Home Construction Fences

Wood remains the most common building material that owners of country houses and cottages use to construct various fences on the site. A fence between the recreation area and the beds near the cottage, a beautiful wooden fence around a country house or a low wooden picket fence around the flower beds in the yard will look harmonious. But unprotected wood is subject to rapid deterioration due to constant interaction with rain, wind, snow, and sun.

In shaded areas in cottage courtyards, in places with high humidity, boards quickly lose their original appearance and become covered with mold or are affected by fungus. How to treat fence posts and the board fence itself of a country house so that they retain their attractive appearance for more than one year? There are many ways to treat wood available, although fence posts, for example, require different protectants for the outer part and the part that goes into the ground.

Typical mistakes when installing wooden poles

Initially, it is important to understand the reasons why fence support posts deteriorate and what they need to be treated with. This happens, first of all, under the influence of moisture, which, permeating the wood, creates “good” conditions for the development of all kinds of bacteria. And if the top of the pillar manages to dry out under the sun and wind, then at the point of contact with wet soil the process becomes irreversible. The tree begins to rot, becomes covered with mold, and insect pests appear there. The rotting processes in the lower part of the column are somewhat slower, but inevitable. There is no better way to prevent this process than to treat fence posts with antiseptics and waterproof their lower part.

Typical mistakes made by summer residents when installing wooden poles include incorrect selection and installation of logs, as well as non-compliance with the rules for processing the underground part.

When choosing poles, you should pay attention to the general condition of the wood - the absence of signs of rot, blueness, and pests. Wood moisture content should not exceed 15%. Logs must be sanded and dried before being treated with antiseptics.

It is important to determine where the top of the log is and where the bottom is, since the pole must always be dug in with the butt up. This prevents water from “sucking” through the capillaries. Under no circumstances should you wrap the treated end of the tree with roofing felt, since if moisture gets into such a “glass”, it will remain there forever, creating conditions for rotting.

Wooden poles need to be treated with preparations that have antiseptic, moisture-proof and fire-retardant properties.

The first signs of rot in the boards

There are many types of putrefactive fungi: Stereum, Daedalea, Polyporus, Lenzites, Fomes and hundreds of others; the appearance is not so important, especially since the treatment of fence boards against rotting is the same.

However, all fungi can be roughly divided into three types, based on the type of decay they cause:

- white rot, the main symptom of which is the appearance of yellow, gray or white stains on the wooden surface, which gradually soften it, making it wet and fibrous;

- brown (brown) rot - because of it, the wood begins to chip and crumble, turning into unusable dust;

- soft rot is typical for damp conditions: in the house it attacks bathrooms, saunas and kitchens, fences - in places adjacent to wet soil, for example, in the shade.

Article on the topic: How to paint a wooden house

Signs of rot are a change in surface color, the appearance of cracks, destruction of the structure and a decrease in strength.

There are several stages of destruction:

- initial, which is characterized by a change in color without a change in structure: the fungus does not affect the shell;

- developed, with which pits, scratches, and cracks appear in the surface;

- final, with final destruction of the structure and disintegration of wood

At the initial stage, it is still possible to stop the destruction on your own; further stages require deep impregnation in industrial conditions: the boards are placed in special baths and allowed to acidify. In this case, we are not talking about how to treat a wooden fence, but about what and when to replace it with - it will be cheaper and more durable.

Wood rots more strongly at air humidity of 75-100%, large temperature changes and when the boards are not dried enough, their moisture exceeds 15%. If the latter can be dealt with by purchasing from trusted suppliers, then the first two points cannot be dealt with. In the changeable and humid climate of central Russia, wooden fences always run the risk of becoming infected with fungus and quickly becoming unusable.

Therefore, careful and regular treatment of posts to prevent rotting is something that every owner of a wooden fence should take care of.

Compositions for treating the underground part of pillars

There are many folk methods on how and with what to treat fence posts.

Here are a few of them:

- Coating with birch tar or spruce resin (the oldest and most proven method).

- Treatment with used automobile oil (the cheapest method). The oil is applied in several layers in a heated state, thoroughly saturating all ends and cracks. 90% of the waste composition is mineral oil - a good water-repellent antiseptic. The acid salts contained in the waste kill any fungus in the wood.

- Firing and processing with bitumen. The part of the log that will be buried in the ground can be burned either over a fire or with a gas burner, creating a charred layer of several millimeters. The burned part is treated with molten tar or bitumen.

The protective layer is applied in two steps, so that each layer of bitumen impregnation can harden; it is necessary to withstand the drying period of the first layer for about a day. Bituminous impregnation is correspondingly black in color, so treat only that part of the wooden fence post that will be hidden in the ground.

It is not recommended to apply bitumen impregnation to wooden poles during fog or rain.

The construction market also offers all kinds of synthetic waterproofing compounds - mastics, pastes, etc. For example, bitumen mixtures Biom-2 or “Izhora”, several layers of which, in combination with fiberglass mesh and protective film, create excellent waterproofing with high protective properties, designed for 10-15 years of operation. Moreover, a 15-kilogram bucket of such a mixture costs only 450 rubles.

Neomid 430 eco is a preservative, non-washable antiseptic for external use, which provides maximum protection for wood during prolonged contact with soil and moisture. Protects against damage by wood-destroying and wood-staining molds, algae, mosses, and wood-boring insects for up to 35 years.

It is strictly not recommended to install untreated posts.

Paint "Special Forces"

The obvious disadvantage of this product is its high price. In all other respects, it is ideal for working with metal surfaces. This is a three-component paint. It contains a rust converter, a primer and the enamel itself. When working with Spetsnaz, there is no need to apply primer or heavily clean the supports. However, although it is written that it is applied to rust, it is better to remove it. Degreased with either white spirit or solvent 647.

Paint is applied to the cleaned pipe with a brush. After the first layer, there may be unpainted areas, but after applying the second, there will be no such areas. For exterior use three coats are required. “Spetsnaz” dries quickly, therefore, being in an open jar for a long time, it begins to thicken. It is diluted to the desired consistency with the same white spirit.

The enamel is packaged in 900 g jars and comes in ten colors. After drying it takes on a matte finish. Now there are many names of three-in-one paints: “Rzhavostop”, “Nerzhamet”, “Hammerite” and others. What they all have in common is application to a rusty surface. Although, to clear your conscience, it is better to clean up. And the price range is not cheap. Although these types have their own advantages, many prefer a primer with or without subsequent painting. For painting pipes, they also use aluminum silver powder, which is dissolved in varnish for exterior use.

Step-by-step instructions for installing and protecting support poles

Step one.

We determine where the butt of the log is and mark that this will be the top of the post. Before you begin installing fence posts, you should treat its lower part with a penetrating antiseptic to a height of 1.5 meters. It is better by immersing for two days in a 5% solution of copper or iron sulfate. You can also use a 5% solution of potassium dichromate in 5% sulfuric acid; the remaining solution will need to saturate the soil around the dug post. This will provide antifungal protection for 15-20 years.

Step two.

After impregnation with an antiseptic, the buried part is treated with one of the types of waterproofing (bitumen, tar, mastic, mining, etc.).

Step three.

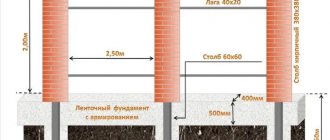

We carry out the process of installing the pole. There are several different methods, some of which provide additional protection for the pole from interaction with wet soil.

Option one (cheapest). The treated end of the post is buried in the ground and compacted thoroughly. After a few years, you should definitely check its base for the appearance of fungus or rot.

Option two. Prepare a hole a little more than a meter deep and twice as wide as the diameter of the post. The bottom is covered with gravel, then a “glass” without a bottom is placed around the perimeter, made of geotextile or other non-woven material, which will protect the gravel backfill from clogging with earth. The entire space is covered not with soil, but with gravel or rubble, carefully compacted and poured with mining.

Option three (the most expensive, since the purchase of pipes is added to the costs). Using a sleeve made of a metal or asbestos-cement pipe into which a wooden pole is inserted. Since the sleeve rises 10 centimeters above ground level, the tree will not have direct contact with the ground, and therefore will be subject to rotting processes.

The process of installing a wooden post into a sleeve requires care and time. To prevent the post from falling inward, you should select a piece of pipe (100 cm) with a diameter smaller than the diameter of the post by about 10 centimeters. The log is placed on trestles and a circular cut is made at a height of about 30-40, and then the required layer is removed using an ax. The resulting cylinder should fit into the pipe freely.

First, this part of the post is impregnated with drying oil or waste and allowed to dry for several days. Then the tar is heated over a fire to a liquid state, the hewn end of the post is thickly coated with a hot mixture with a brush, and a piece of pipe is inserted. The gap between the tree and the pipe and the lower part of the post are also treated with tar. The resulting pillar is buried so that the top of the pipe protrudes slightly above the surface of the ground.

Step four.

Impregnation of the visible part of the pillar with an antiseptic and application of the base coating (paint, varnish). To further protect the pole, experts recommend covering it with a tin lid.

How to calculate parameters

First you need to decide which way the steps will go. They can be on one, two or three sides. You determine this based on personal preferences and the finances that you can/want to allocate for construction. The height of the porch depends on the height of the plinth and should be 50-70 mm below the edge of the door leaf. This small step prevents precipitation from getting inside the house. Perhaps more importantly, it prevents the doors from becoming blocked if the porch rises up due to frost heaving (if the doors open outward).

Determining the dimensions of the upper platform

The layout of the porch begins with determining the size of the upper platform. If the doors open outward, you should be able to stand on the landing to open the doors. That is, its depth should be 30-40 cm greater than the width of the door leaf. According to GOST recommendations, the dimensions of the platform should be 1.5 times the width of the doorway. More is possible - less - undesirable - inconvenient.

If your doors are 80 cm wide, then the depth of the upper platform at the very minimum is 120 cm. Its width is determined based on the tastes and proportions of the house, but it should definitely be greater than the width of the doorway.

We count the number and sizes of steps

You know the height of the porch: 50-60 mm below the door leaf. The recommended height of the step (riser) is 15-20 cm. Divide the height of the porch by the height of the steps, you get the approximate number of steps. The number rarely turns out to be a whole number. The remaining centimeters can be divided between all steps or one of them can be made higher. Another option is to create a small step at the bottom, although this may be awkward.

The optimal width of the step (tread) is 25-30 cm. Knowing the number of steps, the depth of the upper platform, the depth of the steps, you can calculate the full dimensions of the porch. Using them you can already develop the foundation for the porch.

Article on the topic: How to get rid of the smell of burning in a wooden house

When choosing the parameters of the steps, you must adhere to the recommendations of SNiP: the sum of the tread and double riser should be in the range of 600-640 mm. For example, you calculated that the height of the step (riser) is 17 cm, the tread (depth) is 280 mm. After performing the calculations we get: 170 mm * 2+280 mm = 620 mm. We fit into the recommended parameters, which means there is no need to change anything.

Protective coatings for the visible part of the pole

The upper part of the column, which is located above ground level, also requires special protection with both antiseptics and protective paints and varnishes. To understand how to treat fence posts, decide on the type of coating. If it is important to preserve the texture of wood, then coatings such as Pinotex or Belinka, Biotex, and AVIS timbercoat varnish have long proven themselves on the market.

If you plan to apply paint, then both simple domestic oil paint based on zinc white, as well as the largest foreign wood paints (Finland), “Selena” (Poland), “Alpa” (France), “Akzo NV” (Netherlands) are suitable. , "Belinka Belles" (Slovenia).

Before applying a coat of paint, the wood is always primed.

The paintwork should be renewed every three to five years to protect the wood from rotting and damage by insects.

Manufacturing and preparation

If the wood is not cut, it must be dried in natural conditions, folded under a canopy. Drying time is about a year. For construction, specimens that have completely completed the drying period are used.

The bark is removed from the surface. To do this, use an axe, a scraper, or a shovel. The trunks are placed in a vertical position so that there is a reliable stop at the bottom. The debarking is removed from the top, gradually lowering so as not to damage the body of the trunk.

If knots protrude from the sides, they are cleared with a plane, ax, or saw. To grind the surface, use an electric tool or use sandpaper attached to a block. A carving is made on the area of the pillar and a convex ornament is made, if such is provided for in the project.

Corrosion

Metal corrosion is a natural phenomenon that cannot be completely prevented, but this destructive process can be significantly slowed down. The oxidation process occurs with the participation of oxygen and aqueous solutions containing acid, alkali or salt.

Iron is not found in nature in its pure form, but is found in iron ore. Humanity invented the production of steel and came up with ways to preserve it. Factories use methods of phosphating steel by immersing it in various solutions, as well as electrochemical treatment. This coating is in the nature of a primer and requires subsequent painting. Steel is coated with other metals. Cheaper ones are aluminum and zinc.

There are silicate coatings - these are different types of enamel. Enamel is fragile and not entirely suitable for a fence. Cement has approximately the same expansion temperature as steel and serves as an insulator against aggressive environments. Good insulation is a polymer film applied in several layers in the factory.

READ ALSO: How to Install Mortgages for Wickets in Brick Pillars

Is it worth using wood at all?

Disputes on this issue have not subsided for a very long time. On the one hand, wooden poles are an environmentally friendly material that is quite durable (especially for species such as larch or oak). At the same time, wood can be easily processed - there are craftsmen in the private sector whose fences and houses can be called a work of art.

PHOTO: goldvoice.clubThese are the kind of miracles you can find in private sectors

On the other hand, wood does not tolerate precipitation, winds, or exposure to ultraviolet radiation very well, which cannot be said about concrete and metal. Of course, everyone will have to solve the problem of material independently, but do not forget that wood has long been revered in Rus'. And it's not just about construction. In ancient times, people went into the forest and prayed to the trees, taking strength from them by hugging them.

PHOTO: pl.pinterest.com You get the impression that you are in a real fairy tale - the heroes are as if they were alive