What is the most important thing when improving your home? Undoubtedly a quality finish. Although something completely different will be more important. Namely, to correctly resolve the heating issue. But a boiler room in a private house is not an idle question at all. The fact is that its structure requires compliance with numerous norms and rules that must be followed without any changes. Any failure to comply with them leads to very serious consequences.

In addition to the installation of the boiler room itself, it is necessary to carefully approach its finishing. This is a mandatory condition that will affect not only the operation of all devices, but also the approval of equipment by inspection organizations.

It is better to immediately decide who will do all the work. If the finishing of the boiler room can still be done completely independently, then it is better to involve specialists in the installation of the boiler and additional equipment.

Requirements for the boiler room

It is believed that the most preferable option for resolving all issues would be to construct a separate room for installing all heating equipment and monitoring its operation. In addition, this will allow you to make the walls, floor and ceiling from the material required for this. That is, you don’t have to redo anything.

There are certain nuances that it is advisable to foresee in advance. In this case, it does not matter at all whether the boiler room is located in a separate building or inside the house.

- Based on the area of the facility, you need to immediately calculate the required boiler power.

- It is advisable to purchase all equipment in advance.

- The place for the boiler room inside the house should be located along a blank wall. If there are window openings, they need to be blocked. The same applies to doorways.

- The door to the boiler room is selected according to the required size. The main rule is that it must be fireproof. A simple interior fabric will not do.

- The dimensions of the room are determined by special standards: • thus, the total volume of such an object must be more than 15 m³; • the distance from floor to ceiling cannot be less than 250 cm; • the area on which the boiler will be installed starts from 4 m²; • all these requirements apply to all types of heating devices.

- The best wall finishing material would be tiles.

If a gas boiler with a power of up to thirty kW is used, then it will not require a separate boiler room in a private house. It can even be placed in the kitchen. Naturally, for this you will also have to follow a number of certain rules.

Advice! It is better to initially contact an organization that checks compliance with all rules and regulations for the installation and operation of boiler equipment. This is the only way to protect yourself from subsequent reworking of all the work done.

Construction of a separate room

Before you start building a hotel boiler room, you need to make a plan for it, which is agreed upon with the gas service workers. Also, this object must be included in the technical plan of the site.

- the structure being erected must have a foundation; it must not be adjacent to the house;

- a separate platform is arranged for the boiler, which should be twenty centimeters above the floor;

- there must be a direct exit from the premises to the street;

- A hood must be selected separately, which can be done independently.

On a note! There are special modular designs. They already include everything you need. But their cost is quite high.

How to make a ceiling in a wooden houseDo-it-yourself ceilingRough ceilingCeiling construction

In this video I’ll show you how to make a ceiling in a wooden house with your own hands, I’ll tell you about some secrets when filing a rough ceiling, which worked well when building a bathhouse from timber, so I decided to use them when installing a ceiling in a house made of timber. Watch other videos on the channel dedicated to building a house from profiled timber with your own hands:

Waterproofing a strip foundation with glass insulation // DIY foundation // Laying a plinth: https://www.youtube.com/watch?v=1NoDm…

Markings for laying the first row of a brick plinth//Laying a plinth with your own hands: https://www.youtube.com/watch?v=YmjAU…

Laying the first row of bricks//Single-row corner ligation system: https://www.youtube.com/watch?v=sPDY8…

We cover the vertical seams in the brickwork // Basement: https://www.youtube.com/watch?v=krW7j…

Laying the second row of bricks//Single-row corner ligation system: https://www.youtube.com/watch?v=b_oEx…

How to level the foundation // Leveling the foundation // Setting angles to the horizon // Review of the laser level: https://www.youtube.com/watch?v=87mJT…

Ventilation in the basement: https://www.youtube.com/watch?v=IzGe1…

Is it possible to fill the foundation in parts // Do-it-yourself foundation: https://www.youtube.com/watch?v=y7BG2…

Penoplex instead of a lining board: https://www.youtube.com/watch?v=JOoDW…

Stencils for assembling timber into a “Warm Corner”: https://www.youtube.com/watch?v=Dj8T6…

Connecting timber into a warm corner: https://www.youtube.com/watch?v=1w-Hh...

How to trim profiled timber in the corners when assembling it into a “Warm Corner”: https://www.youtube.com/watch?v=dtHGk…

The simplest exhaust ventilation//Ceiling insulation with sawdust: https://www.youtube.com/watch?v=wbvF5…

Assembling a house from timber using dowels: https://www.youtube.com/watch?v=fpQkF...

How to bleach wood // Frost vs Whiteness: https://www.youtube.com/watch?v=AEhlS…

Floor joists in a house made of timber: https://www.youtube.com/watch?v=uXKKe...

Simple do-it-yourself septic tank//Sewerage for a private house: https://www.youtube.com/watch?v=MJRxU…

Installation of shrinkage compensators (aka adjustable lift (jack): https://www.youtube.com/watch?v=nAoDM…

Floor beams//Installation of floor beams: https://www.youtube.com/watch?v=CxIoh…

Installation of studs during the construction of a house made of profiled timber //Shrinkage of a house made of timber: https://www.youtube.com/watch?v=S1Nuz…

The simplest exhaust ventilation in a private house. Part 2//How to get rid of condensation in ventilation: https://www.youtube.com/watch?v=SH_PY…

Preserving a house made of timber for the winter // Preparing an unfinished house for winter: https://www.youtube.com/watch?v=CI6mE…

Heating a private house//Breneran solid fuel boiler//Leningradka//Single-pipe heating system: https://www.youtube.com/watch?v=VpkPf…

Spring unit strength. Beginning of the 2022 construction season: https://www.youtube.com/watch?v=tL6AF…

Mauerlat // House made of profiled timber // Application of the “Strength” knot.: https://www.youtube.com/watch?v=tXq_2…

House made of profiled timber//Do-it-yourself house//Gables: https://www.youtube.com/watch?v=SpB2-…

Installation of truss beams//Lay down with chopped gables: https://www.youtube.com/watch?v=kCSia…

Installation of the ridge of a house made of timber // Ridge beam: https://www.youtube.com/watch?v=8pKMV…

Splicing rafters along the length: https://www.youtube.com/watch?v=PXBFx...

DIY roof. Part 1//Preparation of gables: https://www.youtube.com/watch?v=rAsAk…

DIY roof. Part 2//Installation and fastening of rafters: https://www.youtube.com/watch?v=Zu6XK…

DIY roof. Part 3//Installing slides//Roof sheathing//Banner instead of roofing felt: https://www.youtube.com/watch?v=mHj79…

Do-it-yourself pigtail // Preparing the opening // Making a casing: https://www.youtube.com/watch?v=JRKqm…

Water well//Do-it-yourself well//How to drill a well//Zhelonka: https://www.youtube.com/watch?v=M2l9Y…

Cellar in the house//Filling the floors in the underground//Basement of a private house: https://www.youtube.com/watch?v=3Jfxt…

Laying sewer pipes underground//Do-it-yourself sewerage in a private house//Sewer slope: https://www.youtube.com/watch?v=6Nscs…

What happened to the house after the winter//House made of profiled timber//Review of a house made of timber: https://www.youtube.com/watch?v=JGC4C…

Leveling a wall in a wooden house//Bent a wall from a timber//How to level a wall: https://www.youtube.com/watch?v=0O87Q…

Finishing the boiler room

According to all existing standards, all surfaces of the room must be made of non-combustible materials.

- If the walls were made of wood, then this design requires more careful processing. To do this, they are impregnated with fire-resistant compounds and covered with reflective thermal insulation. They are then covered with fire-resistant plasterboard.

- The floor must be leveled; for this, a mixture of cement and sand is used.

- Waterproofing should also be provided. The floor is covered with special materials (rolled or coating), and a section of the wall is grabbed at a height of ten centimeters.

Features of private house renovation

For a wooden house, installation of water supply in a dacha, installation of sewerage, installation of plumbing for a private house, installation of plumbing in a private house, toilet. Long gone are the days when water had to be brought into a wooden house from a well, and washing only in a bathhouse. Today, every modern house has a connected sewerage system and water supply, so installing a bathroom in it is not difficult for professionals.

Typically, the layout of a bathroom in a wooden house is drawn up during the design of the building itself. However, in the process you can equip a bathroom in a finished house. To make it easier to connect all communications, it is recommended to install a bathroom on the first floor or in the basement of the house. Installation of plumbing in a bathroom in a wooden house

Installing plumbing in a wooden house is not much different from installing it in an apartment. Having chosen a bathtub, it is better to place it along the wall. This arrangement reduces the load on the floor beams.

An interesting option for a country house is a wooden bathtub. It looks beautiful and original in bathroom design. Such bathtubs are often made of cedar or larch wood; they are not afraid of destruction, as they are treated with special compounds. A wooden bath has healing properties, but it is very difficult to care for, because... careful handling of wood is required.

Install a sink in the bathroom, or better yet, two, because in a country house there are frequent guests. If space and funds allow, you can install a jacuzzi. And if we are talking about a small bathroom, a shower stall would be the ideal option. rooms in a wooden house Bathroom floor in a wooden house

Bathroom for a wooden house, installation of water supply in a country house, installation of sewerage, installation of plumbing for a private house, installation of plumbing in a private house, toilet. The first floor has another advantage. A bathroom filled with water is heavy, so it is necessary to strengthen the floors and ceilings. It is more convenient to do this on the ground floor. The floor must be strengthened, because the floors can also become deformed. To strengthen the floor covering by 25%, it is necessary to reduce the distance between the beams and increase their cross-section compared to other rooms. The ceiling level should be lower than in other rooms by 10 cm. This will allow you to lay the rough flooring, waterproofing and screed for laying tiles, if any.

Water gets on the bathroom floor, so waterproofing saves the floor from rotting. The best materials for waterproofing bathroom floors are fiberglass and glassine. Waterproofing mixtures can be used to treat not only the floor, but also the walls to a height of 20 cm from the floor.

In a bathroom in a wooden house, wooden floors look organic and beautiful. They also need to be impregnated with an antifungal compound. The best type for a bathroom is teak, although it is a rather expensive option. You can replace it with larch, which has good water-repellent properties. Wooden floors are laid without cement screed directly on the insulation. Bath walls in a wooden house

Bathroom for a wooden house, installation of water supply in a country house, installation of sewerage, installation of plumbing for a private house, installation of plumbing in a private house, toilet Before finishing, walls, like floors, must be treated with an antiseptic. The material for the walls should be highly resistant to excess humidity in the room.

How to decorate the walls of a bathroom in a wooden house? You can traditionally use ceramic tiles or mosaics. This is a classic solution that is always fashionable and relevant. The walls turn out quite beautiful, you can choose the desired color. Using light tiles you can visually enlarge the room. Mirror tiles also look beautiful in such a bathroom, but they are difficult to maintain.

Walls decorated with . Their design can imitate wood or stone. This material is resistant to temperature changes and is quite durable.

As a result

Installing a boiler room requires a very competent approach. Not only the creation of a comfortable microclimate, but also the safety of all residents of the house depends on this. Thus, you should approach each stage carefully. Savings on finishing materials should not be allowed. It is better to entrust the installation of the boiler and equipment to professionals.

The comfort of living in a private house can be increased by efficiently heating it with autonomous heating systems. With their help, you can regulate the internal temperature, creating a favorable microclimate. There are several types of boilers and types of fuel, but regardless of the chosen option, it is necessary to properly arrange the room with the equipment. The decoration of a boiler room in a private house affects the functionality and safety of the technical room.

Little tricks

The decoration of the boiler room can be original and stylish. Brightly colored porcelain tiles combined with designer items and accessories will perfectly fit into the interior of your home. A matte surface interspersed with veins will add volume.

Cleaning will not be difficult. On a light surface, dust is not visible at all.

Doors are installed in two places. One is connected to the house, the second to the street. The entrance is equipped with additional structures. Fire-resistant metal sheet will strengthen the fire barrier. An estimated time of 60 minutes is enough to block the fire and call the fire department.

It is better to take classic, compact, no-frills lamps. Regular lamps will also work. Keep a small flashlight in a visible place in case of a power outage.

Don't get carried away with decoration. After all, the boiler room belongs to the utility rooms. The main boiler here is what you need to think about. Therefore, curb your appetites and direct your creative energy to other objects.

Premises requirements

Finishing work in the boiler room in the house is carried out in compliance with regulatory requirements regarding the premises in which the boiler is installed:

- the area of the boiler room should not be less than 8 m2;

- the height of the walls of the room should not be less than 2.5 m;

- one boiler room can be designed for one or two boilers;

- an exhaust hood must be installed in the boiler room;

- the fire door must have a width of at least 800 mm and open outward;

- the floor is tiled or covered with steel sheets;

It is unacceptable to store flammable and flammable substances and materials on the boiler room premises, as well as unnecessary items that do not affect the functionality of the room. Passages and space around equipment must be free.

Description of species

There are several types of boiler houses.

Built into the house

This type of boiler room is appropriate both in the basements of one-story houses and on their first floors. The main disadvantage is the insufficient level of security. In addition, many boilers create a lot of noise. To some extent, this is justified by the ease of use of boiler equipment. Most often, built-in complexes are located in kitchens and corridors. There must certainly be a separate exit to the outside and a number of fire partitions.

In the annex

A boiler room attached to a residential building (located, for example, in a garage) will suit those who do not need particularly high power. The boiler room will be cozy and will save money. The door will have to be covered with sheet iron and/or asbestos. When adjacent to residential premises, additional sound insulation is carried out. It is not prescribed by standards, but it is necessary.

There should always be an exit to the outside from the attached boiler room. In some cases, it is not allowed to have a passage into the house itself. Only experienced engineers can understand these limitations. The thermal power of the equipment should not be selected with a reserve, but only in full accordance with the needs of the residents. The regulations apply not only to heating equipment, but also to methods of supplying heat to the building itself from its extension.

Detached building

They try to make such buildings as close as possible to residential buildings. Various technical communications are used to communicate between them. In separate boiler rooms it will be possible to place any heating boilers and use any types of fuel. The use of boilers of almost unlimited power is allowed. Heating mains are used to supply heat to the home.

Block-modular

This option is optimal when it is impossible to install a boiler room inside the house, and it will not be possible to build a separate building. Such structures are assembled using factory components and are installed quite quickly. The length of the special container is a maximum of 2.5 m. The steel structure is insulated inside. The delivery set usually includes multilayer thermally insulated pipes. Block-modular boiler houses can be powered by:

- liquefied gas;

- coal;

- diesel fuel;

- firewood;

- natural gas.

How can you line the inside of a boiler room?

Before deciding what the walls in the boiler room should be like and how to decorate them in a private house, you need to familiarize yourself with the technical characteristics of building materials for their fire resistance. When choosing the best way to decorate block walls in a small boiler room in a country house, it is important to remember that the design of the boiler room is not the determining factor when choosing a material - its practicality comes to the fore. For walls made of aerated concrete, concrete or brick, choose plaster or water-based paint. Tile or metal panels are used as decorative finishing.

How to paint the floor on the veranda at the dacha with your own hands

Painting your porch is an excellent option for protecting your flooring. Paint protects the floor from damage and corrosion. Various materials can be painted:

- wood - boards, MDF, decking boards;

- concrete.

How to paint the floor on the veranda at the dacha, except with acrylic paint

For painting the wooden floor of an open veranda, the most optimal are acrylic, alkyd, nitro-enamel and oil paints. For good wood, you can also use stain or varnish. Before painting the veranda boards, the floor must be cleaned of remnants of the previous paint, if any, and sanded.

It is better to paint concrete floors with epoxy, acrylic paint or polyurethane enamel. Epoxy paint is not exactly painted on - it is rather “rolled” across the floor with a special spatula until an even layer is formed. It does not wear off over time and gives a very bright color.

How to paint the floor on the veranda at the dacha? Choose acrylic paint and polyurethane enamel. They are applied with a regular brush or roller. Before painting, it is better to clean the surface from dust and prime it, which will ensure better adhesion of the paint.

Preparatory work

Installation of equipment requires a level base. Therefore, first of all you will need to level the floor. There are many ways, the choice depends on the design and material of the building, as well as on the desired speed of work:

- A traditional wet screed allows you to get a perfectly flat base, but it dries within 28 days. If the screed has already been poured, it can be leveled with construction self-leveling compounds.

To level the walls, use plaster, plasterboard or CSP boards.

Preliminary processing

The heating system is installed on a flat surface, so first of all you should make it so using one of the following methods:

- For an ideal result, you can choose a wet screed; it allows you to efficiently level any surface. But there is also a disadvantage to using it - the long drying process, which lasts about a month. To correct old screed, it is recommended to use self-leveling mixtures.

Wet screed Source stroy-podskazka.ru

- If you need to carry out work in an accelerated mode, a semi-dry screed, which is a wet material, will help. After application, it needs to be leveled, since the mixture itself does not have this ability.

Semi-dry screed Source stroy-podskazka.ru

- One of the most modern methods is dry screed. It is done using expanded clay, with sheets of plasterboard and plywood laid on top.

Dry type screed Source stroy-podskazka.ru

Boiler room interior

The interior of the boiler room should be primarily functional. When developing it, it is important to think through every little detail. Consider the location of window and door openings, sockets and switches. Choose a light color scheme to make the room look cozy. It is important to think about the lighting - it should be intense and uniform.

Depending on the area of the room, you can provide a storage area in the form of shelving. Furniture must be made of metal. It is advisable to allocate a place for a fire extinguisher in case of an unforeseen fire hazard.

»

Ventilation

For high-quality operation of a gas heating device, an uninterrupted air flow is needed. It should be enough to both maintain combustion and remove gases.

To ensure good air exchange, a minimum power device in a dilapidated building usually requires natural ventilation of the furnace room. Air enters here from cracks in windows and doorways, as well as through other non-densities.

If the boiler room has sealed window and door openings, then additional ventilation is necessary.

Fireproof or fireproof building materials

What is fire retardant material? Fire-resistant, fire-resistant or fire-resistant material is a material that, after undergoing chemical treatment, has certain physical properties that allow such material not to ignite instantly, but to hold and prevent the expansion of fire, while naturally reducing the likelihood of a fire in the room where such material is used .

A very important issue from the point of view of arranging a boiler room for the safe operation of a solid fuel boiler and more. The importance of creating a fireproof room cannot be overestimated. So the main negative characteristics of building materials:

- Smoke formation

- Flammability

- Flammability

- Toxicity

Also, all materials are divided into two main types, if we speak in the context of arranging a boiler room: flammable and non-flammable. We are interested in non-flammable or fire-resistant materials.

General information

Despite the wide range of fuels, the use of solid fuel boilers remains the best option for rural areas, where in most cases there is no gasification.

Of course, you can use electricity, but in this case heating will cost much more. True, many people prefer traditional Russian stoves to boilers. However, this option is only suitable for relatively small houses. If the housing is large and has several floors, then you cannot do without a boiler.

It should be borne in mind that wooden houses are more demanding in terms of fire safety. Therefore, the arrangement of a boiler room requires a special approach and compliance with certain rules, which we will read below.

The walls of the boiler room must be lined with non-combustible material

Non-combustible and fire-resistant building materials list:

In particular, fire-resistant finishing materials for walls, which are also suitable for the floor in the boiler room. It is advisable to lay and route heating pipes in layers of heat-insulating, fire-resistant material. Also, such fire-resistant materials are suitable for stoves, if we talk about their finishing and finishing of the room in which the heating device is located:

- Plasters, gypsum, cement

- Natural stone: sandstone and slate

- Concrete

- Aluminum

- Steel

- Granite

- Glass

- Porcelain tiles

- Ceramic tiles

- Mineral wool

- Fire resistant drywall

The above types are also suitable as fire-resistant materials for stoves. By the way, here is a very good video showing in practice the importance of using non-combustible thermal insulation:

Separately, it is necessary to say about special fire-resistant impregnations, which can also be added to the plaster. Even wood impregnated with fire-retardant impregnations does not burn and will not become a source of fire, it will only smolder. After eliminating the original source of fire, smoldering stops. Such impregnations prevent the flow of oxygen into the wood, and therefore prevent combustion.

It is also worth remembering about mineral wool. Today this is the best fire-resistant material. Mineral wool not only does not burn, but is also an environmentally friendly material; even at elevated temperatures it does not emit substances harmful to the environment and humans. There is also special cotton wool for fireplaces and furnaces, and finishing the chimney from the inside. On one side, such cotton wool has a heat-reflecting surface. Capable of withstanding temperatures up to 1000 °C

If we talk about wallpaper, then they are not as dangerous in terms of flammability as it would seem. If the surface under the wallpaper is made of fire-resistant material, then there are no problems. In general, it’s worth mentioning separately about equipping walls in such a way that they are fireproof.

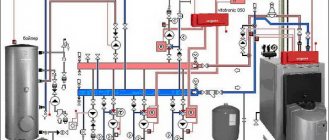

Heating system piping

The operation of the entire system will also depend on the correct selection and assembly of the pipework. There are one- and two-pipe distribution systems. A single-pipe system involves a series connection of heating radiators. The supply pipe goes to the first radiator, a pipe goes from it to another radiator, and so on. The one-pipe system is simple and does not require a large number of pipes, but it is impossible to use a thermal valve.

According to the improved scheme, one pipe runs through all the rooms, and the supply and return from each heating radiator are cut into it. In this case, you can install special thermal valves that allow you to shut off the supply of coolant to one or another heating radiator. Using a circulation pump will circulate the coolant through the system faster.

Fire-resistant materials for walls

So: partitions, vertical ceilings, walls should not be hollow inside, for fire safety purposes, if these same walls are made of flammable materials. The exception is wooden structures, which are separated from each other by diaphragms. If we talk about non-combustible materials for walls, then insulation made from such material must be vapor barrier. If the insulation is made of flammable material, then the voids between the sheets of insulation must be filled with slow-burning materials. This way, in the event of a fire, the flame will not spread.

In short: if, for the sake of economy, flammable insulation is used, then it should be separated sectionally by non-flammable gaskets, for example, metal sheets, so that the fire does not spread throughout the entire building.

In this regard, it is worth mentioning especially dangerous flammable materials.

Tips for use

To ensure that the equipment heats the house efficiently and there are no breakdowns, follow the following requirements.

- Almost all modern boilers operate in three modes: economical, automatic and maximum. The first is used when the room is left unattended. If the air temperature drops to +5 °C, the system turns on. After the coolant heats up to a certain degree, the equipment stops. This way, the pipes will not freeze or burst. Automatic mode is required for normal use. The person sets the desired temperature, upon reaching which the work stops. This mode is the most optimal, because with good heating of the room, fuel consumption is low. The maximum mode is used when you need to quickly warm up the house, for example, after a long absence of the owners. It is not profitable to use this mode constantly, since fuel will be consumed very quickly, and the system will quickly fail under heavy loads.

- After each heating season, preventive maintenance must be carried out. Soot accumulates on the burner walls and must be removed. If this is not done, the efficiency of the device will decrease.

Our tips and recommendations will help you install an oil-fuel boiler quickly and efficiently. You will cope with the task yourself, without hiring a specialist, and save on it. The system will function properly and delight you and your loved ones on frosty evenings. And if comrades or colleagues want to install similar equipment at their place, they will turn to you as a person knowledgeable in this matter, and it will not be difficult for you to share your experience.

Combustible materials

- Polyurethane foam (Mounting foam) is a very flammable material that emits a lot of fumes and toxic substances when burned.

- Expanded polystyrene (foam) is a popular material for insulation, but do not forget about its dangerous, flammable qualities.

- Bitumen (bitumen roofing)

- Linoleum - releases very toxic substances when burned.

We hope this article will help you create a safe heating system. Non-combustible building materials are extremely important in building a safe and warm home. Forewarned is forearmed! Another important element of boiler room safety is proper calculation of boiler room ventilation.

General characteristics of gas boilers

pros

- Ease of use . The gas supply is continuous, therefore, if the wick has been extinguished, the sensors (in some models) will work, sending a signal to the ignition system, which will re-ignite the burner. If the models do not have such sensors, then the gas supply will simply stop. All this does not require constant monitoring.

- High efficiency – up to 97%.

- Available fuel in most regions of the country - consumers do not need to stock up on fuel before the start of each heating season.

- Versatility . Gas boilers are used to heat both small apartments and large spaces.

Minuses

- Installation of boilers requires approval from the gas service. To do this, it is necessary to: develop design documentation, conclude an agreement with maintenance and installation organizations. In addition, you will need an agreement on the division of powers and responsibilities for equipment. Therefore, before contacting and you will avoid difficulties.

- Mandatory organization of a furnace (boiler room) - it is impossible to install a boiler in a residential area.

- The burner may wear out when the pressure in the line decreases, which will lead to a decrease in efficiency.

- It is necessary to use boilers adapted to Russian conditions - not all foreign models are effective for operating in harsh climates.

How to install a boiler

We would like to note right away that the installation of equipment of this specific nature cannot be carried out near the water supply system - this is fraught, at a minimum, with a short circuit. Next, the master who will be involved in connecting such equipment will have to act approximately according to the following plan:

- familiarization with the basic connection diagram, which includes: boiler, temperature sensors, shut-off and drain valves, pump; heating batteries, filters, expansion tank, piping;

- marking;

- securing the unit to a marked location using anchor bolts and dowels;

- stopping the water supply by means of shut-off valves before connecting to the heating system;

- installation of a protective casing;

- securing cables;

- connecting to the power supply and turning on the water supply;

- checking the tightness of the system;

- commissioning

Advantages

- Environmental friendliness

- Operational safety, subject to all requirements;

- High efficiency – 98%;

- Adjustment in manual and automatic mode;

- Easy installation and management.

Flaws

- Expensive electricity.

- Sensitive to voltage changes in the network.

- Not used for heating water for domestic needs.

- Under certain conditions there is a risk of electric shock.