Due to its many advantages, tiles made of gypsum (alabaster, selenite) are a common decorative finishing material.

Using a special coating for tiles, you can create an individual design

Here is an incomplete series of positive properties of alabaster and products made from it:

- relatively small specific gravity;

- the ability to manufacture products of any configuration by hand casting;

- ease of processing and adjustment of alabaster tiles and stucco;

- fire resistance;

- environmental friendliness;

- dielectric properties;

- resistance to chemicals;

- ease of restoration work;

- possibility of artistic design of products.

However, gypsum also has serious disadvantages that impose restrictions on the use of selenite tiles:

- hygroscopicity (the ability to accumulate moisture from the environment);

- low moisture resistance (destructs with prolonged direct contact with water);

- low resistance to impact (even a light impact will leave a chip or shell on the surface).

If you initially planned to have a light coating, you need to take into account that the varnish gives some darkening

These disadvantages make selenite tiles unsuitable for exterior finishing work and cladding of rooms with high humidity and, especially, open contact with water.

By using modern technologies for additional processing of gypsum tiles, it is possible to minimize these disadvantages and successfully use gypsum finishing not only in dry rooms, but also in rooms with seasonal humidity fluctuations.

Improving the performance of gypsum finishes

Manufacturers of alabaster cladding most often offer consumers products that have already undergone a process of improving characteristics and are varnished. The price of such material is higher due to the cost of additional processing. Knowing the optimization technology, you can purchase gypsum cladding without protective treatment, for example, the popular hand-made Monte Alba decorative tiles, and independently improve the properties of the material, and then varnish it. Let's consider what the pre-treatment of gypsum products is before applying varnish, types of varnish compositions and methods of their use.

Impregnation of gypsum tiles with hydrophobic agents

To neutralize the hygroscopicity of gypsum products, they are hydrophobized, which consists of impregnation with water-repellent compounds (hydrophobizers) based on organosilicon polymers. Due to the deep (up to 20 mm) penetration of water repellents into gypsum without the formation of a film, porosity is reduced, but the vapor permeability of the products is maintained, the degree of hygroscopicity and the susceptibility of tiles to mold are reduced.

Water repellents are offered by manufacturers in the form of ready-to-use solutions, as well as concentrated formulations that require dilution. The method of use is indicated on the packaging of the mixture.

The general requirement for the use of hydrophobic compounds is that they be applied to completely dry gypsum tiles that are free of dust. Gypsum products are processed on all sides in two layers until saturated, without waiting for drying. This processing method reliably isolates the cladding not only from the humidity of the outside air, but also from the moisture of the base material. For application, depending on the area of the surface to be treated, a brush or roller is used.

Water repellent Tiprom

The treatment should be carried out wearing protective glasses and gloves, avoiding contact of the composition with exposed skin. Contamination of adjacent glass and metal parts with a water-repellent agent must be promptly eliminated, as the composition hardens quickly.

- water-repellent silicone composition White Hill;

- silicone impregnation “Optimist C405 – Natural stone”;

- a range of Tiprom water repellents.

Silicone waterproofing impregnation – Natural Stone

Varnishing the plaster finish

After hydrophobization of the alabaster tiles, the base is faced by laying gypsum products on an adhesive mixture selected in accordance with the type of wall surface. A day after installation is completed, they begin to decorate the finish with paints.

To protect the artistic layer of the cladding, it is necessary to cover the tiles with a protective varnish layer. This operation begins after finishing the decoration, but not earlier than 5-10 days after finishing laying the tiles, so that the tile adhesive under the finishing not only hardens, but also dries.

To apply a protective coating to gypsum tiles, acrylic or oil varnish is used. These materials differ in properties, so we will consider each separately.

Protecting alabaster tiles with acrylic varnish

Acrylic varnish is a ready-to-use aqueous dispersion of resins, a milky liquid, the application of which to interior and exterior decoration is used for protective and decorative purposes. This solution is resistant to cracking and forms a durable, transparent film on the surface, which after drying can be removed using a special solvent.

The acrylic-based coating is resistant to detergents, moisture and ultraviolet radiation, and temperature fluctuations. The composition is odorless, harmless to humans and the environment, dries quickly and becomes transparent. Acrylic varnish is diluted with water to the desired consistency and applied to the surface with a brush, roller or spray.

Varnish for natural and piece mineral surfaces

Acrylic varnish is available in three types: glossy, matte or semi-matte.

When applying a glossy solution to gypsum tiles, it should be taken into account that the cladding will receive shine and glare from the lighting, which will distort the colors of the tile decoration.

Matte acrylic varnish will preserve the velvet surface of the tile, imitating rough-cut natural stone, without changes. This composition is an ideal protective coating for Monte Alba tiles.

The semi-matte type of varnish occupies an intermediate position between the two described types in terms of its effect on the cladding.

When dry, a thin film is formed that prevents moisture from being absorbed into the plaster.

When decorating gypsum cladding, which was painted with water-based paints, 10% acrylic varnish can be added to the emulsion to enhance adhesion to the gypsum. After covering with two layers of such paint, only one layer of varnish can be applied to the alabaster tile.

Important! If you do the opposite, add paint to the acrylic solution, the coating will end up with paint-colored stripes, which is not always desirable.

An example of a successful choice of protective and decorative coating for gypsum finishing is Finnish paint and varnish products.

Coating gypsum tiles with oil varnish

Oil varnish is a solution of natural or artificial resins in oils of plant origin. After application to the base, such varnish first forms a film on the surface of the layer, and then dries throughout its entire thickness and serves as a strong protection for the surface from mechanical and physical damage.

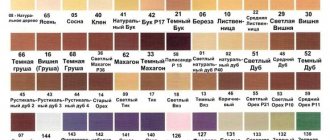

Oil varnishes, like acrylic varnishes, are available in glossy and matte finishes. To bring the solution to the desired consistency, special thinners are used that do not change the characteristics of the varnish. Oil-based varnishes are available colorless or transparent, but have some tint, so when choosing a material for coating gypsum tiles, you need to take into account the compatibility of the varnish shade with the color of the alabaster finish. All oil solutions, including colorless ones, darken a little after drying, which also needs to be taken into account when decorating gypsum tiles.

The most durable coating is provided by yacht oil varnish, so its use to protect plaster cladding is most advisable. After thoroughly mixing with the thinner, the varnish is applied to the finish in a thin layer with a brush or roller. The solution should be well distributed over the surface, avoiding the formation of drips. Yacht varnish dries, depending on the room temperature, in about a day.

Varnish for gypsum tiles is an indispensable thing for giving the surface the desired shade or glossy shine.

After the first layer has dried, the cladding is inspected for the presence of drips, which must be carefully sanded with fine sandpaper before applying the second layer. The second layer of varnish also dries for about a day, after which the varnished finish is wiped with a clean, damp, soft rag to eliminate any residual adhesion.

Decorative tiles "Monte Alba", covered with a protective layer of yacht varnish, despite the corrugated surface, are easier to keep clean and last longer.

Shellac varnish

This type is usually used when performing decoupage and finishing work. This varnish is made on an alcohol base and is considered an excellent option for coating a gypsum base. Shellac can be applied over any type of modern paint and looks very good over metallics. This solution creates a thin layer of polish that looks very beautiful. It is used not only for plaster, but even for processing wooden furniture.

Shellac is made both transparent and colored, so it can be applied without first using paint. Some types of tint varnishes treat the stone, giving it the effect of artificial aging. Many experts mix shellac with rosin in a one to one ratio. This impregnation for plaster creates a beautiful protective layer on the surface, which completely eliminates the occurrence of stains. Using this plaster varnish, ordinary stone takes on the appearance of marble.

Before painting sand-lime brick

To paint a brick wall, you can use both a roller and a brush.

- Think about the advisability of painting, because painting the brick should be repeated periodically after about 5 years.

- Be aware that it will be very difficult to remove paint from a brick wall in the future.

- Painting new brick walls is possible only a year after their construction, so that their drying, leaching and weathering are completed, otherwise you may get many defects in the painted layer.

- A carefully prepared surface for painting will make your work much easier.

For this:

- remove old peeling paint, otherwise it will mix with fresh paint and the painting will not be even;

- fill all cracks and chips and sand them after the putty has dried. If necessary, renew masonry joints;

- clean the wall, thoroughly removing all traces of mold and dust. Thoroughly rinse the brick wall with ordinary water supplied under low pressure. If the pressure is too strong, the cement may be damaged. Grease stains, mold and paint residues are washed off with soapy water. To wash dirty walls, you can use sodium orthophosphate; it is sold in powder form. The powder is mixed with water according to the instructions. Detergents containing sodium orthophosphate are also suitable.

- If the old paint has not come off, use a scraper rather than a wire brush, as the brush may leave scratches on the brick. After removing the paint, sand the brick with regular fine-grit sandpaper. Then the wall must dry completely, otherwise, due to moisture in the porous bricks, cracks, chips and blisters will appear in the paint layer. It is better to paint bricks in the summer, when the moisture from the bricks evaporates in dry, hot weather.

- There are sometimes white stains on brick buildings. These are efflorescences, salt formations formed when salts reach the surface of the brickwork. All efflorescence should be removed with water and a stiff brush; after the wall has dried, re-treatment may be required.

- Be sure to apply a primer varnish (filler, sealant) on the dry wall with the indication “for brickwork.” It is applied to the wall with a roller or brush. If you want to leave the natural color of the brick, use special sealants to care for the brick. Next, the surface should dry completely. There is no need to apply varnish to painted walls.

- Apply primer to the wall. It can be oil or latex based. It is better to use a special primer with improved water resistance for brick. The quality of painting depends on whether you primed the surface well. First prime the areas where there were grease stains or mold, then you can apply several layers on top of these. The primer must dry completely. The top layer will be dry in about 1-2 hours. After the primer has completely dried, you can begin painting. To improve adhesion to paint, you should treat the wall with a sander using medium-hard sandpaper;

- The wall can be painted with oil, latex or special paint for bricks that repels moisture well. It is better if the primer and paint are made on the same basis. Oil paints create the most beautiful surface on brick walls. For durability it should be painted at least twice. Painting is carried out with a brush or roller, the roller is taken thicker so that every particle of the facing brick is painted over.

For walls in the interior

The walls do not need paint to be vapor permeable, and they can be painted with paints of different compositions. The walls in the interior should be painted with paint that is resistant to alkaline environments, and the walls of the bathroom and kitchen should be resistant to water. To paint a brick fireplace portal or brick stove, you should choose heat-resistant paints.

To create original wall decor, different paints are used. In addition to paints that form a film on the surface, there are compounds that penetrate into the bricks. Although they are expensive, they are much more durable. The texture of the paints can be matte or glossy to varying degrees, and you can choose the one most suitable for your interior.

If you are not afraid of difficulties, want to update your brick house and already know how to paint a brick, then rest assured that painting bricks is very effective and will give the facade or interior a very updated and extraordinary style. And once the brick walls are painted, there are many options for further finishing of your home.

Gypsum, as a material, has a fairly wide range of colors, from completely white to soft pink shades. But don't limit yourself - plaster paint can transform the material into bronze or ivory, so why not do it!

You only need a couple of tablespoons per average batch for the finished structure to gain greater strength - the glue binds individual particles of gypsum. A mixture of gypsum and slaked lime demonstrates an amazing effect, but all that is needed is to add one part of calcium hydroxide to the standard ratio. Of course, the product or surface will not become invulnerable, but it can survive a fall to the floor from a table or a blow from a blunt object. If you have a finished product on your hands, you can soak it in a concentrated solution of zinc sulfate or iron sulfate. Zinc salt will not change the color of the product, but vitriol will turn it yellow-brown.

Varnishing rules

Thanks to varnishing, the performance characteristics and attractiveness of gypsum can be significantly improved. Everyone decides for themselves what varnish to coat a decorative gypsum stone with, because each product has its own shine, color, shade, and other characteristics. Here is a list of basic rules and recommendations that must be followed during varnishing to obtain the best result:

The use of shiny varnish reduces the effect of naturalness, but makes the products more festive. If the room is decorated in natural, earthy colors and styles, then it is advisable to purchase a matte varnish solution.

Gypsum in construction and repair

Construction gypsum is obtained from gypsum stone, previously burned and ground into powder. Next, it is kneaded until a paste-like mass is obtained, better known as alabaster. It is widely used for construction and repair work, the manufacture of various decorative products, and also as binding materials at intermediate stages of construction and repair work.

It is gypsum mortar that is most often used for modeling and stucco molding, the production of small architectural forms, pouring decorative tiles or artificial decorative stone (brick).

The mixture sets and hardens quite quickly. Therefore, you need to be able to work with him in order to achieve your plans. The working substance has a white tint.

The material is quite easy to prepare and use, affordable and has a wide range of applications. Another advantage is environmental safety (as it is made from natural raw materials). It is able to “breathe” by maintaining a certain level of humidity.

The use of gypsum materials in interior decoration is very, very popular. With its help you can create real interior masterpieces.

The use of decorative gypsum bricks for interior cladding

It is worth mentioning the following properties of the material:

- ease of installation and processing;

- ease;

- non-flammability.

However, in operation the gypsum base shows itself differently. Alabaster, unfortunately, is afraid of water (since gypsum powder is dissolved by water), and is subject to abrasion and mechanical stress.

To increase the strength of gypsum materials, manufacturers use various reinforcing additives (plasticizers, acrylic, polyvinyl acetate glue).

So today there are several brands of building gypsum on sale, differing in the degree of compression resistance. The highest grades are used in the production of decorative elements, even for facade (exterior) decoration of buildings.

Application:

- plastering walls and ceilings in rooms of varying functionality, where humidity does not exceed 60%;

- arrangement of all kinds of partitions;

- production of stucco interior decor;

- production of dry sheet gypsum, plasterboard and other gypsum-based building materials and solutions;

- production of all kinds of architectural and facing products (including bricks);

- souvenirs and interior items (figurines, flower pots, columns, stands, etc.).

Acrylic varnishes

This type has an acrylic base, with the addition of modifiers, water and special resins. The acrylic composition is not very thick, its consistency is similar to cream, and is used for indoor and outdoor work. Acrylic-based plaster varnish is used as a topcoat because it creates a highly durable layer that is water-repellent. Special additives in this varnish protect stone and tiles from fading and the negative effects of ultraviolet rays.

In stores you can buy glossy, matte and semi-matte acrylic varnish for coating plaster. The glossy look gives an attractive shine, but it strongly reflects light rays, this nuance must be taken into account during painting. Matte acrylic varnish makes the product solid, it looks very impressive and expensive. After drying, the acrylic varnish becomes transparent and keeps the stone attractive and protected for a long time. You can use acrylic varnish for plaster stones indoors, because acrylic compounds are safe for humans, apply very easily and simply, and dry quickly enough.

Plaster painting

If desired, gypsum materials can be given a completely unimaginable look, including imitating naturalness (for example, wood). Various technologies of toning, coloring, and “aging” are used here.

Marble tinting. A well-dried gypsum product is impregnated with heated drying oil or shellac-rosin alcohol solution. The impregnation adheres well, without streaks, creating protection against moisture. Gradually the dried primed surface becomes similar to aged marble.

Thanks to tinting, gypsum decor easily imitates marble

Wax tinting. An impregnation is used, consisting of wax dissolved in turpentine (gasoline) with a slight addition of yellow oil paint. After the impregnation dries, the surface is rubbed until glossy.

Ivory-like tinting. A soap maker, nitro varnish and a little yellow oil paint are used. The surface is given a matte finish by rubbing with talcum powder.

Patination. Various shades of brown or brown-green are selected and mixed with other substances. It is recommended to paint in three layers, and in the recesses the treatment is usually carried out with a mixture of a more viscous consistency. The technology of applying the dye is also important here:

- the first layer is lighter, after which it is lightly sanded and wiped with acetone;

- the second layer – the coloring mixture is darker and thicker;

- third layer - to give it a matte finish, a little wax is dissolved in the paint.

The following additives will help to shade or enhance the imitation: bronze powder, talc and chromium oxide, graphite powder, sienna, ocher, umber, soot, green cobalt, lead or. These are all semi-professional methods of painting gypsum-based materials. Traditional plaster paints are available for sale.

The most commonly used paint mixtures for interior work are acrylic water emulsions or dispersions.

After drying, they create a durable protective film that protects the base from moisture. In addition, all water-based paints are environmentally friendly, which means they can be used inside any premises, including residential ones.

When making decorative brick or stone based on gypsum, the working solution is tinted. For this, various powder pigments are used. Tinting the mortar makes it possible to obtain finished bricks that are uniformly colored throughout the entire structure (then operational defects will be less noticeable).

To create an imitation of texture (veins), paints of several shades of color are used. And a finishing varnish coating will help increase the protection of the surface of gypsum brick or stone (after all, gypsum is quite fragile by nature).

Experts advise not to delay painting gypsum finishing elements, as the adhesive properties of the materials deteriorate over time. If this happens, then it’s a good idea to use a primer, and only then paint. The primer will also increase the strength of the gypsum base and create some protection against moisture penetration.

Construction plaster offers unlimited possibilities for original interior decoration. Widespread availability and ease of use have made the material very popular. And having in your arsenal paints, miniums, varnishes, gold leaf and other pigment substances, you can achieve real palace luxury.

In most cases, designs are made of or paint coatings. In this case, the brickwork takes on a completely different aesthetic, unique and individual look. In addition, the finishing coating well protects the walls of the building, especially the outside, from the negative effects of the environment. You will learn how to paint brick and what materials to choose for this by reading our article.

If you compare painting with plastering, it is undoubtedly easier to do and the cost of repairs will not hit your wallet hard. In addition, painting brickwork yourself does not require specific skills or complex tools.

What paint is suitable

Considering the range of paints and varnishes produced and sold, the question of how to paint a brick should not torment you much.

IMPORTANT: Let us immediately note one very important point. A brick surface decorated with paint and varnish coatings must “breathe”. This means that the paint must be selected appropriately, that is, vapor-permeable.

Otherwise, if this extremely important point is not taken into account, you will end up with a damp box that is practically unsuitable for living.

Properties of compositions

Let's determine what properties brick paint should have:

- The paint must be vapor permeable;

- For this purpose, it is necessary to choose a heat-resistant one, that is, one that can withstand temperature changes from –50°C to 50°C above zero. This is especially true in the northern regions, where such temperature changes are the natural norm;

- The composition of the material must be suitable for finishing brick surfaces. You should take into account in advance the fact that not every composition is suitable for this purpose;

- Brickwork, as a rule, has a high content of alkaline compounds, and this in turn can negatively affect the finishing coating, which is not intended for this purpose. Conclusion: it is advisable to take these points into account when choosing a particular type of paint.

Brick, in fact, was not originally intended for painting with your own hands. Being produced in a factory, it can have different geometric and color parameters and does not require any design manipulations.

Choose the right materials yourself

If the question of finishing arises, then it is advisable to use only those materials that fully meet all the stated requirements.

TIP: There is no need to particularly trust sellers when... The best option would be if you read the composition yourself and evaluate how suitable it is for your purposes.

Many experts strongly recommend using silicate, cement or acrylic polymer-based compositions when decorating brickwork. Also, a silicone-based composition is perfect for external walls, but please note that it is much more expensive.

When choosing, it is better to give preference to compositions that do not contain solvents, since such coatings dry much faster, and this is a very important point, especially when finishing facades.

TIP: When choosing paint, do not forget to also purchase primers. Although many are convinced that painting bricks can be done without pre-treatment, the best option would be to prime the base with those types of primer solutions that are similar in composition to the chosen paint.

Painting of bricks should not be done with such types of compositions as, for example, fire-retardant paints for metal Polistil or, no less well-known, electrically conductive paint Zinga, since these protective coatings are intended for metal elements.

For particularly complex coatings, when the question arises, for example, of how to paint sand-lime brick, a water-based acrylic composition is most suitable here. Painting sand-lime brick requires a preliminary primer. If you do not follow this procedure, the coating will not last long.

In some cases, when cladding the external walls of a house or any other building, decorative bricks are used for painting. The composition of this material includes components that interact well and firmly adhere to paint and varnish coatings. Acrylic-based solutions are suitable for finishing such cladding.

The same compositions are used, for example, for painting a brick balcony or any other internal walls of buildings.

In general, compositions based on acrylic or silicone are completely universal and can be used on almost all surfaces, both stone and wooden, or covered with a plaster layer. They contain state-of-the-art polymer components that promote high-strength adhesion to substrates even as complex as silicate ones.

The surface treated with these materials is smooth and easy to clean. Another advantage worth noting is the maintainability of coatings. For repairs, it is not at all necessary to repaint the entire wall, but it is enough to update only the problem area.

Painting process

The preparatory part of the wall design process is mandatory and includes the following steps:

- All peeling and interfering parts of brick and masonry cement mortar are cleaned from the wall and, if necessary, the seams are partially renewed;

- Before painting, it is advisable to strengthen the base with an acrylic primer. To do this, use a fairly wide brush or, even better, a spray gun to apply one layer of primer evenly over the entire surface. Often one layer will be enough.

- After priming, the base must be thoroughly dried.

Applying paint

It is more advisable to apply paint using an electric spray gun, especially if a sufficiently large area of walls is being treated. If you don’t have a spray gun, a regular wide brush or a large paint roller with a shaggy working base will do.

The technology itself and instructions for applying paint and varnish coatings are practically no different from applying them to any other base.

It is advisable to apply semi-matte latex-based paints in two layers in order to paint the surface completely and evenly.

It is advisable to use lighter compositions to decorate the facade or interior walls. Thus, you will visually expand the interior space, and soften the dark shade of the stone wall outside.

Weather conditions when carrying out work on finishing external walls must be taken into account first of all. So, for example, the most favorable time for holding such events is early autumn, it is also called “Indian summer”, when the sun’s rays are not so scorching and the winds will not cover the newly decorated façade with dirt and dust.

It must be remembered that when decorating brick walls with paint and varnish, sooner or later it will still have to be updated. In order for the coating to last as long as possible, it is necessary to choose only the appropriate types of paints, the price of which can be significantly higher than usual.

Necessary tools for coating decorative stone

They will be needed not only for painting tiles, but also for preparing paints and varnishes. To obtain a homogeneous composition of the required consistency you need:

- drill or screwdriver with mixing attachment;

- measuring container;

- tray or bath.

Using an electric tool will allow you to prepare the paint with an even distribution of the dye throughout the volume. To paint gypsum stone yourself, you must have:

- set of brushes;

- spray gun with nozzles or airbrush;

- metal spatula or scraper.

Before starting work, any remaining adhesive, mortar and dirt are removed from the surface of the tile. After this, they are wiped or blown with air. Do not use a brush after cleaning tiles for painting. If the application of paint and varnish is carried out with a spray gun, then it should be placed at a distance of about 0.4 m from the surface to be painted. This will ensure an even layer without drips or sagging.