High-quality ventilation, ensured by air circulation with the ability to regulate the intensity and direction of air flows, makes it possible to provide comfortable conditions for a person staying indoors for a long time. An anemostat for ventilation successfully copes with this work - a device that is very similar to a conventional ventilation grille, but differs significantly from it both in design and in the complexity of the tasks performed.

Purpose of the anemostat

Taking into account the functionality, the supply and exhaust anemostat can be used in the following systems:

- air heating;

- air conditioning;

- ventilation.

Using the device in the bathroom

The unit is installed not only in residential premises, but also in large shopping complexes, public buildings and production workshops. Taking into account the characteristics of the object and installation location, the device can perform several functions:

- regulate the amount of oxygen supplied to the room;

- distribute air masses;

- cover the air duct opening.

If we consider the oxygen distribution function, it operates most effectively in supply systems. Due to the plate-shaped shape, it is possible to direct air masses along the surface of the wall, and not into a specific area. Ventilation anemostats provide aero convection and eliminate the likelihood of strong air currents in the room.

Using the device in the office

Application of the device in production

Using the device in the room

What in the end...

I hope I clearly explained what an anemostat is. Therefore, I strongly recommend replacing conventional diffuser grilles with them. Thanks to this, you can avoid drafts in the room, as well as regulate the inflow and outflow of air masses. In addition, the latter will be more evenly distributed throughout the room.

Question

Write in the comments what you think - is it so important to regulate the outgoing air flow? After all, the more waste materials leave the room, the faster they will be replaced by fresh ones?

Using an anemostat in a ventilation system

An anemostat is the final element of the ventilation system, responsible for the uniform distribution of air masses in a closed room. Essentially, this is an alternative version of a diffuser or a conventional ventilation grille.

The device is actively used in air heating, air conditioning and ventilation systems of both domestic premises and industrial buildings.

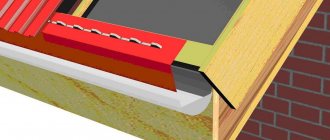

Image galleryPhoto from The anemostat is designed for controlled supply of air supplied by a mechanical ventilation system. The aerodynamic configuration of the valve is responsible for the uniformity of air flow in the anemostat design; the devices are equipped with a flange for connection to air ducts. Anemostats with air ducts connected to them are installed behind suspended ceilings, internal cladding of frame walls, and false ceilings. - walls Smooth adjustment of the air flow is carried out by rotating the central part of the valve Anemostat for supply and exhaust ventilation Aerodynamic shape of the valve Installation in a spring ceiling Device for smooth regulation of the flow

The main task of the anemostat is the formation and distribution of air flow entering the room from the outside or vice versa, directed into the exhaust pipe.

The anemostat is represented by a small piece of pipe with a movable “cap”. The air distribution element cuts into the outlet of the ventilation duct from the side of the room

“Plafond” is responsible for a number of additional, but no less important functions:

- adjusting the volume of supplied air;

- elimination of drafts - the device provides aero-convection, thereby eliminating the likelihood of air turbulence;

- effective ventilation of the room - fresh air streams fill the entire interior space of the room;

- blocking the air duct opening.

Some models of air distributors are equipped with a filtration element that retains dust particles from incoming street air.

Anemostats are available in different colors, which allows you to decorate the ventilation duct to match the tone of the finishing materials and make the air duct less noticeable

What is an anemostat?

In order for air to flow through the ventilation pipe, a distribution element must be used. These include an anemostat.

The device is a metal or plastic product made of several elements. A small piece of pipe is inserted into the cavity of the ventilation duct. It is secured with self-tapping screws. A flange in the form of a small plate is attached to it. The round part is attached to the housing spacer using a screw. The plate is a movable element, thanks to which you can regulate the air supply. An anemostat may include several plates of different diameters, which improve the process of air distribution indoors.

There are several holes on the flange. By rotating the plate counterclockwise, the slots increase in size, which increases traction. Whether the air rises or falls depends on the purpose of the structure.

The anemostat is used both to supply fresh air to the room and to remove waste fumes. The device can be installed on the system to regulate the supply of warm or cold air. The main advantage of the anemostat compared to grilles and diffusers is the ability to adjust the intensity of the air supply.

Anemostats of different types

Typical device and principle of operation

The design of the anemostat is extremely simple.

Standard equipment includes:

- round body;

- fastening coupling;

- flanged adjustable baffles;

- disk with threaded rod.

A spacer with an adjusting screw and a movable plate is inserted inside the ventilation duct.

The shield moves perpendicular to the air duct along the anemostat pipe. The operating mode of the air distributor is selected independently and controlled by the position of the damper (+)

When moving the cover counterclockwise, the passage gap increases, and accordingly, the air inflow or outlet increases. The cross-country ability of the device increases when the lampshade is turned clockwise.

Some anemostats have two plates: one is concave with a larger diameter, the second is of a standard shape. This modification distributes air better.

Recommendations for installing a diffuser

Diffuser installation

- The fastening element should be selected depending on the shape of the membrane and the structure of the ceiling, walls or floor.

- This element must be installed at the construction stage of the building structure, in accordance with the design plan.

- Make a mark on the placement of the fastener on the surface where you plan to install it.

- Mark the place where the ceiling and its frame are attached (when embedded in plasterboard, or mounted in a suspended ceiling).

- Mark the dimensions of the structure on the wall (to determine the occupied space).

- Using a grinder, make a reduction in the wall (the gap should be approximately 5 mm).

- Next, you need to insert the air distributor housing and put a mark on the wall to indicate the mounting points.

- Using a hammer drill, make holes of the required diameter.

- Apply sealant to the joints with the wall and fasten the element.

- Attach the nozzle using bolts and self-tapping screws.

- The front panel is dismantled and air distribution parameters are set.

- After installation of the membrane is completed, the configuration stage is performed. It includes the connection and connection of the measuring nipple and micronanometer.

- The device should be washed when it becomes dirty using warm water and detergent.

Thus, the process of using air distributors when designing ventilation is not a very complicated action. Installation, dismantling and maintenance of the air flow distributor can be done with your own hands using special tools and without special costs. Perhaps the most important point is the calculation of maintenance, the efficiency of the distributor and oxygen circulation, and proper and careful placement on the surface of the wall or ceiling for harmonious use in the interior.

Design and functional features

Depending on the nature of the distribution and direction of air jets, three types of anemostats are distinguished: supply, exhaust and universal.

The supply type air distributor is equipped with a shield concave inward. The shape of the plate has minimal aerodynamic resistance, due to which the air masses are distributed evenly. Such an anemostat is installed in the supply ventilation air ducts.

The divider is mounted in the supply ventilation system and redirects air flows along the surface of the ceiling or wall - depending on the installation method

In the exhaust air vent, the outer cover has a rounded, smooth shape to effectively remove exhaust air.

The universal supply and exhaust anemostat is equipped with two dividing hoods.

The nuances of using the combined model:

- when installing in an exhaust system, it is permissible to use two slots formed by plates at the same time;

- working in the supply ventilation system involves opening one gap created by a concave shield; In this case, the exhaust hole must be closed.

The selection of the appropriate mode is carried out manually - a technological gap of the required size is installed.

If the supply air duct is equipped with a universal anemostat and the exhaust mode is set, then the flow of fresh air will blow vertically downwards and not be distributed under the ceiling

Rating of the best plastic anemostats

ERA 12.5APP

A universal device that is made of durable material and is capable of providing good air supply and exhaust. The flange diameter is 125 mm, which is a good solution and is suitable for most public spaces and apartments. Installation does not take much time, the main thing is to follow the order of work.

Grill type – overhead. The total diameter of the structure is 197 mm, so the product will not take up much space. The plastic is coated with a protective layer that does not turn yellow when exposed to UV light. The strength indicators are not as high as those of steel structures, but the equipment is best suited for installation in a room where there is high humidity.

ventilation anemostat ERA 12.5APP

Advantages:

- Does not corrode;

- Does not turn yellow;

- Low cost;

- Optimal dimensions;

- Long service life.

Flaws:

AIRONE exhaust D 100 mm

A high-quality device designed for installation in supply and exhaust systems. Also, some builders recommend using an anemostat for air conditioning or organizing air heating. To simplify the connection with a round air duct, the manufacturer equipped the device with a flange with a diameter of 100 mm.

The equipment is designed for placement in suspended ceilings, but if desired, it can be installed on walls. Due to the fact that the central part rotates easily, smooth adjustment of the air flow that passes through this device is ensured. The outer part is made of durable plastic, characterized by impact resistance and high resistance to aggressive influences and atmospheric conditions.

The anemostat can be used in places where frequent temperature changes occur. The housing is fire-resistant, which corresponds to fire safety.

Average cost: from 150 rubles.

ventilation anemostat AIRONE exhaust D 100 mm

Advantages:

- Reliability;

- Easy installation;

- Low price;

- Suitable for exhaust systems;

- Installed on wall and ceiling;

- Impact resistance.

Flaws:

Planet A 125 VRF

A plastic device that is easy to install and has a long service life. For greater convenience, the product is equipped with an installation flange and a locking ring. This solution facilitates quick and high-quality installation in round air ducts. The central part rotates freely, making adjustment smooth.

The product is installed on the ceiling using self-tapping screws. The anemostat is designed for long-term use, so the outer part is made of durable materials that are not exposed to UV rays and work even with frequent temperature changes. Uniform distribution of air masses is ensured due to the aerodynamic shape of the valve. To ensure a tight fit, the inner part is equipped with a sealing element.

Average price: from 280 rubles.

ventilation anemostat Planet A 125 VRF

Advantages:

- Tight fit;

- High service life;

- Not susceptible to precipitation;

- Ensures proper air circulation;

- Convenient installation thanks to spacer feet;

- Aerodynamic shape.

Flaws:

VENTS A 150 PRF

The device is intended for installation in supply ventilation and air conditioning systems. The structure is installed in walls and suspended ceilings. The main purpose is to ensure proper circulation of air masses throughout the entire area. The product is made of durable plastic that can withstand high loads and not deform over time.

The shape of the structure is aerodynamic, which ensures uniform distribution of air flow throughout the entire area. The central part, as in other elements, moves freely, thereby ensuring smooth adjustment. For easy installation, the manufacturer added spacer legs and an O-ring.

Average price: from 500 rubles.

ventilation anemostat VENTS A 150 PRF

Advantages:

- Reliability;

- Uniform distribution;

- Efficiency;

- The presence of an o-ring;

- Doesn't spoil.

Flaws:

Anemostat and diffuser: similarities and differences

Despite the fact that both devices perform similar tasks, the operating principle of the air distributors is different. The diffuser itself is not designed to regulate the flow rate.

The angle of inclination of the lamellas of the supply and exhaust diffuser is fixed, and to adjust the volume of air flow, various modifications of manually controlled dampers are provided.

Unlike an anemostat, the diffuser grille body is round, rectangular or square. Linear oblong models have high throughput

Selection criteria: what to look for

Different devices are designed for use in certain conditions. When choosing, pay attention to technical characteristics and control methods.

Case material

Anemostats made of wood, steel or plastic are suitable for living rooms. For rooms with high humidity (showers, baths, swimming pools, baths, saunas) only plastic options are intended. Metal or wooden appliances quickly fail in such conditions.

Anemostats made of wood, metal and plastic.

Compliance with specified specifications

The size of the anemostat is selected taking into account the diameter of the air channel. Before purchasing the device, appropriate measurements are taken. When calculating the required throughput, the volume of the room, humidity and air pollution are taken into account. To find out whether the actual parameters correspond to the declared ones, you need to test the device under standard conditions.

Control type

This parameter is selected taking into account the installation location. Manually operated devices are designed for wall mounting. It is recommended to choose automatic models when placing them on the ceiling.

Types and design

The design of the anemostat may vary slightly depending on the model and manufacturer, but in most cases the device consists of the following elements:

- a round body with spacers and mounting tabs, in the center of which there is a thread for holding the disk;

- an adjustable disk to which a threaded rod is attached for movement in the housing;

- mounting flanges to hold the device in the ceiling or wall.

Some models do not contain a mounting flange, but the housing is inserted directly into the hole. Anemostats with several additional disks in the form of concentric rings are also produced. This is necessary to divide the flow into a larger number of cone-shaped jets, or with a large diameter of the device.

Devices come in different types, models and sizes depending on what the product is specifically used for. They are marked with the diameter of the air duct for which they are designed. The devices differ in standard sizes 80, 100, 125, 150, 200 mm.

Anemostats are distinguished by a design that is adapted to work in a supply or exhaust system. The adjustable disks of the supply anemostats have a concave shape on the outside to create minimal aerodynamic resistance. For the same purposes, devices with a curved disk shape are used in exhaust systems.

Usually, it is impractical to produce a purely exhaust device, so a universal one is made (supply and exhaust anemostat), which works well in all systems. Adjustable discs for all types are designed in such a way that between them and the housing it is possible to establish the required clearance for air movement.

Another important feature is the material. Based on this factor, anemostats are divided into the following types:

- Plastic. Made from polystyrene, PVC, ABS plastic. Inexpensive and lightweight devices. It is preferable to install them in air conditioning systems. When working with hot air, you need to monitor the quality of the plastic so that no harmful substances are released from it when heated.

- Metal, which are made from steel, aluminum, stainless steel. The metal anemostat is durable and can operate when supplying or removing highly heated air. They are more expensive than plastic ones.

- Wooden ones are rare. They are mainly manufactured for installation in saunas, baths, or if the design of the room requires it.

Visual options

Most often, anemostats are made from classic white plastic. Such devices are characterized by low price, light weight, and corrosion resistance. They go well with all interior elements and are not conspicuous, so they can be installed in any room.

In addition to plastic, devices are made of metal with a golden or silver tint. The products are suitable for arranging air heating systems.

They can withstand high temperatures, but are much more expensive than plastic ones. For houses with wooden walls, devices made of the appropriate material are ordered.

Types of anemostats

Structurally, products can be divided into 3 types.

- The only difference between them is the structure of the plate:

- Supply air: have a plate concave inward. Thanks to this, the air passing into the room is distributed along the surface (wall or ceiling - it doesn’t matter).

- Exhaust hoods: have a convex (towards the room) plate. This makes it easier for air to flow from the room into the exhaust duct.

- Supply and exhaust. They have a smooth (flat) plate with rounded edges. Can be used in both exhaust and supply systems.

In addition to the difference in the design of the plate, both supply and exhaust, and supply and exhaust anemostats are designed the same. Supply air units are used to bring fresh air into the room. Usually in such models the plate has a concave shape.

Exhaust products include a dome-shaped plate. Thanks to this shape, air penetrates faster into the vent. An exhaust anemostat helps get rid of exhaust air, fumes, dirt and unpleasant odors in the room.

A combined type anemostat can be used both for air supply and as an exhaust vent. Usually the combined device consists of several plates, with the help of which the operation of the ventilation hole is adjusted.

In order for the air distributor to act as an exhaust hood, the plates are installed in such a way that a slot gap is formed. To allow air to flow into the room, one of the slots of the anemostat is covered with a plate.

How are anemostats different?

The main thing that distinguishes devices for different purposes is the nature of the distribution of air masses.

An anemostat, intended for supply ventilation or an air conditioning system, has a central part configuration in which, roughly speaking, the forced air is evenly distributed parallel to the surface on which the device is installed. The usual shape of the divider is a plate concave on the outside.

An anemostat, designed for exhaust ventilation, is capable of taking in a significant flow of air that passes through it, encountering almost no resistance. In this case, the shape of the central part is such that an air flow in the form of a vertical cylinder is sucked in (in the case of installation on the ceiling). This ensures that air is quickly removed from the center of the room.

The universal anemostat has two divider plates. One works when exhaust ventilation is used, the second - when air is pumped into the room. The appropriate mode is selected manually by closing the currently unnecessary gap.

The amount of air that the anemostat passes through itself during ventilation operation is also very easily regulated. The central plate - divider can change position, reduce or increase the technological gap.

Review of popular brands

Anemostats are represented on the ventilation systems market by various manufacturers. The leader among sales is Vents products. They are worthy competition from air distributors Dospel, Blauberg, Lessar and Systemair. Let us consider the proposed modifications of popular manufacturers in more detail.

Vents

- The Vents company sells six series of anemostats:

- A*BP – combined plastic;

- A*VRF – universal with a plastic flange;

- A*PR – inlet plastic;

- A*PRF – inlet with mounting flange, material of manufacture – plastic;

- AM*VRF – universal metal with flange;

- AM*VRF N – supply and exhaust made of stainless steel.

Combined anemostats A*VR and A*VRF are made of polystyrene or ABS plastic. Both models are suitable for wall or ceiling mounting.

ModelA 80 VRA 100 VRA 125 VRA 150 VRA 200 RA 200 VR

| Clear cross-sectional area, m2 | 0.002 | 0.006 | 0.008 | 0.009 | 0.009 | 0.009 |

| Shelf size. air duct, mm | 80 | 100 | 125 | 150 | 200 | 200 |

| Valve stroke normal, mm | 0…8 | 0…20 | 0…22 | 0…23 | 0…16 | 0…19 |

| Form | Round | |||||

| Material | Plastic | |||||

| Adjustment | Adjustable |

The difference is that A*VRF anemostats are equipped with a flange and a restrictive ring, allowing you to quickly and easily fix the air distributor in the ventilation duct.

Models A200VR, A200VRF and A200/150VRF are equipped with two control elements - this ensures better redistribution of air masses.

Supply anemostats A*PR and A*PRF are available in two diameters: 150 mm, 200 mm.

- Relevant characteristics of the air distributors:

- cross-sectional area – 0.011 and 0.012 sq.m;

- The maximum normal stroke of the plate is 21 and 22 mm.

The cost of Vents plastic air distributors without a flange is 4-9 USD, depending on the dimensions and the presence of a flange.

Metal models of combined anemostats (AM*VRF and AM*VRF N) are presented in four standard sizes: 100, 125, 150 and 200 mm.

The price for steel products with a polymer layer is 9-12 USD, for stainless steel anemostats – 25-100 USD.

Dospel

The Dospel company (Poland) specializes in the manufacture of ventilation equipment and accessories.

- Air distributors are presented in three subcategories:

- AN* – plastic air supply devices;

- ANM*EV – exhaust metal anemostats;

- ANM*SV – supply distributors made of metal.

AN series lampshades are available in diameters of 100, 125 and 150 mm. The maximum opening of the sash reaches 16, 13 and 21 mm.

Dospen supply and exhaust distributors are made of stainless steel and powder coated. Both series (ANM*EV and ANM*SV) are available in five sizes: minimum – 100 mm, maximum – 250 mm.

The estimated cost of plastic models is 4 USD, metal ones – 6-19 USD.

Blauberg

- The German corporation Blauberg Ventilatoren offers the following types of supply and exhaust air distributors:

- VPR – plastic with mounting flange. They are made from polymers that are resistant to UV rays and temperature influences; the plastic contains antistatic additives. Overall dimensions are suitable for air ducts of 80-200 mm. Maximum cross-sectional area – 0.009 sq.m.

- VMR – metal anemostats. The production material is steel, on top there is a layer of white polymers. The model range includes four positions from 100 to 200 mm.

- VSR - for ceiling or wall mounting. Smooth regulation of air flow. Easy installation with mounting flange. Equipped with a rubber seal. Made from stainless steel.

- VMBR - for supply ventilation systems, air conditioning and air heating systems. For installation in walls or ceilings. Ensure proper air flow and circulation in the room. Manufactured from steel with polymer coating. The special aerodynamic shape of the valve ensures uniform air distribution. Smooth regulation of air flow due to rotation of the central part of the valve. Equipped with a mounting flange for easy connection to round air ducts with a diameter of 100-200 mm. The mounting flange is fixed to the ceiling using screws. The inside of the anemostat is equipped with an O-ring for a tighter connection.

The high strength characteristics of both models determine their wide range of applications: residential, utility, office, retail premises, kindergartens and medical institutions.

Lessar

Lessar has production facilities in China and various European countries. The company's products are in demand due to their decent quality and affordable prices. Anemostats are produced in a limited range - metal devices of exhaust and supply type.

- Distinctive features of Lessar air distributors:

- model range: LV-DCP – for supply ventilation systems, LV-DCV – for exhaust air ducts;

- channel cross-section: 100, 125, 160 and 200 mm;

- anemostat capacity – 10-500 cubic meters/hour;

- cost – 5-10 USD (depending on the dimensions of the product).

Lessar anemostats are much cheaper compared to similar metal models from other manufacturers.

Systemair

The Swedish brand Systemair sells a standardized line of ventilation equipment: fans, air handling units and air distributors.

- Types of Systemair anemostats:

- Balance-E. Exhaust type device made of regenerated polypropylene. The material withstands high temperatures (up to +100°C) and chemical compounds in moderate concentrations. Four variations are designed for air ducts of 100, 125, 160 and 200 mm. The maximum air gap is 20 mm.

- Balance-S. Inlet anemostat, made of the same plastic as the previous model. Available in three sizes: 100, 125 and 160 mm.

- EFF. A universal steel distributor capable of operating in “exhaust” and “supply” modes of air. EFF modifications have a diameter from 63 to 200 mm, the stroke of the central cone is up to 28 mm.

- TFF. Supply anemostat made of steel. The design includes an inlet cone and a flat soundproofing disc. Available in diameters 80-200 mm.

Models Balance-E, Balance-S and EFF are installed using a mounting ring or directly into the duct. TFF is fixed in the ventilation duct with spacer springs or in the mounting frame.

Help in selecting products

The plastic diffuser has become especially popular due to its low cost, ease of installation and maintenance, and the fact that it is not subject to corrosion. Therefore, this type of product is often used in rooms where there is high temperature and humidity. For a bathroom, kitchen, swimming pool, toilet, you can’t think of a better option.

The metal anemostat and diffuser are more durable and resistant to various mechanical damage, and therefore their service life is much longer. This variety is used in various air heating systems and in rooms with high temperatures.

Wooden diffusers are most often a design work and, in addition to their direct functional duties, serve as decoration in the corresponding interior.

Differences in material

Most often, anemostats are made of plastic: this material is cheap, lightweight, resistant to corrosion, and at the same time durable and easy to maintain. Plastic models are recommended for use in conditions of high humidity (for example, in swimming pools, showers, bathrooms, kitchens).

In addition to plastic, anemostats can also be made of metal. Such products are suitable for ventilation systems with air heating, or for rooms with high temperatures. Metal anemostats are more expensive than plastic ones.

Anemostats made of wood (plate), metal and plastic

If desired, you can order a wooden plate to be made so that the anemostat is invisible in a house with wooden trim. You can rarely find such products in stores, but any furniture workshop can easily handle this task. You can also contact a carpenter who has the equipment.

Differences in purpose: supply, exhaust, combined

Structurally, products can be divided into 3 types. The only difference between them is the structure of the plate:

- Inlet

: have a plate concave inward. Thanks to this, the air passing into the room is distributed along the surface (wall or ceiling - it doesn’t matter).

- Exhaust

: have a convex (towards the room) plate. This makes it easier for air to flow from the room into the exhaust duct.

- Supply and exhaust

. They have a smooth (flat) plate with rounded edges. Can be used in both exhaust and supply systems.

Supply, supply and exhaust and exhaust anemostats

In addition to the difference in the design of the plate, both supply and exhaust, and supply and exhaust anemostats are designed the same.

Product characteristics

The key characteristics of ventilation anemostats (both exhaust and supply) are:

- Diameter _ Must be selected according to the diameter of the air duct. Typically, anemostats are made in diameters of 80, 100, 125, 150 and 200 mm.

- Slot hole area . The higher this indicator, the more air the anemostat will let through. On average, models with a diameter of 125-200 mm have an area of about 0.006-0.009 m².

- Tray of the plate (how far the plate can move). On average - from 0 to 23 mm.

The area of the slot opening (and therefore the amount of air that can pass through the anemostat) directly depends on the diameter of the product and on the stroke of the plate.

On average, the cost of a plastic model with a diameter of 100-150 mm (the most popular type of product) is about 200-300 rubles. Metal ones of the same size will cost 300-400 rubles.

About manufacturers and models

In the markets of the CIS countries, similar products can most often be found under the brands Systemair, Era and Vents.

Vents brand anemostats (the most common) are divided into several series:

- A-BP. Supply and exhaust plastic models, with a diameter from 80 to 200 mm.

- A-WRF. Supply and exhaust plastic models, with a diameter from 80 to 200 mm.

- A-PR. Supply plastic models, with a diameter of 150 (1 plate) or 200 (2 plates) mm.

- A-PRF. Supply plastic models, with a diameter of 150 (1 plate) or 200 (2 plates) mm.

- AM-WRF. Supply metal (steel with polymer coating) models, with a diameter from 100 to 200 mm.

- AM-VRF-N. Supply metal (stainless steel) models, with a diameter from 100 to 200 mm.

The model name is supplemented by the diameter. That is, in the store the full name will look like: Vents A 100 VRF (diameter - 100 mm).

Another, more convenient - automatic - option is presented on the Russian and Ukrainian markets. The model is called AVK 100-1-12, and is intended for ventilation ducts with a diameter of 100 mm. The control of the dish (i.e. opening and closing) is implemented in the form of a wall switch (looks like a regular light switch).

Operation of an electric anemostat (video)

Specifications

The main parameters of the devices under consideration include:

- Shield power reserve. This term refers to the maximum distance that the poppet-shaped regulator can move. Values from 1 to 23 mm are considered average.

- Diameter selected taking into account the parameters of the ventilation duct. Most of the devices have standard sizes (from 8 to 20 cm). It is possible to manufacture a device with individual parameters upon request.

- Hole area. The throughput of the system, which is regulated by flanges, depends on this characteristic. For devices with a diameter of 12-20 cm, the hole area should be 0.006-0.009 square meters. m.

How to install an anemostat indoors

To begin with, it is worth noting that the location of the anemostat relative to the horizon line does not in any way affect its functions. The main thing is that the flow of air masses is strong enough so that it is enough for the required cubic capacity of the room.

Typically, in office premises, ventilation supply pipes are installed up to the level of suspended ceilings, so anemostats can often be seen hanging at the level of the suspended ceiling. The anemostat can also be installed on the wall, and it can be fixed either on the air duct itself or attached to the wall itself, which is more correct from an aesthetic point of view.

If the room is of industrial importance and the ventilation system is not covered by anything, anemostats are simply fixed at the end of the supply pipes of the air ducts.

Methods for installing anemostats

To have an aesthetic appeal, manufacturers make anemostats with hidden fasteners. If you look at an already installed device, no mounting assumptions will be visible.

To do this, you can find a special fastening coupling inside the anemostat. Having selected the correct combination of the diameter of the device and the air duct, you need to insert the device into the air duct and tighten the fastening coupling.

Another mounting option is also possible for devices with special mounting flanges. To do this, you need to connect the flanges to the walls of the air duct pipe and tighten the bolts.

Installation instructions

Typically, the installation of devices is carried out after finishing work has been completed. In the place where the end of the air duct pipe is located, a hole of the required diameter is drilled. Specialists installing ventilation systems do this using special attachments for a drill; if you don’t have one, a regular electric jigsaw will do.

After which, having access to the air duct, the anemostat is fastened using a fixing coupling or flanges.

Often, a flexible hose is installed above the suspended ceiling from the main ventilation line. After drilling a hole in the right place, the hose is brought to the hole and installation follows the same scenario.

Useful tips

In the case of manual control of the anemostat, it is necessary to provide for the laying of a power cable before starting finishing work for further regulation of the operation of the device. And during installation, do not forget to connect the cable to the device.

In cases where the finishing work has not yet begun, and the device needs to be fixed to the air duct, the main body of the device with a mounting coupling is attached to the air duct, after which the hole in the air duct is closed, and the decorative components with the plate will be put on after the finishing work.

Functions and operating principle

The nature of the devices' operation is simple. The movement of the shield helps to change the volume of air entering the room. This allows you to maintain a comfortable temperature in your apartment or house at any time of the year.

Electrically driven equipment

When using devices with manual adjustment, you have to change the position of the plate yourself. The electric drive helps you avoid performing this action.

Using additional controls, the user sets the operating parameters of the device. Subsequently, the anemostat begins to function without human intervention.

Installation of an anemostat

The anemostat can be installed in a plasterboard structure, both on the ceiling and on the wall. The most convenient way to do this is with the help of a flexible air duct, which is connected to the main ventilation pipe, which is hidden by drywall.

Installation must be carried out during the construction (or major renovation) phase, since the plasterboard structure must be disassembled so that the duct can be laid to the hole.

The installation steps are as follows:

- A flexible air duct is installed from the main ventilation duct to the desired location in the ceiling (wall).

- In the selected location, a round hole of the same diameter as the air duct is drilled in the drywall.

- The anemostat model is selected based on the diameter of the air duct.

- An anemostat pipe is inserted into the air duct docked to the hole.

- The circle that remains outside (on the side of the room) is attached to the plasterboard sheet with self-tapping screws.

Installed air duct with anemostat (before installing the ceiling)

If you select a model with automatic control, you need to run a cable and install a switch.

After this, you can engage in further repairs and finishing: the installation site for the anemostat has been prepared, and the plasterboard structure can be completed. The only caveat: to prevent construction debris and dust from getting inside the ventilation duct, the resulting hole must be sealed until the repair is completed.

Upon completion of all finishing work, the following remains to be done:

- Install the support part inside the body (pipe) of the anemostat, onto which the screw with the plate is attached. The same supporting part is connected to a decorative circle, which covers the mounting circle with self-tapping screws. It is installed inside the pipe, in special grooves.

- A screw with a plate is screwed into the installed supporting part.

After this, you can adjust the amount of air entering (or removing) by turning the screw clockwise or counterclockwise.

Installation of an anemostat (video)

In what cases is a ventilation grille, diffuser, anemostat useful?

Makes it possible to regulate the amount of supplied air, and if necessary, the hole through which the air flows enter is completely blocked.

Some models of anemostats are additionally equipped with filters that clean the air coming from the street from dust. Structurally, the devices are very simple. They are a round housing that is installed on the ventilation duct. Inside the anemostat there is a spacer that holds it inside the shaft, and adjustable flange partitions. They determine the intensity of the air flow.

When you turn the lid of the device clockwise, the gap allowing air to pass through increases. When turning in the opposite direction, it decreases accordingly. All anemostats are divided into three types:

— Supply. The shield distributing air flows has a concave shape. Thanks to this, its aerodynamic resistance is minimal, and the incoming air masses are distributed as evenly as possible.

— Exhaust. The shield has a rounded shape, which will allow you to effectively remove polluted air from the room.

- Universal. They are equipped with two shields of different shapes, so they can operate in different modes.

However, to choose the right device, it is not enough to determine its type. There are a number of other important technical characteristics that need to be taken into account.

Hole dimensions

This value determines the throughput of the device. Since the anemostat involves adjusting the intensity of the air flow, there is a so-called run-up of indicators. The larger it is, the more accurately you can configure the device.

Anemostat diameter

The dimensions of the air distributor head must correspond to the cross-section of the ventilation duct. Devices with a diameter of 80 to 200 mm are produced, so in any case you can choose the optimal size model.

Power reserve

Shows how much larger the hole size is in the maximum open state than in the minimum open state. This difference can be quite significant and varies from 8 to 30 mm. The greater the power reserve, the more accurately the anemostat is adjusted.

Control type

There are two options: mechanical and automatic. The first one is extremely simple and is implemented in most models. However, in some cases it is not entirely convenient to use it, for example, if the anemostat is located at a considerable height or on the ceiling. In this case, an automatically controlled device is installed that responds to signals from the remote control. True, for it you will have to additionally stretch the cable and mount the control unit.

And another important point in choosing an anemostat is the material from which the device is made. The most affordable are devices made of plastic. They are available in a wide variety of designs: color, design, texture. The advantages of such devices include high resistance to high humidity, absence of rotting and corrosion. Plastic structures are lightweight and easy to install. They are very unpretentious in maintenance and easy to care for. Due to this, they are widely used in offices, residential buildings and production.

Among the disadvantages of plastic devices, low strength and sensitivity to high temperatures should be noted. That is why they are not suitable for working with hot air masses. Metal anemostats do not have these disadvantages.

They are made of aluminum or stainless steel. Metal appliances have an attractive appearance that goes well with a variety of interior design styles. In addition, they are strong and durable. Among the disadvantages of such anemostats, it is necessary to mention their rather large mass, which makes their installation somewhat difficult, and their high cost.

As an exclusive solution, anemostats made of wood are produced. These are piece products that are made to order. They look organically in a wood-decorated interior. If they are intended to be installed in a sauna or bathhouse, mandatory additional treatment of the wood with special protective compounds is required.

An anemostat is a necessary element of the ventilation system, providing a comfortable microclimate in the house

It is important to choose the right device, then it will last a long time and perform its functions effectively

— Inna Yasinovskaya Photo: buyreklama.ru, allegroimg.com, kak-i-chto.ru, oventilyacii.ru

Home » Dictionary of construction terms » A

Scope of application

Anemostats are used for installation inside ventilation and air conditioning systems, as well as for air heating networks. They are installed in residential, public, industrial premises, as well as large shopping complexes. The functions of this air distributor are as follows:

- Efficient indoor air distribution. Due to this function, aeroconvection is carried out, which prevents the formation of strong air currents inside the room.

- Decorative masking of the ventilation duct opening.

- Regulating the volume of supply air inside the room.

Due to its small size, the device is almost invisible in the interior, and there are many options for designing the external surface of the anemostat.

The purpose of anemostats: why they are installed

To regulate the air flow through the ventilation system, diffusers, ventilation grilles and anemostats are used. The first two devices have certain characteristics that allow them to pass only a certain amount of air.

Unlike them, the anemostat has a movable design that allows you to adjust the strength of the air flow both manually and automatically.

An anemostat is often confused with a diffuser. Although they may seem similar to the average person, the diffuser has a fundamental difference - it does not have air flow regulation. And the anemostat has such a function.

Main manufacturers of anemostats

There are three large companies on the Russian market that produce anemostats. These include Vents, Era and SystemAir. was founded in the 90s of the 20th century. This brand produces ventilation and air conditioning equipment all over the world.

produces ventilation grilles, diffusers and anemostats. The company was founded in 1997. Products are sold in 85 regions of Russia.

started its operations in Sweden in 1974. Today the organization includes 56 companies. Ventilation products are sold in 45 countries, including Russia.

Anemostats

Anemostat models are produced in six lines depending on their size and material used:

- A-BP;

- A-PR;

- A-VRF;

- A-PRF;

- AM-VRF-N;

- AM-WRF.

A-BP includes both plastic and metal anemostats. These are mid-priced models. A-BP line anemostats are available in diameters from 8 to 20 cm.

A-PR is a line of supply anemostats. Models with two plates are available.

Models A-VRF are combined devices. They are suitable both for bringing fresh air into the room and for drawing out unpleasant odors. Under this line, both small and large-sized anemostats with a diameter of 20 cm are produced.

A-PRF is a series of supply-type anemostats. They are suitable for installation on a wide ventilation hole with a diameter of 15 to 20 cm.

The AM-VRF-N line produces supply models of various sizes. All of them are made of stainless steel.

AM-VRF models are available in both supply and exhaust types. The diameter of the anemostats can be from 10 to 20 cm. All models are made of steel with a special reinforcing polymer layer.

Anemostat “Vents” A 100 VR

Anemostats from

produces several lines of popular models of anemostats: APP, APVP and AVP.

Supply-type models can be purchased in the APP line. This is a device with an interesting quadrangle design. The plate is concave towards the vent.

APVP are combined supply and exhaust devices. They include several disks, the outer one of which has a convex shape. Available in several diameters, common sizes with a plate diameter of 12.5 and 16 cm.

Anemostat AN125 supply and exhaust “ERA” made of white plastic

The AVP line is an exhaust type of anemostat. You can purchase the device in one of three sizes: with a diameter of 10, 12.5 or 16 cm.

Group anemostats

SystemAir offers anemostats made of metal and plastic. They can be either supply/exhaust type or combined.

Supply air anemostats made of plastic are represented by the BALANCE-S line. It includes three models of devices with a diameter of 10, 12.5 and 16 cm.

BALANCE-E is a line of exhaust plastic anemostats. The size range is the same as that of the supply line, except for the presence of a large device with a diameter of 20 cm.

Air supply air vent "SystemAir"

Metal air supply anemostats are one of the most popular in the SystemAir product range. The size range of devices includes small models with a diameter of 8 cm, as well as non-standard devices for a ventilation hole of 15 cm. The design also differs from other brands. BOR anemostats resemble a convex rectangular grille. And ELEGANT offers devices in an unusual black color.

Metal hoods are made in a classic design and are available in six size ranges. They are suitable for large diameter ventilation openings.

Combined anemostats are available in four models: OVE, OVR, OVX and VTK. The OVX model is made in the form of a narrow rectangle. VTK is a self-regulating anemostat with a more complex design than other models.

Anemostats are an excellent alternative to diffusers and grilles on ventilation openings. It becomes possible to adjust the air flow, which will make the air in the room more comfortable.

Popular makes and models

In general, there is no need to worry about the quality of devices on the modern market. Most of the presented anemostats are made of ordinary plastic, and the design itself has no weak points, except that in the case of sliding slats it is worth choosing a more expensive device.

Most specialists choose devices from leading brands such as Era or Vents. The range of brands has all the common types and forms of devices.

DIY diffuser installation

To avoid any problems during the installation of equipment, you need to prepare the hole for installation in advance. The opening must match the size and shape of the fixture.

The components for mounting the diffuser are always supplied with special fixing latches. With their help, the unit can be installed both in a flexible air duct and in a rigid duct.

Installation Features:

Installing a diffuser in a hard channel

- Before purchasing an air diffuser, you need to accurately measure the size and shape of the hole for the device. The unit must be selected in strict accordance with these parameters.

- Installation of the device consists of smoothly moving the device into a pre-prepared hole until a characteristic sound appears - a click. Installation of the device must be done carefully to avoid damage to the housing (if pressed hard, the housing may burst).

- Then you need to carefully inspect the surface and make sure that there are no irregularities or protrusions between the opening and the unit.

- If installation defects are found, you need to check all the latches and make sure that they work. Otherwise, you need to press on the required part of the device until it locks.

Installing a diffuser in a soft channel

- First you need to remove the sleeve from the hole in the wall and attach a device to it for dispersing air flow.

- Then, the sleeve is placed in the channel, followed by the unit.

- When the system begins to come into contact with the wall surface, you need to fix the device. To do this, you will need to slowly, without making much effort, press on the diffuser until the fastening mechanisms work.

- Make sure there are no installation defects (protrusions, irregularities above the wall surface).

Installing a diffuser in ductless exhaust ventilation (hole in the wall)

- Initially, you need to prepare a hole in which the unit will be installed to dissipate air flows. For these purposes, it is recommended to use a pipe whose parameters will correspond to the size of the diffuser.

- The opening in the wall itself can be made from a pipe. To do this, you need to measure the length of the hole from the outer wall to the inner one, then adjust the pipe to these dimensions.

- Insert the fitted pipe into the hole and install the device into it according to the principle described above.

- The pipe can be secured to the hole using mounting foam.

If the diffuser components do not include latches for fastening, they can be replaced with glue, anchors, sealant or self-tapping screws.

Tips for arranging natural ventilation

Each room in country buildings or a country house has features that must be taken into account when installing ventilation devices.

In the bathroom

For a toilet and bathroom in a country building, it is necessary to provide the possibility of micro-ventilation through windows or doors.

In the bath

When installing ventilation in the bathhouse, it is necessary to place a supply duct at the location where the stove is installed. Street air penetrates from below, gradually displacing warm air to the ceiling, heating itself. The exhaust valve in the steam room is installed under the ceiling.

I open the valves when necessary to quickly dry the steam room or washing room.

In the boiler room

If a country house is heated with gas, it must have a separate room for placing equipment. A gas boiler is an object of increased danger, therefore the requirements for boiler hood equipment are quite serious.

The boiler room ventilation is mounted separately and does not cut into the common exhaust pipe; most often, an external pipe is used to get rid of smoke and gas.

Supply units are used to deliver outside air to boiler rooms. The weak point of the natural supply and exhaust system in boiler rooms is its dependence on wind power. In calm, windless weather, it is impossible to provide good traction.

Rotating ventilation ducts reduces efficiency by 10%.

In living rooms

To ensure effective air circulation between individual rooms in the house, it is necessary to install small holes or gaps between the door leaf and the floor at the bottom of the door leaves.

In the kitchen

When installing an exhaust ventilation grille above the stove, you need to place this device at a distance of 2 meters from the floor. This position of the hood allows you to effectively remove excess heat, soot and odors, preventing them from spreading throughout the room.