Rationally located and trouble-free plumbing in the bathroom is an important component of the comfort of the owners. Its flawless connection is a guarantee of good relations with neighbors from the apartment below. To achieve the ideal, you need professional installation, the price of which not everyone agrees with.

But there is an opportunity to significantly reduce the cost of replacing old plumbing. If you install a bathtub yourself, then the home craftsman will only have to pay for consumables. However, an excellent result can only be achieved if you follow the technological rules that we are ready to share with you.

We suggest that you familiarize yourself with a detailed description of the process of installing and connecting plumbing fixtures made of cast iron, acrylic, and steel. We thoroughly outline the nuances of connecting to the sewerage system. The information we present is supplemented by photo collections, diagrams, and videos.

Guidelines for choosing a suitable bath

Modern industry offers us bathtubs of different shapes and colors, made from various materials. Due to the variety of models, the home owner is always faced with the problem of choice.

If the shape of the container and its color concern us more from an aesthetic point of view, then the important performance characteristics of the product depend on the material of manufacture: its practicality, appearance and durability.

In addition to the material, dimensions and configuration of the bowl, the choice of bath is influenced by the size of the hygienic room, the height of the sides that is convenient for all members of the family, and the presence of additional accessories and functions.

In the production of bath bowls the following are used:

- Steel. Steel plumbing attracts with its affordable price and abundant assortment. Thanks to its lightness, installation can be completed without the help of assistants. The disadvantages include high heat transfer, the ability to deform, sag under the weight of large people, and “noisiness” when taking water into the bowl.

- Cast iron. Expensive, reliable, durable. It does not make noise when filling with water and perfectly maintains the temperature in the container. Due to its impressive weight, installing a cast iron bathtub cannot be done alone. Plumbing fixtures are quite fragile; if handled carelessly, you can break the bowl or damage the enamel.

- Acrylic. A lightweight and inexpensive option that is easier and more logical to replace than to repair. It doesn’t sound when filling with water, it retains heat, but it doesn’t last long enough and isn’t very stable. You can easily handle the installation yourself.

If there are people in the family with impressive weight, it is advisable to install sanitary containers made of steel and acrylic on pedestals made of brick or additional supports constructed from it.

These measures will ensure stability and stabilize the position of the bottom. For owners with a less solid build, instead of capital brick fixtures, it is enough to install an additional frame made of a bar or a steel profile.

A frame made of a wooden block or a metal profile will provide the opportunity to tile a unique bathtub wall or arrange niches under the plumbing for storing hygiene items (+)

The shapes of the bathtubs are also pleasingly varied. In addition to the rectangular structures familiar to our eyes, there are oval and square ones. For small bathrooms, corner models are increasingly being used. And in addition to products in which it is more convenient to take a bath while lying down, those that are specifically designed for procedures in the “sitting” position are also in demand.

Image gallery

Photo from

A set of plumbing equipment in the bathroom

Supply of communications to the installed bathtub

Siphon installation and connection to the sewer system

Finishing the bathroom after installing the bathtub

The subtleties of choosing a bath that suits you personally are described in detail in another popular article on our website.

Mount the wall mount

Massive cast iron bathtubs stand confidently on legs and do not require additional fixation. But light steel and especially acrylic ones are also attached to the wall for reliability.

Acrylic and steel bathtubs

YouTube channel Cersanit Romania

Such bathtubs are most often fixed with brackets in the form of hooks on which the bowl is hung. Homemade metal profile stops for drywall are also used, which perform the same function.

YouTube channel "Alexander Cherepitsa"

In both cases, the fastenings are installed on dowels, for which holes are drilled. Using the line of the top of the bathtub, mark the holes for the stops so that they are strictly under the edge of the sides and evenly distribute the load.

Cast iron bath

Products made of cast iron weigh from 80 to 200 kg, so they stand reliably and do not require additional fastening.

Preparing the premises for the upcoming installation

If you have already made a choice in favor of a specific model, you should complete a number of preparatory work before installation. In addition, you should choose a place in advance, decide how you will install the bath: you plan to do the work yourself, invite workers or call your friends.

After drawing up a unique plan for upcoming actions, it is necessary to assess the condition of the premises, and if a need for repairs is detected, carry them out.

When should walls be tiled?

It is best to install a bath before tiling the walls during a major renovation of the room. This sequence of work will allow you to achieve the best practical and aesthetic results.

Installing tiles after installing the bath allows you to most effectively seal all the gaps and cracks so that moisture does not accumulate in them, which creates an ideal environment for the development of bacteria and mold.

If you were not going to renovate the bathroom, but only wanted to replace the bathtub itself, you need to choose a model that will be slightly higher than the previous one. At least 1.5 cm.

Note that the tiles under the edge of the old bathtub are different in color from the rest of the tiles: they have not been faded. In addition, it may have a dirty surface that cannot be washed. Therefore, it is better to hide it.

It takes a lot of effort to seal all the seams in the tiles adjacent to the bathtub surround, but the result is worth it: your bathroom should be a place of concentration of strength, not infection

How to properly prepare the floor?

The floor in the bathroom should not only be perfectly flat, but also durable. This is especially important if we have to work with a cast iron product, which has a fair amount of weight even without water.

If we lay floor tiles under the bathtub with our own hands, then they should be laid using the pressing method to prevent the formation of voids underneath. Otherwise, the tile may crack during use of the bath.

Any bathtub filled with water creates a significant load on the floor surface. To distribute it evenly, wooden logs can be used. Practice has shown that larch is optimally suited for this purpose.

The wood is prepared by treating it with antibacterial and antiseptic solutions. Then the logs are impregnated with PVA putty or drying oil.

The logs not only redistribute the load, but also successfully solve the issue of increasing the height of the product. Sometimes we need to raise the bathtub so that we can install a siphon with a deep elbow. Such siphons will prevent sewage waste from entering in the opposite direction. If you raise the bathtub slightly, for example, less hair will accumulate in the siphon.

Before installing and connecting the bathtub, the walls and floor in the room must be repaired and strengthened if necessary

Nail scissors

They differ in their purpose:

- slightly rounded or completely straight are used for trimming nails;

- for the cuticle, the tool should be a little longer, have a soft stroke, and the blades should be thin and sharp;

- universal with rounded blade;

- scissors-tweezers - blades, like cuticle scissors, there is a spring between the handles.

What to look for:

- Material. Zinc, nickel and alloy steel are often used. Give preference to the latter option - such scissors are inexpensive and do not get dull for a long time;

- Quality. The blades are sharp, located in one line tightly to each other, have a smooth surface without flaws;

- Convenience. The tool must be selected according to the hand of the master who will use it. To check, just make a few cutting movements in the air.

When purchasing, check the quality guarantee. But it is better to order a manicure device from a good master - it will cost more, but will meet all your requirements.

Selecting suitable drain fittings

When choosing drain fittings, it’s easy to get confused by how wide the range of products offered on the market is. But really, what characteristics should you pay close attention to when purchasing, and what can you ignore?

Reinforcement material

The building materials market offers us two types of materials: PVC (polyvinyl chloride) and polyisopropylene. We come across PVC more often, that’s why we choose it.

But relatively expensive polyisopropylene is not only stronger than polyvinyl chloride, but also has a whole list of indisputable advantages, these are:

- Hardness _ This material is significantly harder than its competitor, which reduces the likelihood of mechanical damage during bath installation.

- Durability. Its strength characteristics do not decrease over time.

- Surface quality. The surface of this material is smoother than PVC, which means that dirt sticks to it less.

The efficiency factor is also extremely important. The efficiency of polyisopropylene is higher than that of PVC, since the friction of water against the walls of smooth pipes made of this material is much less.

Qualities of drain elements

Most of the plums you see for sale are made in China. During their installation, a bolt is used. Regardless of what material it is made of, over time this bolt will oxidize, rust, or otherwise corrode.

You can buy a stainless steel bolt separately, but its contact with the mesh will certainly form a solder, which will significantly reduce the repairability of the product.

The industry offers drain fittings for bathtubs in two versions: made of PVC (polyvinyl chloride) or PP (polypropylene). If you are interested in the longevity and reliability of the device, it is better to prefer polypropylene as a material that is more resistant to household chemicals

When buying drain fittings, do not hesitate to check its contents and make sure that all the elements stated in the passport are present:

- Drain mesh. The most economical of all commercially available nets is a model that consists of two intersecting crossbars. It perfectly traps hair, preventing clogging. The most practical option is considered to be one with round holes located around the perimeter of the product. The most reliable is a mesh that has profiled oblique holes. However, this is also the most expensive model.

- Cork chain. It would seem that the chain is a detail that is not of significant importance. But that's not true. Usually we use the chain that we come across as part of the kit. It is not advisable to do this. Buy separately the one that fishermen use. Its surface is covered with protective paint, which prevents water from spoiling its appearance over time.

- Overflow pipe. In older bathtub models, the overflow pipe is made of metal, but modern production offers a better option. Use a corrugated pipe that has a large diameter, and, therefore, throughput. The high capacity of the pipe significantly reduces the risk of water overflow.

There are some installation nuances that are worth considering. For example, if the outlet valve of the drain fitting is wide enough, you can make the connection without using a collar. The resulting gap is simply filled with silicone-based sealant or silicone itself.

Warming the bowl

A very significant point, it makes it possible to significantly reduce the consumption of warm water, which is important given modern prices for utilities. After insulating the bowl, the bathtub’s heat saving performance is significantly superior to all commercially available expensive analogues. In addition, it does not add weight and perfectly dampens unpleasant sounds when filling with water.

How is the bowl insulated?

Step 1. Work must be done in an overturned position. Recommended immediately after installing the siphon with overflow and legs. Buy two or three cans of polyurethane foam. The cheaper the better. The fact is that cheap foam during hardening significantly increases in volume, and this is exactly what we need. More volume means more air bubbles, less heat loss. And the low price is explained by the low compression force; this parameter does not play any role in our case.

Steel bathtub turned upside down

Step 2: Clean the outside of the tub. If there is grease on it, you will have to wash it off with solvents. Working with solvents is unsafe for health; ensure maximum ventilation of the room. It is better to work outdoors rather than indoors. Be sure to use respiratory protection.

Step 3. After the solvent has completely dried, moisten the surface of the bottom with a spray bottle. Moisture increases the adhesion coefficient of foam to the bottom by an order of magnitude. In addition, water promotes optimal chemical reactions and the foam will harden much faster.

Step 4. Shake the foam canister thoroughly and put on a special plastic tube. Start covering the bottom with foam. The process will go faster if you apply it in sectors from bottom to top. The foam should lie in even rows at a distance of no more than a centimeter. Wider rows are not a problem; after hardening, the gaps will correct themselves. If the surface dries out, re-wet it with a sprayer. Do not touch the wet foam with your hands, do not try to “stick” it to the surface. You won't get anything other than additional problems. The foam will no longer increase in volume, and it is almost impossible to wash your hands. You will have to scrape it off for a long time and tediously with a knife.

Foam application

Applied foam

Step 5. Wait until the foam hardens, check the uniformity of the coating, and blow out any gaps.

Practical advice. If the foam falls off from vertical surfaces, then turn the bathtub in different directions and finish only the horizontal ones. It will take longer to work, but the result is worth it.

Step 6. Cut off the excess foam near the edge of the bathtub, it should not interfere with making the frame for the screen. The distance depends on the type and method of installation of the screen.

This completes the preparatory work for installation. The bathtub has a siphon, legs and insulation.

Detailed Installation Guide

All. The workplace is ready. Let's start installation. Since installing different types of bathtubs has its own characteristics, we’ll talk separately about this procedure for each type of bathtub. Let's start with an acrylic model.

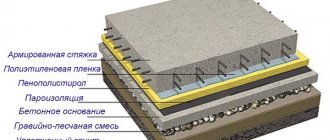

In general, the connection diagram for any bathtub is similar to this one. There are some features of working with a particular model caused by the properties of the materials from which it is made

Installation of acrylic sanitary ware

When you choose an acrylic bathtub in a store, pay attention to the fact that the kit includes special guides for attaching the legs of the bathtub. They are called lodgements. They are installed across the container. It is into them that the legs should be screwed.

The trays are attached to the surface of the bathtub using self-tapping screws included in the product package. Self-tapping screws must fit into holes specially designed for them.

Otherwise, they may simply make a hole in the bathtub. When drilling, use a drill equipped with a limiter. Holes cannot be made deeper than three-quarters of the length of the self-tapping screw.

The holders are installed. Now the bathtub should be carefully placed on the side surface and the drain fittings should be connected. Do not forget to thoroughly treat all gaskets that will be used with silicone before installing the drain fittings.

If you don’t want to make trouble with your neighbors downstairs and pay them for expensive repairs, make sure that the drain gasket is installed outside.

When connecting the drain, special attention should be paid to the tightness of all connections and the quality of the gaskets. Bathtub safety is extremely important

Of course, the design of the bathtub has threaded connections of the elements. Do not tighten them tightly, because the installation process is not easy, the joints and individual elements of the bath may become damaged and will have to be replaced.

If we install a bathtub, it must fit closely to three of the four walls. Make sure that the bathtub outlet is connected to the sewer pipe. Now you can level the bathtub using the rule, and treat the outlet connection with the pipe with sealant.

When the sealant begins to cure, take a fork wrench and tighten all loose threaded connections.

This is one of the options for connecting a bathtub to the waste line, which is made with high quality and is extremely simple, as it should be

That's it, the sealant has completely frozen. Now you need to check all existing joints for leaks. All shortcomings are eliminated, and if they are not there, then proceed to process the gaps between the walls and the bathroom. To do this, use the same sealant.

Nuances of installing a steel container

There are no special nuances when installing a steel bathtub. It is mounted in almost the same way as acrylic. The work algorithm is the same except for the method of attaching the legs. The legs are attached to the steel container using wedges, pins or bolts. When using bolts for this purpose, be aware that you will have to tighten them one by one and gradually.

No matter how much it seems to you that everything is attached correctly, you should not immediately tighten the bolt all the way. It is possible that fine adjustment of the legs will be necessary, which will become impossible if the bolts are completely fixed.

We have already said that during the process of filling a steel bath, a stream of water hitting the walls of the container makes a loud sound. To muffle it, you can place pieces of automobile rubber in the space between the surface of the bathtub and the fastening of the legs or fill it with polyurethane foam.

You can read about how to seal the joint between the wall and the bowl here.

Features of installing a cast iron bathtub

Cast iron is a heavy material. And the bathtub made from it has a lot of weight. To prevent this massive object from damaging doorways and furniture, you need to properly organize the installation work. The bathtub should be adjusted and connected directly in the bathroom, without moving the container to other rooms.

Some cast iron bathtubs can be equipped with decorative legs. Such models become a real interior decoration and a designer find. If, in the process of adjusting the level of such a bathtub, you use raising gaskets, you can completely destroy all the efforts of the designer.

Check out the legs of this charming cast iron model. Of course, it is impossible to unscrew or lengthen them by placing some materials under them, but they must stand on a perfectly flat surface

You can get around this point by filing the legs at the base, but only a professional can perform this work efficiently.

There are also special features when connecting the drain to the sewer. It is better not to place a cast iron bathtub on its side. You can simply lift the front of the container. This will create additional space, which will be enough to complete the work. The structure should be temporarily fixed in the desired condition using wooden blocks.

The general principle of performing the work is maximum accuracy and no possibility of moving a heavy container.

You will find guidance on installing a cast iron container on bricks, if this solution is necessary, in the step-by-step guide posted on our website.

The nuances of installing a plastic bathtub

Plastic bathtubs are a cheap analogue of acrylic models, therefore the installation process for these models is similar to each other. But of course there is a difference. For a plastic structure, a special cushion must be created, the task of which is to relieve the load on the bottom of the product.

The pillow can be made of wood (larch) or cement. Bathtubs made of plastic should be used very carefully. Caring for it with aggressive detergents is strictly prohibited. If these nuances are ignored, then after 7, or even 5 years, the bathtub will need to be thrown out.

Depending on the opinion of the masters

If conditions allow you to choose any of the options, you can trust the craftsmen doing the repairs. Specialists with extensive experience will determine the optimal sequence themselves and tell you about all the possible pros and cons.

1. If a whole tile comes from the side of the bathtub, rather than a short cut, the picture turns out to be more attractive. When planning to bring a bathtub into a tiled bathroom, it is advisable to approximately determine at what height the side will be before laying the tiles.

2. Before sealing the “seam” between the wall and the bathtub with silicone sealant, it is recommended to fill the bowl with water until it drains. You can drain the water only after the sealant has dried. It is claimed that if you “seal” an empty bathtub, then after filling it can come off the wall. To protect the bathtub and walls from traces of sealant, before work you need to stick mounting tape on them.

3. If you want to “drown” the bathtub into the tiles that were laid long ago, you can make a shallow groove in the tiles. The width of the groove is the size of the side of the bathtub. The bathtub is pushed into the groove, the joint is treated with sealant and/or moisture-resistant grout.

Construction of a bath screen

The space between the bathtub and the floor does not need to be closed if the outer surface of the model has an attractive appearance. But more often we still try to close this gap.

This can be done using, for example, a sliding screen. This bathroom accessory is sold in stores, but some people prefer homemade screens. Homemade products attract with their uniqueness and low cost.

Those who think that a bathtub screen is only used to cover the side of the bathtub are mistaken. It can become a storage place for all kinds of household chemicals and hygiene products.

Ideas for decorating with tiles

This installation method also has a couple of weaknesses:

- The complexity of applying cladding is increasing, for this reason it will be necessary to invite a qualified tiler to carry out the work, and not a self-taught enthusiast;

- If you need to install a new bathtub, you will need to buy a model that is exactly the same in all dimensions.

Conclusions and useful video on the topic

Installing any bathtub is not as easy as it might seem. This video presents some editing nuances that you should pay attention to. Take a look and see if you can do this job yourself:

We have outlined to you the theory of how to install different types of bathtubs with your own hands. All that remains is to apply the acquired knowledge in practice. We warn you that theory is not always easily translated into practice.

You will have to skillfully use different tools, as well as demonstrate knowledge of the intricacies of the installation process. Particular attention should be paid to cast iron products. Take reasonable care to avoid injury to your hands and feet.

or you can tell about how you installed a bathtub yourself and connected it to the sewer in the block below. Please comment and share useful information. We and site visitors are interested in your opinion.

Grounding

This procedure is required when installing a steel and cast iron bathtub.

It is better to entrust the grounding to a specialist, but if you decide to do all the work yourself, then take into account the nuances of the technology:

Bottom reinforcement

How to strengthen the bottom of the bathtub so that it does not sag? bricks as additional support . The use of such a base will strengthen the structure, but in case of dismantling difficulties will arise.

The method of arranging the support is called combined, since bricks are used together with the factory base.

- First, install the legs and adjust them in height;

- Measures the distance from the floor to the bathtub and determines the height of the brick support;

- Carry out masonry work;

- Check the length of the legs and the height of the brickwork (they must match exactly to evenly distribute the load on the supports).

- The masonry is covered with a dense layer of polyurethane foam and a bathtub with legs is placed on it;

- The font is filled with water for better “gluing” with the brick.

The nuances of leveling and connecting a plumbing fixture with your own hands

The bathtub is installed level. In this case, they adhere to the following principle: you need to raise the lowered part, and not lower the raised one. It must be remembered that the height of the bath is of no small importance. First, the alignment of the device is completed, and then only it is connected to the sewer, otherwise there is a possibility of the siphon breaking.

There are two ways to level a bathtub:

- Diagonally

. When implementing this method, the rule is placed on opposite corners of the font. On top of it is a level. Level the device by twisting its legs until the instrument shows that the goal has been achieved. Then the rule with the level is transferred to other angles located diagonally relative to each other. This process must be repeated twice to ensure that the desired result is obtained. - Along the sides

. In this case, the rule is first placed along one side of the bathtub, and then the other. One and two sides of the font are adjusted in order. This procedure is repeated several times, since when one side is adjusted, the other may lose its correct position. The method of adjusting the tilt of the bathtub when installed along the sides is more labor-intensive than diagonally. If the flooring is not perfectly level, a lot of work remains.

Special models

Corner

Assembly and installation of corner fonts follows the same rules. The only thing is that such products must be placed only on the frame that comes with the kit, this is due to the peculiarities of the shape of each model. As a rule, the manufacturer completes its product with detailed instructions. Therefore, any man should be able to handle the assembly and installation of corner bathtubs.

Hydromassage

But hot tubs are not so easy to assemble. This will require much more time and effort. Indeed, in addition to the direct installation, it is also necessary to connect the pump system and configure everything correctly. But don’t be afraid of this, because we have described all the nuances in detail in this article: