Finishing the facade of a building with siding allows you to protect the structure from the negative influence of external factors. This finishing material has a large list of advantages:

- attractive appearance;

- practicality;

- low cost;

- ease of installation work;

- durability;

- wide selection of colors and shapes.

The installation process is relatively simple and consists of creating a supporting frame, onto which panels of finishing material are subsequently mounted. A smooth, solid wall can be covered in literally a few days, but you will have to tinker with window and door openings.

The finishing of siding on windows and doors is not particularly different from each other. The only difference is the presence of a low tide to remove precipitation when covering the windows. When covering doorways, the function of low tide is performed by a threshold or a threshold.

Basic principles of cladding

Taking into account three important principles determines the direction that is set when covering doors with modern siding:

- Siding may only be attached to prepared sheathing. This allows you to use additional options for insulating the facade. Moreover, a ventilated gap is provided, which is required for complete condensate drainage.

- Compliance with a clearly defined sequence of work during installation activities. For this reason, the surface is first thoroughly prepared, two strips (starting and finishing), corners of the internal and external structure, and finishing strips are installed. In each case, siding is used only with platbands, so it will not be possible to do without them. After proper preparation, you can install the siding.

- Taking into account the temperature effect on siding. Panels can expand and contract under the influence of temperature. In this regard, it is recommended to take into account the temperature regime when installing elements with the optimal tightening force of the fasteners used.

If you take into account the three principles described above, there is a chance to guarantee a successful siding finish. These aspects are classic, so they play an important role in both interior and exterior decoration using the material in question. Otherwise, completing the assigned tasks is greatly simplified.

The door on the street is subject to constant temperature changes, therefore, the door finish must withstand such changes

Plastered slopes

This type of finishing is suitable for external and internal work. To work, you will need starting and finishing plaster, spatulas of different sizes, a building level, and a primer. Decorative plaster or paint can be chosen as a finishing layer.

If the slopes are severely damaged after installing the door, apply the starting plaster in several layers to properly level the surface. Let each previous layer dry before continuing. Be sure to apply a primer between layers of plaster - the slopes will be strong and reliable.

Apply the finishing solution in a thin layer and, after complete drying, treat with a fine mesh. Paint smooth slopes or apply decorative plaster to them.

We introduced you to different ways of finishing entrance door slopes. Typically, homeowners perform such work themselves. Choose the method you like and try to apply the acquired knowledge in practice. You will succeed.

We recommend watching this video:

Finishing the facade of a building with siding allows you to protect the structure from the negative influence of external factors. This finishing material has a large list of advantages:

- Material calculation

Before installing siding around windows and doors, it is necessary to calculate the number of necessary components, which include near-window strips, J-profiles, ebbs, trims, corner strips and finishing strips.The use of certain components depends on the configuration of the window or doorway. If they have wide slopes, then it is necessary to use near-window strips. If doors and windows are flush with the wall, use platbands.

As a rule, the length of the components for siding is 3 meters. When calculating the required amount of material, you should divide the total perimeter of all doors and windows by 3. The length of components may vary depending on the manufacturer; this feature should also be taken into account when making calculations.

Siding storage and transportation options

In order to decorate your home with siding, every person must remember the rules for storing and transporting the material. Otherwise, you cannot count on a positive result. Panels are allowed for use only if their quality has been maintained optimal:

- Packaging materials with siding should always lie on a flat surface. Support along the entire length of the material is required.

- You can only stack up to fifteen packs on one stack. Otherwise, the material will be subjected to excessive pressure, which will be dangerous for its quality.

- The temperature inside the packaging material cannot exceed 60 degrees Celsius. If you leave packaged siding under the hot scorching rays of the sun, it risks losing its original characteristics, despite its resistance to external factors.

Proper storage allows you to successfully use the siding in the future.

Rules for caring for siding

What should be the proper care for siding? What aspects are recommended to be taken into account?

- The panels can be washed with water using a classic hose.

- To remove heavy dirt, use a brush with soft bristles or a soft cloth.

- Abrasive cleaners or brushes with stiff bristles can cause scratches on siding. For this reason, it is recommended to avoid such materials. Pure chlorine, organic solvents, varnish removers, grease stains, and furniture surface polishing agents can be negative.

- The most serious remedy that is allowed to be used consists of water and vinegar. In this case, it is mandatory to observe the proportions: 70% - water, 30% - vinegar.

Proper care is guaranteed to extend the life of the cladding.

Preparatory stage

High-quality window finishing from the outside requires certain preparation. Such work includes:

- removal of decorative elements;

- cleaning the surface from old plaster;

- removal of old wooden parts;

- dismantling of communications.

In addition, technical devices and fixtures - antennas and air conditioners - are also removed. The surface is cleaned and dried. It is better to carry out such preparation if it is planned to cladding the entire façade of the building.

How to carry out winter installation

Installation of siding can be carried out at temperatures not lower than -15 degrees.

Covering doors with siding is allowed even in the cold season. To eliminate unwanted risks, it is recommended to take into account important aspects of the planned event:

- The siding should rest for several hours. A mandatory requirement is compliance with a suitable temperature regime. The material must be cured at outdoor temperature, which at the same time should not be lower than +15 degrees Celsius. Otherwise, the cold will have a negative impact on the material that has not yet been installed on the door.

- It is advisable to use a suitable cutting technique for cutting. The best options would be a saw with small teeth or a grinder with an angular design. Scissors designed for cutting metal will not be desirable.

- It is recommended to remember the tolerance that affects the compression - expansion of the material. The optimal tolerance is eight to ten millimeters.

How to install siding on a door surface

Mandatory requirements - taking into account the basic rules that determine the result of installing siding on the door surface:

- Satzding panels can become wider or narrower. Such changes depend on temperature exposure. In this regard, strong screwing of screws or nails is not recommended. It is best to leave about one millimeter between the siding and the head of the screw or nail. One millimeter will be enough for the panels to successfully move from one side to the other and vice versa.

- The vertical profiles of the sheathing used cannot be placed more often than every thirty to forty centimeters.

- It is recommended to leave about 6 millimeters at each side gap. This will be enough for natural compression and expansion of the panel. If installation is carried out at low air temperatures, the distance is always increased to eight to ten millimeters.

- During installation, do not apply strong upward or downward pressure on the panel when securing it. Otherwise, the radius of the installed panel will shift, and the locks will actively rub against each other. Light force may only be applied in one direction: from bottom to top. Such force is allowed only until the connection between the lock and the lower part occurs.

- A nail or self-tapping screw may be driven into the central part of the perforated hole. The main task is to remember that forceful hammering is not recommended. Otherwise the panel will be damaged.

Installation of siding on the door

Combined finishing

To work you will need tools and materials:

- Brush, spatula.

- Perforated corner.

- Building level.

- Polyurethane foam.

- Primer, putty.

- Liquid Nails.

- Glue, dowels.

- MDF panels.

Installation of slopes on the front door begins after its installation is completed. Start with standard surface preparation:

- Check the strength of the wall around the door and clean the work surface from dust with a brush.

- Fill the gaps between the wall and the door frame with foam. Let it harden and remove the excess with a knife, carefully leveling the surface of the base.

- To ensure that the plaster mixture adheres better to the base, treat the cleaned surface with a primer.

- Install the beacon profile for plastering.

When the preparation of the base is completed, proceed to the main stages of work.

Stage No. 1. Applying plaster or putty

For rough finishing, use cement-sand mortar or starting façade putty. Both types of solution perfectly level and insulate the surface. Prepare a mixture of lime mortar, sand and cement yourself. Dilute the putty to the desired consistency.

Apply the solution from top to bottom. First level the surface above the door, and then start plastering the sides. The layer should be thick. Remove excess with a wooden strip. To keep outside corners strong and neat, install perforated corners by pressing them firmly into the plaster. Leave the surface to dry completely.

Features of using siding

Recently, finishing doors with siding has become widespread. Often this option for finishing door structures is used in commercial and industrial premises:

- warehouses;

- offices;

- workshops.

Siding is an ideal option for both the exterior and interior. In addition, the material is ideal for covering large doors.

Siding can be wooden or metal. Even if you plan to decorate a metal door with your own hands, a successful event is recommended. In addition, success is guaranteed. Metal siding is ideal even for finishing large doors on the outside, because any precipitation or temperature influences cease to be dangerous.

Accessories

In order to cover window and door openings with siding, you will need special components and galvanized profiles.

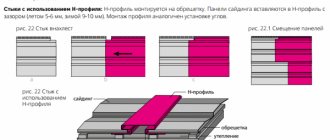

For installation, J-profiles are used, which must be installed around the perimeter of the entire opening. When finishing windows with slopes, double-sided corner profiles are used.

If the windows of the building do not belong to the European standard (are not equipped with ebbs), ebbs and canopies should be mounted separately.

Near-window strips are used to cover slopes, and platbands are used to frame openings that run flush with the wall of the building.

If the finishing of the slopes of windows and doors is carried out using a near-window strip, then it is important to use a finishing profile - it will fasten the near-window strip.

Advantages of siding panels

Why is this material becoming more and more popular?

- optimal resistance to moisture, which loses any negative properties;

- a decent level of fire safety, thanks to which any risks associated with a fire in the premises are successfully eliminated;

- optimal resistance to any impact;

- long-term operation and guaranteed durability;

- frost resistance and heat resistance. Only before carrying out installation activities is it recommended to protect the material from the negative influence of temperature;

- eliminating the need for special processing: impregnation, painting, maintenance.

The above advantages fully explain why the material is becoming popular.

Description of material

This material began to be produced relatively recently, but has already become widespread due to its advantages relative to other finishing materials. It is a cladding panel 1 mm thick, which has different shape variations.

Among the advantages for siding are::

- Low price of all work on facade arrangement due to the low cost of the material itself and the installation process;

- resistance to constant exposure to UV rays and moisture;

- long service life, which, if installation work is carried out correctly, is 50 years;

- no need to carry out additional work on processing or finishing the material itself . The siding is not painted or impregnated with any substances, because... n resistant to corrosion processes and combustion;

- variations in appearance that allow you to choose the most suitable option for a harmonious design;

- the possibility of carrying out installation work regardless of weather conditions and time of year , because the material is resistant to temperatures from -50 o +50;

- The installation process requires a minimum amount of tools, as well as construction skills. Even a beginner can install siding;

- ease of care during use.

There are some disadvantages to using siding for cladding.:

- The installation process requires special care and scrupulous approach . In case of an error made during the process of attaching the material, there is a greater likelihood of damaging the panel;

- gaps remain in the areas where the panels are joined , which makes it necessary to lay special materials that provide protection from wind and moisture;

- siding is not highly resistant to mechanical damage , but this is compensated by an easy replacement process in case of damage to the panel.

Vinyl siding differs into the following types:

- Fineber;

- Tecos;

- Deke;

- Under a log;

- Under a stone;

- Ship board.

Vinyl siding

Selection rules

First of all, you need to decide on the optimal material. For example, finishing an iron door with your own hands should only be done using reliable metal siding. Understanding the technical properties of the material used ensures that there is no risk of disappointment in the achieved result.

Wood siding is losing popularity as it gives way to metal and vinyl varieties. Metal products are susceptible to corrosion, so they often require special anti-corrosion treatment. Otherwise, vinyl becomes the most worthy material.

The choice of high-quality, beautiful and suitable material in color and texture, and proper installation guarantee successful door trim.

and also How to properly decorate a house with siding

Tool preparation

As mentioned above, no special tools are required for installation work.

The list of tools that must be prepared before starting work is as follows:

- Sharp knife;

- Jigsaw . Used as an alternative to a knife; with its help you can get a beautiful and neat cut;

- Drill or hammer drill . Needed to enlarge and make new holes necessary for attaching panels;

- Screwdriver;

- Building level . It is most convenient to use the laser variety;

- Roulette.

CAREFULLY!

You can use a grinder to cut the material, but it is recommended to use it only at low power. Otherwise, when cutting, the material begins to melt and deform at the edges.

Tools