After installing the door, the overall appearance is a sad sight. Numerous cracks, chips and protruding wires cannot be hidden in the wall. Defects can be eliminated only with the help of strips that will close the gap between the frame and the wall. Choosing door frames is quite simple thanks to the large assortment on sale.

But in order to choose the best option, you need to know what shape and material of the door frame is suitable in a particular case. Such a small element as door frames will give the structure a complete look, and the door itself will be attractive and expressive.

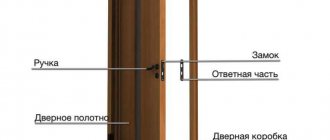

What are cash cards on the door

Platbands for interior doors are a system of strips of different sizes. They come in a variety of styles and designs.

Can be supplied complete with door leaf and frame. Then the same materials are used, and all elements are designed in the same style.

If you wish, you can talk about an individual cash out option. If you want to decorate the entrance group in an original way, order elements with a unique design. Some craftsmen make such door designs themselves.

Necessary equipment for installation

Good fastening of platbands is impossible with insufficient preparation. The technician must have all the required equipment on hand before installation:

- miter saw, hacksaw for cutting metal;

- for measuring panels - a tape measure, for drawing a simple pencil or chalk, a plumb line, a square are required for planning;

- a miter box is the best thing you can use to cut out a beautiful corner. Used for even cutting of the workpiece at an angle of 45 degrees;

- a level for installation on the wall, a hammer, if attached to nails, for tapping on the structure and identifying empty spaces.

Why do we need platbands?

They perform two functions – technological and design. Cashing doors is necessary to create an aesthetic and solid appearance. At the same time, the role of the platband is reduced to

- Masking defects and gaps between the frame and the wall, small wall defects at the joints.

- Reduced air flow, reduced drafts.

- Increasing the thermal insulation of living spaces.

- Improved sound insulation between different rooms.

Cashing is used to decorate doors; it is also suitable for various structural and architectural elements: arches, bay windows and portals.

Design differences

The installed platbands are strips that are attached to the edges of the opening. However, the design of the products is different:

- A simple casing is an overhead strip that is attached mechanically or with glue directly to the wall or door frame.

- The telescopic casing in cross-section represents the letter “G”. The tenon on the element fits into a groove in the box, providing a secure but movable attachment. The plank can be inserted all the way or pulled out to set the same level with the wall without the use of extensions.

- The hollow element is used for hidden laying of wires and network cables. Power cables cannot be laid in such casing.

Many people try to frame doorways themselves, because there are many video tutorials on installation on the Internet. To do this, you have to purchase tools that may no longer be needed. And the lack of experience and the peculiarities of the premises lead to the fact that a lot of time has to be spent on installation.

In the Vivaldi company you can purchase doors, slopes and order installation. Using professional tools, master installers perform the work quickly, without unnecessary debris and with high quality.

Size standards

Installation of platbands on interior doors is carried out within certain standards. They are related to the overall dimensions of the opening and door leaf.

Since they are often supplied with a box, the dimensions correspond to the entire set. However, if necessary, the size can be adjusted if the door needs to be adjusted to the existing opening.

The door leaf is made in heights ranging from 190 to 235 cm with a width of about 80 cm. The width and cashing for standard doors varies from 6 to 10 cm. You can choose based on preferences and ease of installation in the room. The most common width sizes are 6.4 cm or 7 cm. The usual thickness is 1.2 cm, but it can be increased.

The profiled strip can be flat, semicircular, with rounded corners, or figured. Therefore, cashing differs in terms of thickness. It also depends on the material used in the work.

Sawing and measuring platbands

How can you install the casing yourself? Naturally, the simplest option will be to choose a door in which the platbands will already be included as a component element, however, it will be much more profitable to independently purchase individual parts. The complexity of this method lies only in the correct selection of colors. But the manufacturing process itself is not at all complicated and anyone can cope with this work, the main thing is to find the necessary materials and have a great desire and interest in the upcoming work.

All we need for this are wooden planks. In specialized construction stores you can easily find wood with shapes and cutters that has already been pre-processed.

If you prefer to do all the work related to cuttings yourself, then you will need to achieve a very even and smooth surface. After the first treatment, the platbands must be cleaned of dust and other contaminants, and then, using the required color, the platbands must be coated with stain or paint.

When using trim pieces, this step will be very important. All measuring work for straight platbands should be done as follows: first we measure the height of the side parts, then the top, edges that need to be articulated with the outer lines. Everything goes according to the exact measurements.

In such models, where it is necessary to make cuts at a certain angle, the top is measured. All boundaries are marked from the inside. From this point a cut of forty-five degrees is made in the direction of increasing value. The same manipulation is carried out with the side parts; the elements should also converge when cut, forming a portal.

It is quite difficult to cut out the platband efficiently and evenly, so you need to resort to the help of special sawing equipment. We put the casing in the miter box. The dimensions of the connector are forty-five degrees, we install a hacksaw. Thus, each element can be easily filed.

So, how many platbands will be required for the door? To frame one portal you need three parts: the top and two sides. Sometimes, when designing an interior in antique styles or using Japanese design, a capital is additionally installed.

When sawing the platband, you need to take into account some indicators: this is the slope and the side of its direction. All these conditions must be taken into account in order to articulate all the details of the future design.

Types of platbands

The types of cash for an interior door differ according to several criteria. These include shape, material, internal structure, design features of fastening.

According to the internal structure, cash for doors can be monolithic or penetrated with a cable channel. It plays an important functional role: it allows you to lay various types of wires in it according to the principle of hidden wiring. These include fiber optic cables, telephone or electrical cables.

It is important! According to the methods of attaching platbands to interior doors, there are:

Overlay platbands. Another name is slopes. Fastening methods: using hardware - nails and screws. Secured with glue or sealant.

Telescopic. They are a special design

Telescopic

This type of platband involves fastening on the basis of a groove that runs in the door frame. It includes the edge of the plank, bent in the shape of the letter G, forming a tight and durable joint of the tenon-groove type.

The broadest classification of door cashing is based on the type of material used in the work. The range of materials represented by the building materials industry is very large: wood, various types of plastic, metal, ceramics and others. Each of them has its own specifics and set of capabilities in terms of simplicity and ease of installation, texture, color and design possibilities.

Wooden

The most traditional material for door casing is wood of various species, varieties and varieties. Panels are produced from solid wood and from spliced sections. Tree species: coniferous and deciduous. They can be coated with varnishes, paints, and transparent mastics that preserve the natural cut pattern.

The planks are produced in various sizes: from 4 to 14 cm, the surface has various types of processing. It can be smooth or textured. For lovers of complex design, door trims can have complex appliqué or applied wood carvings; patterns can also be burned out. Such options are made in folk style.

MDF

Planks made of wood fiber material containing finely dispersed fractions. Hence the abbreviated name - MDF. Externally they resemble a wooden surface. They are durable and environmentally safe. Well processed. The cash on the door is covered with a protective film, which allows it to resist moisture.

There are options for planks that are veneered with natural wood, this gives them a natural look.

Plastic

Polymer materials used for cashing are practical and convenient. They are lightweight and easy to maintain. They are little affected by sunlight and moisture. Convenient to assemble and install. The question of how to attach platbands to interior doors is easily resolved: with an adhesive base. They can have different colors and different surface characteristics: matte or glossy, various textures are possible.

It is easy to make technological grooves in them for cable channels for laying electrical wiring, telephone networks, and fiber optic cables.

Metal

Metal cash structures are highly durable. Therefore, their purpose is the outer part of the entrance doors; however, a high-tech or steampunk room in style also corresponds to this type of design.

Distinctive features, in addition to strength, are the absence of deformation, insensitivity to moisture, and lack of tendency to corrosion. The latter quality is due to the fact that metal structures are made from anti-corrosion materials. This also results in high fire resistance. They are coated with powder coating or nitro-enamel, specialized dyes. Modern technologies make it possible to produce coloring components of different colors, a smooth glossy surface, and powder coating creates a different cashing texture.

Plaster

Door trims for interior doors made of plaster belong to the category of design elements. Plastic material allows you to form any shapes and decorative patterns. This design is typical not only for doorways, but also for architectural options that use arched structures, niches, portals, and bay windows.

In most cases, plaster cash is adjacent to the same design of the room as a whole. This style contains complex sculptural forms, various stucco patterns, and bas-reliefs. This is often accompanied by ceiling moldings. As for the material, it is environmentally friendly, but not very durable. It is susceptible to moisture and mechanical stress, and therefore requires caution in operation. However, modern technologies make it possible to add additives that strengthen the original material and make it quite durable. The question of how to attach the platbands is solved using a fixing mixture.

Ceramic

Ceramic types of tiles mean various types of tiles made of clay and artificial stone. They are applicable where there is a humid atmosphere - in baths, saunas, bathrooms, and other similar ones.

Polyurethane

Polymer materials have found their application in this type of work, such as installing trim on doors. Among them, the most applicable are polyurethane and duropolymer. They resist moisture penetration well and can withstand different temperatures. Can be painted with dyes in different shades.

The plasticity of the material allows you to create compositions and linings of different configurations not only for the doorway, but also for arches and niches.

Material of manufacture

The material from which door frames are made is directly related to the quality of the products. Therefore, when choosing products, it is necessary to pay special attention to this issue.

The classification of platbands according to the type of materials from which they are made is as follows:

- from MDF;

- metal;

- wooden;

- ceramic;

- telescopic models;

- made of plastic.

Ceramic designs are a stylish door design, used when the walls of the room are also tiled with the same tiles. This option is less practical, reliable and durable than the others.

MDF door trim is a profitable and practical option. The cost of the product is low, and the quality is not inferior to wooden ones. The only negative is the high ability of this material to absorb moisture, so it is not recommended to install them in the bathroom, as this can lead to deformation of the structure.

Wooden

Wooden door frames are characterized by high quality and aesthetically attractive appearance. The material used is pine, an environmentally friendly raw material. To maintain a long service life, the structure is varnished.

Plastic

Modern materials such as plastic are the most practical option for designing plastic doors, since the material does not rot, does not absorb moisture, and is easy to care for.

It has less aesthetic qualities than other door design methods. Suitable for technical rooms, balconies, loggias. It copes well with the function of preserving heat in a room, which allows this design to be used as an external design for door or window openings.

Metal

This type of product is most often used as trim for metal doors. Iron products are made from steel or aluminum. Due to this, the structure is strong, durable and fire-resistant.

This type has a laconic, even shape. To install such a structure, in addition to the standard set of tools, you will also need a grinder.

What to look for when choosing

When selecting a door frame, emphasis is placed on the following factors:

- Plank sizes. Its compatibility with the character of the door is important. A thin, narrow door cash will go well with a light canvas. The massive option is successfully combined with wide thick planks.

- Material. The requirement for it is a harmonious combination with the rest of the additional elements and the style of the door leaf.

- Features of cashing installation. Some installation options are accessible even to a novice specialist; in other cases, you have to resort to the work of an experienced craftsman.

- Design characteristics. They are associated with the surface treatment of the planks. It can be smooth or covered with patterns and various shapes.

Design

It’s good when the interior design matches the design of the doors and a similar texture is used in the implementation of the project. The door leaf continues the style of the room, its walls, ceiling, floor. Finishing with platbands will complete the composition of the room, making it decorated and functional.

Beautiful door frames help visually dilute the room, make it brighter and more interesting. It is necessary that the color of the structural elements goes well with the door, wallpaper, and floor covering. The materials of the products should harmoniously complement each other.

Installation of platbands on interior doors

Regardless of whether the work of a master is used, or the installation of cash on the door is carried out by the owner himself, it is worth monitoring compliance with technological requirements.

Rules for installing platbands

Attention! The width of the slats should correspond to the overall dimensions of the door leaf.

Installation of platbands completes the repair and finishing work. Only installation of the baseboard follows.

Telescopic types of platbands on interior doors are not necessarily fixed to the frame. They can be fixed on the additional strip.

Preparatory work

The installation of platbands on interior doors begins when finishing work has been carried out on the walls and flooring, and the door frame has been inserted into the opening. Only the baseboard will be installed after this as it is not a support for the cashing. The latter will rest on the floor.

The wall next to the opening should be carefully leveled so that there are no gaps after installation.

Measurements and cutting

The installation of platbands on interior doors is carried out after measurements, which are determined by the joining options: the planks can be joined at different angles. For any option, first calculate the height of the side posts. And from it the length of the transverse element is already determined.

Installation with corners cut at 45°

The main trick to how to install platbands on interior doors at an angle of 45° comes down to clearly sawing off the strip at this angle. This applies to both the vertical and transverse parts of the casing.

This goal is achieved using tools:

- A miter box, a hand cutter, which is a kind of template.

- A rotating hand saw, it allows you to rotate the cutting part at the required angle.

Installation with 90° corners

It would seem a simple way to install platbands on interior doors at right angles: place two vertical and transverse strips at 90°. However, it requires measurements and careful cuts. This option is available for planks without complex curves. Sometimes adjustments to exact dimensions will be necessary.

Product Features

The interior door is located in the opening, which is recommended to be beautifully decorated. Platbands are attached on both sides around the perimeter. Under them there are screws and other fasteners, as well as wires and foam. The main function of cashing for interior doors is decorative. Installation on entrance openings is carried out in order to protect the home from drafts and prevent heat loss.

The classification of products divides them by shape, materials, type of fastening and size. Each variety is presented in a rich assortment. Home owners can choose both cheap and expensive products made of plastic, wood or metal.

Simple and figured platbands

Since doorways are usually rectangular, the platbands are produced in the same shape, but they differ on the front side. On this basis they are divided into 3 types:

- semicircular;

- curly;

- flat.

A product with a smooth (flat) front surface in cross section is a rectangle. Semicircular strips can be symmetrical or teardrop-shaped. The first option is convenient because it is easier to fit into the interior. A semicircular casing, in which the convexity is shifted to one side, looks very interesting, but it requires an appropriate environment.

Curly platbands are exclusive products. Their difference is a protruding pattern on the front side. An example of design is grooves alternating with bulges. The relief can form stripes, geometric shapes or complex patterns. Such beautiful platbands on the door make it a central part of the interior composition.

Overhead and telescopic products

When choosing platbands, it is necessary to consider how they will be attached. Overlay strips are easy to install, and this is their main advantage. The following materials can be used for installation:

- sealant;

- PVA glue;

- self-tapping screw;

- regular or liquid nails.

Fixation of telescopic platbands is carried out due to the shape. This solution looks simple, but installation may be difficult if the edge of the plank does not fit snugly into the recess of the box. The advantage of such fastening is that there is no need to use additional materials and fasteners. If the difference between the wall and the frame differs by 10-15 mm, the telescopic platband is pulled out slightly to hide the gap.

When the difference in thickness exceeds 2 cm, interior doors are installed using extensions. They allow you to equalize the thickness of the box and the opening. In this case, telescopic strips are attached to the extensions.

Docking options

The classification according to the type of joining is due to the fact that the planks can touch each other at an angle of 90 or 45 degrees. In the upper part of the opening, the ends of the planks are connected to each other and a corner is formed in this place. If it is straight, you can do without trimming, then the joining will be vertical or horizontal. The method is suitable for mounting rectangular (flat) products.

When it is necessary to connect the ends at an angle of 45 degrees, it is necessary to trim each plank. The connection turns out beautiful, but it is important to be careful so that the cut points are perfectly even. Semicircular and figured platbands are joined only in this way, because when connected at a right angle, one plank will rise above the surface of the other.

How to attach platbands to interior doors

An important question is how to attach platbands to interior doors. Fasteners in the form of nails, screws and adhesives such as fixing mixtures will be useful.

Using finishing nails

In many cases it is convenient to use finishing nails. They have flat heads, convenient for working with wood and MDF. Hardware approximately 4 cm long is selected.

How to nail trims to interior doors: First, markings are made and holes are drilled according to the diameter of the nail. After driving into the hole, the cap can be removed or masked, for example, with wax or mastic.

Liquid nails

Installation of platbands on interior doors based on a fastening mixture of liquid nails is successful in the case of light planks: plastic, polyurethane. Wooden products may not last long with the help of an adhesive composition. In addition, the composition is subject to temperature changes; as it dries, it gradually loses its binding properties.

Fastening with self-tapping screws

Installing platbands on interior doors using self-tapping screws works best if the casing is made of wood. Hardware is selected with a length of about 2.5 cm with a D of 0.6 cm.

Markings are made in 5 cm increments, then holes are drilled, although self-tapping screws can be driven in without drilling. Hats are masked with wax or mastic.

Attachment by beaks

The L-shaped telescopic casing has a beak-type lock. It is inserted into a groove located in the box or additional element and snapped into place. This creates a strong and tight connection between the parts.

Preparing for work and a little theory

Before preparing the tool and buying components, let's figure out what kind of door frames exist.

Common materials

Wooden door trim is a classic finishing option; there are both budget models made of pine or linden, as well as elite species such as oak, beech or overseas wenge wood.

Working with wood is more difficult, since the material is living, and therefore subject to temperature and humidity deformations. If you decide to give preference to this option, then keep in mind: the wood must be dry and preferably impregnated with an antiseptic.

No matter how beautiful the platband from freshly sawn wood may look, after just six months it may begin to deteriorate or unpleasant cracks will appear.

Natural wood is deservedly considered a classic.

The second and currently most popular contender in our rating is MDF. Almost 70% of consumers choose MDF door frames The material is completely environmentally friendly, because the wood is glued together not due to synthetic additives, but due to the high content of natural glue lignin in wood.

The weak point of MDF is considered to be swelling in conditions of high humidity, but for the planks to deteriorate, the humidity must be really high, so the cladding cannot be installed in a steam room or on entrance doors from the street. The kitchen and even the bathroom in a city apartment are quite suitable for installing MDF.

The line of MDF planks includes trim covered with veneer (a thin cut of natural wood); this cladding is absolutely no different from high-quality wooden products.

MDF cladding is a successful combination of optimal price and high quality.

Now gone are the days when plastic products could be identified at first glance. Good plastic trim from the same MDF can only be distinguished by a specialist, and most importantly, the price for this product is quite affordable, plus it is much easier to install plastic with your own hands.

In addition, plastic is indifferent to any humidity; high-quality models tolerate temperature changes and direct sunlight. Perhaps the only place where it is not recommended to place plastic is a steam room, this ban is explained by the fact that many synthetic compounds begin to break down at temperatures above 70ºC.

Plastic platbands have a beautiful appearance and high performance characteristics.

There is still metal cladding on the market. As a rule, metal is used only for installation on the street, but this is a very narrow niche, because a trim on the front door is often not required, since its “duties” are performed by the load-bearing outer frame of the metal door, and wood is now practically not installed at the entrance.

A few words about the instrument

In order to install any door frames efficiently, they need to be cut accurately, evenly and without chipping, and for this it is advisable to have a miter saw on the frame, and the frame must be rotated and fixed at a certain angle.

Miter saw on the bed.

If your plans do not include buying a cross-cutting tool, then you can get by with a hacksaw, but this requires some skill, since without experience it is very easy to chip along the edge.

From the auxiliary tool you need:

- Hammer;

- Plumb;

- Level;

- Roulette;

- Knife;

- Pliers;

- Pencil.

Many resources also recommend buying a miter box for cutting planks at an angle of 45º, so, it’s not worth spending money on a Chinese “disposable” miter box, the quality is low and there is not much use from it. In addition, there is a universal method of pruning without a miter box, and this method is much more effective, but more on that later.

Method of pruning using a miter box.

Materials you will need:

Finishing nails.

- Special finishing nails with a small head;

- Liquid nails glue or polyurethane foam, plus a gun for the tube;

- Masking tape.

It is more convenient to apply polyurethane foam using a gun.