gas boiler with an atmospheric burner. But such a device has different power levels, which is why it is profitable to use it from an economic point of view.

In addition to diesel fuel, liquid fuel boilers can also use gas. For this purpose, replaceable burners or special burners are used that can operate on two types of fuel.

Liquid fuel boiler